Choosing Your Restaurant Preparation Table

Share

In any professional kitchen, amidst the controlled chaos of sizzling pans and shouted orders, one piece of equipment stands as the quiet anchor of the entire operation: the prep table. It's far more than just a place to chop vegetables. It's the central hub where raw ingredients begin their journey to becoming the dishes your customers rave about. Stay informed about the latest industry trends and get exclusive deals on restaurant equipment and supplies to ensure your kitchen is always ahead of the curve.

The Unsung Hero of Your Commercial Kitchen

Think of your prep table as the primary workbench for your culinary team. This is where the real magic happens—the chopping, mixing, assembling, and plating. The right setup can make the difference between a smooth, efficient service and a chaotic, bottlenecked disaster.

A well-chosen prep table isn't just a piece of stainless steel; it's a strategic tool. When you get it right, everything else in the kitchen flows better.

- It boosts your team's speed. A properly organized station cuts down on wasted steps, letting your chefs work faster and with less fatigue.

- It's a cornerstone of food safety. The right materials, like non-porous stainless steel, and features like integrated refrigeration are critical for keeping ingredients at safe temperatures and preventing cross-contamination.

- It keeps everything organized. During a dinner rush, a cluttered workspace is a recipe for mistakes. A good prep table provides a dedicated home for tools and ingredients, keeping the line moving smoothly.

This isn't just anecdotal, either. The growing focus on kitchen efficiency is reflected in the market. The global food prep tables market hit a value of around US$1.2 billion in 2024, and it's expected to keep climbing. Why? Because smart restaurant owners know that investing in quality equipment is fundamental to success. You can discover more about this market expansion from industry analysts who track these trends.

Ultimately, selecting the right prep table is a decision that directly impacts your kitchen's speed, safety, and bottom line. It’s an investment in your team and your entire operation. This guide will walk you through exactly how to make the best choice.

Decoding the Different Types of Prep Tables

Not all prep tables are created equal, and believe me, picking the right one can make or break your kitchen's rhythm. Let’s start with the absolute foundation: the classic stainless steel work table. Think of this as the culinary world's universal workbench. It’s the durable, all-purpose surface that’s essential for just about everything, from chopping vegetables to butchering meat and portioning out ingredients.

This table is the backbone of so many kitchens for a reason. Its simplicity and resilience are unmatched. The non-porous surface is a must-have for keeping things clean and hygienic, and its no-frills design means it can fit into any kitchen layout. But as menus get more complex and workflows more specific, the tables need to keep up.

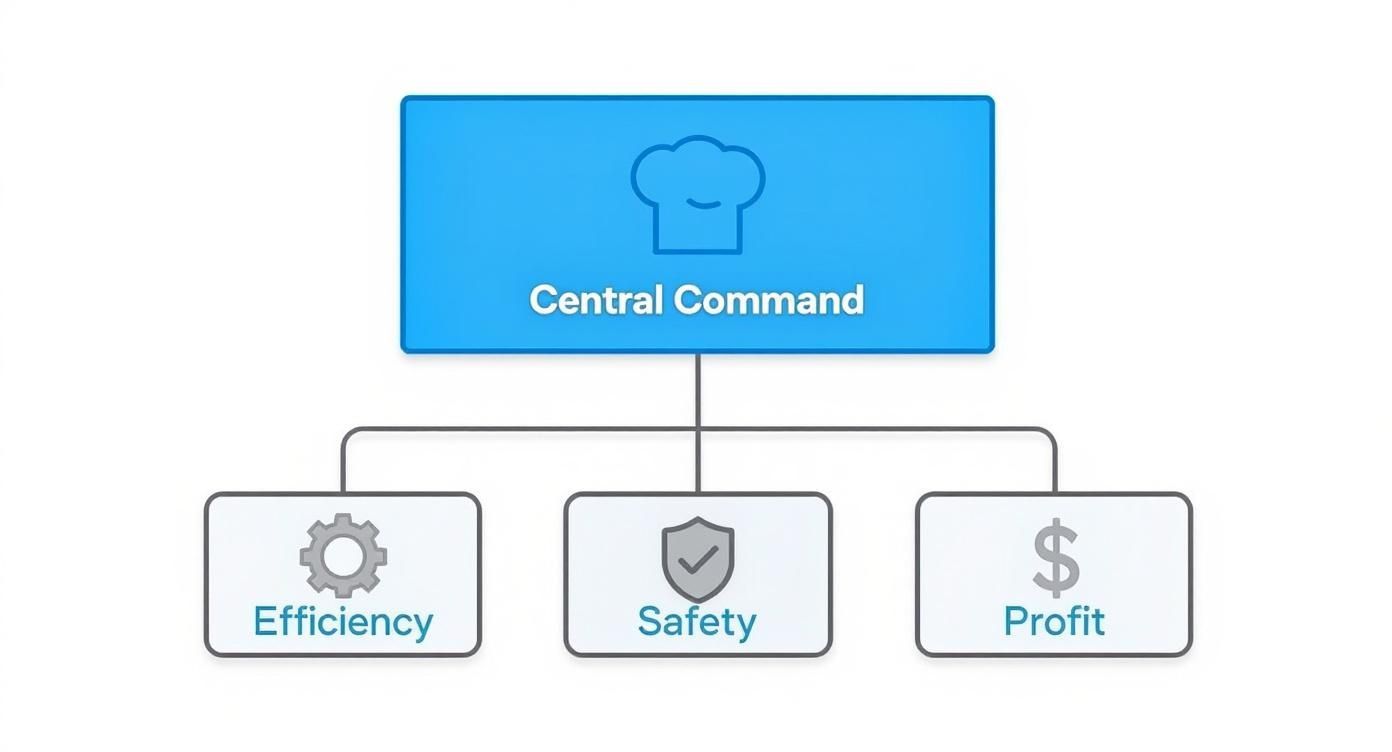

The infographic below really drives home how a prep table functions as the central command post for your kitchen, directly impacting your efficiency, safety, and ultimately, your bottom line.

As you can see, a prep table is so much more than a piece of furniture. It’s a strategic tool that supports the very core of a successful kitchen operation.

Specialized Prep Tables for High-Volume Menus

When speed and consistency are the name of the game, you need to bring in the specialists. These units are designed with specific functions built right in, creating a seamless assembly line for your most popular menu items.

-

Refrigerated Prep Tables: These are absolute game-changers. By building refrigeration right under the work surface, they keep crucial ingredients like meats, cheeses, and fresh produce perfectly chilled and literally at your fingertips. This simple design cuts down on countless trips back and forth to the walk-in, which means less wasted time and better food safety.

-

Salad and Sandwich Prep Tables: If you're cranking out sandwiches and salads, these are non-negotiable. They feature a refrigerated rail on top, holding an array of pans filled with every topping and ingredient you need. Your staff can build orders lightning-fast without ever leaving their station. To see just how much they can transform your service, check out our deep dive on refrigerated sandwich prep tables.

-

Pizza Prep Tables: Tailor-made for pizzerias, these tables typically have a wider and deeper refrigerated rail to hold all those bulky topping pans. The work surface itself is often made of marble or another material that stays naturally cool—perfect for stretching and handling sticky pizza dough.

To help you visualize which table fits where, here’s a quick comparison of the main types you'll encounter.

Comparison of Restaurant Prep Table Types

This table breaks down the primary types of prep tables to help you match the right equipment to your menu and workflow.

| Table Type | Primary Function | Common Features | Ideal For |

|---|---|---|---|

| Stainless Steel Work Table | General-purpose prep, butchering, and plating | Flat, non-porous surface; undershelf for storage | All kitchens, especially those needing flexible, multi-use space. |

| Refrigerated Prep Table | Keeping cold ingredients close at hand during prep | Undercounter refrigerator or freezer; stainless steel top | Any kitchen preparing items with cold ingredients to reduce food waste and save time. |

| Salad & Sandwich Prep Table | Rapid assembly of salads, sandwiches, and wraps | Refrigerated top rail for pans; cutting board | Delis, cafes, and quick-service restaurants with a high volume of build-to-order items. |

| Pizza Prep Table | Dough handling and pizza assembly | Extra-deep refrigerated rail; often a marble or granite top | Pizzerias and Italian restaurants that need a cool surface and space for many toppings. |

Choosing the right type is the first step in creating a workspace that works for you, not against you.

Why Specialization is a Big Deal

The growing popularity of these specialized tables isn't just a passing trend; it's a direct response to a major shift in the restaurant world. For instance, the market for just sandwich and salad prep tables was valued at a staggering US$1.2 billion in 2024 and is on track to hit US$1.71 billion by 2032.

What's driving this? It's the explosion of quick-service and fast-casual spots that rely on hyper-efficient, standardized workflows to get food out the door fast.

A specialized prep table isn’t an expense; it’s an investment in operational velocity. By matching the table to the menu, you eliminate wasted motion and create a hyper-efficient workstation that pays for itself in labor savings and increased output.

In the end, taking the time to understand these different types means you can choose a prep table that doesn’t just fit your space, but actually enhances the unique way your kitchen runs.

Choosing the Right Materials and Construction

A prep table might seem like one of the simpler pieces of equipment in your kitchen, but don't be fooled. Its real value lies in the details—the materials and the way it's built. Picking the right table isn't just about finding one that fits the space; it's about investing in a workhorse that can handle the chaos of a busy service while meeting tough hygiene standards.

When it comes to materials, there's a clear winner for almost every kitchen: stainless steel. Its surface isn't porous, which means it won't harbor bacteria, absorb strange smells, or hold onto flavors from yesterday's prep. It's a true food safety champion. But here's the catch—not all stainless steel is created equal.

Cracking the Code: Stainless Steel Grades and Gauges

When you're looking at specs for a prep table, you'll see two numbers that matter a lot: the grade and the gauge. Think of the grade like a recipe for the steel itself—it tells you how well it will fight off rust and corrosion.

- 304-Grade Stainless Steel: This is the gold standard for any surface that touches food. It has more chromium and nickel in its makeup, giving it incredible protection against rust, even when faced with acidic foods like tomatoes or harsh cleaning chemicals. If you're prepping directly on the surface, this is what you want.

- 430-Grade Stainless Steel: This is a more wallet-friendly option. It's still a solid material, but with less nickel, it's a bit more likely to show signs of corrosion down the road. It’s perfectly fine for table legs, undershelves, or tables tucked away in dry storage—just not the best choice for your main worktop.

Then there's the gauge, which is simply a measure of the steel's thickness. The tricky part? With gauge, a lower number means thicker, stronger steel. A heavy-duty table built for serious work will use 14-gauge or 16-gauge steel, thick enough to handle heavy mixers or relentless chopping without denting. Lighter-duty tables often use 18-gauge steel, which is fine for less intense tasks.

Beyond the Steel: Other Materials and Build Quality

While stainless steel is king, some kitchens have different needs. Bakeries, for instance, often swear by wooden butcher block tables. The wood surface is fantastic for kneading dough and won't dull your knives, but it's porous and demands serious, consistent maintenance to keep bacteria at bay.

No matter the material, how the table is put together is just as critical.

The way a table is built tells you everything about its stability and how long it will last. A wobbly, poorly finished table isn't just annoying—it's a genuine safety risk in a fast-moving kitchen.

Keep an eye out for signs of quality craftsmanship. Welded legs, for example, are almost always more stable than bolted ones, which have a nasty habit of loosening over time from all the kitchen vibrations. Check the edges, too. A rolled or marine edge features a raised lip designed to contain spills, keeping liquids off the floor where they can become a dangerous slipping hazard. It’s a small detail that makes a huge difference in safety and cleanup time.

For a deeper dive, our guide to commercial kitchen tables has even more tips on picking equipment that’s truly built to last. A well-made prep table with the right materials is more than just a piece of furniture; it’s a foundational investment in your kitchen’s efficiency and safety.

Key Features That Boost Kitchen Efficiency

Think of a modern restaurant preparation table as more than just a flat surface. It’s a high-powered productivity hub, a command center designed to solve some of the biggest headaches in any commercial kitchen: wasted steps, food safety risks, and pure chaos. Restaurant owners and chefs can discover the latest news and exclusive deals on restaurant equipment by looking for smart, strategic features that make a prep table an active part of your workflow.

The single biggest game-changer is integrated refrigeration. When you build cold storage right under the work surface, your chefs have every critical ingredient within arm's reach. This one feature cuts out dozens, even hundreds, of trips to a walk-in cooler over the course of a busy shift. Those saved seconds add up fast, translating directly into real labor savings.

This design has become a cornerstone of both efficiency and food safety. It's no surprise that the global market for these refrigerated workhorses was valued at around US$7.67 billion in 2024 and is expected to climb to US$10.30 billion by 2031. This isn't just a trend; it's a direct response from kitchens demanding smarter workflows and less food waste. You can explore more data on this expanding market to see just how big the impact is.

Streamlining Workflow with Integrated Components

True efficiency comes down to one thing: minimizing wasted motion. Tables designed with built-in components turn a single spot into a self-contained workstation. A chef can prep, assemble, and plate without ever taking more than a step or two.

Here are a few of the most impactful additions:

- Pan Rails: These are the recessed slots you see holding food pans full of toppings, sauces, and chopped veggies. They are the secret weapon behind any fast-paced sandwich, salad, or pizza line.

- Built-in Sinks: A small prep sink right on the table is a lifesaver. It’s perfect for a quick rinse of produce or utensils, which drastically cuts down on cross-contamination risks without a trip to the main dish pit.

- Integrated Cutting Boards: Imagine a removable, NSF-certified cutting board that fits perfectly over the work surface. It gives you a stable, sanitary chopping area that’s a breeze to clean.

A prep table with the right integrated features turns a single station into a complete assembly line. It reduces a chef's physical footprint, which translates directly into faster ticket times and a less chaotic kitchen.

Smart Storage Solutions for Peak Organization

A cluttered workspace is a slow workspace. Nothing kills momentum faster than having to hunt for a specific tool or container during the middle of a dinner rush. Smart storage built right into the table's base keeps everything you need organized and right where you can grab it.

Look for these essential storage options:

- Undershelves: This is the most common feature for a reason. An open undershelf is the perfect spot for bulky items like mixing bowls, stock pots, or cases of ingredients that you need to access quickly.

- Cabinets and Drawers: For things you want to keep protected from spills and dust, enclosed cabinets are the way to go. Drawers are fantastic for organizing smaller items like hand tools, whisks, and plastic wrap.

- Over-shelves: Don't forget to think vertically! An over-shelf adds storage above the work surface, keeping frequently used spices, oils, or small appliances close by without eating up valuable prep space.

When you choose a restaurant preparation table, you’re doing more than just buying a piece of steel. You’re investing in a system. By matching the features to your specific menu and workflow, you’re setting your kitchen up to be more productive, safer, and ultimately, more profitable.

A Practical Guide to Sizing and Placement

The most amazing restaurant preparation table in the world is useless if it’s in the wrong spot. It's easy to get caught up in features and materials, but choosing the right size and thinking through its placement is just as critical. Get it wrong, and you can cripple your kitchen's flow, creating bottlenecks and safety hazards right when service gets chaotic.

Before you even start browsing, grab a tape measure. The golden rule here is to leave a bare minimum of three feet (36 inches) of clear walkway around any side of the table where people will be working. This isn't just a friendly suggestion—it's a vital safety standard. It gives your team enough room to move quickly without bumping into each other, especially when they're hustling with hot pans or sharp knives.

Think of your kitchen layout like a city's road system. Your prep tables are the main intersections. If you don't leave enough space, you'll create a permanent traffic jam that slows everything down and dramatically increases the risk of accidents.

Mastering Ergonomics and Workflow

It’s not just about making the table fit; you have to consider how your team will actually use it. Most standard prep tables stand about 34-36 inches high. This height is designed to be comfortable for the average chef, helping to reduce back strain during those long, grueling shifts. A table that promotes good posture is a small detail that pays off big time in staff well-being and productivity.

Then there's the classic "kitchen work triangle"—the path between storage (your fridge), preparation (the prep table), and cooking (the range). Even though modern kitchens can have much more complex layouts, the basic principle of an efficient workflow still holds true.

Your restaurant preparation table needs to create a smooth, logical path between key stations. An ideal setup minimizes wasted motion and makes the whole process feel intuitive. For example:

- Path 1: From the walk-in cooler directly to the prep table.

- Path 2: From the prep table straight over to the cooking line.

- Path 3: From the prep station over to the dish pit.

Your Pre-Purchase Spatial Checklist

By optimizing this flow, you cut out wasted steps and build a natural rhythm for your entire kitchen crew. Before you click "buy," run through these simple spatial questions to make sure you're making the right call:

- Measure Twice: Have you measured the entire footprint available, not just the spot where the table will sit?

- Account for Swing: Will cabinet doors, refrigerator doors, or oven doors have enough room to open all the way without smacking into the table?

- Check Clearances: Is there at least a 36-inch clearance on all sides where staff will be actively working or walking by?

- Map the Workflow: Does the table’s position actually shorten the trip between cold storage and the cooking line?

- Consider Ergonomics: Is the table height right for your team? Can they work at it for hours without discomfort?

Answering these questions first helps ensure your new prep table becomes a genuine asset—one that boosts your kitchen's efficiency instead of an obstacle your team has to fight with every day.

Keeping Your Prep Table in Fighting Shape for Years to Come

Your prep table is one of the hardest-working pieces of equipment in your kitchen. It’s an investment, and like any good investment, it needs looking after. A solid maintenance routine isn't just about making it last longer; it's fundamental to food safety and keeping your whole operation running smoothly.

Think of it this way: a few minutes of care each day can save you from the nightmare of a failed health inspection or a sudden, costly breakdown during the dinner rush. Setting up a simple daily, weekly, and monthly cleaning schedule is the key to keeping your prep stations ready for action.

The Daily Reset

At the end of every single shift, a deep clean is non-negotiable. This is your frontline defense against cross-contamination and bacterial growth.

- Scrub and Sanitize: Grab a food-safe sanitizer and a clean cloth. Wipe down the entire work surface, the backsplash, and all the edges. Get right into those corners and seams where food bits love to hide.

- Pans and Inserts: Pull every single food pan and insert out of the refrigerated rail. They need a thorough wash, rinse, and sanitize, then let them air dry completely before putting them back.

- Don't Forget the Rest: Give the legs, undershelves, and any cabinet or drawer fronts a good wipe-down. Grime builds up everywhere.

Going Deeper: Weekly and Monthly Checks

Daily wipe-downs are essential, but the real secret to longevity lies in the less frequent, deeper-cleaning tasks—especially for your refrigerated models.

A gleaming, well-cared-for prep table tells a story. It shows health inspectors, your staff, and even your customers that you take food safety seriously. It's a sign of a well-run kitchen.

For refrigerated tables, the mechanical parts need some love, too. Once a month, make a point to clean the condenser coils. When they get clogged with dust and grease, the compressor has to work overtime, which means higher energy bills and a much greater risk of a total system failure. While you're at it, check the door gaskets for any tears or gaps—that's precious cold air (and money) escaping.

Taking a comprehensive approach to maintenance ensures your equipment runs like a well-oiled machine for years. For more ideas on building a bulletproof cleaning schedule, check out our guide on commercial kitchen equipment maintenance. Following these simple steps will make sure your prep table remains a reliable workhorse in your kitchen.

Frequently Asked Questions About Prep Tables

Picking out a new restaurant preparation table can feel a little overwhelming with all the different specs and options out there. It’s easy to get bogged down in the details, but getting the right answers upfront means you’ll invest in a piece of equipment that actually works for your kitchen and can handle the daily chaos. By staying informed about industry trends, restaurant equipment, and supplies, you can make the best decision for your needs.

Key Considerations for Your Purchase

The first thing most people ask about is the material. What's the best metal for a commercial kitchen? When it comes to any surface where you'll be prepping food, 304-grade stainless steel is the gold standard, no question. The higher nickel content makes it incredibly tough against rust and corrosion, which is a lifesaver when you're dealing with acidic foods like citrus or tomatoes and harsh sanitizers.

You might see cheaper tables made with 430-grade steel, and that's fine for legs or maybe a dry storage shelf. But for your main work surface? You really need the durability of 304-grade to prevent pitting and wear over time.

Another question that comes up more than you'd think is about backsplashes. Are they really necessary?

A backsplash is a simple feature that makes a huge difference. If your table is going against a wall, it stops food, liquids, and stray utensils from falling into that impossible-to-clean gap. It's a small detail that drastically improves sanitation and keeps your walls from getting stained and damaged.

Finally, let's talk about size. Before you even start looking, measure your kitchen space. You absolutely need to leave at least a 3-foot clearance around the working sides of the table so your team can move around safely and efficiently.

Once you know your spatial limits, let your menu guide the rest. A bustling deli slicing meats and cheeses all day will need a much longer refrigerated table than a small coffee shop that just needs a spot for plating pastries. Think through your kitchen's workflow and map out where the table will go to make sure it helps the flow of service, rather than creating a new traffic jam.

At Encore Seattle Restaurant Equipment, our job is to help you find the gear that builds a smarter, safer kitchen. We've got a huge selection of new and used prep tables, and our team is always here to offer real-world advice to help you choose wisely. Discover exclusive deals on restaurant equipment and supplies when you take a look at our current inventory online at https://encoreseattle.com.