Choosing Commercial Kitchen Tables That Work

Share

Don't think of commercial kitchen tables as just a place to chop vegetables. They're the command center of your culinary operation. The right table makes your workflow smooth and keeps your kitchen safe, while the wrong one can cause serious bottlenecks and even sanitation headaches. This isn't just a purchase; it's a foundational investment in your kitchen’s daily success, and staying informed on the latest trends and deals can give you a significant edge.

Your Kitchen’s Unsung Hero: The Work Table

Think of your commercial work tables as the literal backbone of your kitchen. They support every single task, from the first slice of an onion to the final wipe of a plate. They aren't just static pieces of metal; they're an active part of every service. A good setup streamlines movement, keeps tasks organized, and ultimately helps your team get high-quality dishes out faster.

Choosing the right table goes way beyond just measuring the space. You have to really think about your menu, your workflow, and what your team actually needs to do their job well. For example, any busy kitchen I’ve worked in dedicates specific tables to certain jobs. It’s the only way to prevent cross-contamination and keep things running efficiently. Understanding industry trends can help you make a smarter choice.

Dedicated Tables Tame the Chaos

Ever seen a kitchen try to survive a dinner rush with one undersized table? It’s pure chaos. Chefs are bumping elbows, raw chicken is getting dangerously close to finished salads, and someone is always yelling about where the tongs went. It's a classic sign of a poorly planned space.

This is why creating dedicated workstations is so critical. By giving each table a specific job, you bring a sense of logic and order to the madness.

- Prep Stations: This is your workhorse area for chopping, butchering, and mixing. These tables have to be tough-as-nails and incredibly easy to sanitize.

- Assembly & Plating Areas: Usually right on the line, this is where the magic happens and dishes come together. They need to be kept impeccably clean and positioned for a fast hand-off to your front-of-house team.

- Equipment Stands: Give your heavy gear like mixers, slicers, or sous-vide circulators their own sturdy, dedicated home. This keeps your main work surfaces clear for action.

Trust me, this separation is non-negotiable. Any seasoned chef will tell you that the line between a smooth service and a total disaster often comes down to simple organization. A well-zoned kitchen just runs better, with fewer mistakes and shorter waits for customers.

A study on restaurant efficiency found that kitchens with clearly defined workstations can slash ticket times by as much as 20%. That’s not just a small tweak; it directly leads to more table turns and higher revenue.

The Real Cost of a Bad Decision

Picking the wrong commercial kitchen table creates problems that are much bigger than just a minor annoyance. A table made from the wrong material can become a breeding ground for bacteria, putting you at risk for serious food safety violations and a failed health inspection. One that’s too small for the job creates a cramped, frustrating workspace that tanks team morale and can even contribute to staff turnover.

On the flip side, a smart investment in the right tables pays you back every single day. It gives your team the tools they need to work safely and efficiently, protects the integrity of your food, and shows everyone—from your staff to your customers—that you run a professional operation. Let's walk through how to make that investment the right way.

Choosing the Right Table Material: What Really Matters

When you're outfitting a commercial kitchen, the material of your work tables isn't just a detail—it's the foundation of your workflow, food safety, and long-term budget. Get this choice right, and you'll have a durable, easy-to-clean surface that health inspectors love. Get it wrong, and you're in for a world of frustration.

Let’s be clear: stainless steel is the king of the kitchen for a reason. Its non-porous surface is a fortress against bacteria, corrosion, and the harsh sanitizers you use every day. But not all stainless steel is the same. Understanding the difference is crucial to making a smart purchase that lasts.

The demand for high-quality, specialized prep tables is booming. The global market hit USD 1.18 billion in 2023 and is on track to reach USD 1.62 billion by 2029. This industry trend shows that operators are recognizing the need for equipment that can handle the intense demands of modern foodservice.

Decoding Stainless Steel Grades: 304 vs. 430

Those numbers you see tossed around—like 304 and 430—are the key to understanding a table's quality. They refer to the steel’s grade, which tells you everything about its durability and where it should be used.

-

304-Grade Stainless Steel: Think of this as the gold standard for any surface that touches food. It has more chromium and nickel, giving it fantastic resistance to rust and corrosion. If your prep line involves a lot of acidic ingredients like citrus, tomatoes, or vinegar, a 304-grade top isn't just a good idea; it's essential for longevity.

-

430-Grade Stainless Steel: This is the workhorse for everything else. It's a more economical option that’s still tough, but with less nickel, it's more vulnerable to rust from constant moisture or acid. It's perfectly suited for table legs, undershelves, or as a stand for a mixer. It just shouldn’t be your primary food prep surface.

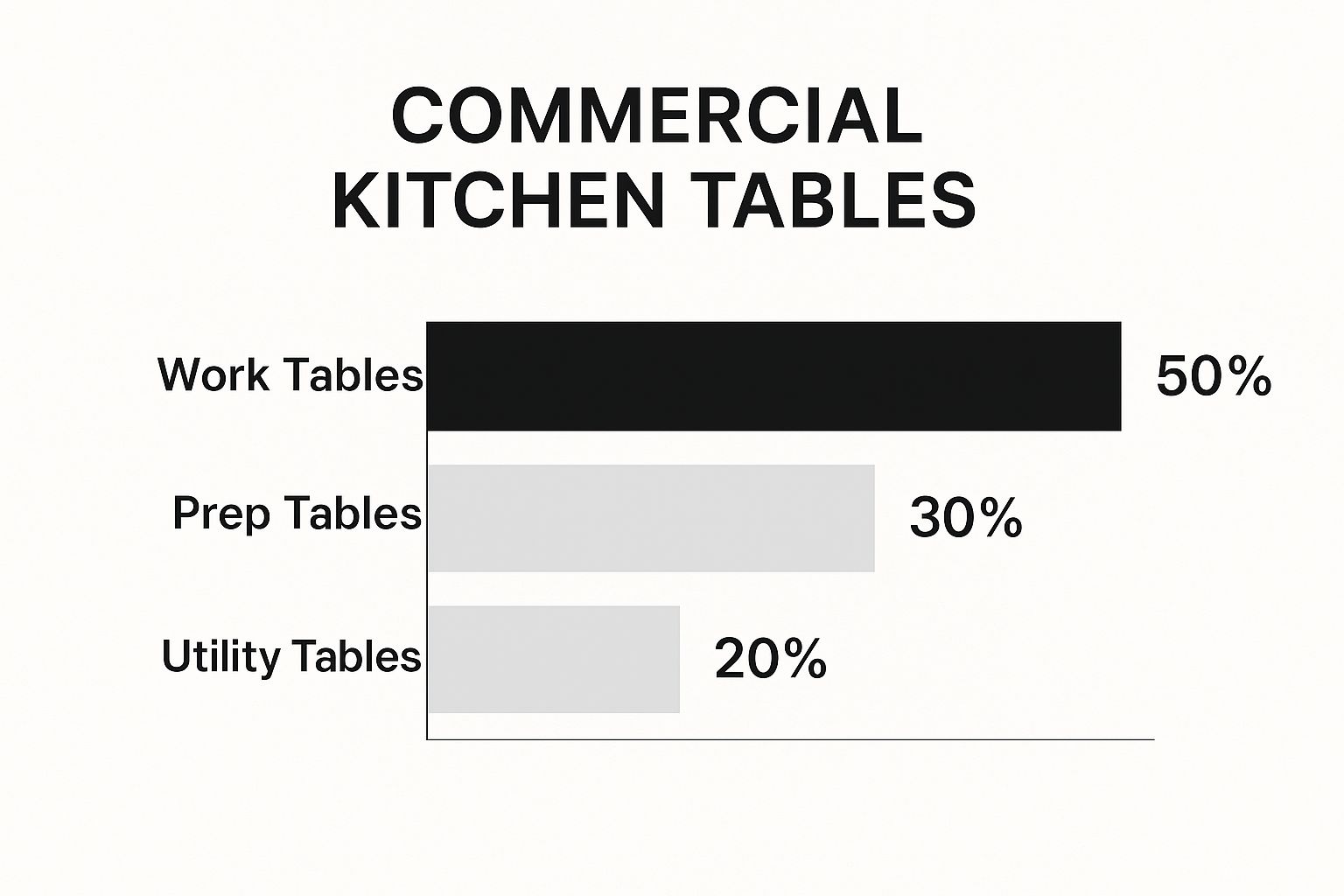

The most common table types tell a story about what kitchens truly need.

As you can see, general-purpose work tables are the backbone of most operations, which is why choosing the right material for them is so critical.

To help you decide, here’s a quick breakdown of the common stainless steel grades you'll encounter for kitchen tables.

Stainless Steel Grade Comparison for Kitchen Use

| Steel Grade | Corrosion Resistance | Best For | Cost Level |

|---|---|---|---|

| 304 | Excellent | Main prep surfaces, sinks, high-moisture areas, acidic foods | Higher |

| 430 | Good | Table legs, undershelves, equipment stands, dry storage areas | Lower |

| 201 | Fair | Legs and shelving in very dry environments; budget-focused | Lowest |

Ultimately, the best strategy is often a hybrid approach: a 304-grade top for food safety and durability, paired with 430-grade legs and shelving to manage costs effectively. Savvy chefs look for these kinds of deals to optimize their budget without compromising quality.

What About Other Materials?

While stainless steel handles most jobs, a few other materials have their own specific, valuable roles in a professional kitchen.

Galvanized Steel is essentially carbon steel that's been dipped in a protective zinc coating to prevent rust. It's strong and very budget-friendly, which makes it great for support structures like table legs and undershelves. However, and this is critical, it is not food-safe. Many kitchens save money by getting tables with stainless steel tops and galvanized bases. This is a smart move, as long as you keep food where it belongs. Finding the right place for everything is key, which is why our guide on commercial kitchen storage solutions can be a huge help.

Pro Tip: Never, ever prep food directly on a galvanized surface. The zinc coating can easily flake or leach into food, especially acidic ones. This is a major health code violation and a serious safety risk.

Wood tops, typically "baker's tops" made of hard maple, are a specialist's tool. They are fantastic for bakeries and pizzerias because the wood surface has a natural grip that's perfect for kneading dough and working with flour. The catch? Wood is porous and demands serious upkeep. It needs to be scraped clean and regularly oiled to stop it from drying out, cracking, and becoming a sanitation nightmare. Before you even consider one, check with your local health department for their specific rules on wood surfaces in kitchens.

Getting the Size and Layout Right for Peak Efficiency

Once you’ve settled on the material, your next move is figuring out the right size and placement for your commercial kitchen tables. This isn't a minor detail; it's a make-or-break decision for your kitchen's workflow. A table that's too big instantly becomes a roadblock, causing traffic jams and killing your team's rhythm. On the flip side, a table that’s too small will hamstring your prep staff, leading to cramped spaces and pure frustration.

This isn’t something you can just eyeball. You need a solid plan. So, grab your tape measure and get to work. Sketch out your kitchen’s layout, marking where all your heavy equipment sits, where the doors are, and which paths see the most foot traffic. This simple map will be your best friend when choosing tables that actually fit and improve your space.

Finding the Perfect Dimensions

The "right size" is all about striking a balance. You need enough surface area for your team to work effectively, but you also need to maintain wide, clear walkways for safety and speed. Every kitchen is different, of course, but there are some industry-standard dimensions that give you a great place to start.

- Height: Look for tables between 34 and 36 inches high. This is the ergonomic sweet spot for most chefs. It lets them chop, mix, and prep for hours without hunching over and wrecking their backs.

- Depth: A 30-inch depth is the go-to for most kitchens. It provides plenty of real estate for tasks without making staff reach uncomfortably. If you're tight on space, a 24-inch deep table can be a smart, space-saving choice for specific stations.

- Length: This is where you have the most flexibility. Lengths can run anywhere from a nimble 36 inches to a massive 96 inches or more. What you need really depends on the job. A long, unbroken table is fantastic for an assembly line, whereas several smaller tables might be better for individual prep areas.

A smart layout is the backbone of any productive kitchen. For a more comprehensive look at optimizing your entire workspace, our guide on commercial kitchen design layout is packed with strategies for building a safer, more efficient kitchen.

Matching Table Style to Your Kitchen’s Needs

Size is just one part of the puzzle. The style of the table plays a huge role in how useful it is. Picking the right type for each station can solve a lot of common headaches, like a lack of storage or safety issues with heavy equipment.

A crowded kitchen is an inefficient kitchen. As a rule of thumb, always leave at least 36 inches of clear walkway in your main traffic lanes. This gives staff enough room to move without colliding, even during a chaotic dinner rush.

A standard flat-top work table, for instance, is your everyday workhorse—perfect for all kinds of general prep. But let’s say you need a place for your heavy stand mixer or a commercial slicer. Don't just stick it on a regular table. A dedicated, heavy-duty equipment stand is the safer, smarter choice. They're built to handle the weight and vibrations and are often lower to the ground for easier operation.

If you’re constantly fighting for storage, look for a table with an undershelf. This one feature practically doubles your storage capacity, giving you the perfect spot to stash small appliances, ingredient bins, or pots and pans. You can also find tables with built-in sinks, which create a fantastic, self-contained station where staff can wash and prep produce without having to walk across the kitchen. It’s all about minimizing steps and keeping the workflow smooth.

Budgeting for Long-Term Kitchen Value

It’s easy to get sticker shock when shopping for kitchen tables, but fixating on the initial price is a classic mistake I see all the time. The real value isn't on the price tag; it's in the total cost of ownership. Think about durability, the maintenance it'll need, and how it will actually perform in your kitchen day-in and day-out. By staying informed, you can find exclusive deals on restaurant equipment that offer high value without the high price.

Several things drive the cost of a new table. The material is the biggest one. A 304-grade stainless steel table will always cost more because it’s a beast when it comes to fighting off corrosion. Size is another obvious factor; a 96-inch workhorse is going to have a bigger price tag than a little 48-inch prep station. And don't forget the extras—casters for mobility, backsplashes to keep walls clean, and undershelves for storage all add up.

Total Cost of Ownership

Thinking about what a piece of equipment will cost you over its entire life is where smart operators save money. A well-built, heavy-duty table might feel like a big spend upfront, but it pays you back over time. How? For starters, it stands up to dents, dings, and rust, so you aren't shopping for a replacement in a couple of years.

Plus, its smooth, non-porous surface is faster and easier for your team to clean and sanitize. That translates directly into saved labor costs, shift after shift. Investing a bit more now for a table that lasts often means you spend far less on replacements, repairs, and even labor down the road. To see how these tables fit into the bigger picture of your kitchen's needs, it's worth reviewing a complete commercial kitchen equipment checklist.

When to Invest and When to Save

So, where should you put your money? It comes down to how the table will be used.

-

Go Premium For: High-volume prep stations where you'll be butchering, chopping, and constantly working. In this case, you need the toughest, heavy-duty, 304-grade stainless steel table you can get. The same goes for any table near a sink or dish machine—you absolutely need that superior corrosion resistance to prevent rust.

-

Save Money On: Lighter-duty tasks. If you just need a stand for a mixer or a surface for dry storage away from the main action, a more economical 430-grade or even a galvanized base table will do the job perfectly well without the premium cost.

The market for commercial cooking equipment, which includes these vital work surfaces, was valued at USD 13.8 billion and is expected to hit USD 22.4 billion by 2033. This isn't just a random statistic; it shows a clear industry trend towards investing in quality, reliable gear. You can dig into what's driving this growth by exploring the full market analysis.

Installation and Upkeep: Making Your Investment Last

So, your new commercial kitchen table has arrived. Getting it out of the box is easy, but what you do next is what really counts. Proper assembly and a solid cleaning routine aren't just suggestions—they're essential for getting the most out of your table, keeping your staff safe, and acing every health inspection. A poorly assembled table is a serious hazard, and a dirty one is a direct threat to your business.

First things first, let's talk about setup. I've worked in enough kitchens to know that a perfectly level floor is a rare sight. This is exactly why almost every commercial table comes with adjustable bullet feet. Grab a level and place it on the tabletop. Tweak each foot individually until that bubble is dead center and the table has zero wobble. If you're planning to load it up with heavy equipment, I highly recommend bolting the legs to the floor with brackets. It's a small step that adds a huge amount of stability.

Creating a Maintenance Plan That Actually Works

Once your table is set up and stable, your focus should shift to keeping it in prime condition. The key isn't a massive deep clean once a month; it's about building simple, daily habits that prevent rust, kill bacteria, and stop wear and tear before they start.

Here’s a practical routine your team can follow starting today:

- End of Every Shift: Wipe down every surface with warm water and a mild, food-safe detergent. Pro tip: always wipe with the grain of the steel, not against it. This prevents tiny scratches. Rinse it with clean water and, most importantly, dry it completely with a soft cloth. This stops those annoying water spots and mineral deposits from forming.

- Once a Week: Give it a more detailed clean. Use a dedicated, non-abrasive stainless steel cleaner. Make sure to hit the corners, edges, and the undershelf—that's where crumbs and gunk love to hide. This is also the perfect time to give the legs a quick check and tighten any bolts that might have loosened.

- When You See It: Deal with issues as they pop up. You can buff out minor scratches with a stainless steel polishing kit. For a tough stain, a simple paste of baking soda and water often does the trick. Whatever you do, never use steel wool, abrasive scouring pads, or any cleaners with chlorine. They will absolutely destroy the passive layer that protects the steel from rust.

A well-maintained table isn't just about looking professional. It's a core part of an efficient kitchen. When your equipment is cared for, you cut down on long-term replacement costs and avoid unexpected downtime. That’s a win for your bottom line.

This trend toward durable, easy-to-maintain equipment is a huge deal in the industry. The global market for commercial kitchen appliances is expected to jump from USD 98.56 billion in 2025 to USD 133.02 billion by 2030. A big part of that growth is the demand for gear that can slash maintenance costs by as much as 30%. You can get a better sense of where things are headed by checking out more analysis on the commercial kitchen appliance market.

Common Questions About Commercial Kitchen Tables

https://www.youtube.com/embed/btR9CWYB1TM

When you're ready to pull the trigger on a new commercial kitchen table, a few final questions always seem to pop up. Getting straight answers to these practical details is key to buying with confidence and making sure you get a piece of equipment that's going to work as hard as you do.

Let's walk through some of the most common questions I hear from chefs and restaurant owners. We'll get into the nitty-gritty of materials, dimensions, and features that can make a huge difference in your day-to-day operations.

What Is The Best Stainless Steel Grade For A Prep Table?

For any surface where food is prepped directly, 304-grade stainless steel is the gold standard, no question about it. It has a higher content of nickel and chromium, which gives it fantastic resistance to rust and corrosion. Think about all the acidic things it'll come into contact with—lemon juice, vinegar, tomato sauce. The 304 grade stands up to all of it, making it the only real choice for a workhorse prep surface.

Now, that doesn't mean the entire table needs to be 304-grade. A smart way to save some money without sacrificing quality is to look for tables with 430-grade stainless steel legs or undershelves. These parts aren't touching food, so they don't need the same level of corrosion resistance. This is the kind of exclusive knowledge that helps you find the best deals on the equipment you need.

How Do I Clean And Sanitize My Stainless Steel Table?

Keeping your tables in top shape is all about a simple, consistent routine. For daily grime, all you need is warm water and a mild detergent. The key trick is to always wipe in the direction of the metal's grain—you can see the faint lines if you look closely. This prevents micro-scratches and keeps the finish looking good.

After washing, rinse it with clean water and—this is important—dry it completely with a soft cloth. Letting it air dry is what causes those annoying water spots and mineral streaks. Once it's clean and dry, you can apply a food-safe sanitizer, just follow the instructions on the bottle.

Critical Tip: Whatever you do, keep harsh cleaners away from your stainless steel. Abrasives like steel wool or chlorine-based products like bleach will destroy the protective layer on the steel, leading to scratches and, eventually, rust.

Should I Get A Table With A Backsplash?

My advice? If the table is going against a wall, get the backsplash. It's a small feature that solves a huge headache. That little 1.5 to 2-inch lip at the back stops food, liquids, and even small tools from sliding into that dreaded gap between the wall and the table.

Sure, it adds a little to the cost upfront, but think about the time you'll save on cleanup. More importantly, it boosts your kitchen's hygiene by getting rid of a hard-to-clean trap for gunk and bacteria. Most experienced chefs wouldn't have it any other way.

What Is The Standard Height For A Commercial Work Table?

You'll find that almost every commercial work table sits between 34 and 36 inches high. That's not a random number. It’s the ergonomic sweet spot that allows most people to work comfortably for hours without hunching over or reaching up.

This is more than just a comfort issue; it's a safety and productivity one. A properly sized table reduces the strain on your staff’s backs, necks, and shoulders during those long, grueling prep shifts. It’s one of those small details that contributes to a better, more efficient kitchen environment for your whole team.

Ready to discover the latest news and exclusive deals on restaurant equipment? At Encore Seattle Restaurant Equipment, we help restaurant owners and chefs stay informed about industry trends and find the perfect commercial kitchen tables for any operation. We offer a vast selection of new and used equipment to meet any need and budget. Explore our inventory and get expert advice by visiting us at https://encoreseattle.com.