Commercial Kitchen Equipment Checklist for 2025

Share

Outfitting a commercial kitchen is one of the biggest investments a restaurant owner or chef will make. Success hinges on choosing the right tools that balance performance, budget, and space. This comprehensive commercial kitchen equipment checklist goes beyond a simple list of items. It’s a strategic guide designed to help you navigate one of the most critical phases of building or upgrading your culinary operation.

We will provide a detailed, item-by-item breakdown of the essential equipment every kitchen needs, from core cooking appliances to vital safety systems. This resource is built for full-service restaurant owners, food truck entrepreneurs, café managers, and catering companies alike. You will gain practical insights, specific feature analyses, and honest assessments to make informed purchasing decisions.

Throughout this guide, we'll connect you with the latest industry trends and exclusive deals. Our goal is to help you build a kitchen foundation that supports efficiency, meets compliance standards, and positions your business for long-term growth. Let's equip your kitchen for success, starting with the right plan.

1. Commercial Refrigeration Systems

Commercial refrigeration systems are the lifeblood of any professional kitchen, forming the essential foundation for food safety and inventory management. This category includes everything from large walk-in coolers for bulk storage to smaller reach-in refrigerators and freezers for line-of-sight access during service. Without reliable cold storage, perishable inventory would spoil, leading to significant financial loss and severe health code violations. These units are specifically engineered for heavy-duty use, featuring robust compressors and durable construction to withstand the demanding environment of a commercial kitchen.

Implementation and Key Considerations

When selecting a system, consider your kitchen's workflow. Walk-in coolers, like those used by Whole Foods Market from brands like Kolpak, are ideal for receiving and storing bulk deliveries. Reach-in units from manufacturers like True Manufacturing or Traulsen are better placed near prep stations for quick access. Under-counter models are perfect for maximizing space at the service line, a strategy effectively used by Starbucks. Staying informed on industry news can often lead to exclusive deals on these essential pieces of restaurant equipment.

Pro Tip: Always choose a refrigeration unit that is approximately 20% larger than your current calculated needs. This provides a crucial buffer for menu expansion, seasonal specials, and business growth without requiring an immediate, costly upgrade.

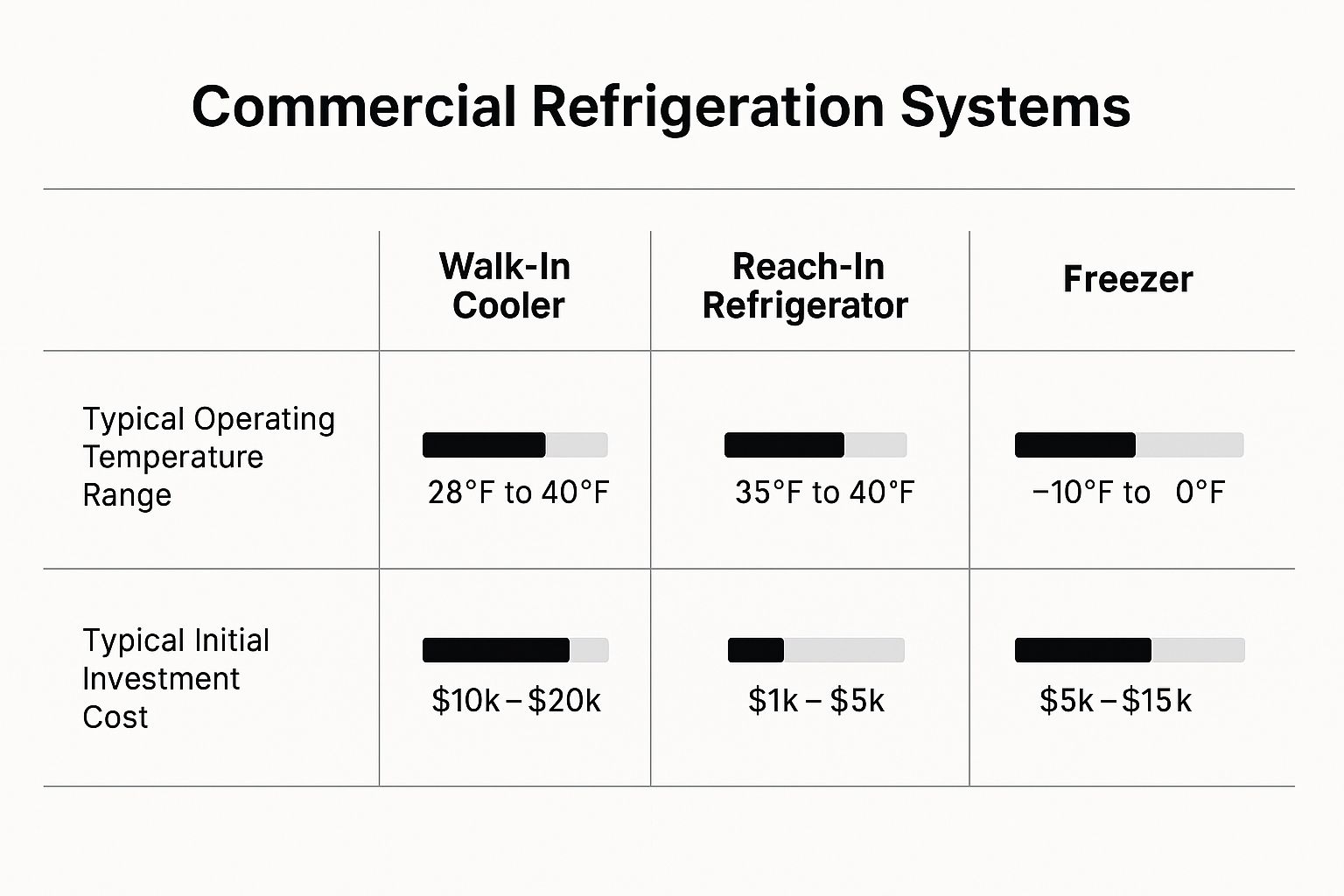

The following chart compares the primary commercial refrigeration options, highlighting their typical operating temperatures and initial investment costs.

As the data shows, walk-in coolers represent the highest initial investment but provide the largest storage capacity, while reach-in units offer a mid-range balance of cost and accessibility. Regularly monitoring industry trends and exclusive deals on equipment can help you secure these vital assets at a better price point.

2. Commercial Cooking Equipment

Commercial cooking equipment forms the operational core of any kitchen, encompassing the essential appliances that transform raw ingredients into finished dishes. This category includes everything from high-output commercial ranges and ovens to specialized grills, griddles, and deep fryers. These pieces are the workhorses of the kitchen, designed to endure constant, high-volume use while delivering precise temperature control and consistent results, making them a non-negotiable part of any serious commercial kitchen equipment checklist.

Implementation and Key Considerations

Choosing the right cooking equipment requires a deep understanding of your menu and service volume. For instance, Gordon Ramsay's high-end restaurants rely on the power and precision of Wolf commercial ranges to execute complex dishes. In contrast, fast-casual chains like Chipotle Mexican Grill utilize large Vulcan commercial grills to handle their high-throughput demand for grilled meats. Similarly, KFC's signature product depends on the specialized performance of Henny Penny pressure fryers to achieve consistent quality across thousands of locations. Consider combination units, like a range with a griddle top and convection oven base, to maximize space efficiency in smaller kitchens.

Pro Tip: When planning your cook line, ensure there is adequate space around each piece of equipment. This not only facilitates easier and more thorough cleaning but also provides technicians with the necessary access for maintenance and repairs, minimizing downtime.

This video from Vulcan Equipment, a leading manufacturer alongside brands like Garland, offers a closer look at the design and functionality that defines top-tier commercial cooking appliances.

Matching equipment capacity directly to your peak service demands is crucial for operational success. Implementing a strict daily cleaning schedule and staying informed about the latest industry trends and exclusive deals will help protect your investment and ensure your kitchen operates at peak performance.

3. Ventilation and Hood Systems

Often overlooked but critically important, commercial kitchen ventilation and hood systems are essential for air quality management and fire safety. These systems are engineered to capture and exhaust heat, smoke, grease-laden vapors, and odors generated by cooking equipment. A properly designed system not only ensures compliance with stringent fire and health codes but also creates a safer and more comfortable working environment for your staff, directly impacting productivity and morale. Without effective ventilation, a kitchen quickly becomes a hazardous space filled with airborne contaminants.

Implementation and Key Considerations

The type and size of your ventilation system depend entirely on the cooking equipment beneath it. Major restaurant chains often rely on comprehensive systems from manufacturers like Captive-Aire, while specialized facilities such as hospitals may use innovative solutions from Halton. The core components include the hood, exhaust fan, ductwork, and a crucial makeup air unit that replaces the exhausted air. Properly balancing this system is vital for performance and energy efficiency.

Pro Tip: Your hood should extend at least 6 inches beyond the cooking equipment on all sides. This "overhang" creates a larger capture area, ensuring that grease, smoke, and heat are effectively drawn into the exhaust system instead of spilling out into the kitchen.

A key part of any commercial kitchen equipment checklist is ensuring long-term operational efficiency. Installing variable-speed controls on your system's fans can significantly reduce energy costs during non-peak hours. Regular professional cleaning, at least quarterly, is non-negotiable to prevent dangerous grease buildup, a primary cause of kitchen fires. By staying informed on the latest news and industry trends, you can find systems that offer both peak performance and energy savings.

4. Food Preparation Equipment

Food preparation equipment forms the mechanical backbone of a kitchen's prep line, automating and standardizing tasks that would otherwise be labor-intensive and inconsistent. This category includes everything from industrial-grade mixers and food processors to precision slicers and the stainless-steel prep tables that house these operations. These tools are the key to efficiency, enabling chefs to process large volumes of ingredients quickly while maintaining uniform cuts, mixes, and textures. Without them, a kitchen's output would slow dramatically, increasing labor costs and jeopardizing product consistency.

Implementation and Key Considerations

The selection and placement of food prep equipment are critical for a smooth workflow. High-volume bakeries and pizzerias rely on legendary mixers from brands like Hobart for consistent dough. Fine dining establishments often utilize Robot Coupe food processors for creating refined purées and emulsions. Delis and sandwich shops depend on the precision of Berkel slicers to ensure uniform portion control. Integrating these tools into a commercial kitchen equipment checklist is not just about having them; it's about positioning them to create an efficient production line. To discover the latest news and exclusive deals on these items, you can find a wide range of Food Preparation Equipment on encoreseattle.com.

Pro Tip: Invest in training for every staff member on proper operation, cleaning, and safety protocols for each piece of equipment. This minimizes the risk of injury, prevents costly damage, and ensures the longevity of your investment. Keep a small inventory of common wear items like blades and belts to avoid downtime.

5. Dishwashing Systems

Dishwashing systems are the unsung heroes of a commercial kitchen, providing the critical sanitation backbone for all serviceware. This category encompasses high-capacity machines like conveyor dishwashers, door-type units, glasswashers, and powerful pot washers. These systems are specifically engineered to handle the high volume and stringent health code requirements of professional operations, ensuring every plate, glass, and utensil is impeccably clean and sanitized. A reliable system prevents cross-contamination, maintains a professional appearance, and is a non-negotiable part of any commercial kitchen equipment checklist.

Implementation and Key Considerations

The type of system you choose depends heavily on your kitchen's size and output. High-volume operations like hospital and school cafeterias often rely on large conveyor dish machines from brands like Hobart for maximum efficiency. Fast-casual chains might opt for powerful door-type units from manufacturers such as Champion Industries, while hotel kitchens often utilize comprehensive warewashing systems from Jackson. For bars and cafes, dedicated under-counter glasswashers are essential for a quick turnaround of pristine glassware.

Pro Tip: Always pre-rinse dishes with a spray nozzle before loading them into the machine. This simple step dramatically improves washing efficiency, reduces chemical consumption, and prevents food debris from clogging the washer's filters and jets.

Proper maintenance and operation are key to longevity and performance. Adhering to manufacturer guidelines for water temperature and chemical concentrations will ensure optimal sanitization. You can explore a variety of sinks and dishwashers to find the right fit for your operational needs. Regularly monitoring industry updates can also lead to exclusive deals on these essential assets, helping you stay current with the latest warewashing technology trends.

6. Storage and Shelving Systems

Proper storage and shelving systems are the organizational backbone of a high-functioning kitchen, crucial for maintaining inventory, ensuring food safety, and maximizing spatial efficiency. This category encompasses everything from heavy-duty wire shelving for walk-in coolers and dry storage areas to mobile units for flexible prep needs. Without a well-designed storage plan, kitchens risk cross-contamination, inventory loss, and chaotic workflows that directly impact service speed and safety compliance. These systems are built for durability and sanitation, designed to withstand heavy loads and frequent cleaning.

Implementation and Key Considerations

When planning your layout, consider the flow of goods from receiving to service. Metro shelving systems, for example, are industry-standard for walk-in coolers due to their open-wire design that promotes air circulation. In dynamic environments like catering operations, mobile storage units from manufacturers such as Cambro offer unparalleled flexibility. For meticulous dry goods organization, hospital kitchens often rely on Quantum storage bins to separate and protect ingredients. This strategic placement ensures that every item has a designated, accessible home, forming a key part of your complete commercial kitchen equipment checklist.

Pro Tip: Always install stationary shelving at least six inches off the floor and away from walls to comply with health codes, prevent pest harborage, and simplify cleaning. Pair this with a strict First-In, First-Out (FIFO) rotation system to minimize waste.

By integrating a robust storage strategy, you create a safer and more efficient operational environment. To stay informed on the latest industry trends and discover exclusive deals on restaurant equipment and supplies, you can explore various Storage and Shelving Systems. Regular inventory audits and clear labeling are the final touches that transform simple shelves into a powerful management tool.

7. Ice Machines and Water Systems

Often overlooked yet crucial to beverage service, food preservation, and even some culinary techniques, ice machines and water systems are non-negotiable assets in any commercial kitchen. This category covers everything from high-volume ice makers that keep pace with a busy bar to sophisticated water filtration systems that ensure purity and taste consistency. A reliable supply of clean ice and quality water is fundamental not just for beverages but for food safety, prep work, and extending the lifespan of other equipment like steamers and coffee makers. These systems are designed to produce and store ice efficiently and hygienically, making them a cornerstone of operational excellence.

Implementation and Key Considerations

When choosing an ice machine, the key is to match production capacity to your peak demand. Under-counter models are perfect for bars and service stations, while larger, modular units are better for high-volume needs. For instance, Starbucks relies on Hoshizaki machines for their consistent, clear ice, while large venues like sports stadiums often use high-capacity Manitowoc equipment. An integrated water filtration system is equally important, as it improves the taste and clarity of ice and protects the machine from scale buildup, a common issue in hard water areas.

Pro Tip: Your ice machine should be professionally cleaned and sanitized at least every six months. This prevents slime and mold buildup, ensures compliance with health codes, and significantly extends the life of the unit.

Properly sizing your equipment is the most critical step in this part of your commercial kitchen equipment checklist. Consider not only drinks but also its use in salad bars, seafood displays, and food prep. Subscribing to industry newsletters can provide alerts on new models and exclusive deals, helping you invest wisely in these essential systems.

8. Work Tables and Food Prep Surfaces

Work tables and food prep surfaces are the fundamental platforms of kitchen productivity, providing the durable, sanitary space required for everything from chopping vegetables to plating finished dishes. As a core component of any commercial kitchen equipment checklist, these surfaces include stainless steel tables for general use, specialized butcher blocks, and integrated prep stations. Their design prioritizes hygiene and resilience, offering a non-porous, easily cleanable area that is essential for preventing cross-contamination and adhering to strict food safety standards. These tables are built to withstand constant use, heavy impacts, and rigorous cleaning protocols.

Implementation and Key Considerations

The layout of your work surfaces directly impacts kitchen efficiency. Stainless steel tables from manufacturers like Advance Tabco or Eagle Group are versatile workhorses, ideal for placement between cooking and refrigeration units to create a logical workflow. For specialized tasks, such as in high-end steakhouses, a John Boos butcher block table provides a dedicated, durable surface for meat fabrication. The key is to arrange these surfaces to minimize staff movement and create ergonomic, dedicated zones for different prep tasks, from assembly to plating.

Pro Tip: Implement a color-coded cutting board system (e.g., red for raw meat, green for produce) to create a visual, easy-to-follow protocol for preventing cross-contamination. This simple step significantly enhances food safety with minimal investment.

Choosing the right material and configuration is critical. Stainless steel offers unmatched durability and ease of sanitation, while butcher block is preferred for specific butchery tasks. Consider tables with integrated features like undershelves for storage or backsplashes to protect walls. Staying informed about the latest industry news and equipment trends can also reveal new materials and ergonomic designs that could further optimize your kitchen's layout and efficiency.

9. Smallwares and Utensils

While large appliances form the backbone of a commercial kitchen, smallwares and utensils are the essential tools that enable day-to-day culinary execution. This broad category encompasses everything from pots, pans, and chef's knives to serving utensils, cutting boards, and specialized gadgets. These items are the direct interface between the chef and the food, and their quality, organization, and availability directly impact kitchen efficiency, consistency, and even staff morale. Without a well-stocked and managed inventory of smallwares, even the most advanced kitchen cannot function effectively.

Implementation and Key Considerations

When outfitting a kitchen, the specific smallwares needed depend heavily on the menu. A fine-dining establishment will invest heavily in high-performance knives from brands like Wüsthof, while a high-volume institutional kitchen might prioritize durable, NSF-certified cookware from a manufacturer like Vollrath. For buffet and catering operations, innovative serving and storage solutions from companies such as Cambro are indispensable for maintaining food quality and presentation. A crucial part of any commercial kitchen equipment checklist is a detailed inventory of these smaller, but vital, assets.

Pro Tip: Implement a color-coded system for cutting boards and utensil handles (e.g., red for raw meat, green for produce) to prevent cross-contamination. This simple, visual system is a cornerstone of food safety protocols and is easy for staff to follow during busy service periods.

Organizing smallwares is just as important as purchasing them. Use pegboards for hanging pots and pans, magnetic strips for knives, and clearly labeled bins for various utensils. This not only saves precious time during service but also helps in quickly identifying missing items. Regularly monitoring industry news can reveal exclusive deals on these supplies, allowing for cost-effective inventory replenishment.

10. Safety and Sanitation Equipment

Beyond cooking and cooling, a well-equipped commercial kitchen must prioritize the health and safety of its staff and patrons. Safety and sanitation equipment is non-negotiable, encompassing everything from fire suppression systems and first aid kits to dedicated eyewash stations and sanitizing tools. This equipment forms the backbone of a safe working environment, ensuring compliance with stringent health and safety regulations and preventing accidents, injuries, and cross-contamination. Neglecting this part of your commercial kitchen equipment checklist can lead to catastrophic failures, legal liabilities, and irreparable damage to your reputation.

Implementation and Key Considerations

Integrating safety equipment requires a strategic, location-based approach. Automated fire suppression systems, like those from industry leader Ansul, are mandatory installations over all cooking surfaces. Eyewash stations from manufacturers like Bradley should be placed in or near dishwashing and chemical storage areas. Furthermore, accessible first aid kits and clearly labeled sanitation stations, often utilizing Rubbermaid Commercial products, should be distributed throughout the kitchen to ensure immediate access during an emergency. This comprehensive setup is crucial for creating a culture of safety.

Pro Tip: Schedule and log regular, documented inspections for all safety equipment. This includes monthly checks of fire extinguishers, semi-annual servicing of suppression systems, and weekly audits of first aid supplies. This diligence not only ensures compliance but also keeps your equipment in peak condition for when you need it most.

Maintaining an updated inventory of all cleaning chemicals and their corresponding Safety Data Sheets (SDS) is a legal requirement and a critical safety practice. All staff must be thoroughly trained on the location and proper use of every piece of safety and sanitation equipment. Regularly monitoring industry news and trends can alert you to new safety standards and exclusive deals on essential supplies.

Commercial Kitchen Equipment Checklist Comparison

| Equipment Type | Core Features / Characteristics | User Experience & Quality ★ | Value Proposition 💰 | Target Audience 👥 | Unique Selling Points ✨ |

|---|---|---|---|---|---|

| Commercial Refrigeration Systems | Temperature control (-10°F to 40°F), NSF cert., digital alarms | ★★★★☆ Energy efficient, reliable | 💰 $3,000-$50,000+, free WA freight | 👥 Chefs, restaurateurs, foodservice ops | ✨ ENERGY STAR units, scalable storage |

| Commercial Cooking Equipment | Heavy-duty rigs, high BTU, multiple zones, safety features | ★★★★☆ Durable, consistent results | 💰 $2,000-$20,000+, vent. required | 👥 High-volume kitchens, commercial chefs | ✨ Versatile units, rapid heating |

| Ventilation and Hood Systems | Stainless steel, fire suppression, makeup air, variable fans | ★★★★☆ Improves air quality & safety | 💰 $15,000-$50,000+, pro install | 👥 All commercial kitchens | ✨ NFPA 96 compliant, grease filtration |

| Food Preparation Equipment | Stainless steel, speed controls, safety interlocks, NSF cert. | ★★★★☆ Boosts productivity | 💰 $500-$10,000+ per unit | 👥 Bakeries, cafés, sandwich shops | ✨ Reduces labor, consistent portions |

| Dishwashing Systems | High-temp sanitizing, automatic chemical dispensing | ★★★★☆ Efficient, sanitary | 💰 $5,000-$25,000+ | 👥 Restaurants, hospitals, schools | ✨ Energy & water efficient, health compliant |

| Storage and Shelving Systems | NSF-certified, adjustable, corrosion-resistant, mobile units | ★★★★☆ Organizes & maximizes space | 💰 Moderate setup cost | 👥 Kitchens needing inventory control | ✨ Mobile units, FIFO rotation support |

| Ice Machines and Water Systems | Multiple ice types, antimicrobial, ENERGY STAR rated | ★★★★☆ Reliable ice & filtered water | 💰 Mid to high investment | 👥 Beverage-focused businesses | ✨ Built-in filtration, antimicrobial |

| Work Tables and Food Prep Surfaces | Stainless steel, adjustable, storage options, casters | ★★★★☆ Durable & ergonomic | 💰 Variable, depends on config | 👥 All commercial kitchens | ✨ Customizable, ergonomic design |

| Smallwares and Utensils | Commercial-grade, NSF cert., ergonomic, dishwasher-safe | ★★★★☆ Essential, easy to replace | 💰 Lower cost, recurring budget | 👥 All kitchen staff & food prep | ✨ Wide range, quality brands |

| Safety and Sanitation Equipment | Fire suppression, eyewash, sanitizer dispensers, signage | ★★★★☆ Compliance & protection | 💰 Installation + upkeep costs | 👥 All foodservice operations | ✨ OSHA & fire code compliant |

Equipping Your Vision for Success

Navigating the extensive world of commercial kitchen equipment can feel overwhelming, but building a successful culinary operation starts with a solid foundation. This comprehensive commercial kitchen equipment checklist has provided a strategic blueprint, moving beyond a simple list of items to offer a detailed analysis of what truly matters: functionality, workflow integration, and long-term value. We've explored the critical roles of high-performance cooking ranges, the non-negotiable necessity of efficient ventilation, and the often-underestimated impact of well-designed work tables and storage systems.

The core takeaway is that every piece of equipment is an investment in your restaurant's core identity. The right commercial refrigerator doesn't just keep food cold; it protects inventory and ensures food safety, directly impacting your bottom line. Similarly, a high-capacity dishwasher does more than clean plates; it maintains sanitation standards and keeps your service running smoothly during the busiest hours. Your choices in smallwares and food prep tools directly empower your staff to execute your menu with precision and consistency.

From Checklist to Action Plan

Mastering this checklist means you are not just purchasing steel and circuits; you are strategically building a system. An effective kitchen is a well-oiled machine where each component, from the ice machine to the prep counter, works in harmony. This holistic approach prevents costly mistakes, such as buying oversized equipment for a small space or underestimating your refrigeration needs, which can lead to operational chaos and financial strain.

As you move forward, transform this checklist into a dynamic action plan by considering these next steps:

- Finalize Your Menu: Your menu is the ultimate guide. It dictates whether you need a charbroiler or a griddle, a convection oven or a combi oven.

- Measure Your Space: Create a detailed floor plan. Account for every inch, including clearance for ventilation hoods, door swings, and workflow paths for your staff.

- Set a Realistic Budget: Use this guide to create a tiered budget. Distinguish between essential "day-one" purchases and items that can be acquired later. Explore both new and high-quality used options to maximize your capital.

- Stay Informed: The restaurant industry is constantly evolving. Keep up with the latest equipment innovations, energy-efficiency standards, and industry trends to make smarter, future-proof investments. Staying informed about the latest news and discovering exclusive deals on restaurant equipment and supplies is key.

Ultimately, a well-equipped kitchen is the engine that drives your culinary vision. By thoughtfully selecting each piece of equipment, you are creating an environment where efficiency, safety, and quality can thrive. This careful planning empowers your team, elevates your product, and positions your business for sustained growth and success in a competitive landscape.

Ready to turn your checklist into reality? The experts at Encore Seattle Restaurant Equipment can provide personalized guidance, helping you select the perfect new or used pieces that fit your space, menu, and budget. From layout design to flexible financing, they are a trusted partner in building your dream kitchen. Find unbeatable pricing and expert advice at Encore Seattle Restaurant Equipment.