Master Your Commercial Kitchen Design Layout

Share

A successful commercial kitchen design layout is so much more than just arranging equipment. It’s the engine that drives your restaurant's speed, quality, and ultimately, its profitability. A smart design creates a seamless flow, keeps your staff sane, and ensures every plate that leaves the kitchen meets your standards—all of which directly impacts your bottom line. Helping restaurant owners and chefs discover the latest news and exclusive deals on restaurant equipment and supplies is key to staying informed about industry trends.

Why Your Kitchen Layout Defines Your Restaurant's Success

The real heart of your restaurant isn't the dining room; it's the kitchen. You have to think of it as your operational command center. A well-planned layout turns a potentially chaotic space into a high-performance work environment. Get it wrong, and you’re signing up for constant bottlenecks, frustrated staff, and agonizingly slow ticket times.

During a busy dinner rush, every second counts. Your kitchen's structure is what determines whether your team works in perfect harmony or just keeps tripping over each other.

This isn't a new concept. The evolution of kitchen design has always been a march toward greater efficiency and safety. As a general rule of thumb, industry guidelines suggest dedicating about 40% of a restaurant's total space to the back of house—mostly the kitchen—while the other 60% goes to customer-facing areas. This balance gives your operational core the breathing room it needs without short-changing the guest experience. You can explore more details on how these principles translate into modern kitchen space allocation.

The Foundation of a Profitable Kitchen

Before you even dream about that shiny new six-burner range, you need to get laser-focused on workflow and function. A strategic commercial kitchen design layout isn't just a puzzle of fitting everything in; it’s about creating a logical journey for food, from the delivery truck straight to the customer's plate.

This means you need to get a few key things right from the start:

- Workflow Efficiency: The layout has to support a natural, forward-moving path for ingredients. This simple idea is crucial for minimizing backtracking and preventing those clumsy (and dangerous) staff collisions.

- Space Optimization: Every square foot of your kitchen is prime real estate. A great design uses space intelligently, often incorporating vertical storage and multi-function equipment to get the most out of a tight footprint.

- Safety and Compliance: This one is non-negotiable. Your design must account for proper ventilation, fire suppression systems, and sanitation stations right from the planning stage. Building around these requirements is much easier than trying to shoehorn them in later.

A well-designed kitchen layout is the silent partner in your business. It works behind the scenes to enhance productivity, boost staff morale, and ultimately deliver a better dining experience for your customers.

Aligning Layout with Your Concept

What kind of food are you serving, and how are you serving it? These are the most critical questions that will shape your kitchen design. The needs of a high-volume quick-service restaurant (QSR) are worlds apart from a fine-dining spot with an intricate, multi-course tasting menu.

For instance, a pizza joint is going to need a ton of space for bulky deck ovens and long, refrigerated prep lines. A ghost kitchen that's all about delivery, on the other hand, will likely favor a super-compact, assembly-line layout to pump out orders as fast as possible.

When you start thinking like a designer, you can choose a foundational layout that genuinely supports your unique operational needs. This foresight is what sets the stage for success long before you ever serve your first customer.

To help you visualize this, here’s a quick rundown of the most common layouts and what they’re best for.

At-a-Glance Guide to Common Kitchen Layouts

| Layout Type | Best For | Key Feature |

|---|---|---|

| Assembly Line | QSRs, Pizzerias, Sandwich Shops | A linear, forward-moving workflow that maximizes speed and consistency. |

| Island | Restaurants with a star chef or complex menus | A central block for cooking, with other stations arranged around the perimeter. |

| Zone-Style | Hotels, Large Restaurants, Catering | Dedicated areas (e.g., sauté, grill, fry) that operate as mini-kitchens. |

| Galley | Food Trucks, Small Cafes, Ghost Kitchens | Two parallel walls or counters, making efficient use of very narrow spaces. |

| Ergonomic | Any kitchen focused on staff well-being | A layout designed to minimize strain, steps, and wasted motion for the crew. |

Choosing the right blueprint is the first major step. Once you've identified a layout that aligns with your restaurant concept, you can start diving into the nitty-gritty details of equipment placement and station design.

Mastering Workflow With Five Essential Kitchen Zones

A truly great commercial kitchen layout flows like a well-rehearsed dance. It’s not about having the biggest space or the fanciest gear; it’s about creating a rhythm where every section works in perfect harmony. This synergy doesn't happen by accident. It's carefully engineered around five essential zones that map the journey of food from the delivery truck to the customer's fork.

Let's move past the abstract and get into how these zones actually work on the ground. Understanding how they connect is the secret to building a kitchen that feels intuitive and efficient, making life easier for your entire team.

The First Stop: Receiving and Storage

Everything starts at the back door. This is your kitchen’s first point of contact with the outside world, and it's your frontline for quality control. The layout here needs to be all about speed and organization. Your delivery door should be as close as physically possible to your dry storage and walk-in coolers.

Think about it. A driver drops off 20 cases of fresh produce. If your team has to lug those heavy boxes across a busy kitchen, dodging the hot line and active prep stations, you’re not just wasting time and effort. You’re also creating safety hazards and risking temperature-sensitive food.

To get this zone right:

- Forge a clear path: You need a wide, unobstructed walkway from the receiving door straight to your storage units. No exceptions.

- Set up a staging area: A few simple shelves right inside the door give staff a place to set things down, check invoices, and inspect goods before they get put away.

- Keep storage separate: Your design must have distinct, dedicated areas for dry goods (your pantry), refrigerated items (walk-in cooler), and frozen products (walk-in freezer).

A poorly designed receiving area creates a domino effect. Every extra step your staff takes here is a moment they aren't spending prepping and cooking, and that inefficiency trickles down through the entire service.

The Creative Hub: Food Preparation

This is where your raw ingredients begin their transformation. The prep zone is often broken into at least two smaller areas to combat one of the biggest risks in any kitchen: cross-contamination. Your layout has to create a physical separation between where you handle raw proteins and where you work with ready-to-eat foods like vegetables and greens.

This might mean using two completely separate tables. At the very least, it demands a strict color-coded cutting board system and easy access to handwashing sinks. The placement is also crucial—the prep area should logically feed ingredients toward the cooking line.

It’s a one-way street. Ingredients come from storage, hit the prep station, and then flow to the cooks. There should be almost no backtracking. Placing a salad prep table right next to the produce cooler, for example, shaves off countless steps and valuable minutes during the dinner rush.

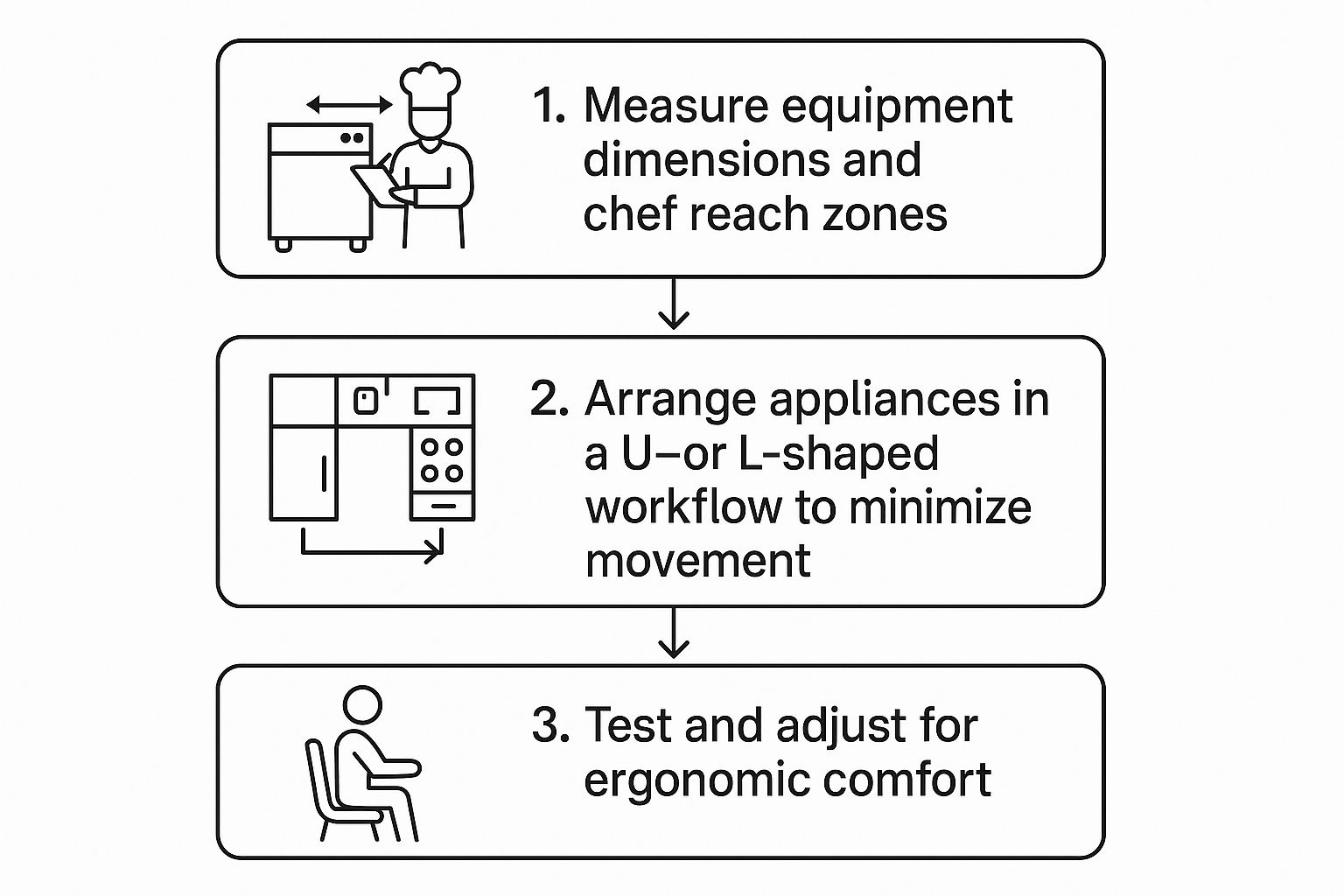

The image below gives a great visual of how to arrange your zones and equipment for a more ergonomic flow.

This just goes to show how a human-centered design can make all the difference in comfort and output.

The Heart of the Action: The Cooking Line

"The line" is where the real show happens. It's the hottest, loudest, and most intense part of the kitchen, and its design has to support speed, clear communication, and absolute consistency.

Equipment needs to be laid out in a logical sequence that mirrors your menu. For a burger joint, that might mean the griddle comes first, then the fryer for the fries, and finally a finishing station under heat lamps. It's an assembly line for food, ensuring a smooth, forward motion from start to finish.

And you can't forget ventilation. This is non-negotiable. Your exhaust hood needs to extend over every piece of equipment that produces heat, grease, or smoke. It's not just a code you have to meet; it's fundamental to air quality and creating a safe, bearable environment for your chefs.

The Final Hand-Off: The Service Area

Once a dish is fired and plated, it heads to the service area. This zone is the final quality check and the critical bridge between your back-of-house and front-of-house teams. It could be an expo window where servers grab their orders or a dedicated packing station for takeout and delivery.

Placement here is everything. The service area needs to be right next to the cooking line but just separate enough that servers and cooks aren't tripping over each other. Heat lamps, plating surfaces, and organized space for garnishes are all key parts of a well-oiled service zone.

The Unsung Hero: The Cleaning and Dishwashing Zone

Often treated as an afterthought, the dish pit is one of the most vital parts of your operation. If you get a bottleneck here, the entire restaurant can grind to a halt. The line runs out of sauté pans, the bar runs out of glasses, and the dining room runs out of plates.

Your dishwashing zone needs to be tucked away from the main prep and cooking areas to keep dirty dishes from contaminating fresh food. The workflow is just as important here as anywhere else. You need a logical flow: a drop-off window for dirty dishes, a pre-rinse station, the commercial dishwasher, and then a clean drying rack and storage area. Making sure your dish station can handle the volume of your busiest night is a detail you simply can't afford to get wrong.

Choosing the Right Layout for Your Restaurant Concept

Once you’ve mapped out your essential work zones, the real puzzle begins: arranging them into a layout that actually works. Choosing a commercial kitchen layout isn't about picking what's trendy; it’s about making a hard-nosed strategic decision that lines up perfectly with your menu, your service style, and the four walls you have to work with.

Get this wrong, and you'll hamstring even the most talented kitchen crew with permanent bottlenecks and daily frustrations. But get it right? Your layout becomes your MVP, supercharging your team’s ability to pump out quality food at a serious pace.

Let's dive into the most common layouts and see which one truly fits your business.

Assembly Line Layout

For sheer speed and consistency, nothing beats the assembly line. It’s exactly what it sounds like: a linear flow where each station handles one specific task before passing the dish along. Think of it as the engine powering the world's most successful quick-service restaurants (QSRs), pizzerias, and high-volume sandwich shops.

A build-your-own burrito spot is the perfect example. You'll have one station for tortillas and proteins, the next for rice and beans, another for toppings and salsa, and a final one for wrapping. This setup practically eliminates wasted movement and cross-traffic, letting you achieve maximum output even with a less experienced team. The downside? It’s rigid. This layout is a poor choice for restaurants with complex menus that need more flexibility.

Island Layout

If your kitchen revolves around a dynamic head chef or a specific cooking method, the island layout can be a game-changer. This design anchors the space with a central block—the "island"—which typically holds your primary cooking line: ranges, grills, and fryers. All the other zones, like prep and dishwashing, are then organized around the perimeter.

This setup naturally creates a command center, making communication and supervision a breeze. The chef can oversee everything from a single vantage point. It’s an ideal format for open kitchens or fine-dining concepts where the culinary action is part of the guest experience. The biggest constraint, however, is space. An island layout demands a large, square-shaped kitchen and simply won't work in a narrow venue.

A great layout isn't just an operational choice; it's a financial one. A design that shaves seconds off ticket times and reduces staff collisions directly boosts table turnover and cuts labor costs, adding to your bottom line every single night.

Zone-Style Layout

For massive operations like hotels, event caterers, and sprawling restaurants, the zone-style layout is often the only way to go. This model essentially creates several specialized mini-kitchens under one roof. The space is carved into distinct stations based on function—a fry station, grill station, sauté station, salad station, and so on.

Each zone is mostly self-sufficient, stocked with its own dedicated equipment and ingredients. This allows multiple cooks to fire different components of complex orders at the same time without tripping over each other. While incredibly effective for complicated menus at high volume, it’s demanding. It requires a larger, highly skilled staff and a significant amount of square footage to pull off.

This need for specialized kitchen spaces reflects a broader industry trend. There's a growing demand for custom kitchen design services, with tailored solutions holding the largest market share. In fact, North America accounted for over 35% of global revenue in 2023, underscoring this strong preference for layouts built for specific operational needs. You can dig deeper into this trend toward custom kitchen designs if you're curious.

Galley Layout

When every square inch counts, the galley layout is your best friend. You'll find this design in most food trucks, ghost kitchens, and cozy cafés. It arranges all equipment and workstations along two parallel walls, creating one central aisle for traffic.

Its compact design is incredibly efficient for a skeleton crew of one or two people, since everything is just a quick pivot or a single step away. The key to making a galley kitchen work is smart equipment selection—you need reliable, space-saving units. Exploring different commercial units to find the perfect fit is crucial, especially when it comes to essential refrigeration solutions like these. The main limitation is pretty obvious: it can't support a large team. That narrow corridor gets congested fast.

Layout Comparison Island vs. Zone vs. Assembly Line vs. Galley

To make the decision a bit easier, here’s a head-to-head comparison of these four primary layouts. Use this table to weigh the pros and cons against your specific concept.

| Layout Style | Pros | Cons | Ideal Restaurant Type |

|---|---|---|---|

| Island | Excellent for communication and chef supervision; creates a central focal point. | Requires a very large, open kitchen space; not suitable for narrow rooms. | Fine dining, open-kitchen concepts, culinary schools. |

| Zone | Highly efficient for complex, high-volume menus; allows for specialization. | Needs significant square footage and a larger, skilled staff. | Hotels, large full-service restaurants, catering operations. |

| Assembly Line | Maximizes speed and consistency; easy for staff to learn. | Inflexible and not suited for complex or varied menus. | QSRs (Quick-Service), fast-casual, pizzerias, sandwich shops. |

| Galley | Extremely space-efficient; minimizes staff movement. | Limited capacity for staff; can become congested easily. | Food trucks, ghost kitchens, small cafes, coffee shops. |

Ultimately, choosing the right commercial kitchen layout is one of the most important decisions you'll make. It will dictate your operational capacity and efficiency for years. Take the time to carefully consider these options against the unique demands of your concept to build a kitchen that works for you, not against you.

Where to Put Everything: Strategic Equipment Placement

Placing equipment in your kitchen isn't a game of Tetris. It's a calculated strategy that revolves around how people move, work, and stay safe. A truly great kitchen is designed for your staff, not just to cram in appliances. The real goal is to build a space that feels intuitive, cuts down on physical strain, and ultimately leads to faster service and a happier team.

It’s about more than just making things fit. I think of it as choreographing a dance. Every tool, every surface, every station needs to be exactly where a chef needs it, right when they reach for it. This kind of thoughtful placement is what separates a frustrating kitchen from a high-performance one.

Beyond the Basic Work Triangle

You’ve probably heard of the residential "work triangle" that connects the sink, stove, and fridge. In a commercial kitchen, we blow that concept up to connect entire workstations, but the core idea is the same: eliminate wasted steps.

A line cook shouldn't have to trek across the kitchen to grab something from a low-boy fridge after they've already started cooking. Those seconds add up over a busy service. I've seen kitchens where the layout is so inefficient that chefs are practically running a marathon every night.

You can measure a kitchen's efficiency by how well it follows these ergonomic principles. You're aiming for a sweet spot where the distance between key workstations is between 1.2 and 2.7 meters. This keeps the flow tight and efficient. For a deep dive into the science, you can find more on ergonomic workflow optimization on pmc.ncbi.nlm.nih.gov.

This intentional design doesn't just reduce fatigue; it keeps your team focused on the food, not on a frustrating commute between stations.

An ergonomic kitchen is a safer kitchen. When staff aren't constantly rushing across busy traffic lanes or twisting awkwardly to reach tools, the risk of slips, falls, and other accidents drops significantly.

To get there, here are a few practical placement tips I always recommend:

- Fridge Next to Prep: Put your under-counter or reach-in refrigerators right next to your main prep tables. This creates a seamless "grab-and-prep" motion that makes the whole mise en place process faster.

- Dish Pit Away From the Line: Your warewashing station is a hub of heat, steam, and noise. Position it away from the cooking line. This prevents traffic jams and keeps the line itself more comfortable and focused.

- A Logical Cook Line: Arrange your cooking equipment in the sequence it's actually used. For a steakhouse, that might mean a flow from the grill to the broiler, then to a finishing station with heat lamps. It creates a natural assembly line.

Thinking About Clearance, Air, and Vertical Space

Smart equipment placement is also about what’s around—and above—the machinery. Health and fire codes have strict rules about the clearance space required between equipment, especially anything that produces heat, and the walls. These dimensions aren't suggestions; they are non-negotiable for passing your inspection.

Ventilation is another huge piece of the puzzle. Your hood system has to cover every piece of equipment that creates grease-laden vapor. We're not just talking about the range; this includes your fryers, griddles, and charbroilers. You have to plan for the hood’s massive footprint early on, as it basically dictates the layout of your entire cook line.

Finally, remember to look up. Use that vertical space! Wall-mounted shelving above prep stations is perfect for keeping essential tools and small wares within easy reach, freeing up precious counter space. On the cook line, overhead pot racks do the same job. If you're starting from scratch, our guide to building a commercial kitchen equipment checklist can help you map out everything you'll need.

By combining an ergonomic workflow with smart planning for clearances and vertical storage, you'll create a kitchen that isn't just a machine for production, but a safer and genuinely better place to work. This upfront thinking will pay you back every single service.

Navigating Health Codes and Safety Regulations

You can have the most brilliant kitchen layout on paper, but it’s completely worthless if it fails its first health inspection. This is where your beautiful design collides with the hard reality of local regulations. Let me be blunt: ignoring these rules isn’t just a risk. It’s a guarantee of expensive delays, frustrating retrofits, and a headache you don’t need.

Trying to decipher the maze of health codes, building permits, and safety standards can feel like a nightmare. But from my experience, the single best way to protect your investment is to understand what inspectors are looking for from day one. Don't think of code compliance as a hurdle—it should be a foundational part of your design process.

The Inspector's Checklist: What They Really Look For

When an inspector walks into your future kitchen, they see things you don't. They’re not just admiring your shiny new equipment; they're looking at the space through a lens of public health and employee safety, armed with a very specific checklist.

Your layout has to be designed to prevent violations. The most important thing you can do is talk to your local health department and licensed contractors before you finalize anything. They’ll give you the local codes you have to live by, saving you from making a costly mistake based on a bad assumption.

Here are the non-negotiables that are always under the microscope:

- Handwashing Sinks: You need dedicated sinks just for washing hands. They can't be used for food prep or dishes, period. An inspector will immediately check for their placement in key prep areas and on the cook line.

- Equipment Spacing: There are strict rules for how much space you need between equipment and walls, and between each appliance. This isn’t just for looks; it’s critical for proper cleaning and fire safety.

- Approved Materials: Forget about unsealed concrete or standard drywall. Your floors, walls, and ceilings must be smooth, non-porous, and easy to sanitize. This is one of the first things they'll notice.

- Proper Ventilation: Your ventilation hood isn't just a suggestion; its size and power must be correctly matched to the cooking equipment underneath. This is a massive checkpoint for fire prevention and air quality.

"Your local health department isn't your enemy; they are your most important design consultant. A 30-minute meeting with them during the planning phase can save you 3 months of delays and thousands of dollars in rework."

Beyond the Health Department: Fire and Accessibility

Your compliance journey doesn’t stop with the health inspector. You also have to satisfy fire codes and accessibility laws, and both will have a major say in your final layout.

NFPA Fire Safety Protocols The National Fire Protection Association (NFPA) dictates the standards for fire prevention. This directly impacts your fire suppression system (like the ubiquitous Ansul system), which is tied into your vent hood. Your layout must thoughtfully place nozzles, pull stations, and fire extinguishers where they are effective and easily accessible.

ADA Accessibility Requirements The Americans with Disabilities Act (ADA) ensures your kitchen can be safely used by everyone. This means your aisles need to be wide enough for a wheelchair, typically requiring a clear path of at least 36 inches. ADA rules also influence counter heights and mandate that all work paths remain free of obstructions. Building this in from the start is infinitely easier than fixing it later.

Getting any of this wrong can bring your entire project to a screeching halt. By tackling these regulatory must-haves in your initial design, you’re building a kitchen that isn’t just efficient—it's safe, compliant, and ready for a smooth opening day.

Your Top Kitchen Design Questions, Answered

Planning a commercial kitchen is a huge undertaking. It’s a massive investment of both time and money, so it’s completely normal to have questions swirling. Getting the details right from the start is crucial.

I've been in this business a long time, and I hear the same worries from chefs and new restaurant owners over and over. Let's walk through some of those common sticking points—from budgeting nightmares to layout mistakes—and give you the clear, practical answers you need to feel confident about your project.

How Much Does a Commercial Kitchen Actually Cost?

This is always the first question, and the honest answer is: it depends. There’s no magic number, but a solid rule of thumb is to budget anywhere from $250 to over $1,000 per square foot.

What causes such a massive range? The biggest factor is your equipment. Are you outfitting your line with brand-new, top-tier gear, or are you strategically sourcing high-quality used pieces? That choice alone can swing your budget dramatically. Your menu's complexity is another huge driver; a simple cafe has very different needs (and costs) than a fine-dining spot requiring custom-fabricated stations.

To nail down a more realistic number for your project:

- Get multiple quotes. Don't just talk to one supplier or contractor. Shop around to get a feel for the market.

- Create a contingency fund. Plan on at least 15-20% of your total budget for the unexpected. Trust me, unexpected costs aren't a possibility; they're a guarantee.

- Remember the "soft costs." Things like design fees, permits, and installation labor add up fast and are often overlooked in initial estimates.

What Are the Worst Kitchen Layout Mistakes?

Having seen my share of dysfunctional kitchens, I can tell you the most painful mistakes almost always boil down to three things: bad workflow, not enough storage, and poor ventilation. Fixing these after the fact is a nightmare.

The single biggest error is a poorly planned workflow. When staff are constantly dodging each other and crossing paths to get to the fryer or the walk-in, you create bottlenecks. This kills ticket times, raises stress levels, and leads to a chaotic service.

Another classic mistake is underestimating your storage needs. If you don't have enough dry storage or cold holding, your prep areas will be cluttered, and you'll be forced into more frequent, smaller deliveries, which is incredibly inefficient.

Never, ever skimp on ventilation. An undersized hood system is more than just an inconvenience—it's a critical safety hazard. It creates a miserably hot kitchen, won't properly remove grease-laden vapor, and is a surefire way to fail your health and fire inspections.

Do I Really Need to Hire a Professional Kitchen Designer?

I get it—it feels like a big upfront expense when you're already watching your budget. But hiring a professional commercial kitchen designer can save you an absolute fortune in the long run. Think of it as an investment in efficiency and sanity.

A good designer brings a few invaluable things to your project:

- Code Expertise: They live and breathe local health and building codes. This ensures your plans get approved the first time, avoiding costly delays and revisions.

- Supplier Connections: They often have long-standing relationships with equipment suppliers, which can sometimes unlock better pricing or help you find hard-to-get items.

- Spatial Genius: A great designer can see potential in tight or awkward spaces, creating a flow that you might never have thought of. They are masters of maximizing every square inch.

Ultimately, a designer delivers precise, professional blueprints that your contractor can build from. This prevents the kind of expensive, on-the-fly "adjustments" that blow up budgets and timelines. For any project more complex than a basic coffee cart, their expertise is truly essential. For more answers to common operational questions, you can review our frequently asked questions page.

How Does My Menu Dictate the Kitchen Design?

Your menu isn't just a list of food—it’s the absolute blueprint for your kitchen. Every piece of equipment, every station, every inch of counter space should be a direct response to what you plan to cook. The kitchen must be built to support the menu, never the other way around.

Think about it in practical terms:

- A steakhouse is all about intense heat. Its design will be centered around powerful grills and broilers, with significant refrigerated space nearby for aging and holding proteins.

- A pizzeria is literally built around its ovens. The layout requires huge deck ovens, dough-proofing cabinets, and long, refrigerated prep rails for all the toppings.

- A from-scratch bakery is defined by its workflow. It needs heavy-duty commercial mixers, specialized convection ovens, and, most importantly, vast stretches of table space for kneading, rolling, and shaping.

Before a single electrical outlet is placed, you must map out the journey of every item on your menu. This menu-first approach is the only way to guarantee your team has the right tools and an efficient layout to execute your vision flawlessly, night after night.

Ready to bring your vision to life with the right equipment and expert advice? At Encore Seattle Restaurant Equipment, we offer an extensive selection of new and used appliances to fit any concept and budget. From refrigeration to cooking lines, we're here to help you build the efficient, compliant kitchen you need to succeed. Visit us at https://encoreseattle.com to browse our inventory and get started today.