Master Commercial Kitchen Equipment Maintenance Tips

Share

Taking care of your commercial kitchen equipment isn't just about cleaning up at the end of the night. It's about a consistent, dedicated practice of servicing and inspecting your appliances to stop problems before they start. This proactive approach helps your equipment last longer, keeps your food safe, and prevents those nightmare-scenario breakdowns that always seem to happen at the worst possible time.

Ultimately, it’s about shifting from costly emergency repairs to smart, routine upkeep. Doing so keeps your kitchen humming along safely and efficiently, saving you a fortune in the long run.

Why Proactive Maintenance Is Your Best Investment

Changing your mindset from "fix it when it breaks" to a planned maintenance schedule is one of the smartest financial moves you can make as a restaurant owner. This isn't just about dodging a few repair bills. It’s a core strategy for building a more reliable, profitable, and compliant business. Letting equipment slide doesn't just create one problem—it kicks off a domino effect that can seriously hurt your operations.

Think about your walk-in freezer giving out on a Friday during the dinner rush. The immediate chaos is a killer: thousands of dollars of inventory spoiling, service screeching to a halt, and frustrated customers heading for the door. But the pain doesn't stop there. You're now facing emergency repair fees at weekend rates and potentially even health code violations. That entire disaster is what reactive maintenance looks like.

The True Cost of Neglect

A proactive plan turns that chaos into calm. Small, consistent actions—like cleaning a condenser coil or checking a door gasket—are what prevent the catastrophic failures that lead to downtime and lost sales. This isn't just a theory; the numbers back it up.

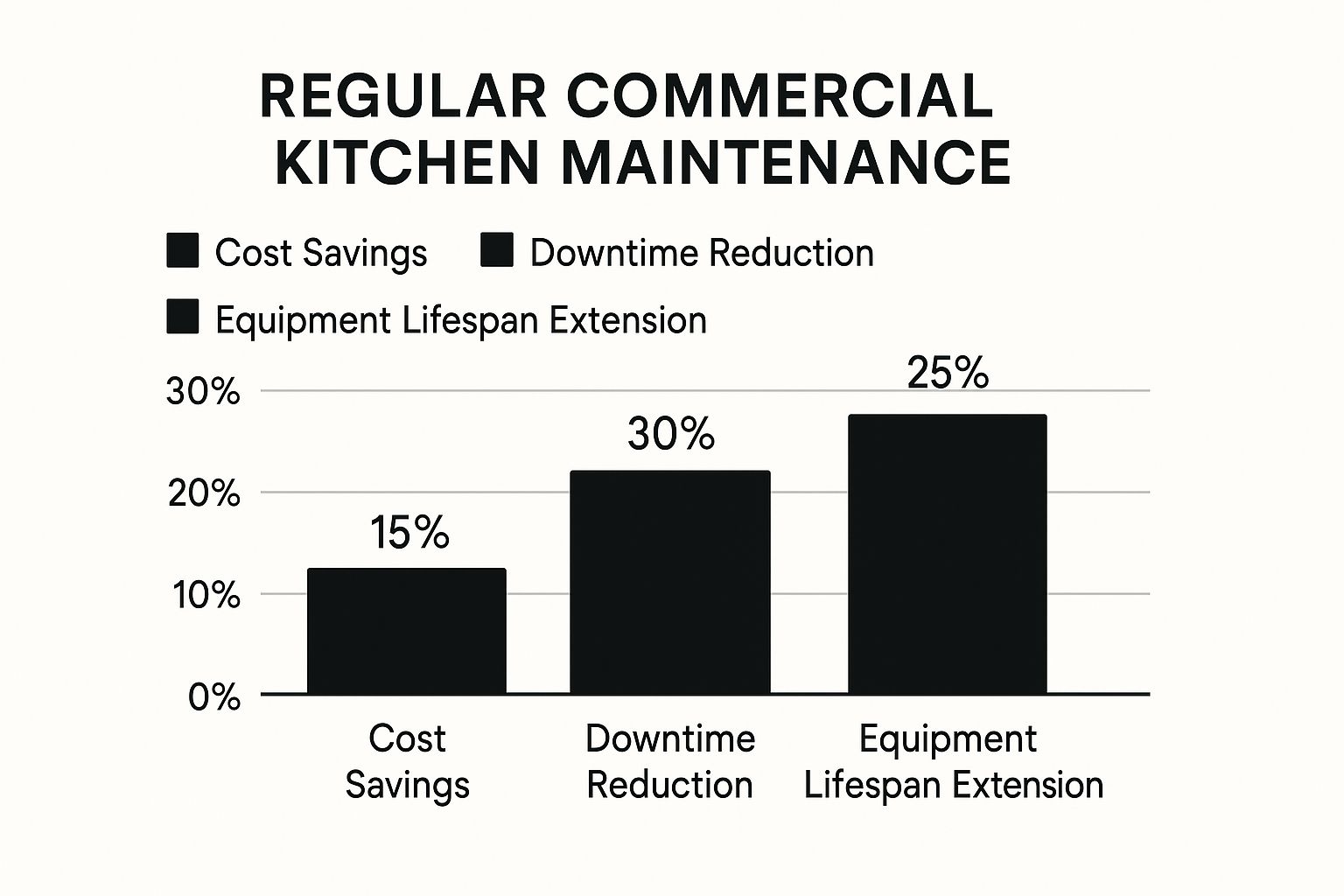

This breakdown shows the real-world benefits of having a regular maintenance program for your commercial kitchen, highlighting major returns in cost savings, operational uptime, and the lifespan of your equipment.

As you can see, the impact is huge. A 30% reduction in downtime is one of the first things you'll notice, and it makes a massive difference in day-to-day operations.

Building a Foundation for Success

The financial stakes have never been higher. Recent industry data shows that the cost to replace essential appliances has skyrocketed. Between January 2022 and October 2024, the price tag on new refrigeration units shot up by 24%, while other equipment saw a 21% jump. These numbers make it crystal clear: taking care of the assets you already have is key to controlling costs.

To get your maintenance strategy on solid ground, it helps to understand the basic principles. If this is a new concept for you, checking out a comprehensive guide defining preventive maintenance is a great way to see how it ensures uptime for all kinds of equipment. A well-designed plan turns maintenance from a headache into a powerful business advantage.

The table below breaks down the financial reality of choosing a proactive schedule over a reactive, "fire-fighting" approach.

Preventive vs. Reactive Maintenance Financial Impact

| Maintenance Approach | Short-Term Cost | Long-Term Cost | Impact on Operations |

|---|---|---|---|

| Preventive | Small, predictable monthly/quarterly fees. | Significantly lower; extends equipment life and avoids major replacement costs. | Minimal disruption; planned downtime during off-hours. Consistent performance. |

| Reactive | Zero cost until failure. | Extremely high; includes premium repair rates, inventory loss, and rushed equipment replacement. | Catastrophic. Unplanned downtime, lost revenue, and damage to your reputation. |

As the comparison shows, the short-term "savings" of reactive maintenance are quickly erased by the massive, unpredictable costs of failure.

The goal of proactive maintenance isn’t just to prevent failures; it's to create an environment of operational predictability. When your equipment is reliable, your team can focus on what they do best: creating exceptional food and memorable guest experiences.

A great way to get started is by putting a structured system in place for your daily, weekly, and monthly checks. You can build one from scratch using our guide on creating a https://encoreseattle.com/blogs/seattle-restaurant-equipment/commercial-kitchen-equipment-checklist to keep your team organized and make sure nothing gets missed. It’s the first real step toward a more efficient and profitable kitchen.

Mastering Refrigeration Maintenance for Peak Performance

Your refrigerators are the unsung heroes of your kitchen. They run 24/7, guarding thousands of dollars in inventory, and it's easy to take them for granted. But treating them as "set it and forget it" appliances is a recipe for disaster. Proper maintenance isn't complicated; it's a handful of simple, repeatable tasks that will protect your food, slash your energy bills, and keep you from facing a catastrophic meltdown.

I once worked with a bistro owner who couldn't figure out why his energy bills were slowly creeping up. It turned out to be a tiny, almost invisible tear in the gasket of his walk-in cooler. That tiny gap forced the compressor to work overtime, quietly burning cash until he found a whole batch of produce spoiled over a weekend. It’s a perfect example of how a small, missed detail can spiral into a major financial headache.

Keep Your Condenser Coils Breathing

Think of condenser coils as your refrigerator's lungs. They’re responsible for pushing heat out of the unit. But in a busy kitchen, they get clogged with a nasty mix of dust, grease, and grime. When that happens, the system can't breathe properly. The compressor has to run longer and harder, which is a massive drain on electricity and puts serious strain on the whole system.

Cleaning these coils is probably the single most effective maintenance task you can do. For most kitchens, a quarterly cleaning is enough. If you’re running a high-volume spot with a lot of grease in the air, you’ll want to bump that up to monthly.

Here’s the simple process:

- Power Down First: Safety is everything. Unplug the unit or shut it off at the circuit breaker before you touch anything.

- Find the Coils: They're usually on the bottom, back, or top of the unit, tucked behind a grille.

- Brush and Vac: Grab a stiff-bristled brush and gently scrub the debris off the coils. Be sure to brush with the fins, not against them, to avoid bending them. Then, use a shop vac to suck up all the gunk you just loosened.

This quick job can boost your unit's efficiency by as much as 30%. That's a real, tangible saving on your utility bill.

Don't Let a Bad Seal Cost You

Remember that bistro owner’s torn gasket? Faulty door seals are a huge energy vampire. A good seal keeps the cold air locked in and the warm, humid kitchen air out. When gaskets get cracked, brittle, or loose, your refrigeration unit is constantly fighting a battle it can't win.

There's a super simple way to check this: the "dollar bill test."

- Stick a dollar bill in the door and close it.

- Try to pull the bill out.

- If it slides out with no resistance, your gasket isn't sealing tight. It’s time for a replacement.

Doing this quick check once a week takes seconds but can literally save you hundreds in energy costs over a year.

Think of your temperature log as more than just a food safety checklist—it's your equipment's early warning system. If you see temperatures suddenly spiking or slowly creeping up, it’s a clear sign that something is starting to fail, whether it's a bad seal or a dirty coil.

Your Temperature Log Is Your Best Friend

You absolutely have to monitor your temperatures consistently. It's non-negotiable for food safety and a lifesaver for your equipment. Your team should be logging the temps of every refrigeration unit at least twice a day. This builds a clear picture of what "normal" looks like.

For hardworking units like prep tables, it's worth digging into the specific maintenance needs for different types of refrigerated sandwich prep tables to really dial in your process.

When you see a temperature drifting out of the safe zone, you can act before you lose product. Is the door ajar? Are the coils blocked? Catching these things early means you can schedule a repair during off-hours instead of paying a premium for a chaotic emergency service call. By building these simple habits into your daily routine, refrigeration maintenance stops being a chore and becomes one of your best tools for protecting your bottom line.

Keeping Your Cooking and Heating Line in Prime Condition

The cooking line is the engine room of your kitchen. Your ranges, fryers, grills, and ovens are the workhorses, and their condition directly dictates the quality of every single dish you send out. If you neglect them, you're not just risking a breakdown—you're gambling with food quality, creating serious fire hazards, and setting yourself up for those dreaded emergency repair calls that always seem to happen on a packed Saturday night.

Proper maintenance for your cooking line is all about building small, consistent habits. It's about moving past a simple wipe-down and embedding practices that truly make a difference in performance and lifespan. A well-cared-for cooking line is simply safer, more efficient, and turns out a better product.

Optimizing Your Fryer for Quality and Savings

A deep fryer can be a huge profit center, but only if you treat it right. Daily filtration isn't optional; it's essential. When you skip it, tiny food particles burn, breaking down the oil and creating nasty, off-flavors that will ruin your fried items. Filtering your oil every single day can actually double its lifespan, which translates to massive savings on one of your biggest consumable costs.

Beyond daily filtering, a weekly "boil out" is a must. This process involves draining the old oil, filling the vat with a specialized cleaning solution and water, and bringing it to a boil. This deep clean strips away all the stubborn, caked-on carbon and grease that a simple filter and wipe can't touch, preventing flavor transfer and helping the fryer heat evenly.

Mastering Your Ovens for Consistent Results

Nothing tanks a service like inconsistent cooking. One of the biggest culprits? An uncalibrated oven thermostat. If your oven is running just 25 degrees too hot or cold, it can completely throw off your cook times, ruining delicate proteins and baked goods. That means more waste and unhappy customers.

You can easily check this yourself. Grab a reliable oven thermometer, place it in the center of the oven, and set the temperature to 350°F. Let it sit for at least 20 minutes after preheating. If the thermometer's reading is way off from what the dial says, it’s time to call in a pro for calibration. This simple check is the secret to getting your recipes to come out perfectly every time.

Also, don't forget about the convection fans. A grimy, grease-coated fan can't circulate air effectively, which leads to uneven baking and annoying hot spots. A quick wipe-down of the fan blades during your weekly deep clean is a small task that pays huge dividends in performance.

I'll never forget a tip from an old executive chef. He insisted we use a specific non-abrasive, cream-based cleaner on our gas range burners. Instead of just scrubbing the grates, we'd remove the burner heads and use a small brush with that cleaner to clear the gas ports. It prevented clogs, ensured a perfect blue flame, and we almost never had ignition issues.

Keeping Your Grills and Ranges Firing Perfectly

Your flat-top grills and gas ranges need attention every single day. That built-up grease isn't just a food safety problem—it's a massive fire hazard. At the end of every service, scrape down the grill surfaces while they’re still warm with a grill brick or a heavy-duty scraper. Finish by seasoning the surface with a light coat of oil to keep rust at bay.

For more specific issues, it pays to be proactive. For instance, knowing the best practices for preventing mold in commercial grills is critical for both health inspections and the longevity of your equipment. It's these detailed cleaning protocols that separate a kitchen that runs smoothly from one that's always fighting fires—sometimes literally.

The industry as a whole is leaning into this level of care. With stricter food safety regulations and more complex cooking technologies, the commercial kitchen equipment maintenance market is growing fast. In fact, it's projected to expand at a compound annual growth rate of about 7% through 2032, as more kitchens realize that preventive maintenance is the key to reducing downtime and getting the most out of their machinery. You can dig into more of these industry trends in this detailed market analysis.

Keeping Your Warewashing Systems Running Flawlessly

Your dishwashing system is the unsung hero of your kitchen's reputation. It's the final checkpoint for sanitation, and when it works, nobody even thinks about it. But the second it goes down, the entire operation grinds to a halt. You're suddenly dealing with costly re-washes, failed health inspections, and—worst of all—unhappy guests.

This isn't just about sparkling plates. Something as small as a single clogged spray nozzle can leave behind dangerous bacteria, creating a massive sanitation risk. I once worked with a bistro that was getting slammed with bad online reviews, all complaining about "dirty silverware." The team was stumped. We eventually traced it back to one tiny nozzle in their high-temp dishwasher, completely blocked by limescale. That one little oversight was actively damaging their reputation, one fork at a time.

Tackle Hard Water with Daily Deliming

If you're in an area with hard water, limescale is your number one enemy. That chalky buildup clogs spray arms, coats heating elements, and chokes the life out of your machine's efficiency. A daily deliming routine isn't just a good idea—it's non-negotiable.

Don't wait for a thick crust to form. Train your closing crew to run a deliming cycle every single night. It’s a simple process of running the machine empty with a special deliming solution. This breaks down mineral deposits before they can harden into a real problem, saving you from the much bigger headache of chipping away at stubborn scale later on.

Mastering Chemical Levels and Temperatures

Your dishwasher sanitizes through a precise combination of chemicals and heat. If that balance is off, you're just spraying dirty water everywhere. Your team has to know how to check and manage these two critical elements every single day.

Your Daily Chemical Check:

- Look at the obvious first. Are the tubes for the detergent and rinse aid properly submerged in the containers? Are there any kinks blocking the flow?

- Test the sanitizer levels. Use chemical test strips or a titration kit to check the sanitizer concentration in the final rinse. This is a quick, simple test that confirms your machine is dispensing the right amount to meet health codes.

Properly calibrated dispensers ensure every rack comes out sanitized and ready for service.

"A commercial dishwasher is a precision instrument. It’s not a brute-force cleaner. If your temperatures are too low or your chemical mix is off, you’re not sanitizing—you’re just creating a bigger problem. Constant verification is the only way to guarantee safety."

That constant verification is everything. Health codes are strict for a reason. For high-temp machines, the wash cycle needs to hit at least 160°F, and that final rinse must reach a sanitizing 180°F. If you're running a low-temp machine, those chemical checks are even more vital because that's what's doing the sanitizing.

Inspecting Key Mechanical Components

Beyond the chemistry, the physical parts of your warewashing system need regular attention. A few simple checks can head off most common failures and make sure your machine is cleaning effectively from corner to corner.

A Quick Weekly Inspection Checklist:

- Spray Arms: Pull them out and look closely at the nozzles. Is there any food debris or mineral gunk? Use a small brush or even a paperclip to gently clear any blockages.

- Filters and Screens: These need to be cleaned multiple times a day, not just at closing. A clogged filter restricts water flow and just redeposits food particles back onto your "clean" dishes.

- Wash Curtains: Check the plastic strip curtains inside the machine. If they're torn or missing, heat and water escape. This tanks the machine's efficiency and sends your utility bills through the roof.

By making these simple tasks a core part of your kitchen's routine, you ensure your warewashing station is an asset, not a liability. You’ll protect your customers, pass health inspections with flying colors, and keep your reputation as spotless as your dishes.

Caring for Your Food Preparation Equipment

Let's talk about the unsung heroes of your kitchen: the mixers, slicers, and food processors. These are your precision tools, the equipment that delivers consistency and speed to your prep line. But unlike a heavy-duty range or a walk-in freezer, they’re full of intricate parts and come with their own unique safety risks. When we talk about maintaining this gear, it’s not just about making it last longer—it's about keeping your staff safe and your food hygienic.

If you neglect these machines, you'll feel the pain almost immediately. A dull slicer blade doesn't just give you sloppy cuts; it's a major safety hazard, far more dangerous than a sharp one. A mixer with a worn-out belt can grind to a halt right in the middle of a dinner rush, throwing your whole kitchen into chaos. It's the small, consistent checks that keep your prep line humming along without a hitch.

Safe and Sharp Slicer Maintenance

The commercial slicer is easily one of the most dangerous pieces of equipment you have. That means maintenance isn't just a good idea; it's absolutely non-negotiable, and safety has to be the top priority.

Before anyone even thinks about cleaning or sharpening that blade, a strict lockout/tagout protocol is the first and most critical step. The machine has to be unplugged—not just turned off, but physically unplugged from the wall. Then, a tag goes on the plug so everyone knows it's out of service. No exceptions.

Once the machine is safely powered down, you can get to work.

- Cover the Blade: Always turn the gauge plate to zero. This covers the blade’s sharp edge and is the first thing you should do before touching any part of the machine.

- Clean Methodically: Grab a designated brush and a food-safe degreaser. When cleaning the blade, always start from the center and wipe outwards. Never, ever wipe toward the sharp edge.

- Sharpen, Don't Grind: Use the slicer’s built-in sharpener just like the manufacturer shows you. A few seconds on each side is typically all you need. Over-sharpening is a common mistake that actually wears down and damages the blade over time.

This disciplined routine is what protects your team from serious cuts and keeps the slicer performing at its best.

Keeping Your Mixers in Fighting Shape

Your planetary and spiral mixers are absolute workhorses, but they can't run forever without a little TLC. The internal gears and belts are what take the most punishment. Those gears need regular lubrication to keep them from grinding together and wearing out. Once friction strips those gears, you’re looking at a seriously expensive repair bill. Make it a point to inspect and lubricate them every quarter.

But be careful what you use.

Any lubricant that goes on or in your food prep equipment must be 100% food-grade. It doesn't matter if the part doesn't touch food directly—microscopic particles can and do travel. Using regular industrial grease is a major food safety violation that can contaminate everything.

While you're at it, give the mixer’s drive belt a quick look. Are there any cracks, frays, or does it feel loose? A failing belt will often start squealing or you’ll notice the mixer struggling under a heavy load. Swapping out a worn belt is a cheap and easy fix that will save you from a complete breakdown when you're slammed.

This focus on maintenance isn't just a best practice; it's a growing industry trend. The global market for kitchen appliance repair is booming, projected to hit USD 13 billion in 2024 and climb to around USD 22 billion by 2033. This shift is being pushed by sustainability efforts and "right-to-repair" laws that encourage fixing equipment instead of replacing it. You can get more details on this growing market over at Business Research Insights.

Don't forget that well-maintained equipment is also tied to your kitchen's overall air quality and safety. For a closer look at how everything connects, our guide on commercial kitchen ventilation requirements is a great resource. By giving these essential prep tools the attention they deserve, you're building a safer, more efficient kitchen that churns out quality food, day in and day out.

Answering Your Top Kitchen Maintenance Questions

Even with the best routines in place, you're going to have questions. Let's be honest, commercial kitchen equipment can be finicky, and knowing the right call to make can be tough. I get asked these questions all the time by chefs and owners, so let's dig into some straight answers to help you protect your gear and keep your line humming.

How Often Do I Really Need a Pro to Service My Equipment?

Your team's daily and weekly cleanings are the lifeblood of your kitchen—that's non-negotiable. But some jobs just need a specialist. Think of your crew as the daily health monitors and the professional technician as the doctor who comes in for a full physical.

A good rule of thumb is to have your most critical systems, like refrigeration and HVAC, professionally serviced at least twice a year. I always recommend a spring tune-up to brace for the summer rush and a fall check-in to prepare for the colder months. For your heavy-hitters on the cook line—your ranges, ovens, and fryers—an annual professional inspection is a solid baseline.

But here’s the reality check: your kitchen’s mileage will vary. A 24/7 diner is going to punish its equipment way more than a small bakery. Always check the manufacturer’s guidelines first, but don't be afraid to adjust that schedule based on your actual use. A good service contract can be a lifesaver here, often bundling preventative visits and helping you dodge those brutal emergency call-out fees.

What are the Biggest Maintenance Mistakes You See?

I've seen it all, and most major equipment failures boil down to a few common, completely avoidable mistakes.

One of the worst offenders is using the wrong cleaning chemicals. I can't tell you how many times I've seen a beautiful stainless steel surface permanently scratched up by an abrasive cleaner or a sensitive digital control panel fried by a harsh degreaser. Always read the label and stick to the manufacturer's approved products.

Another classic mistake is ignoring the spots you can't easily see. Everyone wipes down the front of the prep cooler, but it's the greasy, dust-caked condenser coils in the back that are slowly suffocating the compressor. The same goes for the grease filters in your ventilation hood—out of sight, but absolutely critical for fire prevention and air quality.

But the single biggest misstep? A lack of training. If only one or two people know the proper maintenance procedures, things inevitably get missed when they're out sick or swamped.

A culture of shared responsibility is your best defense against neglect. When every team member understands the 'why' behind cleaning a fryer correctly or wiping down a slicer safely, compliance and equipment longevity improve dramatically.

When Should I Repair Something vs. Just Replace It?

This is the million-dollar question, isn't it? Deciding whether to fix an old workhorse or invest in a new one takes a bit of math and a lot of foresight.

A great place to start is the "50 percent rule." If a repair quote is more than half the cost of a brand-new, comparable unit, it's almost always smarter to replace it.

But don't just stop at the repair bill. How old is that machine? You might be able to patch up that decade-old freezer one more time, but a new Energy Star model could easily save you enough on your monthly utility bill to pay for itself in a few years.

Finally, think about its track record. Is this piece of equipment a "regular," needing a service call every few months? If so, it's time to stop the financial bleeding. The combined cost of constant repairs, lost product during downtime, and the sheer headache of it all makes a new, reliable unit the better long-term investment.

Keeping your equipment in top shape goes hand-in-hand with keeping your kitchen impeccably clean. To maintain the highest hygiene standards and prevent pest issues, you can explore proven natural cockroach deterrents for businesses as another layer of your sanitation protocol.

At Encore Seattle Restaurant Equipment, we know that reliable, efficient equipment is the backbone of your business. We're here to help restaurant owners and chefs discover the latest news and exclusive deals on restaurant equipment and supplies. Stay informed about industry trends, and whether you're looking to replace an aging appliance or outfit a brand-new kitchen, our team is here to help you find the perfect solution at an unbeatable price. Explore our extensive inventory of new and used equipment today at https://encoreseattle.com.