Commercial Kitchen Ventilation Requirements: Essential Guidelines

Share

Your commercial kitchen needs a ventilation system that can pull heat, smoke, and all those greasy vapors right out of the cooking area. This means you'll need to install the right Type I or Type II hood, make sure it has enough airflow (measured in CFM, or Cubic Feet per Minute), and hook it up to a makeup air unit to keep the air pressure balanced.

These systems aren't just nice to have; they're absolutely critical for fire safety, your staff's health, and staying on the right side of the law. Staying informed about the latest equipment and industry trends is key to running a successful restaurant.

Why Your Kitchen Ventilation Is a Lifeline, Not an Appliance

It’s easy to think of your kitchen's ventilation as just another piece of equipment, like an oven or a mixer. But it’s much more than that—it’s the lungs of your entire operation. It's constantly working behind the scenes, pulling out harmful contaminants and pumping in fresh, clean air.

Imagine what would happen without that constant air exchange. Your kitchen would quickly turn into a hazardous space filled with grease particles, carbon monoxide, and chemical fumes from cleaning supplies. The heat and humidity would become unbearable, tanking morale, slowing down your team, and even affecting the quality of your food.

Protecting Your Most Valuable Assets

When you invest in a good ventilation system, you're really investing in the safety and profitability of your business. A system that's up to code is your number one defense against the kind of grease fire that can wipe out a restaurant overnight. It also protects your employees from long-term respiratory problems and makes for a more comfortable, productive work environment.

Beyond just safety, getting your commercial kitchen ventilation requirements right directly impacts your bottom line. An efficient system takes some of the load off your main HVAC, which helps lower your energy bills. Even more importantly, it means you'll pass those health and fire inspections, avoiding the kinds of fines and shutdowns that can put a restaurant out of business.

A well-designed ventilation system is the unsung hero of a successful restaurant. It works tirelessly to protect your people, your property, and your patrons, making it one of the most critical infrastructure decisions a restaurant owner will make.

A Growing Industry Fueled by Safety and Regulation

The market itself shows just how crucial these systems are. The global commercial kitchen ventilation industry was valued at around USD 4.3 billion and is expected to hit USD 6.82 billion by 2032. This growth isn't just happening by chance; it's being pushed by stricter safety rules and a growing awareness of indoor air quality.

North America actually leads the way, holding a massive 36.27% of the market share. This reflects just how established the foodservice industry is here and how seriously we take compliance. If you want to dig deeper, you can read more about the kitchen ventilation market growth and find some interesting insights.

At the end of the day, meeting these requirements is about more than just satisfying an inspector. It’s about building a restaurant that’s safer, more resilient, and set up for long-term success. Discover exclusive deals on the latest restaurant equipment and supplies to ensure your kitchen is always up to date.

Decoding Key Ventilation Codes and Standards

Diving into the world of commercial kitchen ventilation codes can feel a lot like trying to decipher a secret language. But once you get the hang of it, you'll see these rules all point to one thing: keeping your people, your customers, and your building safe. It helps to stop thinking of them as hurdles and start seeing them as the essential blueprint for a safe, successful kitchen.

The two main organizations you'll encounter are the National Fire Protection Association (NFPA) and the International Mechanical Code (IMC). While their rules often overlap and work together, they each have a specific job. Getting a handle on their distinct roles is the first step to making sure your kitchen is fully compliant.

NFPA 96: The Fire Safety Rulebook

The NFPA 96 is the go-to authority for fire protection in any commercial cooking setup. Its official name is the "Standard for Ventilation Control and Fire Protection of Commercial Cooking Operations," and as you might guess, it’s laser-focused on preventing and managing grease fires. This is the standard that tells you everything from how your hood and ductwork must be built to the exact schedule for professional cleaning.

Think of NFPA 96 as your kitchen's dedicated fire marshal. It isn't concerned with how much air your system moves or what temperature that air is. Its sole purpose is to make sure a small flare-up on the charbroiler doesn't escalate into a disaster that takes down the entire building.

Key areas governed by NFPA 96 include:

- Grease Containment: Setting the requirements for hood filters that are designed to trap grease before it has a chance to build up in your ducts.

- Clearances: Defining the mandatory safe distances between hot cooking equipment and any combustible materials like wood studs or drywall.

- Ductwork Construction: Specifying that ducts must be made of welded, liquid-tight steel strong enough to contain a fire.

- Cleaning Schedules: Laying out precise cleaning frequencies based on what you’re cooking and how much you’re cooking.

Cutting corners here can have devastating consequences. If a fire breaks out and an investigation reveals your ductwork wasn't cleaned on the NFPA 96 schedule, your insurance carrier could flat-out deny your claim. That would leave you holding the bag for all the damages. This is why it’s so critical that your ventilation is perfectly integrated with your overall commercial kitchen fire suppression strategy.

IMC: The Master Building Code

If NFPA 96 is the fire specialist, the International Mechanical Code (IMC) is the general contractor. It’s the master building code that covers all mechanical systems, including your kitchen's ventilation. Local city and county inspectors enforce the IMC, which looks at the bigger picture of how your system operates safely within the building's infrastructure.

The IMC is what dictates the "how-to" of your ventilation. It provides the formulas for calculating airflow, ensures the installation is done correctly, and makes sure your makeup air system is up to snuff.

Key aspects regulated by the IMC include:

- Airflow Rates (CFM): It contains the specific formulas and tables needed to figure out exactly how many Cubic Feet per Minute (CFM) your exhaust hood needs to pull.

- Makeup Air Supply: The IMC mandates that for all the air you exhaust, you must bring in an equal amount of fresh, tempered makeup air to keep the building's air pressure balanced.

- Equipment Standards: It requires that your ventilation gear—from the hood itself to the exhaust fan on the roof—is officially listed and labeled for its intended commercial use.

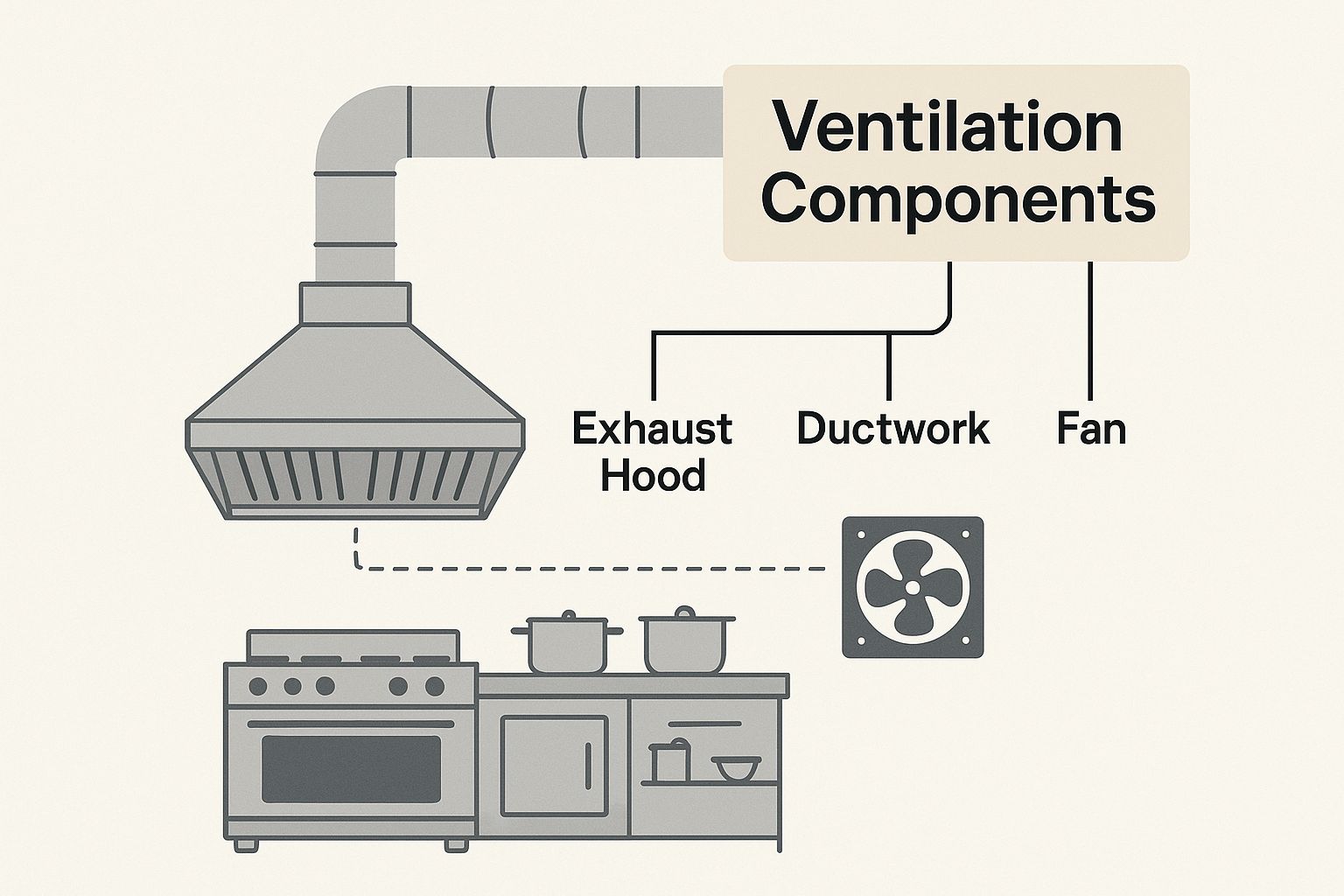

This infographic does a great job of showing how all the key components come together to create a fully compliant ventilation system.

As you can see, every single piece, from the baffles in the hood to the fan on the roof, has a critical role in keeping your kitchen safe and running smoothly.

This intense focus on safety and efficiency is also shaping the industry's future. The commercial ventilation market in the United States is projected to grow at a CAGR of 4.3% from 2025 to 2035, a trend fueled by stricter regulations and a push for more energy-efficient technology. Stay informed about these industry trends to make the best purchasing decisions.

To help you keep these two critical standards straight, here’s a quick summary table.

Key Regulatory Codes at a Glance

| Code/Standard | Primary Focus | Key Requirements |

|---|---|---|

| NFPA 96 | Fire Prevention & Containment | Grease containment, duct construction, fire suppression integration, cleaning schedules. |

| IMC | Mechanical System Functionality | Airflow calculations (CFM), makeup air systems, equipment installation standards. |

Ultimately, both NFPA 96 and the IMC are there to ensure your kitchen is a safe place to work and a safe part of the building. Understanding their roles is the first step toward building a system that’s not just compliant, but truly effective.

Choosing the Right Kitchen Hood System

Your kitchen hood is the single most important part of your ventilation system. Think of it as the first line of defense—its whole job is to catch heat, smoke, and greasy air right at the source, before it has a chance to wander off into your kitchen. Getting this choice right isn't just about ticking a box on a code inspection sheet. It’s a serious investment in fire safety, air quality, and the overall flow of your kitchen.

Pick the wrong hood, and you're setting yourself up for a world of hurt. You could fail inspections, find the system can't keep up with your busiest nights, or even face a costly replacement far sooner than you planned. The trick is to perfectly match the hood to the specific equipment you're running on your cook line. This is how you guarantee it grabs all the bad stuff, keeping your kitchen safe and your staff comfortable.

Type I vs. Type II Hoods: The Great Divide

The first big decision you have to make is whether you need a Type I or a Type II hood. This isn't up for debate or personal preference; it's dictated entirely by what's cooking underneath it.

-

Type I Hoods (Grease Hoods): These are the heavy hitters. If your equipment produces any grease or smoke, you need a Type I, period. We're talking about your charbroilers, griddles, fryers, and ranges. They come equipped with special baffle filters built to trap airborne grease, a critical requirement of NFPA 96 that stops dangerous gunk from building up in your ductwork.

-

Type II Hoods (Condensate Hoods): These are for appliances that only produce heat, steam, and moisture—but absolutely no grease. Think about your high-temp dishwasher, pasta cookers, or most convection ovens. Their job is to manage steam and heat, but they don't have the grease-trapping filters of a Type I system.

Never, ever install a Type II hood over a grease-producing appliance like a deep fryer. It's a massive code violation and an even bigger fire hazard. Double-check your equipment specs to make sure you're getting the right hood for the job.

Matching Hood Style to Your Kitchen Layout

Once you've figured out if you're a Type I or Type II kitchen, you need to pick a style that actually fits your physical space. The right style is all about capture efficiency—making sure the hood is positioned to effectively suck up everything coming off your cooktop. For kitchens looking to boost energy savings and air quality, integrating heat recovery ventilation systems can be a game-changer.

Here are the most common styles you'll see:

-

Wall-Mounted Canopy Hoods: This is the classic. You'll see them in most kitchens, mounted against a wall and hanging over the main cook line. They offer fantastic coverage and are a true industry staple.

-

Island Canopy Hoods: Got a cooking island or equipment in the middle of your kitchen? This is the hood for you. They hang from the ceiling, are open on all four sides, and need some serious airflow to handle potential cross-drafts in the room.

-

Backshelf Hoods: These are more compact, low-profile hoods that are perfect for countertop equipment where you don't have a lot of vertical space. They're less intrusive but have a smaller capture zone, so they're best suited for specific, smaller appliances.

The physical placement of your hood is a core part of your kitchen's workflow and safety. A smart choice from the beginning means you're not just compliant, but you're also building a more efficient kitchen. This is a crucial piece of any solid https://encoreseattle.com/blogs/seattle-restaurant-equipment/commercial-kitchen-design-layout plan. Get it right the first time, and you'll avoid expensive fixes and ensure your ventilation system works for you, not against you.

Mastering Kitchen Airflow and Makeup Air

Getting your kitchen ventilation right is a delicate balancing act. Think of it like breathing: you can't just exhale without ever inhaling. Your exhaust hood is constantly pushing massive amounts of air out of the kitchen. If you don't bring fresh air back in to replace it, you create an imbalance that can throw your entire operation into chaos.

That replacement air has a name: makeup air (MUA). It's an absolutely essential part of any commercial kitchen ventilation system that meets code. A dedicated MUA unit pulls fresh air from outside, conditions it (warming it up in the winter, cooling it down in the summer), and then pushes it back into the kitchen. This is how you keep your building's air pressure neutral and stable.

The Dangers of an Imbalanced System

When your exhaust fan is pulling out more air than your MUA unit is bringing in, you create a condition called negative pressure. It’s like your kitchen has become a giant vacuum cleaner, desperately trying to suck in air from every crack and crevice it can find.

This isn't just a minor issue; it's a major safety hazard with serious consequences. A kitchen that's starved for air can trigger a whole cascade of problems that put your staff, your customers, and your business at risk.

Some of the most critical dangers include:

- Carbon Monoxide Buildup: Gas appliances need a steady supply of oxygen to burn cleanly. In a negative pressure environment, they can't get enough, which leads to incomplete combustion. The result? Deadly, odorless carbon monoxide gas fills your kitchen.

- Pilot Light Extinction: That vacuum effect can literally suck the flames out on your ranges, ovens, and water heaters, creating a very real risk of a gas leak.

- Doors That Won't Open: The pressure difference can make it incredibly difficult to open exterior doors, which could trap people inside during an emergency.

- Poor Exhaust Performance: Your expensive hood system simply can't do its job without enough replacement air. Smoke, grease, and heat will spill back into the kitchen instead of being captured and removed.

An improperly balanced system doesn't just fail inspections—it actively works against you. The moment you notice doors slamming shut on their own or drafts coming from unusual places, it’s a red flag that your kitchen is dangerously starved for air.

A Simplified Look at Airflow Calculations (CFM)

So, how much air does your kitchen actually need? We measure this in Cubic Feet per Minute (CFM), which is just a straightforward way of saying how much air your system moves every single minute. While the precise math should always be left to a certified HVAC professional, understanding the basics will empower you to have an intelligent conversation with your contractor.

The CFM your kitchen requires isn't some arbitrary number pulled out of thin air. It's carefully calculated based on several key factors laid out in the International Mechanical Code (IMC).

Factors That Determine Your CFM Needs

- Type of Cooking Equipment: High-heat, heavy-grease appliances like charbroilers and woks demand a much higher CFM than equipment like ovens or steamers.

- Size of the Hood: The total length and depth of your exhaust hood directly impact the volume of air needed to capture contaminants effectively across its entire surface.

- Kitchen Layout: The hood's location matters. A hood mounted against a wall has different airflow dynamics than one hanging over an island. An island hood, for instance, needs more CFM to deal with cross-drafts from all sides.

Your contractor will use these variables to figure out the exact CFM your exhaust fan needs to pull. From there, they'll spec out a makeup air unit that can supply at least 80-90% of that exhausted air back into the room. This ensures the system stays balanced, safe, and efficient.

Of course, the whole system needs to be sealed up tight to work properly. To prevent air leaks, you must effectively seal ductwork with mastic sealant, ensuring your system maintains the airflow it was designed for. Understanding this crucial relationship between exhaust and supply is the key to mastering your kitchen's environment.

Putting It All Together: Installation and Maintenance

You can have the most advanced ventilation system in the world, but it's only as good as its installation and upkeep. Think of it like a high-performance sports car—it doesn’t matter what’s under the hood if it wasn't assembled correctly or you never change the oil. Getting the installation right from the start and sticking to a maintenance plan is the only way to ensure your system does its job for years to come.

The installation process is a lot more than just hanging a metal box over your cook line; it's a complex task that demands precision. Every single component, from the hood to the rooftop fan, needs to work in perfect harmony. For anyone building out a new kitchen or doing a major overhaul, integrating ventilation properly is a critical piece of the puzzle in larger tenant finish projects.

Nailing this phase saves you from a world of future headaches. It's the foundation for compliance, safety, and getting the most out of your investment.

A Proactive Maintenance Schedule

Once your system is up and running, the real work begins. This is not a "set it and forget it" piece of equipment. It’s a workhorse that needs regular attention to keep your kitchen safe and air breathable. A structured cleaning schedule is your number one defense against fire risk and poor performance.

Here’s a simple routine to follow:

- Daily: The kitchen staff should wipe down all accessible surfaces of the hood, inside and out. This simple step prevents grease from baking on and becoming a much bigger problem. Give the baffle filters a quick look-over, too.

- Weekly: It's time to pull out the hood filters for a deep clean. The most effective method is to let them soak in a strong degreasing solution before giving them a good scrub.

- Monthly: Take a moment to inspect the fan belt. If it looks worn, frayed, or loose, it’s time for a replacement. A failing belt will kill your fan’s efficiency long before it finally breaks.

This commitment to safety and quality isn't just a local concern. European Union countries, for example, spent 14 years developing the EN 16282 standard. This set of rules covers every inch of the ventilation system, from the hood to where the air is discharged, focusing on safety, performance, and environmental impact.

What to Expect From a Professional Hood Cleaning

While your crew can handle the day-to-day stuff, the deep cleaning of the entire system must be left to certified professionals. NFPA 96 dictates how often this needs to happen—usually quarterly, semi-annually, or annually, depending on how much and what kind of cooking you do.

A professional cleaning goes way beyond just making the hood shine. Certified technicians tackle the entire system—the fan, the ducts, and all the rooftop components—to remove the hidden, flammable grease buildup that your staff simply can't reach.

When you bring in a certified service, here’s what the process looks like:

- Prep the Kitchen: They’ll start by shutting off all gas lines and pilot lights. Then, they’ll cover your equipment and counters with heavy-duty plastic to protect everything from the cleaning process.

- Scrape and Degrease: Using special tools and food-safe chemicals, technicians will manually scrape away the thick layers of caked-on grease from the hood, plenum, ducts, and exhaust fan.

- Power Wash: Next, they use a hot-water power washer to blast away every last bit of residue, leaving the entire system clean down to the bare metal.

- Provide Proof: Once they’re finished, you’ll get a detailed service report and an official certification sticker for your hood. This is your proof of compliance for the fire marshal and your insurance company.

Following commercial kitchen ventilation requirements means making regular, professional maintenance a non-negotiable part of your operations. It is the single best thing you can do to prevent a catastrophic grease fire. Plus, keeping your equipment in top shape helps your entire kitchen run more smoothly. For more tips on organizing your space for maximum efficiency, see our guide to https://encoreseattle.com/blogs/seattle-restaurant-equipment/commercial-kitchen-storage-solutions.

Common Questions We Hear About Kitchen Ventilation

Even after you've got the basics down, you’ll still run into specific, real-world questions. Let's tackle some of the most common ones we hear from chefs and restaurant owners, cutting through the jargon to give you practical answers.

How Often Do I Really Need to Clean My Kitchen Hood?

This isn't a suggestion; it's a hard-and-fast rule dictated by NFPA 96. The right cleaning schedule depends entirely on what you're cooking and how much of it.

- Quarterly: This is for the heavy hitters—places doing high-volume cooking, especially with solid fuel like charcoal or wood, or a lot of charbroiling.

- Semi-Annually: Most restaurants with a steady, moderate volume of cooking fall into this category. It's the most common schedule.

- Annually: If you're running a kitchen with light or infrequent use, like a church, day camp, or a seasonal spot, once a year is often enough.

When in doubt, don't guess. Your local fire marshal is the ultimate authority, so always confirm your specific schedule with them to stay compliant.

Can I Get Away With a Residential Hood in a Small Cafe?

Let me be blunt: absolutely not. Putting a residential hood in a commercial kitchen is one of the fastest ways to fail an inspection and create a massive fire risk.

Home-use hoods just aren't built for the relentless heat and grease produced by commercial equipment. They don't have the fire-safe construction, the powerful airflow (CFM), or the grease-trapping filters needed to operate safely. It’s a dangerous shortcut you can’t afford to take.

What Happens If My Makeup Air Unit Dies?

A broken makeup air unit is an emergency, not an inconvenience. When it fails, your powerful exhaust fan keeps pulling air out, but nothing is coming in to replace it. This creates a powerful vacuum, or negative pressure, inside your building.

This negative pressure is a big deal. It can literally pull dangerous carbon monoxide fumes back down your vents, snuff out pilot lights on your equipment, suck foul odors out of the restrooms and into your dining room, and even make your front door nearly impossible to open.

If your makeup air unit goes down, it's a critical safety problem that needs a professional technician—fast.

At Encore Seattle Restaurant Equipment, we live and breathe this stuff. We help restaurant owners and chefs discover the latest news and exclusive deals on restaurant equipment and supplies. We can help you get the right, code-compliant ventilation system to keep your kitchen safe, clean, and running smoothly. Check out our full lineup and get expert advice at https://encoreseattle.com.