Maximize Efficiency with kitchen utensil hanging racks: A Guide

Share

In a bustling commercial kitchen, a well-placed kitchen utensil hanging rack can be the difference between chaos and control. It's one of those unsung heroes that transforms a cluttered prep area into a powerhouse of efficiency. By getting essential tools up and out of the way, yet still within arm's reach, you clear precious counter space, speed up the workflow, and even cut down on cross-contamination risks. This isn't just about finding a place to hang a spatula; it's about fundamentally rethinking how your kitchen flows and staying ahead of industry trends in restaurant equipment.

How Hanging Racks Can Transform Your Kitchen's Workflow

Picture the dinner rush. A line cook is frantically digging through a drawer for the right whisk, wasting seconds that feel like minutes. Now, imagine that same whisk hanging neatly on a rail system right above their station. They grab it without breaking rhythm. That tiny, seamless action, repeated hundreds of time a shift by the entire team, is where the real magic happens.

It’s a simple idea with a massive impact. Moving utensils from drawers and countertops to walls and ceilings reclaims your most valuable asset: horizontal space. That newly freed-up counter can now be used for what it's meant for—prep, plating, and staging—instead of being a graveyard for misplaced tools. This is a core concept in modern restaurant supplies that boosts a kitchen's output.

Maximize Your Space, Maximize Your Speed

The real genius of a good hanging rack system is how it builds an intuitive workflow. Your chefs develop muscle memory, reaching for a tool without a second thought. Those saved seconds on every single task add up to huge gains in efficiency over a busy service. A truly organized kitchen always starts with smart design, and a comprehensive kitchen storage planning guide can be a goldmine for ideas on using every inch effectively.

This strategic organization also brings major safety benefits by:

- Securing sharp knives on magnetic strips, not rattling around loose in a drawer.

- Keeping countertops clear to prevent tools from being knocked to the floor.

- Making it faster and easier to properly sanitize work surfaces.

A disorganized station can slash a chef's efficiency by as much as 20% during peak hours. A utensil hanging rack is the direct solution—it creates a system where every tool has a home, always ready to go.

Ultimately, integrating these systems is a cornerstone of intelligent kitchen design. A productive kitchen depends on the thoughtful placement of every single piece of restaurant equipment, storage included. To dive deeper, you can explore what it takes to create a top-tier https://encoreseattle.com/blogs/seattle-restaurant-equipment/commercial-kitchen-design-layout. By thinking vertically, you're not just storing utensils; you're building a faster, safer, and more profitable kitchen.

Choosing Your Ideal Commercial Hanging Rack System

Picking the right hanging racks for your kitchen isn't just about finding a place to stash your tools. It's a strategic move that can make or break your kitchen's flow. In the heat of service, the difference between a smooth-running line and total chaos often boils down to how fast a chef can grab what they need. Each type of rack brings something different to the table, designed for specific spaces and ways of working.

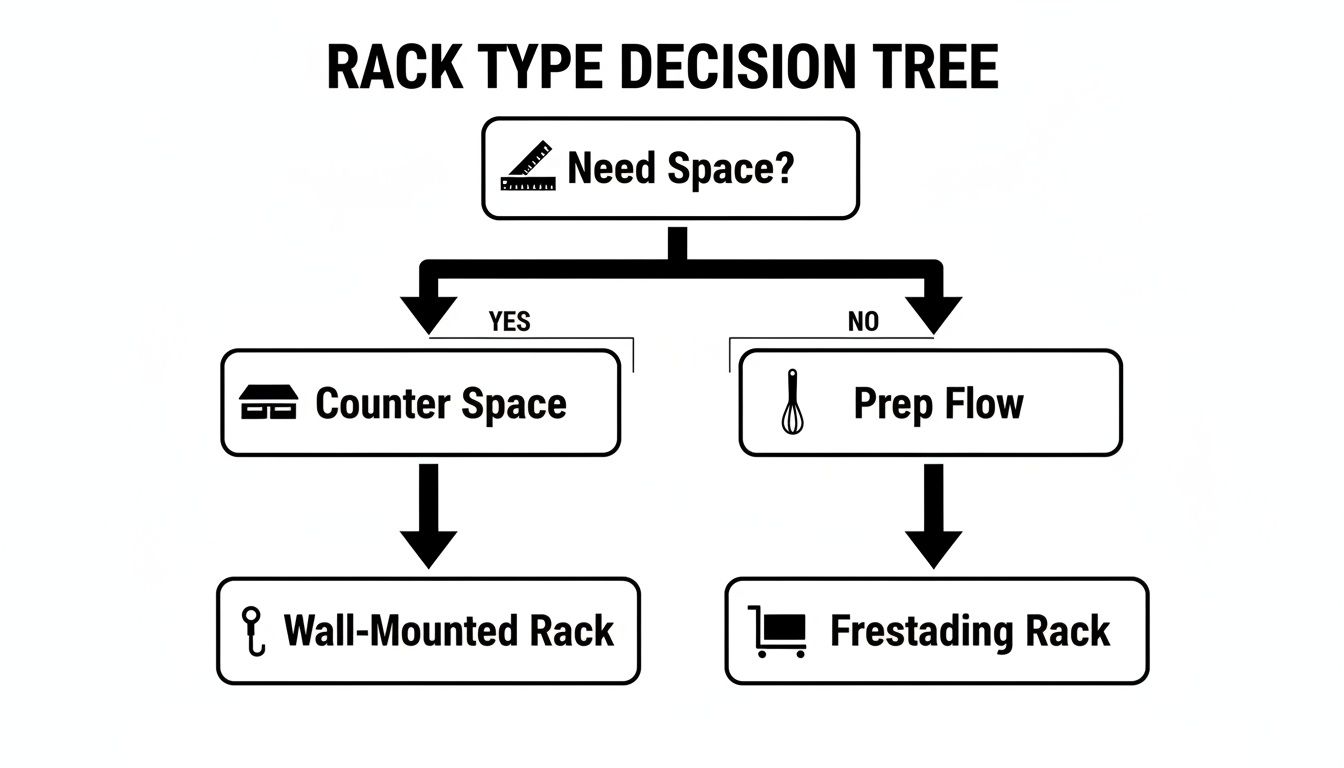

This decision tree helps you think through whether your main goal is to free up counter space or to make your prep flow more efficient.

As you can see, the first step is always figuring out your biggest pain point. Are you drowning in clutter on your prep surfaces, or are your chefs wasting time running around for tools? Your answer will point you toward the right solution.

Wall-Mounted Rail Systems: The Linear Workhorse

For most commercial kitchens, the wall-mounted rail system is the obvious first choice. Think of it as giving your workstation a dedicated toolbelt. It’s a simple concept: a metal rod runs horizontally along the wall, and S-hooks hold everything from whisks and ladles to tongs and small pans.

The real win here is the organized, linear workflow it creates. When you install a rail directly above a prep table or range, your most-used tools are always within arm's reach and in your line of sight. This cuts down on wasted steps and keeps your countertops clear for the real work, which is a massive plus for both speed and sanitation.

Ceiling-Mounted Pot Racks: The Overhead Space Saver

What if your wall space is already spoken for, but you've got high ceilings? That’s where a ceiling-mounted pot rack becomes your best friend. These are heavy-duty grids, usually hung over a central prep island or a line of ranges, giving you instant access to bulky items like pots, pans, and colanders.

By taking advantage of that unused vertical space, these racks can free up entire cabinets for other supplies. It's a smart move in any kitchen, but especially as urban kitchens get smaller and every square inch counts. This industry trend reflects the need for smarter use of space in modern restaurant design.

Grid and Pegboard Systems: The Customization Champions

If your operation relies on a ton of specialized tools—think of a bakery with its countless piping tips, spatulas, and molds—then a grid or pegboard system offers flexibility you can’t get anywhere else. These are wall-mounted panels covered in a grid of holes or wires that let you create a completely custom layout with hooks, small baskets, and shelves.

This modular design means you can build a dedicated station for a specific task, giving every little gadget its own home. It’s an organizational system that can change and adapt right along with your menu. If you're looking for even more storage solutions, check out our guide on how commercial stainless steel shelves can work alongside your hanging systems.

Magnetic Knife Strips: The Safety Essential

We can't talk about hanging racks without bringing up magnetic knife strips. Honestly, these should be considered non-negotiable for kitchen safety and efficiency. Mounted on the wall, they keep your sharpest blades secure, visible, and out of a drawer where they can get banged up or become a hazard.

A magnetic strip does more than just protect the razor-sharp edge of a chef's most prized possession; it dramatically cuts down the risk of accidental cuts. It’s a small change that makes a huge difference in your kitchen's safety culture.

The best setup often involves a mix of these systems, tailored to your kitchen's unique layout and the demands of your menu. To make the best choice, it helps to know about the cookware professional chefs rely on and how they use it. By really looking at how your team works, you can choose racks that don’t just store tools but actually help your crew perform better.

Selecting Materials Built for a Professional Kitchen

Choosing the right material for your kitchen utensil hanging racks is a lot like picking the perfect knife. It's not just about how it looks; it’s about how it performs under pressure, how long it lasts, and how safe it is to use every single day.

Commercial kitchens are tough environments—full of constant heat, steam, grease, and harsh cleaning chemicals. The wrong material will quickly tarnish, corrode, or even become a breeding ground for bacteria. That's not just a replacement cost; it's a serious health hazard.

Think of this decision as an investment in your kitchen's stability. A material that’s a breeze to clean saves your team valuable time, while a durable one prevents the headache and expense of frequent replacements.

Stainless Steel: The Undisputed Industry Champion

When you walk into almost any professional kitchen, you'll see stainless steel everywhere. There's a good reason it's the reigning king. It’s a non-porous material, which is a critical feature. That means it won’t absorb food particles or liquids, making it incredibly difficult for bacteria to grow and much easier to keep compliant with health codes.

But not all stainless steel is created equal. The grade you choose makes a huge difference:

- 304 Grade Stainless Steel: This is the gold standard, often called "food-grade" steel. It has more chromium and nickel, giving it superior resistance to rust and corrosion, especially from acidic foods and sanitizing chemicals.

- 430 Grade Stainless Steel: A solid, more budget-friendly option that's still tough enough for many kitchens. While it performs well, it’s a bit more susceptible to corrosion over the long haul compared to 304 grade, particularly in very humid or coastal environments.

The sheer strength of stainless steel also means it can hold heavy pots and pans without bending or warping. Plus, its clean, professional look fits right into any modern kitchen design. If you want to dig deeper into why this material is so essential, our guide on the benefits of a commercial stainless steel table has some great insights.

Exploring Other Viable Material Options

While stainless steel is the workhorse, other materials can be a perfect fit for specific needs, whether it's for aesthetics or unique functional requirements.

Chrome-Plated Steel

Chrome plating gives regular steel a bright, mirror-like finish that looks a lot like stainless steel but costs less. It's a great choice for dry storage areas or open kitchens where you want a polished look. The catch? If that chrome layer gets scratched or chipped, the steel underneath is exposed and can start to rust.

A rack's finish is its first line of defense. A durable, non-porous finish not only contributes to the rack's longevity but also simplifies your daily sanitation protocols, saving time and ensuring a safer kitchen.

Anodized Aluminum

This material is incredibly lightweight yet surprisingly strong. The anodizing process creates a tough, corrosion-resistant outer layer that makes it much more durable than raw aluminum. It's an excellent option for mobile carts or for walls where you need to minimize weight.

Decorative Metals like Copper or Brass

For a front-of-house display or a stylish bar area, metals like copper and brass add a touch of warmth and elegance. They develop a unique patina over time, which can be a beautiful aesthetic touch. Just know that they require more polishing to stay looking sharp and aren't tough enough for the high-intensity action of a back-of-house prep line.

Commercial Hanging Rack Material Comparison

Here’s a quick breakdown to help you compare your options at a glance:

| Material | Durability | Hygiene Rating | Cost | Best Use Case |

|---|---|---|---|---|

| 304 Stainless Steel | Excellent | Excellent | High | All-purpose back-of-house, high-moisture areas |

| 430 Stainless Steel | Very Good | Excellent | Medium | General use, dry storage, budget-conscious BOH |

| Chrome-Plated Steel | Good | Good | Low | Dry storage, front-of-house, light-duty use |

| Anodized Aluminum | Good | Very Good | Medium | Mobile carts, wall-mounts where weight is a concern |

| Copper / Brass | Fair | Fair | High | Front-of-house displays, bar areas, decorative use |

Ultimately, matching the material to the specific demands of each area in your kitchen ensures you get the best performance and value from your investment.

Getting Installation and Load Capacity Right

A top-of-the-line kitchen utensil rack is useless—and dangerous—if it isn't installed properly. A rack that pulls away from the wall isn't just an annoyance; it's a real hazard in a kitchen where people are moving quickly. Getting the installation right from the start means your investment is secure, functional, and ready for the daily grind.

This process starts way before you ever pick up a drill. It begins with a practical look at what you’re actually going to hang on it. A few whisks and spatulas have completely different support needs than a dozen heavy-bottomed saute pans or cast-iron skillets.

Figuring Out Your Load Capacity

Think of load capacity as the total weight your hanging rack system has to bear, day in and day out. Don't just eyeball it. To get a real number, gather up the heaviest items you plan on hanging—your biggest stockpots, thickest cutting boards, and most solid colanders.

Once you weigh these items, you have a baseline. A good rule of thumb is to choose a rack system with a maximum load capacity at least 25% higher than your total calculated weight. That extra buffer is crucial; it accounts for the dynamic stress of yanking a pan off the hook and putting it back in a hurry during a chaotic service.

The need for smart, heavy-duty storage is a major industry trend. Kitchen utensil racks are a big piece of the global kitchen storage market, which climbed to a massive USD 131.43 billion in 2023. This is especially true in commercial kitchens, where efficiency is everything. The market is expected to grow at a 5.3% CAGR as restaurants find new ways to streamline their operations. You can dig into more of these market trends from Grand View Research.

Finding Solid Support for a Secure Mount

Here’s the most important step of the entire installation: anchoring your rack to something solid. Screwing a heavy rack directly into drywall is a recipe for disaster. Drywall is just compressed gypsum and paper—it was never meant to hold any significant weight.

You have to find the structural supports hidden in your walls or ceiling.

- Wall Studs: These are the vertical 2x4s (wood or metal) that make up the skeleton of your walls. A good stud finder is your best friend here.

- Ceiling Joists: Just like studs, but they run horizontally to support the ceiling. They are absolutely essential for safely hanging any kind of overhead pot rack.

Once you’ve found the studs or joists, mark their dead centers. This is precisely where your mounting hardware needs to go to create a rock-solid foundation that won’t budge.

Choosing the Right Hardware for the Job

The screws and bolts you use are the critical link between your rack and the wall's structure. Picking the right hardware isn't optional; it's a matter of safety.

Don't ever cheap out on hardware. The screws that come in the box are a starting point, but always double-check that they’re right for your specific wall type. Spending a few extra dollars on the right anchors is cheap insurance against a rack full of expensive cookware crashing down.

Here are the go-to options for most commercial kitchen installations:

- Lag Screws: These are beefy, heavy-duty screws that bite deep into wood studs or joists. Their coarse threads give them an incredible grip.

- Toggle Bolts: If you can't hit a stud exactly where you need to, a toggle bolt is the next-best thing for hollow walls. As you tighten it, spring-loaded "wings" open up behind the drywall to spread the load over a much wider area.

- Sleeve Anchors: When you're mounting to a solid wall like concrete or brick, these are what you need. A metal sleeve expands inside the hole as you tighten the bolt, creating an immensely strong friction hold.

By taking the time to plan for your load, find your structural supports, and use the right hardware, you're not just hanging a rack—you're installing a permanent, safe, and reliable part of your kitchen's workflow.

Designing Layouts for Different Kitchen Environments

Knowing the theory behind kitchen utensil racks is great, but seeing them in action is where the real magic happens. A smart layout does more than just hold your tools; it directs the entire flow of the kitchen, almost like it’s anticipating your team’s next move. Let’s walk through a few practical blueprints for different types of foodservice operations.

Think of each layout not as a random collection of hooks and rails, but as a strategic solution to the unique challenges of a business. The goal is to turn potential chaos into a smooth, efficient operation. When every station is intuitive, your chefs can stop hunting for tools and focus on what they do best: creating incredible food.

This kind of clever organization is a fast-growing industry trend. In 2023, 35% of new restaurants opted for hanging racks to get the most out of their space, and it paid off—they reported a 15% reduction in prep time per chef. These systems are a direct answer to one of the biggest headaches in any kitchen: limited real estate. If you want to dive deeper into the numbers, you can explore the dish rack market report from Cognitive Market Research.

The Compact Ghost Kitchen Layout

In a ghost kitchen, every last square inch counts. There’s no dining room, so the entire space is dedicated to pure production. Efficiency isn't just a goal; it's the only way to survive. Your layout has to be lean, mean, and ruthlessly organized.

Here, going vertical is your best friend. The trick is to combine a few different systems to turn your walls into prime storage.

- Wall-Mounted Rail Systems: Run these right above your main prep counter. This keeps everyday essentials like tongs, ladles, and whisks at your fingertips without cluttering the workspace.

- Magnetic Knife Strips: Mount these right next to the cutting station. Knives are secure, visible, and safely off the counter, which prevents accidents and protects your blades.

- Small Grid Panels: These are perfect for lighter, more specialized tools. A small grid with a few baskets can hold squeeze bottles, graters, and peelers, keeping them neatly contained and easy to grab.

This layered approach creates an incredibly functional workstation in a tiny footprint, letting a chef move at top speed.

The High-Volume Restaurant Layout

A buzzing restaurant with a big crew and a complex menu demands a whole different playbook. The central prep island is usually the heart of the kitchen, so the layout has to help multiple chefs work side-by-side without bumping elbows.

The ultimate goal is to create "zones of control" where each chef has everything they need within their immediate reach. This minimizes unnecessary movement, reduces cross-traffic, and keeps the entire line flowing smoothly during the intense pressure of service.

The hero of this setup is a large, ceiling-mounted pot rack hanging right over the central island. This piece of restaurant equipment is a massive space-saver, holding all the bulky cookware—stockpots, sauté pans, and colanders—and freeing up an incredible amount of lower cabinet space. Chefs on any side of the island can grab what they need without taking a single step, which is a game-changer during a busy service.

The Bakery and Patisserie Layout

In a bakery, precision and organization are everything. A pastry chef’s toolkit is huge and highly specialized, with dozens of piping tips, spatulas, molds, and cutters that all need to be kept in perfect order.

For this kind of work, a pegboard system is the undisputed champion. A big pegboard wall essentially creates a visual inventory of every single tool you own. A chef can design a completely custom layout with specific hooks, small bins, and shelves for each category of equipment. This ensures every tiny piping tip has its own home, making it easy to find and even easier to put away, which helps maintain order even when things get hectic.

Your Top Questions About Kitchen Hanging Racks, Answered

Even after you've picked the perfect system, you're bound to have questions about day-to-day use and long-term care. That's completely normal. Getting clear, practical answers is what turns a good storage rack into an indispensable part of your kitchen's workflow.

We've heard just about every question from chefs and owners over the years, so we’ve put together the most common ones right here. Think of this as your field guide to keeping your racks safe, clean, and working hard for you.

What’s the Right Way to Clean and Sanitize These Racks?

For stainless steel, which is the industry standard for good reason, a consistent routine is your best friend. All you need is a soft cloth, warm water, and a mild detergent or a dedicated stainless steel cleaner. Here's the key trick: always wipe in the direction of the metal's grain. This prevents tiny scratches where grime and bacteria love to hide.

When it's time to sanitize, use a food-safe solution and let it sit for the full contact time listed on the label—don't rush it. And whatever you do, steer clear of abrasive scrubbers like steel wool or harsh chemicals like bleach. They can eat away at the steel's protective layer, opening the door for rust and corrosion. A quick daily wipe-down is a non-negotiable in a busy kitchen to stop grease from building up and to stay on the right side of the health inspector.

How Can I Be Sure My Wall or Ceiling Can Handle the Weight?

This is the one area where you can't afford to guess. It’s a critical safety issue. Never, ever anchor a heavy-duty kitchen utensil hanging rack straight into drywall. It simply wasn't designed to hold that kind of weight and will eventually fail.

You have to find the solid structure behind the wall—the wood studs or ceiling joists. A standard wood stud can handle a surprising amount of weight, but only if the load is distributed correctly across multiple anchor points.

If you have any doubt about your building’s structure or you're planning on hanging serious weight—think a whole collection of cast-iron skillets or full stockpots—our advice is always the same: call a professional contractor. Their expertise is your best insurance for a safe, code-compliant installation that protects your team and your gear.

Are There Racks That I Can Adjust or Change Around Later?

Absolutely. Flexibility is a huge part of modern kitchen design. Systems like wall-mounted grids and pegboards are modular by nature. You can move hooks, shelves, and holders around in minutes as your tools or menu change. This is perfect for kitchens that swap out equipment seasonally.

Many rail systems are also built for easy adjustments, with hooks that just slide along the bar—no tools needed. These systems offer fantastic long-term value because they can grow and adapt with your business. You won't find yourself needing a complete reinstall just because you bought a few new pans.

Ready to discover exclusive deals on restaurant equipment and supplies to get your kitchen organized? The team at Encore Seattle Restaurant Equipment is here to help you choose, finance, and install the perfect kitchen utensil hanging racks for your space. Visit us at https://encoreseattle.com to see what's possible and start building a smarter, more efficient kitchen today.