A Practical Guide to Grease Trap Sizing for Restaurants

Share

Getting your grease trap sizing right is all about matching the trap's capacity to the wastewater flow from your kitchen fixtures. The rule of thumb for most restaurants is pretty straightforward: the trap's capacity, measured in pounds, should be at least double the flow rate in gallons per minute (GPM). Nailing this calculation is the key to avoiding plumbing nightmares and keeping the health inspector happy. As you plan your kitchen's infrastructure, remember that the right equipment is an investment in your success—staying informed about industry trends can save you from costly mistakes down the line.

Why Grease Trap Sizing Is a Bigger Deal Than You Think

If you're running a busy kitchen, it's easy to dismiss grease trap sizing as just another detail for the plumber to handle. But trust me, this one decision can make or break your daily operations, your budget, and even your restaurant's reputation. It’s not just a box in the ground; it's your first line of defense against some seriously messy and expensive problems.

A grease trap that's too small is a ticking time bomb. It simply can't keep up with the amount of Fats, Oils, and Grease (FOG) a commercial kitchen pumps out. Before you know it, you're dealing with frequent, disgusting sewer backups that always seem to happen during the dinner rush. Nothing kills a Saturday night service faster than telling a full house the kitchen is closed because the drains are overflowing. The hit to your brand and your revenue is immediate and painful.

The Steep Price of Getting It Wrong

The headaches don't stop at your property line. Cities and towns are cracking down hard on FOG getting into their sewer systems, and for good reason. FOG is the number one cause of sanitary sewer overflows (SSOs), which pollute local waterways and create public health hazards. A single blockage traced back to your restaurant can result in thousands of dollars in emergency plumbing bills and hefty municipal fines. These aren't just minor penalties; they can seriously dent your profits for months.

Digging into the specifics of grease trap sizing is a core part of your compliance risk management strategies because it directly impacts your ability to meet environmental and health codes. An undersized unit makes it virtually impossible to stick to a reasonable cleaning schedule, leaving you exposed during a health inspection. Repeated FOG violations can lead to citations or, in worst-case scenarios, the suspension of your license to operate.

Protecting Your Plumbing and Your Business

So, is the answer just to buy the biggest trap you can find? Not so fast. Going too big creates an entirely different set of issues.

When wastewater sits for too long in an oversized trap, it goes septic. This creates hydrogen sulfide gas—the source of that unmistakable rotten egg smell—and can actually corrode the trap itself, especially if it's made of concrete.

This is why getting the calculation just right is so critical. The goal is to perfectly match the trap's capacity to what your kitchen actually produces. A correctly sized grease trap works like a charm, protecting your plumbing, keeping your kitchen safe and sanitary, and preventing those costly, reputation-damaging shutdowns. Think of it as a crucial investment in the long-term health and success of your restaurant.

Understanding the Core Sizing Calculations

When it comes to sizing a grease trap, you don't need an engineering degree, but you absolutely need to understand the language plumbers and health inspectors speak. The two main ways to get the right size are by calculating Gallons Per Minute (GPM) or by using Fixture Units (FU).

Think of them as two different roads that both lead to the same destination: a correctly sized unit for your specific kitchen. One method focuses on the raw volume of water your sinks can dump at once, while the other uses a standardized points system. Both are perfectly valid, but your local plumbing code will ultimately decide which one you have to use.

The Gallons Per Minute Flow Rate Method

The GPM method is all about direct, logical math. It answers a simple question: "How much wastewater can this sink send down the drain at full tilt?" The calculation itself is straightforward and is based entirely on the physical size of your sink compartments.

Grab a tape measure and a calculator to get started.

- Measure Each Sink Compartment: For every sink basin that will drain into the trap, measure its length, width, and depth in inches.

- Calculate the Volume: Multiply these three numbers together (Length x Width x Depth) to get the total volume of that compartment in cubic inches.

- Convert to Gallons: Divide the total cubic inches by 231. Why 231? That's how many cubic inches are in one U.S. gallon. This gives you the sink's total water capacity.

Let's run through a quick example. A standard three-compartment sink might have basins that are 24 inches long, 24 inches wide, and 14 inches deep. The math would be 24 x 24 x 14 = 8,064 cubic inches. Divide that by 231, and you get 34.9 gallons per compartment.

Now for a crucial detail: drainage time. A full sink doesn't empty in a split second. Most plumbing codes assume a drain time of either one or two minutes. A one-minute drain time is the more aggressive calculation, usually for high-volume kitchens, while a two-minute drain is more common and conservative.

Pro Tip: To find your final GPM, you need to apply a flow rate factor. A sink is rarely filled to the brim, so you'll typically multiply the total gallons by 0.75 (for 75% capacity). Then, divide that number by your required drainage time (1 or 2 minutes) to lock in your GPM rating.

This process gives you a solid, reliable flow rate that manufacturers use to recommend the right hydromechanical grease trap. It ensures the unit can handle a sudden, massive discharge from your sinks without getting overwhelmed and failing.

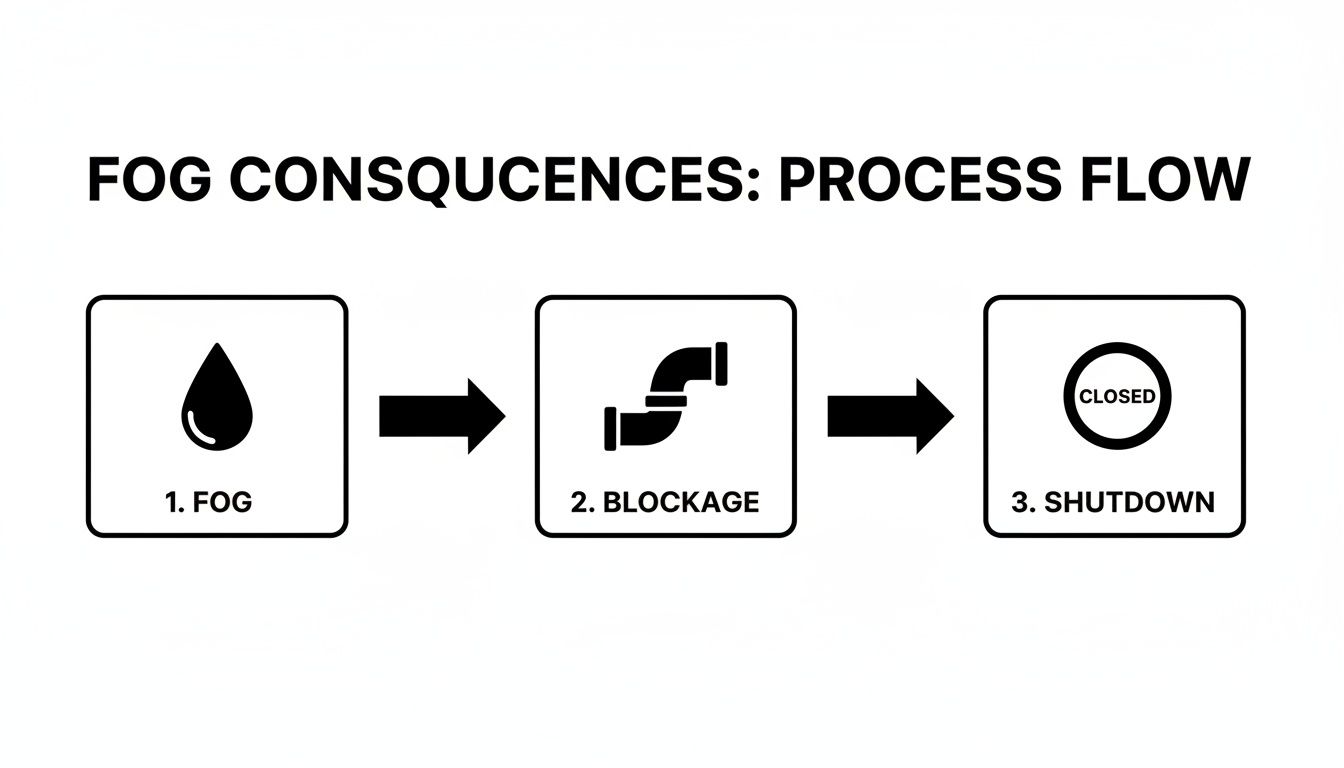

Getting this wrong has serious consequences. As this diagram shows, it's a slippery slope from a little FOG (Fats, Oils, and Grease) to a complete system shutdown.

This isn't just about a slow drain; it's about a chain reaction that can shut down your entire operation. Proper sizing is your first line of defense.

The Fixture Unit Sizing Method

The Fixture Unit (FU) method is a more standardized approach, and it's the one favored by the Uniform Plumbing Code (UPC) and many local health departments. Instead of measuring your sinks, this system assigns a "unit" value to every fixture based on its potential wastewater output.

This creates a universal standard that simplifies everything. Grease interceptors have been part of building codes since the 1920s, and today's sizing charts from the International Plumbing Code (IPC) are all based on these fixture units. A properly sized interceptor can reduce FOG discharge by up to 99%, so accuracy here is key.

Using this method is pretty simple. You just add up the FU values for all the fixtures that will drain into the trap. Once you have that total, you consult a sizing chart—usually provided by your local plumbing authority or the trap manufacturer—to find the corresponding GPM rating or model number you need.

Common Kitchen Fixture Unit (FU) Values

Use this quick reference guide to determine the total fixture unit load for your commercial kitchen based on standard UPC values.

| Kitchen Fixture | Typical Fixture Unit (FU) Value | Notes |

|---|---|---|

| 3-Compartment Sink | 3 FU | This is the standard for most pot washing stations. |

| Commercial Dishwasher | 4 - 6 FU | The value depends on the machine's size and cycle speed. |

| Food Prep Sink | 2 FU | This applies to smaller sinks used for washing produce. |

| Mop Sink / Service Sink | 2 - 3 FU | Depends on the basin size and how it's used. |

| Floor Drains | 0 FU* | *Generally not counted unless they receive direct, high-volume discharge from kettles or other equipment. |

By adding up these values, you get a clear, code-compliant picture of your kitchen's total load. This makes it easy to select a grease trap or interceptor that is certified to handle that specific demand, which is especially helpful for new construction or kitchens with a complex mix of equipment.

Real-World Sizing Scenarios for Your Kitchen

Knowing the formulas is one thing, but seeing how they work in a real kitchen is where it all clicks. Let's move past the theory and dive into three common restaurant examples. We'll run the numbers using both the Gallons Per Minute (GPM) and Fixture Unit (FU) methods to see how they stack up in different kitchens.

These scenarios should help you picture your own setup and connect the math directly to the equipment you use every day. Watching the process unfold makes proper grease trap sizing feel a lot less intimidating.

Scenario 1: The Compact Urban Café

First up, imagine a small, bustling café in a city center. Space is tight, and the menu is simple: coffee, pastries, and sandwiches. The kitchen is lean and mean.

Kitchen Equipment:

- One food prep sink with a basin measuring 18" L x 18" W x 12" D.

- One small, low-temperature, door-style commercial dishwasher.

Sizing with the GPM Method

Let's start by calculating the flow rate from that prep sink. We'll stick to the standard 75% capacity rule and assume a two-minute drain time.

- Get Cubic Inches: 18" x 18" x 12" = 3,888 cubic inches.

- Convert to Gallons: 3,888 ÷ 231 = 16.8 gallons.

- Find 75% Capacity: 16.8 x 0.75 = 12.6 gallons.

- Calculate GPM: 12.6 gallons ÷ 2 minutes = 6.3 GPM.

You'd typically find the dishwasher's flow rate in its manual, but a small unit like this is usually around 2-3 GPM. Add them together (6.3 + 3), and you get 9.3 GPM. In this case, you’d round up and choose a hydromechanical grease trap rated for 10 GPM.

Sizing with the Fixture Unit Method

Now, let's look at it from the Fixture Unit angle.

- Food Prep Sink = 2 FU

- Small Commercial Dishwasher = 4 FU

- Total Fixture Units = 6 FU

When you check a standard UPC sizing chart, a 6 FU load often points to a 20 GPM grease trap. See the difference? The FU method is generally more conservative and leads to a larger size, which is exactly why many health departments prefer it. A 10 GPM unit might get the job done, but if your local code requires FU calculations, the 20 GPM model is what you'll need to install.

Scenario 2: The Busy Pizzeria

Next, we have a high-volume pizzeria that’s churning out greasy, delicious pies all night long. This kitchen is a workhorse, with a constant stream of oily pans and dishes hitting the wash station.

Kitchen Equipment:

- One large 3-compartment sink; each basin is 24" L x 24" W x 14" D.

- One high-temperature commercial dishwasher.

- One floor drain under the pot washing area.

Sizing with the GPM Method

For a multi-basin sink, you only need to calculate the volume for a single compartment, since that's the biggest slug of water you'd ever dump at once. Given the high-volume nature of the kitchen, we'll use a faster one-minute drain time.

- Get Cubic Inches: 24" x 24" x 14" = 8,064 cubic inches.

- Convert to Gallons: 8,064 ÷ 231 = 34.9 gallons.

- Find 75% Capacity: 34.9 x 0.75 = 26.2 gallons.

- Calculate GPM (1-minute drain): 26.2 gallons ÷ 1 minute = 26.2 GPM.

A high-temp dishwasher could easily add another 6 GPM, bringing our total to 32.2 GPM. The smart move here is to select a 35 GPM hydromechanical trap.

Sizing with the Fixture Unit Method

Let's tally the FU values for the pizzeria.

- 3-Compartment Sink = 3 FU

- High-Temp Commercial Dishwasher = 6 FU

- Floor Drain (only gets indirect splash) = 0 FU

- Total Fixture Units = 9 FU

A 9 FU load on a sizing chart corresponds directly to a 35 GPM grease trap. It's a great feeling when both methods point to the same answer. This gives the owner a ton of confidence they’ve made the right choice.

Scenario 3: The Large-Scale Catering Kitchen

Our final example is a big-league catering kitchen that preps food for huge events. The amount of FOG (fats, oils, and grease) they produce is massive, thanks to equipment like tilt skillets and some of the best commercial deep fryers being cleaned down.

Kitchen Equipment:

- Two 3-compartment sinks, each with big 30" L x 30" W x 16" D basins.

- One industrial conveyor dishwasher.

- Multiple floor drains that receive direct discharge from large kettles.

For an operation this big, a small under-sink trap just won't cut it. The local plumbing code will almost certainly mandate a large, in-ground gravity grease interceptor. These are sized in total gallons, not GPM, and the calculation often involves other factors like seating capacity or meals served.

But just for perspective, let's see what the FU method tells us about the flow rate.

- Two 3-Compartment Sinks (3 FU each) = 6 FU

- Industrial Conveyor Dishwasher = 6 FU

- Two Kettle Drains (specialty fixtures) = 8 FU (4 FU each)

- Total Fixture Units = 20 FU

A 20 FU load translates to a flow rate between 75-100 GPM. This high number is the final nail in the coffin for smaller traps. It confirms the need for a gravity interceptor, likely 1,500 gallons or larger, to give the grease enough time to separate from the water. Trying to handle this kind of volume with anything less would lead to constant clogs, backups, and health code violations.

Choosing the Right Equipment for Your Needs

Okay, so you've run the numbers and figured out the capacity your kitchen needs. Now comes the real decision: picking the right piece of hardware. This choice pretty much boils down to two main players: the smaller hydromechanical grease traps you can tuck under a sink, and the big gravity grease interceptors that usually live in the ground outside.

While they both do the same job—trapping fats, oils, and grease (FOG)—they are worlds apart in scale and application. Making an informed decision here is critical for keeping your kitchen running smoothly and staying on budget. Savvy restaurant owners discover that exclusive deals on the right supplies can make a huge impact on their bottom line.

Hydromechanical Grease Traps: The Compact Solution

For smaller operations, hydromechanical grease traps (or HGIs, as they're often called) are usually the perfect fit. We're talking about cafes, delis, food trucks, or any kitchen where space is tight and the wastewater flow is manageable. These units are sized in Gallons Per Minute (GPM), which lines up perfectly with the flow rate calculations we walked through earlier.

Don't mistake them for a simple box. A good HGI has a smart internal baffle system designed to slow down the rush of water, giving FOG a chance to separate and float to the top. Their compact design makes them a lifesaver for retrofitting older kitchens where you just can't tear up the floor for a major plumbing project.

Here’s why they’re so popular:

- Small Footprint: They can often be installed right under a 3-compartment sink or in a nearby utility closet. This saves precious kitchen floor space you can't afford to lose.

- Lower Upfront Cost: The trap itself and the installation are way less expensive than digging a massive hole for an in-ground interceptor.

- Targeted Application: They’re ideal for handling FOG from a specific, high-grease source, like your pot-washing station, without over-engineering your entire plumbing system.

The trade-off? Their smaller size means they fill up faster. You'll need to clean them out frequently—sometimes weekly or bi-weekly—to keep them working effectively.

Gravity Grease Interceptors: The High-Volume Workhorse

Once you get into high-volume restaurants, huge catering kitchens, or institutional food service, you're in a different league. This is where gravity grease interceptors become a non-negotiable part of the plan. These are massive, passive tanks, often 750 gallons or more, that are sized by their total liquid capacity in gallons, not GPM.

The logic here is beautifully simple: size and time. A gravity interceptor holds a huge volume of wastewater for an extended retention time, which lets the FOG naturally separate and float to the surface. There are no complex internal parts, just a giant tank doing its job. Because of their sheer scale, they can easily handle the combined discharge from multiple sinks, dishwashers, and floor drains all at once.

You'll almost always find them buried outside the building, patched directly into the main sewer line. In fact, many local codes flat-out require one for any new full-service restaurant. Getting wastewater into these big interceptors properly is a job in itself, and our guide on selecting the right stainless steel floor sink can give you some great pointers on that part of the setup.

The greatest strength of a gravity interceptor is its massive capacity. It allows for much longer intervals between professional pumping services, usually every 90 days. But this convenience comes with a much steeper price tag for both the unit and the excavation work needed for installation.

Getting this choice wrong can have serious consequences. Undersized traps are a leading cause of sewer system nightmares, contributing to over 50% of sewer backups in some cities. The EPA has pointed out that FOG blockages are behind a staggering 47% of all sanitary sewer overflows every year. For a full-service restaurant serving 250 meals a day, a 100-150 gallon interceptor is often the baseline to hit 95% FOG capture efficiency and avoid becoming part of that statistic.

Ultimately, choosing between a compact HGI and a massive gravity interceptor isn't just about your flow rate calculation. It’s about matching the equipment to your restaurant's daily reality, your physical space, and your budget for both now and the long haul.

Installation and Maintenance Best Practices

Getting your grease trap sizing right is a huge victory, but it's only half the battle. A perfectly sized unit won’t do you any good if it’s installed poorly or completely ignored for months on end. To really protect your investment and keep your kitchen running smoothly, you have to get the installation and ongoing maintenance details right.

Think of your grease trap like any other mission-critical piece of equipment in your kitchen. A proper setup and regular service are absolutely non-negotiable if you want long-term performance and to stay on the right side of the health inspector.

Nailing the Initial Installation

A flawless installation is the foundation for years of trouble-free operation. You should always bring in a licensed plumber for the actual hookup, but knowing what a good install looks like means you can oversee the process and catch any red flags.

First up is strategic placement. I’ve seen traps shoved into cramped, unreachable corners, and it’s always a recipe for disaster. The unit has to be easily accessible for cleaning and inspections. Make sure there’s enough clearance above and around it to fully open the lid and let a service tech do their job without a struggle. For a deeper dive into setting up your wash station correctly, check out our guide on 3 compartment sink rules.

Next, let's talk about the plumbing itself. Every single hydromechanical grease trap installation must include a flow control fitting, sometimes called an air intake. This little device is critical because it limits the water flow to the trap's rated GPM. Without it, a sudden high-pressure blast of water from a sink can force grease straight through the trap and down the drain—completely defeating its purpose.

Creating a Bulletproof Maintenance Routine

Once your trap is in, a consistent maintenance schedule is your best defense against nasty backups, foul odors, and expensive fines. The most important rule of thumb to live by is the "25% rule."

You must have your grease trap pumped out and cleaned once the combined layer of FOG (fats, oils, and grease) and settled solids fills 25% of the trap's total liquid depth. If you let it go past this point, the trap’s efficiency plummets, and you’ll start sending FOG into the city sewer lines.

So, what does this mean in practice? For most restaurants, hitting that 25% mark usually means a professional cleaning is needed every one to three months. Your mileage will vary, of course. A high-volume kitchen frying up burgers all day will need service far more often than a small cafe.

Just as important as the cleaning itself is keeping meticulous records of it.

- Start a Maintenance Log: A simple binder or a digital folder is all you need.

- Log the Details: Every time it's serviced, write down the date, the name of the pumping company, and how much grease was removed.

- Save Your Invoices: Keep every service receipt and invoice as proof of compliance.

This log is your best friend when the health inspector walks in. It proves you’re on top of your FOG management and are following all the local rules. For more tips on keeping your system in top shape, you can find great info on restaurant grease trap cleaning. A well-documented plan shows you're serious about your business, and that goes a long way.

Answering Your Top Grease Trap Questions

After running the numbers, you're bound to have some practical questions pop up. Sizing can feel like a science project, but it's the day-to-day reality of living with the equipment that really matters. We hear these questions all the time from chefs and restaurant owners in the thick of planning, so let's get you some straight answers. Keeping informed about these industry trends and best practices is a key part of running a successful kitchen.

How Often Does a Grease Trap Need to Be Cleaned?

The industry standard is the "25% rule." Simple and effective. Once the top layer of fats, oils, and grease (FOG) combined with the bottom layer of solids takes up 25% of the trap's total volume, it's time for a professional pump-out. Let it go any further, and you'll see a nosedive in its efficiency.

For most restaurants, this means a professional cleaning every 1 to 3 months. But that's just a ballpark. A busy fried chicken spot is going to fill its trap way faster than a small cafe. Your menu and customer volume are the biggest factors. Always double-check your local health department rules, too—they often have the final say on your required pumping schedule.

Can I Just Install It Myself and Save Some Cash?

I know it’s tempting to try and save on labor, but this is one of those jobs you absolutely want to leave to a licensed pro. Installing a grease trap isn't like hooking up a new sink; it's a serious plumbing job that has to meet very strict local and health codes.

A DIY installation gone wrong is a nightmare. You're looking at nasty odors, leaks, sewer backups, and a guaranteed failed inspection. The cost to fix those messes will dwarf what you would have paid a plumber in the first place. A professional will make sure it's vented correctly, has the right flow control fittings, and is 100% compliant from the start.

What’s the Harm in Getting a Grease Trap That's Too Big?

It feels like a safe bet to go bigger, right? More capacity, less worry. But an oversized grease trap can actually cause some unique and stinky problems. If your kitchen's wastewater flow is too low for a giant tank, the water will stagnate and turn septic.

When this happens, the trap starts producing hydrogen sulfide gas. You'll know it by the powerful "rotten egg" smell that just won't go away. Over time, that same gas can eat away at the trap itself, especially concrete models. The real key to an efficient, odor-free system is matching the trap size to your kitchen's actual output.

Does My Food Truck Really Need a Grease Trap?

Yes, it absolutely does. Mobile kitchens are subject to the same health and environmental rules as any brick-and-mortar restaurant. Just about every health department in the country will require your food truck to have a proper grease management system on board.

Usually, this means a compact hydromechanical grease trap built for small spaces. The right size will depend on the sinks you're running. You'll also need to show proof that you're disposing of the collected grease at a licensed facility to keep your permit in good standing.

At Encore Seattle Restaurant Equipment, we know the right equipment is the foundation of a great kitchen. We're dedicated to helping restaurant owners and chefs discover the latest news and exclusive deals on restaurant equipment and supplies. From figuring out the perfect grease trap to outfitting your entire line, our team is here with expert advice and great prices on brands you can count on. Let's find the right solutions for your restaurant.

Find your essential kitchen equipment at https://encoreseattle.com.