Find the Best Commercial Deep Fryers for Your Kitchen

Share

Picking the best commercial deep fryer for your kitchen isn't just another equipment purchase; it's a major investment that directly hits your food quality, speed of service, and bottom line. The market is full of options, but your decision really boils down to three core technologies: gas, electric, and induction. Let's cut through the noise and figure out which one is the right fit for your operation. Stay informed about the latest industry trends and find exclusive deals on the restaurant equipment and supplies that will elevate your business.

Choosing Your Best Commercial Deep Fryer

Finding the right fryer is all about matching the machine to your kitchen's reality. A high-volume wing joint has completely different demands than a small bistro that only fries calamari as an appetizer. Think about your daily frying volume, your budget, and the variety of fried items on your menu—these are the big three that will point you in the right direction.

For example, if you're pumping out hundreds of pounds of fries every day, you need a heavy-duty floor model that can get back to temperature in a flash. But if you're running a food truck where every inch counts, a small countertop unit is the obvious choice. Nailing down these fundamental needs is the first step to making a smart buy.

Matching Fryer Type to Your Needs

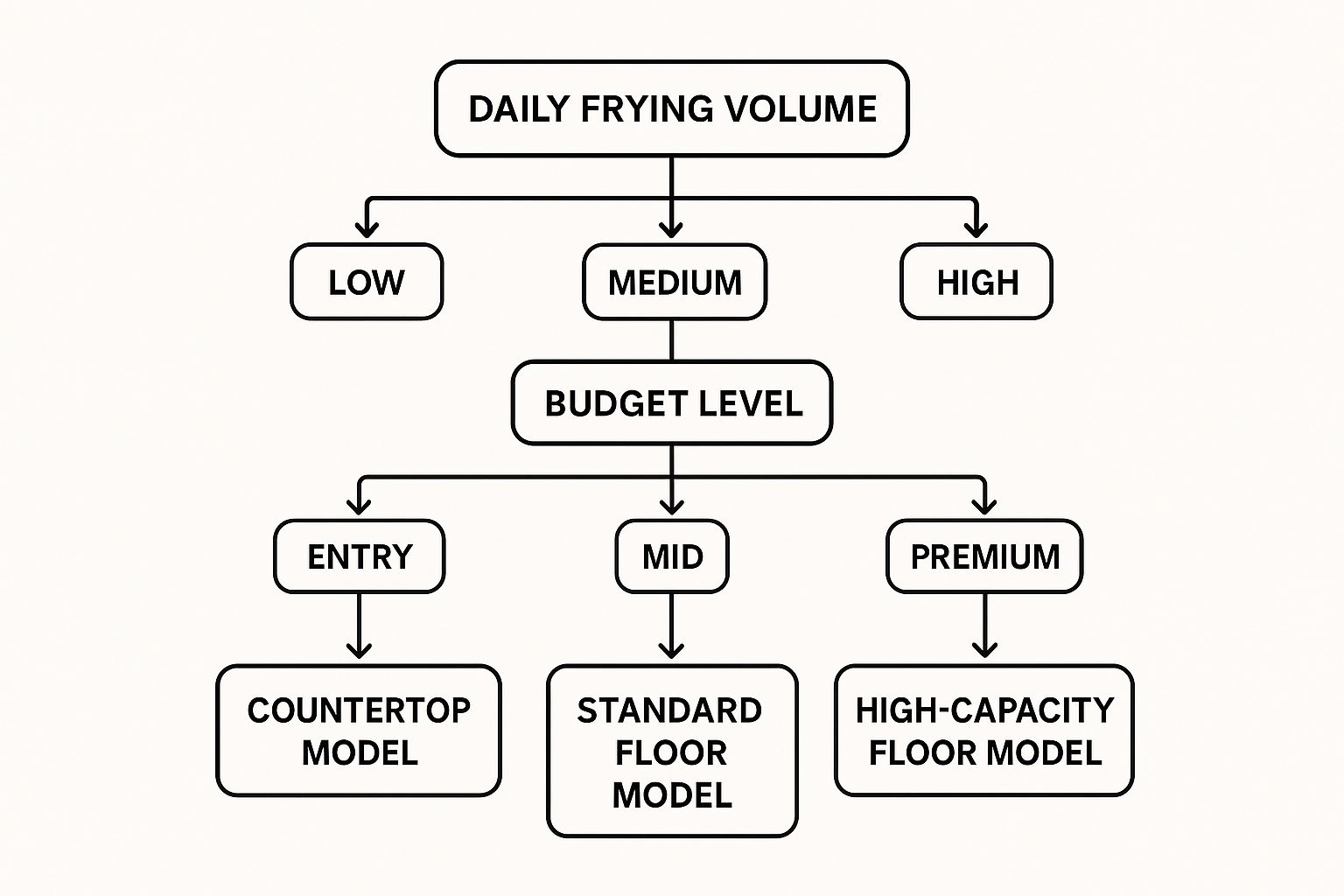

To make that first big decision a little easier, let's start with your operational scale. This simple decision tree lays out how your daily volume and budget can quickly narrow down the options.

As you can see, what you produce dictates the game. Your output points you toward a countertop, standard floor, or high-capacity fryer first, and then your budget helps finalize the pick. This approach keeps you from over-investing in a beast of a machine you don't need or—even worse—buying a fryer that crumbles during the dinner rush.

If you're looking for real-world examples, this Atosa deep fryer review offers a great look at a brand that many kitchens trust for its balance of performance and price.

Commercial Fryer Quick Comparison

To give you a quick snapshot, this table breaks down how gas, electric, and induction fryers stack up against each other on the key things that matter day-to-day.

| Fryer Type | Best For | Energy Efficiency | Heat Recovery Time | Installation Needs |

|---|---|---|---|---|

| Gas | High-volume kitchens, fast-food, quick recovery needs. | Lower (around 50%) | Fastest | Requires professional gas line and ventilation hookup. |

| Electric | Smaller kitchens, food trucks, precise temperature control. | Highest (around 80%) | Slower | Needs a dedicated high-voltage outlet. Simpler setup. |

| Induction | Specialty items, kitchens focused on safety and efficiency. | High (around 70-75%) | Fast | Needs a dedicated outlet. Most expensive upfront. |

This comparison should give you a solid starting point. Gas is your workhorse for speed, electric offers precision and efficiency, and induction is the modern choice for safety-conscious, high-tech kitchens.

Gas vs. Electric vs. Induction Fryers Explained

Before you can pick the right fryer, you need to understand what’s going on under the hood. It’s a lot like choosing a car—you wouldn’t buy a sports car for a construction job. The power source is the single biggest factor determining how a fryer performs, and the choice you make depends entirely on your kitchen's infrastructure and the demands of your menu.

This is a big decision in a massive market. The global deep fryer market is valued at around USD 573.63 million, with North America making up 38.3% of that, thanks to our love for fast food. You can dive deeper into the deep fryer market trends on imarcgroup.com.

The Workhorse: Gas Fryers

Think of gas fryers as the heavy-duty pickup trucks of the kitchen. Hooked up to a natural gas or propane line, they pack a serious punch. Their biggest advantage is raw power, which translates to incredibly fast heat-up and recovery times.

When your line cook drops a massive basket of frozen fries into the vat, the oil temperature plummets. A gas fryer roars back to life, bringing that oil back to the perfect cooking temperature almost instantly. For any high-volume spot slinging wings, fries, or onion rings, that speed is non-negotiable.

The Precision Tool: Electric Fryers

If gas fryers are trucks, electric fryers are more like finely tuned sedans. They work by submerging heating elements directly into the oil, giving you incredibly stable and precise temperature control. There are no wild temperature swings here.

This level of control is essential for delicate foods. Think tempura, doughnuts, or sensitive seafood where a few degrees can mean the difference between perfectly golden and disappointingly greasy.

The real win for electric models is efficiency. With the heating elements sitting right in the oil, very little energy escapes. They're about 80% efficient, while a typical gas fryer loses about half its heat to the surrounding air, making it closer to 50% efficient.

They do take a bit longer to recover their heat compared to gas, but they're often easier to install—no gas lines needed, just a high-voltage outlet. This makes them a great fit for food trucks, smaller kitchens, or as a dedicated fryer for specialty items.

The New Kid on the Block: Induction Fryers

Induction fryers are the innovative electric vehicles of the commercial kitchen. They use a completely different technology—magnetic fields—to heat the fry pot itself, not the oil directly. This gives you the best of both worlds: the pinpoint accuracy and efficiency of an electric model, but with the rapid heat-up and recovery speeds that rival gas.

Plus, they make for a much cooler and safer kitchen, since the fryer's surface never gets scorching hot. The biggest hurdle is the higher upfront cost, but for kitchens prioritizing safety and top-tier performance, induction is quickly becoming the new standard.

Key Features That Define a Great Fryer

Once you've decided on gas or electric, the real details start to matter. The little things in a fryer's design are what separate a workhorse from a headache, directly impacting how smoothly your kitchen runs, how easy cleanup is, and ultimately, your profits. Getting these details right is how you make a smart investment.

Fry Pot Design: What's on Your Menu?

One of the first things to look at is the fry pot design, and the choice really comes down to what you're cooking.

- Open-Pot Fryers: These have a wide-open, unobstructed tank. They are a breeze to clean and are the go-to for lightly breaded foods like french fries, onion rings, or tempura where you don't have a lot of sediment floating around.

- Tube-Type Fryers: In these models, the heating tubes run right through the oil. This design creates a "cold zone" at the very bottom where crumbs and sediment from heavily breaded items (think fried chicken or fish) can settle without scorching. This simple feature is a lifesaver for your oil quality.

Power, Performance, and Recovery Time

Think of a fryer's power rating—measured in BTUs for gas or kilowatts (kW) for electric—as its engine. More power means the fryer heats up faster and, more importantly, recovers its temperature quicker after you drop in a basket of cold food. A high-powered fryer won't get bogged down during a dinner rush, preventing soggy, greasy results.

The Real Money-Saver: Oil Filtration

Now for the single most important feature for managing your long-term costs: filtration.

An integrated oil filtration system is a game-changer. By making it easy to clean your oil every day, these systems can extend its life by up to 50%. That means huge savings on oil costs and consistently better-tasting food.

Yes, a fryer with a built-in filtration system costs more upfront. But the return on that investment is massive, often paying for itself in oil savings alone within the first year. When you explore the best deep fryer brands, you’ll see that the top names have perfected these high-value, cost-saving features.

How Smart Technology Is Upgrading Fry Stations

Your fry station is no longer just a simple basin of hot oil. The best commercial deep fryers today are getting a major tech upgrade, bringing a new level of automation and precision to one of the most hectic spots in any professional kitchen. These aren't just fancy bells and whistles; they’re designed to lock in consistency, slash operating costs, and let your team focus on more important tasks.

Think about features like programmable cooking timers and automatic basket lifts, which are quickly becoming the new standard. A system that can lift a basket of perfect, golden-brown fries out of the oil at the exact right moment means no more burnt batches during a dinner rush. This kind of automation guarantees every order is perfect, no matter how busy things get or who's running the station.

The Rise of AI in the Kitchen

Artificial intelligence (AI) is taking things to a whole other level. Some of the most advanced fryers now use AI to monitor the quality of the cooking oil in real-time, sending an alert when it’s time to filter or change it. Not only does this keep your food tasting great, but it also helps you get the most out of every drop of oil, which is a huge cost-saver.

This wave of innovation is a big reason the market is growing so fast. The commercial deep fryer market is expected to jump from USD 583.92 million to USD 798.24 million by 2032, and AI-powered features are a huge part of that story. You can dive deeper into the numbers in the full market analysis from consegicbusinessintelligence.com.

Smart fryers have moved beyond simple convenience. They've become powerful management tools that track cooking cycles and fine-tune energy use, giving you the hard data needed to lower utility bills and run a more efficient, profitable kitchen.

To see how this fits into the bigger picture, it's worth looking at broader hospitality technology trends. You'll see that this isn't just about fryers; it's part of a larger movement toward smarter, more connected kitchens that work for you, not against you.

Extending Fryer Life with Proper Maintenance

A top-tier commercial deep fryer is a serious investment, and like any valuable piece of equipment, it needs consistent care. Think of it less as a chore and more as a way to guarantee your fryer runs smoothly for years, keeping your food delicious and your kitchen safe.

When you're proactive about maintenance, you sidestep those frustrating breakdowns that always seem to happen during a dinner rush. A clean, well-cared-for fryer is an efficient fryer, which translates directly to consistent food quality and lower operating costs.

Your Essential Maintenance Checklist

The secret to a long-lasting fryer isn't complicated—it's all about routine. A simple cleaning schedule can make all the difference. Here’s a practical rhythm for daily, weekly, and monthly upkeep.

- Daily Care: Skim out any floating debris throughout service. When you close up, filter the oil and give the fryer’s exterior a good wipe-down to cut through the daily grease splatter.

- Weekly Tasks: This is the time for a proper "boil-out." You'll drain the old oil, fill the vat with a water and cleaning solution mix, and bring it to a boil. This process breaks down all that tough, caked-on gunk that a simple wipe can't handle.

- Monthly Inspection: Give the crucial components a once-over. Check that thermostats and high-limit safety switches are working correctly. Also, take a close look at gas lines or electrical cords for any fraying or damage.

It's no surprise that the industry is focused on equipment that lasts. The market for specialty commercial deep fryers is expected to grow from USD 1.3 billion to USD 2.5 billion by 2035, a jump fueled by the demand for safer, more efficient machines.

Prioritizing Kitchen Safety

Maintenance goes hand-in-hand with safety. A kitchen with a deep fryer needs excellent ventilation to handle the heat and fumes, but that's just the start.

Your team needs to be trained on what to do if things go wrong. For example, everyone should know how to operate a fire extinguisher properly—not just assume they do. For a more comprehensive look at keeping all your gear in top shape, our guide to https://encoreseattle.com/blogs/seattle-restaurant-equipment/commercial-kitchen-equipment-maintenance is a great place to start.

Answering Your Top Commercial Fryer Questions

Even with all the options laid out, it's natural to have a few more questions. A new fryer is a serious investment, and you want to be sure you're making the right call for your kitchen. Let's tackle some of the most common questions we get from restaurant owners and chefs just like you.

How Often Should I Change the Fryer Oil?

This is the big one, and getting it right is a balancing act between food quality and your bottom line. There’s no single answer that fits every kitchen, but a great rule of thumb is to filter your oil daily, especially after a busy service. As for a full-on change, you're typically looking at every 3 to 7 days, depending heavily on what you're frying and how much of it.

Your oil will give you some pretty clear signals when it's time for a change. Keep an eye out for these tell-tale signs:

- It looks dark and murky: Fresh oil is light and clear. Old oil is not.

- It smells off: If you catch a rancid, unpleasant odor before the fryer is even hot, that oil is done.

- It starts smoking: Oil that smokes at your normal cooking temperature is breaking down and needs to be replaced.

- The food comes out greasy: When your fried chicken or fries start tasting heavy and oil-logged, it's a sure sign the oil is past its prime.

Here's a tip from the pros: Making daily filtering a non-negotiable part of your closing routine can stretch the life of your cooking oil by as much as 50%. That simple habit translates directly into lower supply costs and consistently crispy, delicious food.

Tube Fryers vs. Open-Pot Fryers: What's the Real Difference?

The debate between tube fryers and open-pot fryers really boils down to two things: how they're heated and what you plan on cooking most. It’s all about matching the tool to the job.

An open-pot fryer is exactly what it sounds like—it has a wide-open, smooth-bottomed fry tank. This makes it a dream to clean. Because there are no nooks and crannies for sediment to hide, it's the perfect choice for lightly breaded foods like french fries, onion rings, or tempura that don't leave a lot of debris behind.

A tube-type fryer, on the other hand, has heating tubes running through the oil. This smart design creates a "cold zone" at the very bottom of the tank. Any heavy breading or crumbs from things like fried chicken or fish and chips fall down into this cooler area, where they won't burn and ruin the oil. This makes tube fryers the undisputed champ for any menu heavy on breaded items, keeping your oil cleaner for much longer.

How Do I Choose the Right Size Fryer?

Getting the size right is crucial for avoiding a major kitchen bottleneck during a dinner rush. A solid way to figure this out is to estimate how much of your most popular fried item you need to cook during your busiest hour. As a general guideline, a fryer can produce about 1.5 to 2 times its weight in oil as food per hour.

Let’s put that into perspective: a standard 50 lb fryer can comfortably push out between 75-100 lbs of french fries an hour. If you're frying a bunch of different things, consider getting two smaller fryers instead of one giant one. This setup prevents flavor crossover (no one wants their donuts to taste like fish) and gives you a vital backup if one unit ever goes down for maintenance.

Ready to find the perfect fryer for your kitchen? We're here to help you discover the latest news and exclusive deals on the best restaurant equipment and supplies. At Encore Seattle Restaurant Equipment, we have a huge selection of top-quality new and used equipment to fit any kitchen and budget. Come explore our inventory and get some expert advice by visiting us at https://encoreseattle.com.