Your Essential Guide to Stainless Steel Floor Sinks

Share

In any commercial kitchen, a stainless steel floor sink is one of those critical pieces of plumbing that works tirelessly behind the scenes. Its main job? To safely and efficiently manage all the wastewater coming from your heavy-duty equipment. Think of it as the central drainage hub for your kitchen, collecting everything from dishwashers, steam kettles, and ice machines. This prevents nasty clogs, backups, and—most importantly—hazardous wet floors.

The Unsung Hero of Your Commercial Kitchen

Picture a chaotic dinner rush. Orders are flying, the fryer is sizzling, and then—disaster. A drain backs up, and a dangerous puddle spreads across the floor, bringing operations to a screeching halt. This is the exact moment when the often-overlooked stainless steel floor sink proves its incredible value.

It’s so much more than just a drain in the floor; it's the very heart of your kitchen's drainage system. This simple fixture is silently protecting your business from slip-and-fall accidents, potential health code violations, and the expensive downtime that always follows a plumbing emergency.

More Than Just a Drain

A standard floor drain is just meant to catch spills or mop water. A floor sink, on the other hand, is a purpose-built basin, specifically engineered to handle the intense demands of a commercial food environment.

Here’s what makes it absolutely essential for any professional kitchen:

- Indirect Waste Management: It safely collects wastewater from equipment that can't be directly plumbed into the sewer line. This is often to create a legally required "air gap" that prevents contamination.

- Solid Waste Filtration: Most come equipped with strainer baskets that capture food scraps, debris, and other gunk, stopping it from ever entering and clogging your main plumbing lines.

- High-Volume Capacity: The deep basin is designed to handle a sudden, massive discharge of water—like from a commercial dishwasher or a tilting skillet—without overflowing onto the floor.

A properly installed stainless steel floor sink acts as a vital buffer between your expensive kitchen equipment and the building's plumbing. It's a frontline defense against clogs that could otherwise shut down your entire operation.

A Foundational Kitchen Investment

Putting in robust fixtures like these is a non-negotiable part of any new kitchen build or major remodel. Understanding how these pieces fit into the bigger picture of upgrading a commercial space highlights their importance. If you're planning a larger project, this commercial building renovation guide provides some great context on the planning and execution stages.

Ultimately, choosing the right stainless steel floor sink is a direct investment in your kitchen’s safety, hygiene, and long-term efficiency. This guide will walk you through everything you need to know, from picking the perfect model to keeping it in top shape, so you can make a smart decision that ensures smooth operations for years to come.

Why Stainless Steel Is the Unbeatable Choice

Think of a stainless steel floor sink as the unsung hero of your kitchen's plumbing. It's tough, reliable, and designed from the ground up to handle the relentless abuse of a commercial kitchen. When it comes to materials for this critical fixture, stainless steel isn't just a popular option—it’s the undisputed champion.

The numbers back this up. Stainless steel is the dominant material across the board for sinks, capturing an estimated 52.98% of the global market in 2024. For restaurant owners and chefs, this isn't just a trend; it's a clear signal of the material's proven advantages where hygiene and durability are non-negotiable.

The Foundation of Kitchen Hygiene

The single biggest reason stainless steel reigns supreme is its non-porous surface. Unlike materials like concrete or even certain plastics, it doesn't have microscopic pores or crevices. This means there's nowhere for bacteria, mold, or food particles to hide.

This slick, smooth surface makes cleaning and sanitizing incredibly simple and effective—a must-have quality for acing any health inspection. It's the same reason stainless steel is used for virtually everything else in a professional kitchen, from prep tables to wall coverings. You can find out more about how this material elevates other kitchen components in our guide on commercial stainless steel shelves.

Durability That Pays Dividends

A commercial kitchen is a battlefield. Heavy stockpots get dropped, loaded carts roll over grates, and caustic cleaning chemicals are used daily. A stainless steel floor sink is built to take this punishment without cracking, chipping, or rusting away. This is where it truly separates itself from the alternatives.

To see why stainless steel is the clear winner, let's look at how the most common materials stack up against each other.

Material Comparison for Commercial Floor Sinks

| Feature | Stainless Steel | Cast Iron | Plastic (PVC/ABS) |

|---|---|---|---|

| Hygiene | Excellent. Non-porous surface prevents bacterial growth. | Fair. Can become porous if enamel coating chips, leading to rust and contamination. | Good. Non-porous but can be scratched, creating areas for bacteria to hide. |

| Durability | Excellent. Resists impact, cracks, and high temperatures. | Good. Very strong but brittle; can crack under sharp impact. | Fair. Prone to cracking from impact or extreme temperature shifts. |

| Corrosion/Rust | Excellent. Highly resistant to rust and chemical corrosion. | Poor. Extremely susceptible to rust if the protective coating is compromised. | Excellent. Completely rust-proof. |

| Chemical Resistance | Very Good. Withstands most cleaning chemicals, especially Grade 316. | Fair. Enamel coating can be damaged by harsh or abrasive cleaners. | Poor to Fair. Can be stained or degraded by certain chemicals and solvents. |

| Longevity | 25+ years. A long-term investment that often outlasts the kitchen itself. | 10-20 years. Lifespan is heavily dependent on maintaining the coating. | 5-15 years. The least durable option, often requiring replacement. |

| Cost | Higher initial cost. Lower total cost of ownership due to longevity. | Moderate initial cost. Can have high long-term costs due to replacement. | Low initial cost. Highest long-term cost due to frequent replacement needs. |

As the table shows, while other materials might save you a bit of money upfront, they can't match the long-term performance and reliability of stainless steel.

Choosing stainless steel isn't just buying a drain; it's an investment in operational peace of mind. Its incredible resistance to corrosion, impact, and heat translates to fewer emergency calls to the plumber and a much lower total cost of ownership over its decades-long life.

Understanding Stainless Steel Grades: 304 vs. 316

Not all stainless steel is the same. When you're looking at floor sinks, you'll mainly run into two "grades": Type 304 and Type 316.

Here’s an easy way to think about them:

-

Type 304 Stainless Steel: This is the workhorse of the food service industry. It offers fantastic durability and corrosion resistance against water, food acids, and all standard cleaning chemicals. For the vast majority of restaurants, bars, and cafes, Type 304 is the perfect all-around choice.

-

Type 316 Stainless Steel: This is the heavy-duty specialist. It has an extra ingredient—molybdenum—that gives it superior protection against chlorides (like salt and brine) and other extremely harsh chemicals. You'd opt for Type 316 if you're running a seafood processing facility, a coastal restaurant with salty air, or use unusually aggressive sanitizers.

For most operators, Type 304 hits the sweet spot of performance and price. But if your kitchen deals with highly corrosive or salty waste, spending a little more on Type 316 is smart insurance that will extend the life of your floor sink even further.

Choosing the Right Stainless Steel Floor Sink

Picking a stainless steel floor sink isn't a simple one-size-fits-all task. The right choice really comes down to the specific demands and daily workflow of your kitchen. It's kind of like choosing between a nimble sports car and a heavy-duty pickup; what works perfectly for a small coffee shop would be completely swamped in a high-volume hotel kitchen.

This decision is about more than just finding a model that fits the hole in your floor. You have to match the sink's capacity, features, and accessories to the sheer volume and type of wastewater your equipment will be dumping into it. Getting this right from day one is the key to preventing future headaches like slow drains, constant clogs, and nasty overflows right in the middle of a dinner rush.

Decoding Size and Depth

The physical dimensions of a floor sink have a direct impact on how well it does its job. The most common size you'll see out there is 12x12 inches, but for more demanding environments, bigger options like 16x16 or even 24x24 inches are available for a reason.

-

Size (Width and Length): Think of the surface area as the "catch zone" for your drain lines. A larger sink, say a 16x16 model, gives you a much more forgiving target when you have multiple lines coming from an ice machine and a prep sink. This means fewer splashes and a better guarantee that all the water ends up where it's supposed to.

-

Depth: This is arguably the most critical dimension of all. A shallow sink (around 6 inches deep) might be fine for a single, low-flow drain. But for the sudden, high-volume gush of water from a commercial dishwasher or a steam-jacketed kettle, you absolutely need a deep sink (10 to 12 inches or more).

A deeper basin acts like a buffer, holding that huge surge of water and letting it drain away at a more controlled rate. This simple feature prevents the plumbing from getting overwhelmed and backing up all over your clean floor. A busy restaurant kitchen draining multiple pieces of equipment at once is a perfect example of where a deep, large-capacity stainless steel floor sink is a non-negotiable must-have.

Essential Accessories That Define Performance

A floor sink is a lot more than just a steel box in the ground. The accessories that go with it are what make it a truly functional part of your drainage system. These aren't just optional add-ons; they are crucial components for day-to-day efficiency and maintenance.

Grate Types and Materials

The grate is your first line of defense. It gives you a safe surface to walk or roll carts over while letting water pour through. Different types offer their own distinct advantages:

- Full Grate: This covers the entire sink opening, making it the best choice for areas with heavy foot or cart traffic. It provides the most coverage and safety.

- Half Grate: Just like it sounds, this covers only half the sink, leaving the other side open. This design is perfect when you have fixed drain pipes that need to empty into the sink while still giving you easy access to the basket below.

- Domed Grate: This one has a raised, dome-like shape that helps keep debris from settling on top and blocking the flow of water.

Think of a sediment basket as the goalie for your plumbing system. Its primary job is to stop solids—from stray bits of food to broken glass—from going down the drain and causing expensive, service-disrupting clogs.

The Crucial Sediment Basket

Often called a strainer basket, this removable piece sits right inside the floor sink, just beneath the grate. It's there to catch any and all solid debris that gets washed in. A quality, perforated stainless steel floor sink basket is easy to lift out, dump in the trash, and rinse clean, making daily maintenance simple and effective. Honestly, skipping this one simple task is one of the fastest ways to end up with foul odors and sluggish drains.

Integrated P-Traps

Some floor sinks come with a P-trap—the U-shaped pipe that holds water to block sewer gases from wafting into your kitchen—built right in. While this can sometimes make installation a little simpler, it comes with a potential downside. If an integrated trap gets clogged, it can be a real pain to access and clear out compared to a standard, external P-trap installed in the plumbing line below. The best choice here often depends on local plumbing codes and what your installer is comfortable working with.

Getting Installation and Plumbing Codes Right

Choosing the right stainless steel floor sink is only half the battle. How it's installed is just as crucial—a flawless installation means years of reliable service, while a botched job can quickly turn into a nightmare of chronic backups, foul odors, and failed health inspections.

This isn't just about hooking up pipes. It's about building a drainage system that meets strict local health and plumbing codes. These rules aren't there to make your life difficult; they exist to protect public health, prevent cross-contamination, and ensure wastewater is managed safely. Ignoring them can lead to hefty fines, failed inspections, or even a forced shutdown until you fix the problem.

The Physics of Drains: Vents and Traps

To understand why the codes are so specific, it helps to know a little about the science behind your plumbing. Two concepts are absolutely fundamental: trapping and venting. They work hand-in-hand to keep your drainage system flowing smoothly and your kitchen smelling fresh.

-

What a P-Trap Does: Every floor sink needs a P-trap. That's the U-shaped bend in the pipe just below the sink. Its job is to hold a small amount of water, which creates a seal that physically blocks sewer gases from creeping up the pipe and into your kitchen. Without that simple water barrier, your workspace would be filled with unpleasant and hazardous fumes.

-

Why Venting is Non-Negotiable: Ever turn a full two-liter bottle upside down? It glugs and sputters as it drains because air is fighting to get in while water is trying to get out. A drain vent prevents this exact problem in your plumbing. It’s a separate pipe that allows air to enter the drainage system behind the water, breaking the vacuum and letting gravity do its job efficiently.

Think of it like trying to drink through a straw with your finger pressed over the other end—nothing moves. That's a drainage pipe without a vent. Proper airflow is what prevents those slow, gurgling drains that signal a problem.

Getting the plumbing right is a core part of any commercial kitchen project. If you're planning a larger overhaul, this detailed kitchen renovation guide can be a huge help in understanding the permits, timelines, and other complexities involved.

Key Installation Best Practices

While you’ll hire a licensed plumber for the actual work, being an informed owner helps you ask the right questions and spot potential issues before they become expensive problems.

Here are the critical points to discuss with your installation team:

-

A Perfect Floor Slope: The floor surrounding your sink isn't just flat; it needs to be precisely graded. A gentle slope, usually around 1/4 inch per foot, is the standard. This ensures that all spills, mop water, and equipment runoff naturally flow toward the drain instead of pooling on the floor, which creates slip hazards and breeding grounds for bacteria.

-

A Completely Watertight Seal: The point where the sink flange meets the floor is a major weak spot if not handled correctly. Your installer must use a heavy-duty, industrial-grade sealant to create a perfect, watertight seal. This is crucial for preventing moisture from seeping under the flooring, where it can cause mold, rot, and attract pests.

-

Local Code Compliance is a Must: Plumbing codes aren't universal; they can vary widely from one city or county to the next. Before a single pipe is cut, you must confirm that your entire plan—from pipe diameters and P-trap placement to the venting layout—is fully approved by your local building and health departments.

The emphasis on these standards is a global phenomenon. In fact, the market for commercial stainless steel drainage products is overwhelmingly concentrated in regions with the strictest sanitary codes. Recent reports show that Europe and North America make up roughly 32.7% and 30.8% of the market, respectively. This demonstrates how compliance directly drives equipment standards and availability in major foodservice hubs.

Keeping Your Floor Sink in Top Shape: Essential Maintenance

Think of your stainless steel floor sink as a critical piece of kitchen equipment, just like your oven or your walk-in cooler. It's a serious investment in your operation's health and efficiency. And like any workhorse, it needs regular care to keep performing at its peak for years to come. If you ignore it, you’re just asking for slow drains, nasty smells, and eventually, a full-blown plumbing emergency that could shut you down.

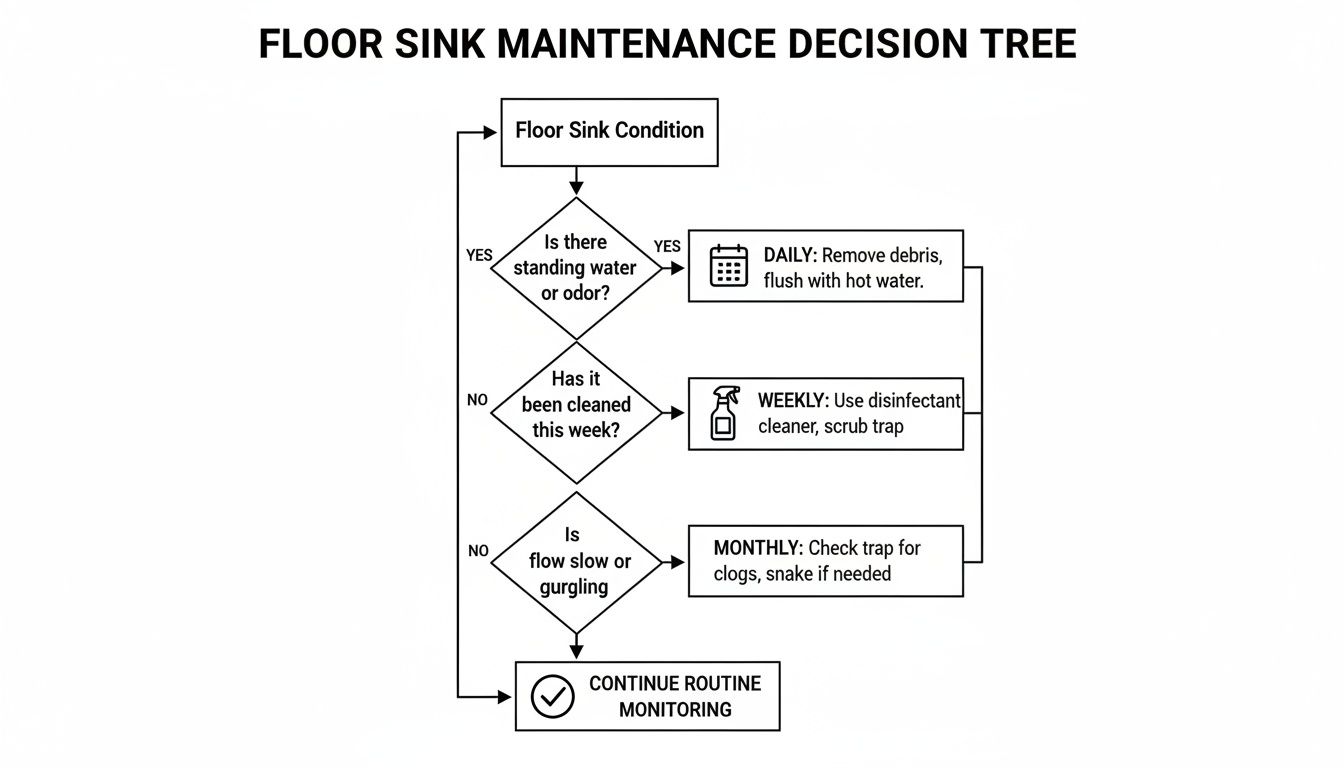

The best defense is a simple, structured cleaning routine. It’s not complicated. By breaking down the tasks into daily, weekly, and monthly jobs, your team can easily stop the slow, sneaky buildup of grease and food debris—the stuff that causes nearly every problem. This isn't just about being clean; it's about being smart and proactive.

A Practical Maintenance Playbook

A consistent cleaning schedule is your secret weapon for a trouble-free floor sink. It’s the difference between a smooth-running kitchen and one plagued by costly plumbing repairs.

Daily Routine (End of Every Shift):

- Empty the Basket: First things first, lift the grate and pull out that sediment basket. Dump all the solid gunk directly into the trash. Whatever you do, don't wash it down the drain.

- Scrub and Rinse: Grab a non-abrasive brush and some hot water. Give the inside of the basket and the sink basin a good scrub to get rid of any clinging grease or food bits.

- Final Flush: Finish by pouring a bucket of very hot water down the drain. This helps flush out any lingering residue from the sink itself and, just as importantly, the P-trap below.

Weekly Deep Clean:

- Bring in the Enzymes: Once a week, treat your system with a commercial-grade, enzyme-based drain cleaner. These aren't harsh chemicals; they use good bacteria to literally eat away at organic buildup without damaging your pipes.

- Inspect the Grate: Pull the grate completely out. Scrub it on both sides, really getting into the corners where grime loves to hide. While you're at it, give it a quick check for any bending or damage.

Monthly Check-Up:

- Watch the Water: Pay attention to how fast the water is draining. If you notice it’s starting to slow down, even a little, that’s your first red flag that a clog is forming deeper in the pipes.

- Check the Seals: Look closely at the sealant where the edge of the floor sink meets your tile. If you see any cracks or peeling, that seal is compromised. It needs to be replaced to stop water from seeping under the floor and causing much bigger problems.

Consistent maintenance isn’t just about cleaning—it's about prevention. A five-minute daily cleanup can save you from hours of downtime and hundreds of dollars in emergency plumbing bills.

What to Use, What to Lose: Safe Cleaning Agents

Stainless steel is incredibly durable, but it's not invincible. Using the wrong cleaning chemicals is a surefire way to cause permanent damage like pitting, ugly stains, or even corrosion.

For day-to-day cleaning, hot water and a simple degreasing detergent are almost always enough. When you need a bit more muscle, you have to choose your products carefully. Harsh chemicals can strip away the passive layer that protects the steel from rust. To dive deeper into this, you can learn more about if you can use vinegar on stainless steel in our other guide.

Here’s a quick cheat sheet for your team:

Safe to Use:

- Enzyme-based drain cleaners

- Mild detergents and soaps

- A paste of baking soda and water for light scrubbing

- Soft cloths, sponges, or nylon brushes

Avoid at All Costs:

- Chlorine bleach and any cleaner containing chlorides. This is the #1 enemy of stainless steel.

- Abrasive scouring powders or steel wool. They will scratch the surface permanently.

- Harsh acid-based cleaners.

- Metal scrapers or wire brushes.

Your Ultimate Floor Sink Purchasing Checklist

Alright, you've done the reading, and now it's time to make a decision. Think of this checklist as your final walkthrough before you sign on the dotted line. It pulls together all the critical points we've covered, helping you spec out and buy the right stainless steel floor sink with total confidence. Get this right, and you're making a smart investment that supports your whole operation.

First, a quick reminder about keeping your sink in top shape. It's not a "set it and forget it" piece of equipment.

As you can see, a little proactive care goes a long way. Simple daily, weekly, and monthly habits are all it takes to keep clogs and nasty odors at bay.

Step 1: Code and Compliance First

Before you even glance at a catalog, your first call should be to your local inspector. This is the foundation of a successful installation. Skipping this step is a surefire way to face costly teardowns and failed inspections.

- Confirm Local Plumbing Codes: Get in touch with your city or county's health and building departments. You need to know their exact rules on P-trap placement, drain venting, and how they handle indirect waste from kitchen equipment. These rules are non-negotiable.

- Verify Air Gap Requirements: Ask which of your appliances—like dishwashers, combi ovens, or ice machines—legally require an air gap. This is crucial for preventing backflow contamination, and it dictates exactly where your floor sink must be installed.

Step 2: Sizing and Feature Specification

With the legal stuff sorted, it’s time to look at your actual kitchen workflow. Choosing the wrong size or features for your volume is a classic mistake that leads to constant drain backups.

- Assess Equipment Discharge: Make a list of everything that will drain into this sink. Pay close attention to their flow rates. A high-volume commercial dishwasher needs a deep basin—at least 10-12 inches—while a small hand-wash sink has much lower demands.

- Choose the Right Grate: Think about traffic. Will heavy carts be rolling over it all day? You'll need a full grate for safety and support. If you have a permanent drain line emptying into the sink, a half grate will give you the access you need.

- Select a Sediment Basket: This is your plumbing's best friend. A perforated, easy-to-remove sediment basket is absolutely essential for catching food scraps and solids before they can create a nasty clog down the line.

Investing in a quality stainless steel floor sink isn't just a purchase; it's a strategic move. The market for them is projected to hit nearly USD 0.9 billion by 2034, growing at a rate of about 6.1% annually. Stay informed about industry trends like this to stay ahead. The foodservice industry is wising up to the value of durable, hygienic drainage that prevents expensive downtime.

Step 3: Material and Installation Planning

Last but not least, let's nail down the material and plan for a leak-proof installation.

- Select Stainless Steel Grade: For most commercial kitchens, Type 304 stainless steel is the workhorse. It hits the sweet spot between durability and cost. However, if you're dealing with high-salinity waste (like from a seafood operation) or aggressive cleaning chemicals, it’s worth upgrading to Type 316 for its superior corrosion resistance.

- Plan for Floor Slope: This is a conversation for you and your contractor. The floor around the sink must have a gradual slope—about 1/4 inch per foot—leading directly to the drain. This ensures every last drop of water and spillage finds its way into the sink, not into a puddle on your floor.

- Specify a Watertight Seal: Insist that your installer uses a top-tier, industrial-grade sealant around the sink's flange. A cheap seal will fail, letting water seep under your flooring and cause rot, mold, and structural damage over time.

By working through this checklist step-by-step, you'll be ready to browse different sinks and dishwashers and have a truly productive conversation with your suppliers and plumber.

Frequently Asked Questions

Even after going through all the details, you probably still have a few specific questions bouncing around. That's completely normal when you're about to make an investment in something as critical as a stainless steel floor sink.

Getting clear, straight-to-the-point answers is what gives you the confidence to pull the trigger and know you're making the right call for your kitchen's drainage. Let's tackle some of the most common questions we hear from restaurant owners and chefs. This should get you ready for those conversations with suppliers and your plumber.

What Is the Difference Between a Floor Sink and a Floor Drain?

This is, without a doubt, the number one point of confusion. The easiest way to think about it is that "floor drain" is the big, general category—like the word "car." A floor sink is a very specific type of floor drain, just like a "sedan" is a specific type of car.

- A standard floor drain is what you see flush with the tile, designed to catch mop water or the occasional spill from the surrounding floor. Its job is to keep the floor dry.

- A floor sink, on the other hand, is a deeper, open basin designed to take a direct hit from equipment drains. Think of the water pouring out of a commercial dishwasher or a steam kettle. Its main purpose is to accept a high volume of wastewater and catch solids in its basket—it's not really there to drain the floor around it.

How Often Should I Clean the Sediment Basket?

That little basket is your first and best defense against a nasty, expensive clog, so it needs consistent attention. For a busy kitchen, the rule of thumb here is simple and not really up for debate.

The sediment basket inside your stainless steel floor sink needs to be emptied and rinsed out at the end of every single shift. No exceptions. Letting food scraps and gunk sit in there overnight is just asking for foul odors, pests, and the start of a clog that will only get worse.

Can I Connect My Three-Compartment Sink Directly to It?

Yes, and you absolutely should. This is one of the most important jobs a floor sink has. When you run the drain lines from your three-compartment sink so they empty into the floor sink, you're creating what the health department calls an air gap.

That physical space between the end of the drain pipe and the water level in the sink is a critical safety measure and often required by code. It makes it impossible for any sewer backup to travel up the pipe and contaminate the sinks you use for washing dishes. It's a simple, but brilliant, feature.

Do I Need a Grate for My Floor Sink?

One hundred percent, yes. A grate isn't an optional accessory; it's a non-negotiable piece of safety equipment. Running a floor sink without a solid grate over it is a major workplace hazard.

It’s doing a few critical jobs at once:

- Prevents Accidents: It covers the open basin, stopping staff from twisting an ankle or taking a nasty fall.

- Supports Traffic: A good grate lets your team walk right over it and even roll heavy carts across without a problem.

- Blocks Large Debris: It's the last line of defense to stop a cleaning rag, a dropped spatula, or other large items from falling in and causing a massive blockage.

Always check that your grate is sitting securely and isn't bent or broken. If it is, get it replaced immediately.

Ready to upgrade your kitchen's drainage system with a reliable, hygienic solution? Encore Seattle Restaurant Equipment offers a wide selection of top-quality stainless steel floor sinks to meet the demands of any commercial kitchen. Stay ahead of the curve and discover exclusive deals on the latest restaurant equipment and supplies. Explore our collection and find the perfect fit for your operation today!