A Chef's Guide to Energy Efficient Commercial Refrigerators

Share

In the fast-paced world of foodservice, it’s easy to see your commercial refrigerator as just another piece of equipment. But I want you to think about it differently. Energy efficient commercial refrigerators aren't just an expense; they're a core asset that can seriously slash your operating costs and boost your bottom line. Stay informed about industry trends, and discover exclusive deals on the latest restaurant equipment and supplies that pay you back every single month.

Think of it as a long-term investment that pays you back every single month on your utility bill, all while improving food safety. This guide is for chefs, managers, and restaurant owners who want to make smarter, more profitable decisions for their kitchens.

Why Your Refrigerator Is a Hidden Profit Center

When you're running a restaurant on tight margins, every single dollar counts. I get it. It’s tempting to focus solely on the upfront cost of a new fridge, but the real financial impact—the true cost or savings—unfolds over the life of that unit.

An old, inefficient refrigerator is like having a hole in your pocket. It's constantly draining your resources by chugging down far more electricity than a modern, optimized model. That extra energy use is quietly eating away at your profits, day in and day out.

On the flip side, when you invest in an energy-efficient model, you turn one of your biggest expenses into a source of savings. These units are built smarter. They use advanced components like high-performance compressors, superior insulation, and efficient LED lighting, all working together to do the same job with less power. The result? A real, noticeable drop in your energy bills. That's cash you can put back into your menu, your team, or your marketing.

The True Cost of Inefficiency

It's easy to miss the slow, steady bleed from an old appliance. Commercial refrigeration can account for a huge chunk of a restaurant's total energy consumption. Much like an unsealed door can cause massive temperature fluctuations, an inefficient fridge creates its own set of problems. This is a key part of preventing energy loss in commercial facilities. Every time that compressor has to kick into overdrive because of poor insulation or a leaky gasket, it's costing you money.

Choosing an energy-efficient refrigerator is one of the most direct ways to control your kitchen's operating expenses. It's a proactive step toward building a more sustainable and financially resilient business.

To help you see past the initial price tag, we've put together a quick summary of the key benefits.

Key Benefits of an Energy Efficient Refrigerator

| Benefit Area | Impact on Your Restaurant |

|---|---|

| Lower Utility Bills | Directly reduces monthly electricity costs, freeing up cash flow. |

| Long-Term ROI | The upfront cost is offset by significant energy savings over the unit's lifespan. |

| Improved Food Safety | Consistent temperatures and better performance protect your valuable inventory. |

| Enhanced Durability | Modern components are often built to a higher standard, leading to fewer breakdowns. |

| Eco-Friendly Operation | Reduces your carbon footprint, which can be a great marketing point for customers. |

This guide is designed to help you look at the whole financial picture. We’ll break down the technical jargon into practical advice, helping you pick a unit that doesn't just keep your ingredients fresh but actively helps your restaurant make more money.

Translating the Language of Energy Efficiency

Choosing a new commercial refrigerator is a lot like buying a new delivery van for your restaurant. You wouldn't just look at the paint job, right? You'd be asking about its miles-per-gallon rating to understand what it’s really going to cost you over the long haul.

Energy efficiency metrics are the "MPG" for your refrigeration. They tell you exactly how much cooling you're getting for every dollar of electricity you spend. Getting a handle on this language is the first step toward making a smarter, more profitable investment for your kitchen.

These ratings aren't just technical jargon—they're a direct forecast of your future utility bills.

Decoding the Labels: AWEF and ENERGY STAR

When you start digging into spec sheets, two names will pop up over and over: AWEF and ENERGY STAR. These are the numbers that matter most.

AWEF, which stands for Annual Walk-In Energy Factor, is a crucial metric designed specifically for walk-in coolers and freezers. Instead of just measuring raw power consumption at a single moment, AWEF gives you the big picture. It calculates a unit's total cooling performance over an entire year, factoring in everything from the compressor and fans to door openings and even seasonal temperature swings.

Simply put, a higher AWEF number means you're getting more cooling for your buck. It’s a far more realistic measure of real-world performance, which is why the U.S. Department of Energy (DOE) made it the standard back in 2020. For operators, this means a new, compliant system often pays for its higher upfront cost in about 3 years—a great return considering the average 8.5-year lifespan of the equipment. For a deep dive into these regulations, you can find valuable information on refrigeration standards.

ENERGY STAR is the one you’ve probably seen before. It’s a broader certification from the U.S. Environmental Protection Agency (EPA). When you see that blue label on a commercial fridge, it’s a guarantee that the unit is significantly more efficient than standard models, typically using 10-25% less energy while providing the same, if not better, performance.

Key Components That Drive Efficiency

Those impressive efficiency ratings aren't magic. They’re the result of specific, advanced components working together to slash energy waste and maximize cooling power.

-

High-Efficiency Compressors: Think of the compressor as the heart of your refrigerator. Old-school compressors were simple: either on at full blast or completely off. Modern units, however, often use variable-speed compressors. They work like cruise control in your car, adjusting their output to precisely match the cooling demand rather than constantly flooring the gas and then hitting the brakes.

-

Electronically Commutated (ECM) Fan Motors: Fans are critical for circulating cold air, but traditional fan motors are notorious energy hogs. ECM motors are a game-changer. They use internal electronics to operate far more efficiently and, as a bonus, they generate less waste heat. That means your compressor doesn't have to work as hard to cool down the heat produced by its own fans.

-

Advanced Insulation: The quality of a fridge's insulation—usually polyurethane foam—has a massive impact on its energy use. Better, thicker insulation means less cold air leaks out and less warm kitchen air seeps in. The result? The compressor kicks on less often, saving you money every single day.

Understanding how these core technologies work gives you a serious advantage. For example, learning the basics of how variable speed drives for energy savings operate shows you exactly how these modern components cut costs. When you know what to look for, you're no longer just buying a cold box; you're investing in a piece of equipment designed to boost your bottom line from day one.

Choosing the Right Refrigerator for Your Kitchen

Picking out a new energy-efficient commercial refrigerator isn't just about finding one that fits an empty spot in your kitchen. It's a critical decision that directly affects your kitchen's flow, how you hold your product, and, of course, your monthly utility bill. The right unit becomes a silent, hardworking member of your team; the wrong one is a constant headache that drains both energy and profits.

Before you even start looking at models, take a hard look at your own operation. What does your menu demand? How much product do you move on a busy night? Watch how your crew moves through the kitchen during service. A little bit of thoughtful analysis upfront ensures you’re making an investment that pays off in both energy savings and smoother, more efficient shifts.

Matching Refrigerator Type to Your Kitchen's Needs

Commercial refrigerators are specialized tools, not one-size-fits-all appliances. Picking the right type for the job is the first—and most important—step toward a more efficient kitchen.

Here’s a look at the most common types and where they shine:

- Reach-In Refrigerators: These are the backbone of most commercial kitchens. Whether you need a one, two, or three-door model, reach-ins are designed for storing everyday ingredients that your cooks need to grab quickly and often.

- Walk-In Coolers: If you're a high-volume spot or you buy in bulk to control food costs, a walk-in is a must-have. It’s a bigger initial investment, sure, but a modern, AWEF-compliant walk-in offers massive storage and can be surprisingly efficient if you manage it well.

- Undercounter & Worktop Refrigerators: These little powerhouses are all about maximizing your footprint. They slide right under your prep counters, putting crucial ingredients right where you need them. Think of all the steps saved not having to run back and forth to the main cooler.

- Prep Table Refrigerators: For any pizzeria, sandwich shop, or salad-heavy concept, these are non-negotiable. A good, energy-efficient prep table with well-insulated lids keeps ingredients perfectly chilled and food-safe right at the prep line, which means faster assembly and less cold air escaping.

A great example is a busy pizzeria. The owner who invests in an efficient prep table with heavy-duty, insulated lids will see a real difference. That simple feature keeps the cold air locked in, so the compressor doesn't have to work as hard. That directly cuts energy use while helping the team get pizzas out the door faster.

Beyond the type, getting the dimensions right is crucial. For a deeper dive into measuring and planning, check out our guide on selecting the correct commercial refrigerator size.

Top Mount vs. Bottom Mount Compressors

One of the key technical choices you’ll face is where the compressor is located. This decision has a real-world impact on maintenance, efficiency, and how long the unit will last, especially given the tough environment of a commercial kitchen.

For most kitchens, a top-mounted compressor is the smarter bet. Heat rises, so placing the compressor up top allows it to breathe and dissipate heat more effectively. It's also farther away from the floor, where all the dust, flour, and grease inevitably end up. This keeps the coils from getting clogged, helping the unit run efficiently with less stress on the machinery.

On the other hand, a bottom-mounted compressor has an ergonomic advantage—the bottom shelf is higher up, making it easier to grab things without bending over. The trade-off is that it’s sitting in the hottest part of the kitchen near the floor, where it’s basically a vacuum for debris. To keep it running efficiently, you'll need to be much more diligent about cleaning the coils.

Solid Doors or Glass Doors?

Finally, you need to decide on the doors. Solid doors are the champions of insulation. They hold in the cold better than anything else, making them the most energy-efficient choice, period. If the fridge is purely for back-of-house storage and won't be opened constantly, solid doors are the way to go to keep your energy bills down.

Glass doors are built for merchandising or for high-speed kitchens where your team needs to see what’s inside before opening the door. While they don't insulate as well, that quick visual check can mean the door is open for a much shorter time. For a busy prep line, that can save a surprising amount of time and energy over the course of a shift.

Calculating Your Return on Investment

Let's be honest—the upfront cost of a new, high-efficiency commercial refrigerator can make you wince. It’s easy to get sticker shock when comparing a top-of-the-line ENERGY STAR model to a standard, less-efficient unit.

But here’s what seasoned restaurant owners know: the initial price tag is just one piece of the puzzle. The real story unfolds month after month on your utility bill. Thinking of this purchase as a long-term investment, not just another line-item expense, is the secret to unlocking major operational savings and building a healthier bottom line.

How the Numbers Shake Out: A Real-World Example

To see how this plays out, let's look at a common scenario. Imagine Chef John's Bistro is running a 12-year-old two-door reach-in. It’s a workhorse, but it’s seen better days. The compressor hums constantly, the door gaskets are shot, and it’s clearly an energy hog.

He decides it's time for an upgrade and is looking at a new ENERGY STAR certified model for $3,500. A basic, non-certified version would only run him $2,500—a $1,000 difference. The cheaper option is tempting, but let's dig into the operating costs.

- Old Refrigerator Energy Use: We estimate it's guzzling around 3,000 kWh per year.

- New ENERGY STAR Model Energy Use: This new unit sips power, using just 1,800 kWh per year.

- Annual Energy Savings: That's a difference of 1,200 kWh Chef John saves every single year.

Assuming a commercial electricity rate of $0.15 per kWh, his annual cost savings add up to $180 (1,200 kWh x $0.15). Not bad at all.

So, how long until that extra $1,000 pays for itself?

The payback period is simple to calculate: divide the additional cost by the annual savings. In this case, $1,000 / $180 = 5.5 years. After just five and a half years, the refrigerator has officially paid back its premium. Every dollar saved from that point on goes directly into the bistro's pocket.

This is a simplified look, but it clearly shows how an efficient model pays you back over time. To get a handle on your own numbers, our restaurant profit margin calculator can help you analyze expenses and pinpoint other areas for savings.

Sample ROI Calculation Old vs New Refrigerator

Here's a quick table to visualize the difference between sticking with an old unit and investing in a new, efficient one.

| Metric | Old Refrigerator (10+ Years) | New ENERGY STAR Model |

|---|---|---|

| Initial Cost | $0 (Already Owned) | $3,500 |

| Est. Annual kWh | 3,000 kWh | 1,800 kWh |

| Est. Annual Energy Cost (@ $0.15/kWh) | $450 | $270 |

| Annual Savings | - | $180 |

| Simple Payback Period | N/A | 5.5 Years (vs. cheaper new model) |

This comparison highlights the long-term financial benefit. While the initial outlay for a new unit is higher, the recurring annual savings quickly start to offset that cost.

Don't Forget About Rebates and Incentives

The payback can get even faster. Many local utility companies offer some pretty sweet rebates for businesses that buy ENERGY STAR certified equipment. These programs are designed to promote energy conservation, and they can seriously cut down your net cost. We help restaurant owners and chefs discover exclusive deals and the latest news on these programs.

For instance, a utility might offer a $250 rebate for a new efficient refrigerator. All of a sudden, Chef John's extra upfront investment drops from $1,000 to just $750. This move shortens his payback period to a little over 4 years. It’s always worth a call to your local energy provider to see what’s on the table—you might be pleasantly surprised.

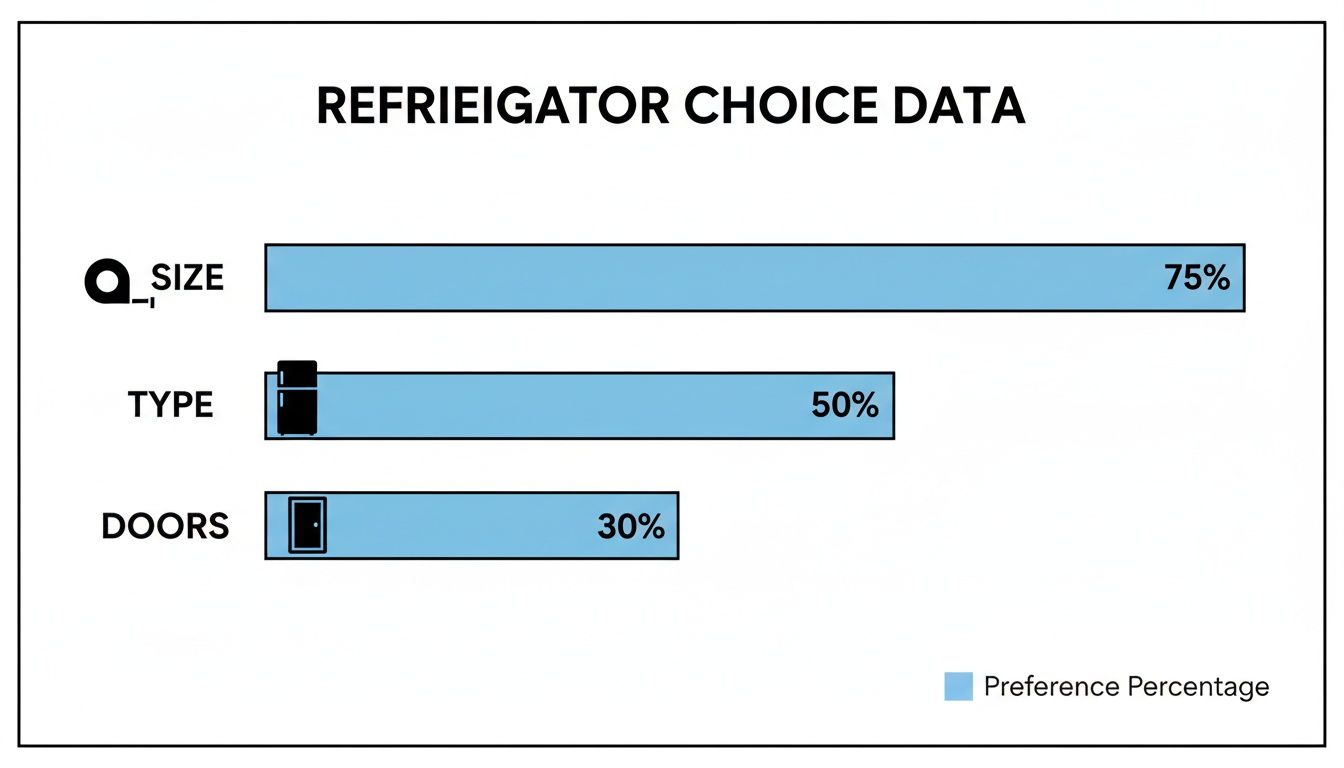

The chart below shows what operators prioritize when shopping for a new unit.

As you can see, getting the right size and type for your kitchen's workflow is paramount, with door configuration also playing a key role.

Building the Business Case for Efficiency

When you combine long-term energy savings with immediate rebates, the argument for choosing an efficient model becomes a no-brainer. The impact on your budget is real. Think about it: commercial refrigeration can account for 5-10% of a supermarket's total energy consumption.

Modern, efficient models can slash that figure by 25% or more thanks to better insulation, advanced fan motors, and LED lighting. By calculating your potential ROI, you turn an equipment purchase into a strategic financial move that strengthens your entire operation for years to come.

Maximizing Performance with Smart Maintenance

Getting an energy-efficient commercial refrigerator in your kitchen is a great move, but it's really just the starting point. The savings you're hoping for don't just happen on their own—they're the result of smart habits and consistent upkeep. Think of it like a high-performance car; you can buy the best one on the lot, but it won't live up to its potential without the right fuel and regular tune-ups.

Small, everyday actions can have a surprisingly big impact on your unit's energy use. Getting your kitchen staff on board with these best practices is just as important as picking the right model. Every little adjustment, from how you stock the shelves to cleaning the coils, adds up to real savings over the life of the fridge.

Crucial Setup and Placement Tips

Where you put your refrigerator matters. A lot. The compressor is the heart of the unit, and as it cools, it pushes out heat. If that heat gets trapped, the compressor has to work overtime, which burns through electricity and puts a ton of stress on the machine.

You've got to give your refrigerator some breathing room. Make sure there are at least 2-3 inches of clearance around the back and sides so air can circulate freely. And whatever you do, don't stick it right next to heat-generating equipment like ovens, fryers, or dishwashers. That just forces it to fight a constant battle against the heat.

The Maintenance Checklist That Saves You Money

A simple, consistent maintenance routine is your best weapon against energy waste and unexpected breakdowns. Building these tasks into your kitchen's schedule is the surest way to protect your investment and keep utility bills down. For a deeper dive, check out our guide to commercial kitchen equipment maintenance.

Here’s a practical checklist to get you started:

- Clean Condenser Coils Quarterly: Dust and grease are efficiency killers. When they clog the coils, the compressor has to struggle to do its job. A quick scrub with a stiff brush every three months can make a noticeable difference.

- Check Door Gaskets Monthly: A bad seal is like leaving a window open. Cold air leaks out, and the unit runs non-stop to compensate. Try the "dollar bill test": close the door on a bill. If you can slide it out with no resistance, it's time for a new gasket.

- Monitor Temperature Settings Weekly: Keep your fridge set to a food-safe temperature, usually between 35-38°F, but no colder. Every degree colder than you need can increase energy use by 1-2%.

Common Operational Mistakes to Avoid

Even the most efficient refrigerator will struggle if it's not used correctly. Training your team to sidestep these common pitfalls is a free way to boost performance and protect your inventory.

Overloading shelves is a classic mistake. It blocks airflow, creating warm spots and forcing the compressor to work harder to cool the entire cabinet. Teach your team to leave space between items to allow for proper cold air circulation.

Another huge one is putting hot food directly into the fridge. This floods the unit with heat, causing a massive energy spike as the system scrambles to bring the temperature back down. Always let hot food cool to room temperature first. These small changes in behavior are what will truly unlock the long-term savings you expect from your equipment.

Keeping Up with Refrigeration Rules and Regulations

Choosing an energy-efficient commercial refrigerator isn't just a smart money move—it's also about staying on the right side of the law. Government agencies like the Department of Energy (DOE) and the Environmental Protection Agency (EPA) are constantly raising the bar, pushing the entire industry toward better efficiency and less environmental impact.

Staying on top of these rules is non-negotiable. It helps you avoid buying a piece of equipment that will be outdated in a few years, need costly upgrades, or even put you out of compliance. Think of it as future-proofing your kitchen. You're making a smart investment today that will work hard for you, legally and reliably, for years to come.

The Big Switch: Moving Away from Harmful Refrigerants

One of the most important industry trends is the type of gas—or refrigerant—used to cool these units. For a long time, the industry standard was a group of chemicals called hydrofluorocarbons (HFCs). They did the job, but we now know they have a high Global Warming Potential (GWP), meaning they're potent greenhouse gases.

The EPA is actively pushing manufacturers to phase out these high-GWP refrigerants. The good news is, the replacements are fantastic. Modern, energy-efficient refrigerators now run on natural refrigerants like R-290 (which is just a high-purity propane). These natural options have an incredibly low GWP, making them much better for the planet. As a bonus, they're often more efficient at transferring heat, which means they can cool your unit using less energy.

Investing in a refrigerator that uses a low-GWP, natural refrigerant like R-290 is one of the smartest things you can do. It keeps you ahead of the curve, ensuring your equipment meets today's standards and won't give you a headache when future regulations kick in.

This isn't some far-off change, either—it's happening right now. The EPA began restricting certain high-GWP refrigerants for new cold-storage warehouses back in 2021. States like California have been even more aggressive, banning high-GWP substances in new refrigeration systems since 2022. You can get a sense of how the latest regulations are shaping commercial refrigeration to see where the industry is headed.

What You Need to Know About DOE Energy Standards

Beyond the type of refrigerant, the DOE also dictates the minimum energy performance for all new commercial refrigeration equipment sold in the U.S. These are the standards that gave us key metrics like the Annual Walk-In Energy Factor (AWEF), essentially forcing manufacturers to get creative and build more efficient coolers and freezers.

At the end of the day, these rules are designed to get the "energy vampires" off the market. And while there have been debates and challenges along the way, the trend is crystal clear: the major manufacturers have already retooled their factories to produce more efficient equipment. Your best bet is to buy a unit that doesn't just meet the DOE minimums, but beats them.

So, what does this mean for your day-to-day operations?

- Peace of mind: You won't have to worry about whether your brand-new fridge or freezer is compliant with federal law.

- Real savings: Equipment built to these tighter standards is engineered from the ground up to use less electricity, lowering your monthly utility bills.

- Unlocking rebates: Only equipment that meets or exceeds these efficiency targets—especially ENERGY STAR certified models—will qualify for those valuable utility rebates.

By keeping these regulations in mind, you can pick a refrigerator that's not just a workhorse for your kitchen, but also a compliant, sustainable, and financially sound asset for your business.

A Few Common Questions

Diving into energy-efficient commercial refrigerators can stir up a lot of questions. As a chef or restaurant owner, you know that the right choice hits everything from your budget to your kitchen’s daily rhythm. Let's clear up some of the most common things people ask so you can make a smart, profitable decision.

Is an ENERGY STAR Certified Refrigerator Really Worth the Extra Cash?

Absolutely. It might sting a little to see the higher price tag upfront, but an ENERGY STAR certified model is one of the shrewdest financial moves you can make for your kitchen. These units are often over 25% more efficient than standard models, and that difference shows up right away on your monthly power bill.

Think about it this way: when you add up the long-term energy savings and the potential utility rebates available, the total cost of ownership plummets. You’ll often make back the extra investment in just a couple of years. After that? It's pure savings, putting money right back into your business.

What's the Single Most Important Maintenance Task for Efficiency?

Cleaning the condenser coils. No question about it. In a busy commercial kitchen, those coils inevitably get caked with dust, grease, and flour.

That buildup acts like a thick blanket, forcing the compressor to work way harder and longer to do its job. A quick cleaning with a stiff brush every few months can slash your energy use, prevent a catastrophic breakdown, and add years to the life of your refrigerator.

Does the Type of Refrigerant Actually Matter?

It matters a whole lot, both for how well the unit runs and for staying on the right side of regulations. The industry is quickly shifting away from older refrigerants that are tough on the environment and embracing natural alternatives.

Take R-290 (propane), for example. It's a newer, natural refrigerant that not only has a very low Global Warming Potential (GWP) but is also more efficient at cooling. It gets the job done faster with less energy. Choosing a unit with a modern, low-GWP refrigerant means you’re already compliant with changing EPA regulations and investing in a machine that won’t be obsolete anytime soon.

Can I Make My Old Refrigerator More Efficient?

You can't swap out the guts of an old unit, but you can definitely take some simple steps to make it run better and waste less energy. Good habits can make a real difference until you're ready to upgrade.

Here's how to boost its performance:

- Keep up with maintenance: Clean those condenser coils regularly so the compressor isn't working overtime.

- Check the gaskets: Once a month, try the "dollar bill test." If you can easily pull a dollar bill out from a closed door, the seal is shot. A new gasket is a cheap fix that stops cold air from pouring out.

- Give it breathing room: Make sure you leave a few inches of clearance around the unit. Inside, avoid cramming shelves full—it blocks airflow and makes the machine work harder.

- Install strip curtains: This is a low-cost, high-impact fix for walk-in coolers. Plastic strip curtains dramatically reduce cold air loss every time the door opens.

At Encore Seattle Restaurant Equipment, we live and breathe this stuff. We specialize in helping chefs and restaurant owners find high-performance, energy-efficient refrigeration that fits their kitchen and their budget. Stay informed about the latest news and industry trends with our help.

Discover Your Next Commercial Refrigerator at encoreseattle.com