Mastering Commercial Refrigerator Size and Dimensions

Share

Choosing the right commercial refrigerator size isn't a one-size-fits-all decision for restaurant owners and chefs. It's a careful calculation based on three things: the physical space you have in your kitchen, what's on your menu, and how many customers you serve each day. A bustling restaurant has completely different cold storage needs than a small neighborhood café, so picking the right unit from the start is absolutely essential for an efficient kitchen and staying ahead of industry trends.

Choosing the Right Commercial Refrigerator Size

Think of your refrigerator as more than just a box that keeps things cold—it's the heart of your kitchen's workflow. Just as a chef organizes a pantry for quick access, your cold storage needs to be set up to keep service moving without a hitch. Going with a generic size often leads to problems like wasted space, spoiled food, and unnecessarily high energy bills. Smart equipment choices are key to navigating today's restaurant industry trends.

The real challenge is finding the right balance between the refrigerator's external footprint (how much floor space it takes up) and its internal capacity (measured in cubic feet). You might find a unit that slots perfectly into a corner, but if it can't hold enough inventory for a slammed Saturday night, you’ll find yourself in a real bind.

Balancing Capacity with Kitchen Workflow

To get it right, you have to dig into the specific demands of your operation. Start by thinking through these key areas:

- Menu Complexity: A farm-to-table concept that relies on cases of fresh, bulky vegetables is going to need a lot more room than a pizzeria working mostly with shelf-stable and frozen items.

- Customer Volume: The more people you serve, the more inventory you need on hand. A restaurant doing 300 covers a night operates on a completely different scale than one that serves 50.

- Delivery Schedule: If you get fresh produce delivered daily, you can probably get by with smaller, more specialized units. But if your main food deliveries only come once a week, you'll need a much larger capacity to hold everything.

The goal is to find that sweet spot where your refrigerator has enough space for your busiest day but isn't a half-empty energy hog during the slow times. Nailing this balance is fundamental to running an efficient and profitable kitchen.

To help you get your bearings, I've put together a quick reference table. It breaks down the most common types of commercial refrigerators and where they fit best in a professional kitchen, giving you insights into essential restaurant equipment.

Quick Guide to Refrigerator Types and Uses

| Refrigerator Type | Typical Capacity (Cubic Ft.) | Best Kitchen Application |

|---|---|---|

| Reach-In Refrigerator | 20-70 cu. ft. | General purpose storage in main prep lines and busy kitchens. |

| Undercounter Unit | 2-12 cu. ft. | Space-saving storage at individual workstations or in bars. |

| Walk-In Cooler | 100+ cu. ft. | Bulk storage for high-volume restaurants and catering operations. |

| Prep Table Refrigerator | 8-30 cu. ft. | Storing frequently used ingredients directly at the prep station. |

Think of this table as your starting point. It helps match the right kind of equipment to your kitchen's reality, setting you up to make a smarter decision when you start looking at specific models and their exact dimensions. Stay informed to find the best deals on the restaurant supplies you need.

Cracking the Code on Capacity and Dimensions

When you first glance at a commercial refrigerator's spec sheet, it's easy for a busy chef to get bogged down by the numbers. The two most important figures you'll see are the external dimensions (how much floor space it takes up) and its internal capacity. But here's the catch: these two are rarely as straightforward as they seem.

Think of it like a shipping container. Its massive outer size gives you a general idea, but it doesn't perfectly reflect the actual, usable space you have to work with inside.

This gap between a refrigerator's footprint and its real-world storage is a critical detail to grasp. A bulky-looking refrigerator might not offer an inch more usable shelf space than a sleeker, more thoughtfully designed model. Getting this right is the first step to avoiding a costly mistake and making the most of your kitchen's cold storage. You need a unit that not only fits through the door but also holds enough inventory to power you through the busiest dinner rush.

The Hidden Factors That Eat Up Space

Several design choices directly impact how much product you can actually store inside a commercial refrigerator. These features are easy to overlook but can make a huge difference in your daily workflow and usable capacity.

Three of the biggest factors are:

- Compressor Location: A top-mounted compressor frees up the lower internal space, making it a breeze to organize things on the bottom shelf. On the other hand, a bottom-mounted unit raises that lowest shelf. This can be more ergonomic for staff, but it does shave off a bit of storage volume at the base.

- Wall Insulation Thickness: In a hot, chaotic kitchen, thick insulation is your best friend for energy efficiency and keeping temperatures stable. The trade-off? That extra padding is on the inside, directly subtracting from your internal cubic footage. A unit that measures 36 inches wide on the outside might only give you 30 inches of usable width inside.

- Door Configuration: The number and style of doors matter, too. A three-door reach-in, for example, has more vertical frame supports breaking up the interior compared to a single-door model of the same total width. Those internal dividers reduce the continuous shelf space you have for larger items like full-size sheet pans or big food containers.

The real lesson here is to look beyond the listed cubic feet. A spec sheet might boast a high capacity, but the layout, shelving, and internal hardware are what truly determine how functional that space is for your specific inventory.

The sheer variety in commercial refrigerator sizes is staggering, shaped by the unique demands of different businesses. The foodservice and retail worlds need everything from tiny under-counter units of just 2-4 cubic feet to massive walk-in coolers that can exceed 1,000 cubic feet.

For high-volume operations, walk-in refrigerators often start with a 6x6 foot footprint and can expand to cover more than 500 square feet, which just shows the incredible scale of modern commercial storage. You can explore more on commercial refrigeration market trends to see how this equipment continues to evolve. Learning to read the technical specs like a pro is the key to making sure the unit you choose will be a workhorse, not a headache, in your kitchen.

A Look at Common Refrigerator Types and Sizes

Now that we’ve covered the basics of external dimensions versus internal capacity, let's get into the actual hardware you’ll find in a professional kitchen. Picking the right commercial refrigerator size really boils down to knowing your options and understanding how each type fits into a specific workflow, whether it's for a cozy café or a massive hotel kitchen.

Think of each refrigerator style as a specialized tool. A reach-in is your all-purpose workhorse for day-to-day storage. A prep table refrigerator, on the other hand, is designed to keep key ingredients perfectly chilled and right where you need them during the dinner rush. Discovering the right restaurant equipment is crucial for success.

The Workhorses of Kitchen Refrigeration

For most restaurant owners, the choice usually narrows down to a few key models. Getting a handle on their standard dimensions and what they’re built for is the first step in designing a kitchen that actually works.

- Reach-In Refrigerators: These are the classic upright units you see everywhere. They come in one, two, or three-door models, which means you can find a size that fits just about any kitchen's needs.

- Undercounter Refrigerators: Built to slide right under a standard-height counter, these compact units put cold storage exactly where your staff is working. It's all about saving steps and keeping the prep line moving.

- Refrigerated Prep Tables: If you run a sandwich shop, pizzeria, or salad bar, these are non-negotiable. They combine a refrigerated base for bulk storage with a top rail that holds pans of ingredients, ready for assembly.

- Bar Refrigerators: From back-bar coolers designed to show off your beverage selection to specialized glass chillers, this category is purpose-built for the fast-paced bar environment. For smaller spots, you might find that a countertop display refrigerator is the perfect fit for grab-and-go items.

The best model isn't just about how much it can hold; it's about where it goes and how it's used. A small undercounter unit placed strategically at a prep station can do more for your workflow than another huge, centralized reach-in.

Comparing Standard Dimensions

To help you picture how these units stack up, the chart below lays out the typical external sizes and internal capacities for the most common types of commercial refrigerators. This kind of industry news helps you make informed choices about your restaurant supplies.

This gives you a clear sense of the trade-off between a unit's footprint and its storage volume, which is crucial for making sure you get the right equipment for the space you have.

Typical Size Ranges at a Glance

Let's attach some real numbers to these ideas to make it more concrete for chefs planning their space.

A standard single-door reach-in, for example, is usually between 25 to 30 inches wide and gives you about 20-25 cubic feet of storage. It’s a fantastic all-rounder for a small or medium-sized kitchen.

Step up to a two-door model, and you're looking at a width of 50 to 55 inches, which doubles your storage to around 40-50 cubic feet—all while using just one electrical outlet. For the big players, three-door units can stretch up to 80 inches wide, offering cavernous storage for high-volume operations. This kind of tiered sizing helps you pinpoint the exact unit that fits both your inventory and your floor plan.

How to Measure Your Kitchen Space Accurately

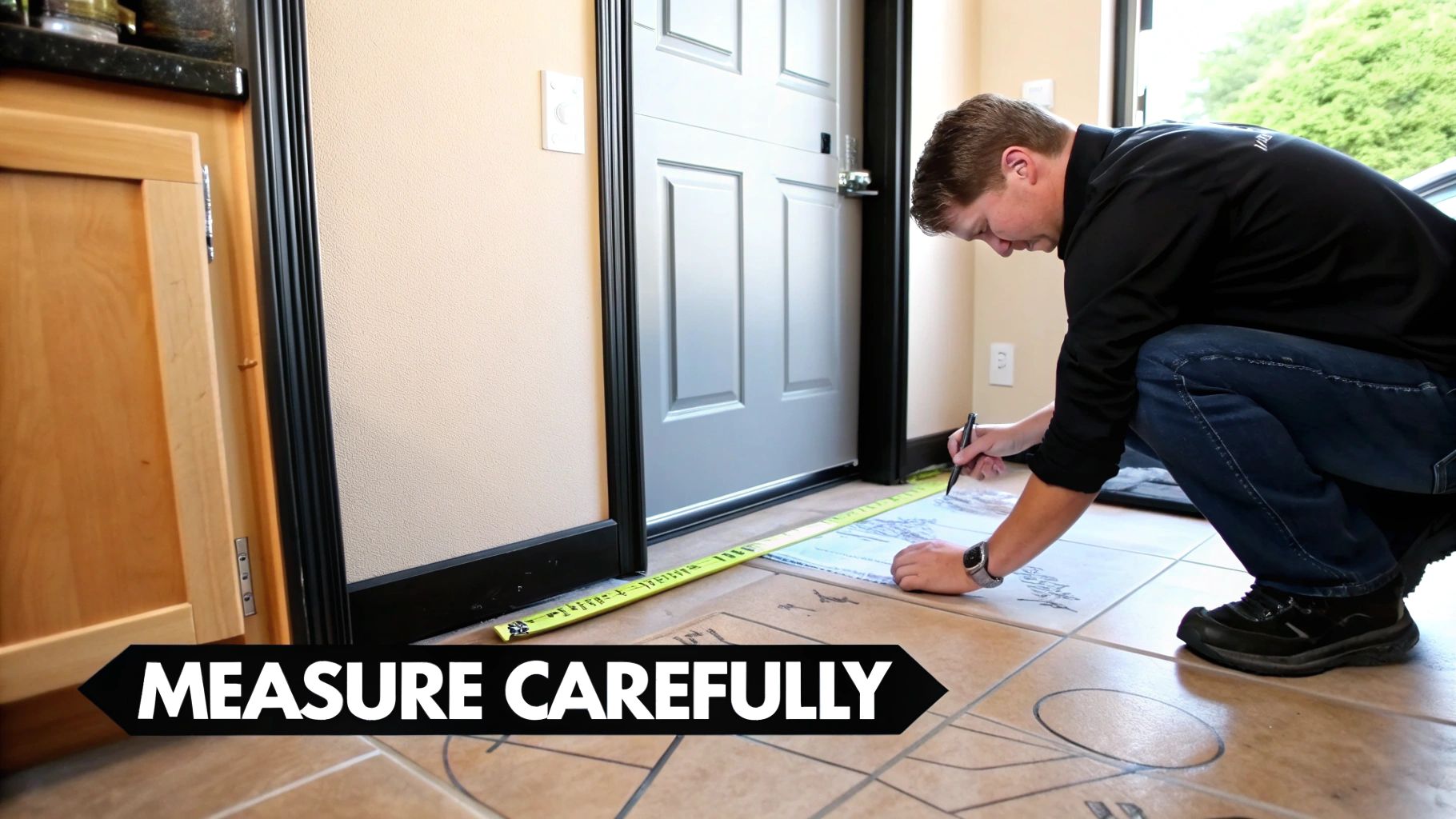

I've seen it happen more times than I can count: a restaurant owner invests thousands in a beautiful new commercial refrigerator, only to have the delivery team show up and realize it won't fit through the door. It’s a costly and completely avoidable mistake.

To prevent this headache, you have to think beyond just the spot where the fridge will live. You need to map out its entire journey, from the delivery truck's ramp all the way to its final home in your kitchen. A simple oversight, like a low-hanging pipe or a tight hallway corner, can turn installation day into a disaster.

Measure the Entire Delivery Path

Before you even fall in love with a specific model, grab a tape measure and start at your front door. Walk the exact path the delivery crew will take and measure every single potential bottleneck along the way.

Here’s your checklist for mapping the route:

- Doorways and Hallways: Get the precise width and height of every single door the unit has to clear. Remember to measure the actual opening—door handles, trim, and the door itself can easily shave off precious inches.

- Corners and Stairwells: That sharp turn from the hallway into the kitchen? Measure the clearance there. If stairs are involved, you need to know the width and the ceiling height to make sure the unit can be angled without getting stuck.

- Ramps and Elevators: For any ramps or service elevators, confirm their dimensions and, just as importantly, their weight capacity. A fully loaded commercial refrigerator is a beast.

Plan for Ventilation and Utilities

Once you're confident the refrigerator can physically get into the kitchen, it's time to focus on its designated spot. Commercial refrigerators are powerful machines that generate a lot of heat, and they need room to breathe to work properly. Skimping on airflow will strain the compressor, leading to breakdowns and expensive repair bills down the road.

Proper ventilation isn't just a friendly suggestion—it's essential for your equipment's health and performance. Most manufacturers require at least 3-4 inches of clearance on the back and sides, and some top-breathing models need as much as 12 inches of overhead space.

Don't forget these other critical details for the final placement:

- Electrical Access: Make sure there's a dedicated, appropriate electrical outlet right where you need it. Never rely on extension cords; they’re a fire hazard and often can't supply the consistent power these units demand.

- Floor Strength: These units are incredibly heavy, especially when packed with inventory. You must be certain your floor can handle the fully loaded weight, particularly if you're not on a ground-level concrete slab.

This kind of detailed planning is what separates a functional kitchen from a frustrating one. To really visualize how all your equipment will fit together, a simple tool like an interior design bubble diagram can be a huge help in the early stages.

It’s also interesting to see how technology is changing the game. Modern, energy-efficient components like inverter compressors and smart defrost systems mean manufacturers can now build larger-capacity units that don't send your energy bills through the roof. This, along with more modular designs, gives today's business owners more flexibility than ever before when selecting their restaurant equipment and supplies.

Matching Refrigerator Size to Your Business Needs

https://www.youtube.com/embed/5-hhfBXykec

Picking the right commercial refrigerator size isn't just about finding something that fits in your kitchen. It's a critical business decision that hits your bottom line every single day. Go too big, and you're literally paying to cool empty air. Go too small, and you're inviting food waste, cramped working conditions, and stressful last-minute runs to the supplier.

The secret for restaurant owners and chefs is to find that sweet spot where your equipment perfectly matches the reality of your operations.

The best place to start? A good, old-fashioned "menu audit." Seriously, take a close look at every ingredient you use. A bustling seafood grill that relies on fresh-off-the-boat fish has entirely different refrigeration needs than a pizzeria that works with frozen dough and pre-packaged toppings. Your menu is the blueprint for your inventory, and your inventory dictates how much cold space you actually need.

Translate Your Menu and Sales into Cubic Feet

Once you’ve got a handle on what you're storing, you can start putting some numbers to it. Think about how many customers you serve. A great rule of thumb is to connect your average daily covers to the cubic feet of storage you’ll require. It's not a perfect science, but it gives you a much better starting point than just guessing.

For instance, a popular restaurant serving 200 covers a night with a menu packed with fresh produce is going to need way more refrigerated real estate than a cozy café serving 50 people mostly coffee and pastries. Don't forget to factor in your supply chain, too. If you get daily deliveries, you can get by with less space. But if your main food delivery only comes once a week, you'll need a much larger unit to hold everything.

The decision about commercial refrigerator size is closely tied to overall efficient operations, and you can explore more about effective small business inventory management strategies to see how these concepts work together to boost your profits.

Planning for Future Growth

Here’s the million-dollar question: do you buy for the business you are today, or the one you hope to be tomorrow? It’s tempting to buy a bigger unit to "grow into," but that move has both pros and cons you need to weigh carefully.

Let's break it down:

- Pros of Buying Larger: You're ready for anything. A surprise rush or a holiday surge? No problem. When you're ready to expand your menu or take on more customers, your equipment is already up to the task without another huge investment.

- Cons of Buying Larger: That extra capacity comes with a higher price tag upfront and bigger energy bills every month. That's money you could be putting into marketing, staff, or other equipment you need right now.

So, what's the right call? It comes down to a calculated risk. If you have a solid, funded business plan that shows clear growth in the next 12-18 months, investing in a slightly larger unit makes a lot of sense.

But if your growth plans are more of a "maybe someday" scenario, it's often smarter to buy the perfect-sized unit for your current needs. You'll operate more efficiently, save money, and avoid paying to refrigerate empty shelves. Staying informed about the latest news and deals will help you decide when the time is right to upgrade.

How Modern Technology Shapes Refrigerator Design

Let's be honest, commercial refrigerators used to be nothing more than big, clunky, energy-hungry boxes. But that's a thing of the past. Today's technology has completely changed the game, letting manufacturers pack more storage into a much smaller physical footprint.

Think of it like comparing an old-school, thick-walled cooler to a modern, vacuum-insulated tumbler. They both keep your drink cold, but one is way more efficient and takes up a lot less space. That's exactly what's happened with commercial refrigeration.

The real magic is in the guts of the machine—specifically, high-efficiency compressors and vastly improved insulation. These breakthroughs mean a brand-new, larger refrigerator can often run cheaper and more efficiently than your older, smaller unit. This is a huge deal when you're deciding on the right commercial refrigerator size, because a smart investment now can save you a ton on utility bills down the road.

Smarter, Not Just Colder

The evolution here is pretty amazing. Not too long ago, every unit was a power hog. Fast forward to 2024, and we’re seeing a massive shift toward smart, IoT-connected refrigerators that actively manage their own space and energy consumption. For more on this trend, you can find some great insights on the evolution of commercial refrigeration equipment on bccresearch.com.

This isn't just about bells and whistles; it's about making your kitchen run better. These advancements are also a crucial piece of the puzzle for managing your supply chain.

The best part? Smart technology gives you pinpoint temperature accuracy and can even send you predictive maintenance alerts. This means less food spoilage and almost no unexpected downtime, keeping your ingredients safe from the moment they arrive to the second they hit the plate.

Getting a handle on these tech benefits is essential for any modern restaurant. To see how this all fits into the bigger picture of food safety and logistics, take a look at our guide on what is cold chain management. Staying informed on these industry trends can give you a competitive edge.

Got Questions? We've Got Answers

Picking out the right commercial refrigerator can feel like a high-stakes decision, and it’s natural to have questions. After all, this is one of the most important pieces of restaurant equipment in your entire kitchen. We hear a lot of the same queries from seasoned chefs and new restaurant owners alike, so let's clear up a few of the most common ones.

How Much Breathing Room Does a Commercial Refrigerator Actually Need?

Think of your refrigerator like a marathon runner—it needs to breathe. Proper airflow is absolutely critical to keeping your unit from overheating and working efficiently.

As a general rule, plan for at least 3-4 inches of open space on the back and sides. For units with a top-breathing compressor, you'll need to give it even more headroom, usually around 10-12 inches above the unit. Always, always check the manufacturer's spec sheet for the exact requirements. Skimping on clearance is a surefire way to cause component failure and land you with an expensive repair bill.

Top-Mount vs. Bottom-Mount Compressor: What's the Real Difference?

Where the compressor lives makes a big difference in day-to-day performance and upkeep. It's not just a random design choice.

- Top-mount compressors are fantastic for cooler kitchens. Since heat rises, they vent hot air up and away from the unit, keeping the mechanics from working too hard.

- Bottom-mount compressors are generally easier for technicians to access when it's time for maintenance. They're also a smart pick for very hot kitchens because they pull in cooler air from floor level, which can reduce strain.

The real decider here is your kitchen's environment. A bottom-mount unit might seem great, but if it's sitting on a scorching hot floor next to the fry station, it will have to fight that much harder to stay cool, which could shorten its lifespan.

Should I Take a Chance on a Used Refrigerator?

We get it—the upfront savings on a used unit can be tempting. But this is one area where a "deal" can quickly turn into a disaster.

A new commercial refrigerator comes with peace of mind: a full manufacturer's warranty, the latest energy-efficient technology (which saves you money every month on your utility bill), and modern food safety features. A used unit is a complete unknown. For equipment that is the absolute backbone of your operation, investing in a new unit is almost always the smarter, more reliable choice for the long haul. Keep an eye out for exclusive deals on new equipment instead.

Ready to find the perfect refrigeration solution for your kitchen? The experts at Encore Seattle Restaurant Equipment are here to help you explore the best brands and find the right size to meet your business needs. Stay informed about the latest industry trends and discover exclusive deals on the restaurant equipment and supplies you need to succeed.