What Is Cold Chain Management for Restaurants?

Share

For restaurant owners and chefs, cold chain management is the unbroken, temperature-controlled journey your ingredients take from their source all the way to a customer's plate. It's not just a single step; it's a complete system designed to maintain a specific temperature range for perishable goods—from the farm, during delivery, in your kitchen's storage, and right up to the moment of preparation.

This entire process is about preserving food safety and quality at every single touchpoint, protecting both your customers and your reputation. By staying informed on the latest industry trends and best practices, you can ensure your operation runs smoothly and efficiently.

The Unbroken Path From Supplier to Plate

The best way to visualize your cold chain is as a relay race. The baton? That's the perfect, safe temperature for your ingredients.

The race starts the moment a farmer harvests fresh produce or a supplier prepares seafood. The temperature "baton" is passed from a refrigerated processing facility to a climate-controlled truck, then to your restaurant's receiving dock, and finally into your walk-in cooler or freezer.

So, what is cold chain management? It's the active vigilance and strict set of procedures that ensure this temperature baton is never dropped. Even a single break in this chain—a delivery truck delayed on a hot day, a freezer door left ajar, or improper handling by a new line cook—can ruin the integrity of your food.

More Than Just Refrigeration

Let’s be clear: having a top-of-the-line refrigerator isn’t enough. True cold chain management is a comprehensive strategy that weaves together three critical elements:

- Processes: Setting up crystal-clear protocols for how your team receives, stores, and handles every temperature-sensitive item.

- Equipment: Relying on well-maintained, high-quality refrigeration units, from your main walk-in to the low-boy fridges on the line.

- People: Training every member of your team to understand why these rules matter and what their specific role is in protecting your ingredients.

This system is your restaurant's most powerful defense against foodborne illness, spoilage, and profit-draining waste. It's what protects the flavor, texture, and nutritional value that define the dishes you serve. When your cold chain is solid, the premium salmon you paid for arrives with the same pristine quality it had when it left the supplier.

To get this right, you need the right tools for the job. You can discover the best restaurant equipment and supplies, along with exclusive deals, by staying connected with industry leaders.

To wrap your head around the fundamentals, this table breaks down the core ideas every restaurant owner and chef needs to master.

Core Principles of Your Cold Chain

| Principle | Why It Matters for Your Restaurant |

|---|---|

| Consistent Temperature | Prevents bacterial growth, ensuring food is safe to serve and protecting your reputation. |

| Product Integrity | Preserves the intended flavor, texture, and appearance of ingredients, which is the foundation of quality dishes. |

| Unbroken Chain | Ensures there are no weak links from supplier to storage where spoilage can begin. Every step is monitored. |

| Accurate Monitoring | Gives you real-time data to catch temperature deviations before they become costly problems. |

| Team Responsibility | Empowers every staff member, from the receiving clerk to the line cook, to be a guardian of food safety. |

Mastering these principles isn't just about following rules; it's about building a culture of quality and safety from the ground up.

The global cold chain is a massive operation, valued at roughly $405 billion in 2024 and on track to hit $1.63 trillion by 2035. Despite this, simple temperature mistakes still result in over $35 billion in food losses every year worldwide—a staggering figure that highlights just how critical careful management is.

To ensure the entire journey from supplier to plate is financially sound and efficient, many businesses explore options like supply chain finance to provide a strategic advantage.

The Core Components of Your Restaurant's Cold Chain

To really understand cold chain management, it helps to think of it as a system with four key pillars. Picture them as the legs on a table—if one gives out, the whole thing comes crashing down. A solid cold chain in your kitchen relies on everything working together: storage, transportation, handling, and monitoring.

Nailing these four components means you're doing more than just storing food. You're actively protecting its quality, safety, and flavor from the second it leaves your supplier to the moment it hits the plate. Each step is a vital link in the chain.

Temperature-Controlled Storage

This is the most obvious part of your cold chain—the hardware you see every day. We're talking about your walk-in coolers, freezers, reach-in fridges, and prep tables. But great storage is about more than just having the right gear; it’s about creating the perfect environment inside that gear.

For example, proper shelving that lets cool air circulate is non-negotiable. An overstuffed cooler with blocked vents will inevitably develop warm spots, which are a breeding ground for bacteria. It's also critical that specialized equipment, like the units keeping your salad and sandwich toppings crisp, are working perfectly. If you're looking for specifics on that front, you can learn more about choosing the right refrigerated sandwich prep tables in our detailed guide.

Temperature-Controlled Transportation

The trip from your supplier to your back door is often the weakest link in the cold chain. This part is mostly out of your hands, which is exactly why choosing the right suppliers is so critical. You have to be able to trust that their refrigerated or frozen trucks are holding a steady, correct temperature for the entire route.

The moment a delivery shows up, your team's first job should be to check the truck's temperature log and inspect the products themselves. A good supplier won't hesitate to share data showing the temperature was stable all the way from their warehouse to your restaurant.

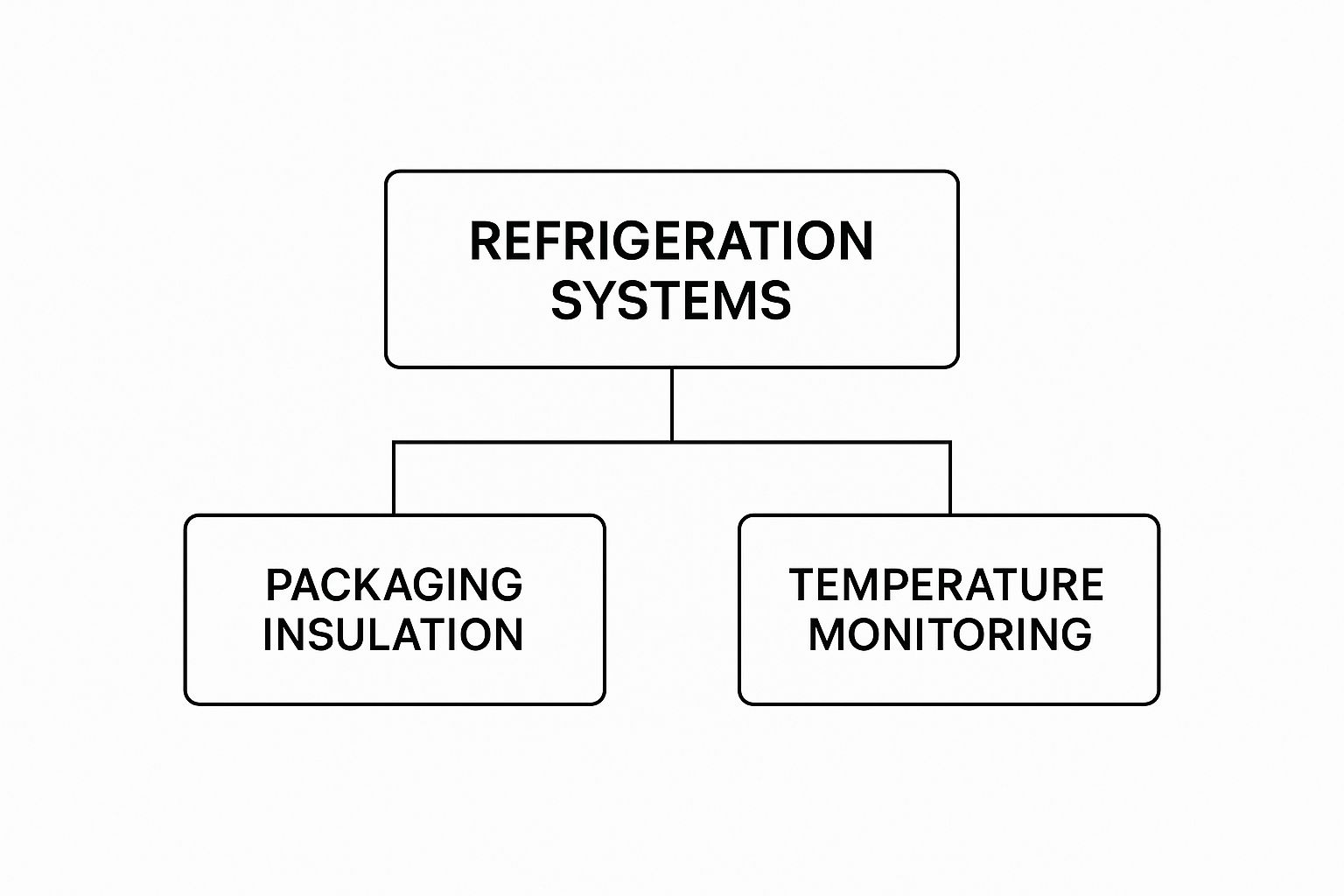

This infographic breaks down how different systems work together to protect temperature integrity—from the core refrigeration unit all the way to the monitoring and packaging that keep it safe.

As you can see, the refrigeration unit is the foundation, but it’s the monitoring and insulation that make it a complete, reliable system.

Proper Handling Procedures

Even the best equipment in the world can't do the job alone. How your staff actually handles ingredients can make or break your cold chain. This process starts the second a delivery truck backs up to your door.

Key Takeaway: Every minute that perishable food sits on a warm loading dock, the risk of temperature abuse skyrockets. Your receiving process must make getting cold items into cold storage the number one priority.

This means training your team to be fast and efficient. They need to verify product temperatures with a calibrated thermometer as soon as they arrive and religiously practice the First-In, First-Out (FIFO) method to make sure older stock always gets used first.

Continuous Monitoring

The last piece of the puzzle is the one that holds it all together: constant watchfulness. Years ago, this meant scribbling temperatures on a clipboard taped to the cooler door. Today, technology has made this process much more accurate and reliable.

An effective monitoring system includes:

- Regular Checks: Staff should be assigned to log cooler and freezer temperatures at the beginning of every single shift.

- Accurate Tools: Every fridge and freezer needs a calibrated, easy-to-read thermometer inside.

- Alert Systems: Modern tech, like wireless sensors, can send an alert straight to your phone if a unit’s temperature climbs into the danger zone.

This proactive mindset transforms your cold chain from a passive set of rules into an active defense system against spoilage and food safety threats.

Why a Broken Cold Chain Costs More Than Just Food

When the cold chain snaps, the first thing we think of is spoiled food in the trash. That's the obvious part. But the real damage cuts much deeper, striking at the three pillars of any successful restaurant: food safety, ingredient quality, and your bottom line.

A single slip-up in temperature control can turn a beautiful, fresh ingredient into a dangerous liability. The consequences aren't just a hypothetical problem for a textbook; they hit your bank account hard and can wreck the reputation you've worked so hard to build.

The Critical Importance of Food Safety

We all know about the temperature “danger zone”—that dreaded range between 40°F and 140°F. This is the breeding ground for nasty bacteria like Salmonella and E. coli, which can multiply with frightening speed. A solid cold chain is your first and most important line of defense, keeping your perishables locked down safely below that threshold.

Think about it. A cooler door left ajar overnight or a delivery that sits on a hot loading dock for an extra thirty minutes—that's all it takes. A seemingly minor temperature breach is a ticking time bomb that can escalate into a full-blown food safety crisis, putting your customers at risk and your operating license in jeopardy.

Crucial Insight: Nothing can cripple a restaurant faster than a foodborne illness outbreak. It triggers health department investigations, opens the door to lawsuits, creates a PR nightmare, and shatters the trust you have with your customers—a trust that can be nearly impossible to win back.

Preserving the Quality of Your Ingredients

Beyond the critical safety aspect, a stable cold chain is what protects your culinary integrity. People come to your restaurant for the vibrant flavors and crisp textures that make your food stand out. An unreliable cold chain quietly destroys those very qualities.

Take a beautiful piece of fresh fish. If it thaws and refreezes even slightly during transit, tiny ice crystals shred the cell walls. The result? When your chef goes to cook it, it's mushy, watery, and bland. The same goes for fresh produce; greens wilt and lose their snap if they aren't kept consistently chilled.

A weak link in your cold chain sabotages the very foundation of your menu. It forces your kitchen team to work with subpar ingredients, and no amount of skill can turn a compromised product into an exceptional dish.

The Direct Hit to Your Bottom Line

Every single item you toss out due to spoilage is cash straight out of the register. This isn't just about the cost of the food itself. It's also the labor you paid to receive and handle it, and the potential revenue from the menu items you can no longer sell. Spoilage is a huge driver of food waste, a problem that bleeds profits day after day. Learning how to start reducing food waste in restaurants is essential for protecting your margins.

The financial damage from a cold chain failure really boils down to three areas:

- Product Loss: Every spoiled case of produce or protein is money you might as well have set on fire.

- Reputational Damage: A bad online review about food quality—or worse, a food safety scare—can scare away customers for good.

- Operational Disruption: When a walk-in freezer dies or you have to reject a huge delivery, it sends your entire kitchen into chaos, disrupting service and killing efficiency.

At the end of the day, a robust cold chain isn't just another operating cost. It’s a fundamental investment in the safety, quality, and financial health of your business.

Building Your Kitchen's Cold Chain Protocol

Knowing the why behind cold chain management is one thing, but actually putting it into practice every single day is another game entirely. Building a bulletproof protocol is how you turn that knowledge into a real-world routine that protects your food, your customers, and your bottom line.

This isn't about creating some massive, complicated manual that just gathers dust. It's about establishing simple, repeatable steps that become second nature for every single person on your team.

It all starts long before an ingredient even shows up at your back door—it begins with vetting your suppliers. A good partner will be completely open about their own cold chain practices, from how they manage their warehouses to the state of their delivery trucks. Don't ever hesitate to ask to see their temperature logs or food safety certifications. Getting this right from the start sets the tone for everything that comes after.

Establishing Ironclad Receiving Procedures

Think of your loading dock as the most important handoff point in your kitchen's cold chain. It’s a critical control zone, and having a well-defined receiving protocol is non-negotiable. This process ensures every temperature-sensitive item gets checked and put away immediately, minimizing its time in the dreaded temperature danger zone.

Your receiving checklist should bake these core tasks into your routine:

- Immediate Temperature Checks: Your team needs to use a calibrated food thermometer to check the temperature of incoming goods before they sign off on anything.

- Visual Inspection: Train your staff to look for red flags of temperature abuse—things like torn packaging, excessive ice crystals, or products that just feel warm or soft when they shouldn’t.

- Prioritized Put-Away: Frozen and refrigerated items get moved first. No exceptions. They should go straight from the truck to their designated storage unit without any delay.

Pro Tip: Give your team the power to reject any delivery that doesn’t meet your temperature standards. Turning away one bad shipment sends a clear message to your suppliers and stops a potential food safety nightmare before it even crosses your threshold.

Mastering Internal Storage and Handling

Once your ingredients are inside, it’s all on you. The golden rule here is First-In, First-Out (FIFO). Every single item needs a clear date label, and new stock always, always goes behind the older stock. This simple habit ensures nothing gets lost at the back of a shelf to expire.

You'll also want to place accurate thermometers in the warmest part of every fridge and freezer. Make it a non-negotiable task for your staff to log these temperatures at the beginning of every shift. And don't forget that regular equipment upkeep is crucial; things like routine refrigerator condenser coil maintenance keep your units running efficiently and reliably.

Training and Corrective Action Plans

At the end of the day, your protocol is only as strong as the team carrying it out. Consistent training is the key, making sure every staff member—from the prep cook to the dishwasher—understands their role in protecting the cold chain. Simple checklists for daily temperature logs and cleaning schedules are great tools for building accountability.

Finally, you have to plan for when things inevitably go wrong. What’s the procedure when a walk-in cooler’s temperature is creeping up? Who is responsible for fixing it, and what exact steps do they need to take? Having a clear plan ready to go eliminates panic and ensures a fast, effective response to protect your inventory.

While a restaurant's cold chain is all about food, these principles are universal. Just look at the healthcare industry, where cold chain logistics is a massive sector projected to hit $6.88 billion by 2032. This explosive growth just underscores how vital precise temperature control is for ensuring product safety, whether you’re talking about life-saving vaccines or a case of fresh greens.

Using Technology for Smarter Temperature Control

Relying on a clipboard and pen for temperature logs is a bit like driving while only looking in the rearview mirror. It tells you where you’ve been, but not where you’re going. Sure, it's a necessary baseline, but it only captures a single moment in time. What happens if a freezer compressor gives out ten minutes after you've signed off on the morning check?

Luckily, technology that was once out of reach for independent operators is now affordable and easy to use. Moving beyond manual checks is no longer a luxury; it’s a smart business decision that provides a constant, vigilant watch over your valuable inventory. Think of it as your kitchen’s own silent security guard, working 24/7. Staying informed about these industry trends can help you discover exclusive deals on the latest equipment.

Automate Your Monitoring with Wireless Sensors

One of the best upgrades you can make is installing wireless temperature sensors. These are small, battery-powered devices that you simply place inside your walk-in coolers, freezers, and reach-in refrigerators. From there, they quietly track temperature and humidity around the clock, sending that data straight to an app on your phone or computer.

The real magic is in the real-time alerts. Imagine getting a text message at 2 AM because a walk-in door was left slightly ajar. Instead of walking into a disaster in the morning, you can call a manager to fix it immediately, saving thousands of dollars in spoiled food.

Key Insight: Technology shifts your cold chain management from being reactive (discovering spoiled food after the fact) to proactive (getting ahead of problems before they cause a loss). A small investment in sensors can easily prevent a catastrophic inventory write-off.

Simplify Compliance with Digital Data Loggers

Another game-changer is the digital data logger. This tool automatically records temperatures at regular intervals, creating a perfect, unbroken digital logbook. When the health inspector shows up, you can forget about frantically searching for a stained and incomplete paper chart. With just a few clicks, you can pull up a clean, professional report.

But these digital logs do more than just make inspections a breeze. Over time, the data reveals trends about your equipment's health. You might notice that a specific prep cooler consistently struggles to stay cold during the peak of service. That’s a clear signal that it needs maintenance before it fails completely during a busy Friday night.

This kind of detailed oversight is quickly becoming the new industry standard. The global cold chain monitoring market was valued at $7.47 billion in 2024 and is on track to hit $15.04 billion by 2030. This growth isn't just a fluke; it's fueled by stricter food safety rules and the adoption of tools like IoT sensors and cloud-based platforms.

You can dive deeper into these market trends and technologies to see where the industry is headed. By bringing these tools into your kitchen, you’re not just buying gadgets—you’re investing in a safer, more efficient, and more profitable operation.

Got Questions About Your Cold Chain? We've Got Answers.

Even with a solid plan, the day-to-day reality of a busy kitchen always brings up new questions. Getting straight answers to these common sticking points is key to making sure your team really gets cold chain management.

Think of this as the Q&A session after the main presentation. We're diving into the specific, practical stuff that chefs and managers run into all the time.

What Exactly Is the Temperature Danger Zone?

This is the big one. If you only remember one thing, make it this. The temperature danger zone is the range between 40°F and 140°F (that’s 4°C to 60°C).

Why is it so dangerous? Because in this temperature range, nasty bacteria like Salmonella, E. coli, and Listeria throw a party. They can double in number in just 20 minutes.

The entire point of temperature control is to keep perishable food out of this zone. A good cold chain keeps things below 40°F, effectively hitting the pause button on bacterial growth and keeping your customers safe.

Fun fact that isn't so fun: Refrigeration doesn't kill bacteria; it just slows them down. That’s why you can’t just rely on a cold fridge—proper handling and respecting shelf-life dates are just as important.

How Often Do We Really Need to Log Temperatures?

Every. Single. Shift.

No exceptions. Consistent temperature logging is your first line of defense and your best proof that you’re doing things right. At the start of each shift, someone should be checking and recording the temperatures of all coolers and freezers.

Why be so strict about it?

- Catch problems early. A log helps you spot a failing compressor or a door that isn’t sealing right before you lose thousands of dollars in product.

- It creates accountability. When it’s part of the daily checklist, it becomes second nature.

- You'll ace your health inspections. Nothing makes a health inspector happier than seeing a detailed, consistent temperature log. It shows you’re serious about food safety.

What Happens if a Delivery Arrives Warm?

This is a make-or-break moment for your cold chain. If a truck pulls up and your thermometer shows the products are already in the danger zone, there's only one right answer: Do not accept the delivery.

It might feel awkward, but it's non-negotiable. Here’s what your receiving team needs to do, no questions asked:

- Log the Proof: Immediately take the temperature of the truck and the product itself with a calibrated thermometer. Snap a picture with your phone for good measure.

- Inform the Driver: Calmly show the driver the reading and explain that you cannot accept the shipment for safety reasons.

- Call Your Supplier: Get on the phone with your sales rep right away. Let them know what happened so you aren't billed for the order and they can sort out the issue on their end.

Rejecting an order is a pain, I know. But it’s far less painful than a foodborne illness outbreak that tanks your reputation. It’s the ultimate way to protect your business and your customers.

At Encore Seattle Restaurant Equipment, we know that a strong cold chain is the foundation of any great kitchen. We're here to help you discover the latest news and exclusive deals on restaurant equipment and supplies. Stay informed about industry trends by checking out our selection of new and used equipment at https://encoreseattle.com.