Commercial kitchen floor drain requirements: Essential guide for restaurants

Share

When you're building or running a commercial kitchen, the last thing you want to think about is the plumbing. But the truth is, your floor drains are more than just a minor detail—they’re a critical part of your operation's health, safety, and even its profitability. Getting the requirements right isn't about ticking a box; it's about building a foundation for success.

These aren't just arbitrary rules. They are carefully designed standards for materials, sizing, and placement that ensure all the water, grease, and grime from a busy service gets whisked away efficiently. This keeps your kitchen clean, prevents dangerous slips, and stops cross-contamination in its tracks. We're here to help you stay informed about industry trends and discover the latest on restaurant equipment and supplies, starting with this essential guide.

Why Floor Drains Are Your Kitchen's First Line of Defense

It's easy to see floor drain requirements as just another bureaucratic headache. I've seen many owners try to cut corners here, only to regret it later. The best way to think about your drainage system is as the unsung hero of your kitchen. It quietly works in the background to prevent the kind of problems that can bring a restaurant to its knees—from devastating slip-and-fall injuries to the health code violations that could get you shut down.

This guide will walk you through exactly what you need to know, from the codes to the hardware. Getting your drainage right from the start is one of the smartest investments you can make, protecting you from expensive repairs and lost business down the road.

The High Cost of Getting It Wrong

Ignoring or simply misunderstanding commercial kitchen floor drain requirements is a recipe for disaster. Over the past two decades, food safety and workplace liability have become huge issues, and regulators have responded with much stricter codes.

A single shutdown due to a drainage problem can mean losing 3 to 10 days of revenue. For a restaurant doing $1.5 million a year, that's a direct hit of $12,000 to $40,000, not even counting the fines, which can easily add thousands more. The financial ripple effects are no joke.

A properly designed drainage system is not an expense—it's an investment in operational continuity, safety, and brand reputation. One failed inspection can cost more in lost business than the initial cost of compliant installation.

A Quick Look at the Core Compliance Areas

To give you a clear picture of what's involved, let's break down the main categories of floor drain requirements. These are the areas where inspectors will focus and where you need to get it right.

Here's a quick summary of the primary areas every restaurant owner needs to address to stay compliant and keep their kitchen safe and operational.

Table: Core Compliance Areas for Kitchen Floor Drains

| Compliance Area | Key Requirement | Why It Matters |

|---|---|---|

| Codes & Standards | Adherence to national (IPC/UPC) and local health codes. | Ensures your design is legally sound and passes inspection from day one. |

| Sizing & Slope | Drains must be correctly sized for water volume; floors sloped for flow. | Prevents water from pooling, which is a major slip hazard and breeding ground for bacteria. |

| Traps & Venting | P-traps and proper venting must be installed on all drains. | Stops sewer gases and pests from entering the kitchen through the drains. |

| Grease Management | Connection to a properly sized grease interceptor is mandatory. | Prevents grease from clogging municipal sewer lines, avoiding massive fines and plumbing disasters. |

| Accessibility & Safety | Drain covers must be secure, slip-resistant, and meet ADA standards. | Protects staff and guests from trips, falls, and other injuries. |

Mastering these requirements isn't just about avoiding penalties; it's about building a smarter, safer, and more efficient kitchen.

What We'll Cover in This Guide

To help you navigate this, we're going to dive deep into the most important aspects of kitchen drainage. You'll finish this guide with the confidence to plan your space correctly. We will cover:

- Navigating Complex Plumbing Codes: We’ll translate the technical jargon from standards like the IPC and UPC into plain English.

- Selecting the Right Hardware: Learn the difference between point drains, trench drains, and floor sinks, and where to use each.

- Implementing a Maintenance Plan: Discover a simple checklist that will save you money and headaches in the long run.

Ultimately, getting this right is fundamental. For complex projects or tricky renovations, bringing in expert professional drainage services is always a wise move to ensure everything is done by the book.

Decoding the Rules: Plumbing Codes and Health Department Mandates

Trying to understand the regulations for commercial kitchen drains can feel like you're untangling a massive knot. You'll hear a lot of acronyms thrown around, mainly the IPC (International Plumbing Code) and the UPC (Uniform Plumbing Code). These aren't just suggestions; they're the bibles for anyone designing or inspecting a professional kitchen.

Most places in the U.S. base their local laws on one of these two major codes. While they're pretty similar, there are key differences you need to know. For example, you'll see the UPC used more out west, while the IPC is dominant in the eastern and southern states. The very first thing you need to do is find out which code your local jurisdiction uses. Everything else builds on that.

Why the Local Health Department Has the Final Say

The plumbing codes provide the blueprint, but it's your local health department that brings those rules to life. They have one job: to stop people from getting sick. And believe me, your floor drains are high on their checklist. Poor drainage is a direct invitation for pests, bacteria, and all sorts of contamination nightmares.

A seasoned health inspector can spot a violation from a mile away. They'll be looking at everything—the materials, how easy the drains are to clean, and whether they're connected correctly to prevent backflow. Getting their sign-off isn't just a suggestion; it's the key to unlocking your doors and staying in business.

The most expensive drain you can buy is the one you have to tear out and do all over again. Before you pour a single yard of concrete, get familiar with your local health department's specific amendments to the code. It will save you a world of headaches and money.

The "Air Gap" Rule: Understanding Indirect Waste

One of the most critical concepts—and something every inspector looks for—is the indirect waste connection. The easiest way to think of it is as a mandatory "air gap" in your plumbing system. Instead of your three-compartment sink or ice machine being piped directly into the sewer, its drain line has to empty into an open-to-the-air floor sink.

This physical gap is a brilliantly simple safety measure. It makes it physically impossible for raw sewage to back up into the very equipment you use to prepare food. This isn't optional; it's a hard-and-fast rule for any equipment that touches food or ice.

An indirect connection is a must for:

- Food Prep Sinks: Any sink where you're washing produce or thawing food.

- Ice Machines and Bins: Keeps your clean ice from ever coming into contact with wastewater.

- Dishwashers: Guarantees that dirty drain water can't siphon back into the machine during a sanitizing cycle.

- Walk-in Coolers: Safely drains condensation without creating a direct path to the sewer.

The NSF Stamp of Approval

When you're shopping for drains, sinks, or any other kitchen equipment, keep an eye out for the NSF (National Sanitation Foundation) certification. This little mark tells you—and more importantly, your health inspector—that the product has been through the wringer and meets tough public health standards.

NSF-certified drains are built differently. They are:

- Made from non-porous, corrosion-resistant materials like stainless steel, which won't give bacteria a place to grow.

- Designed with smooth surfaces and rounded corners, getting rid of those tiny cracks and crevices where grime loves to hide.

- Built for easy disassembly, so your crew can actually get them completely clean.

Installing drains without an NSF certification is like waving a giant red flag at an inspector. It’s a common reason for a failed inspection right out of the gate. Getting a solid grasp on these core rules puts you in the driver's seat. You'll be able to have intelligent conversations with your contractors and ensure your kitchen is built right from the start.

Choosing the Right Drain for Each Kitchen Zone

You wouldn't use a paring knife for a butcher's job, and the same logic applies to your kitchen drains. Picking the right drain for each specific zone is fundamental to an efficient, safe, and health-code-compliant kitchen. It’s not just about getting rid of water; it’s about managing workflow and safety from the ground up.

Think of it like this: a point drain is your precision tool. It’s perfect for handling spills or drainage in a specific, contained spot, like under a steam kettle or an ice machine. It's designed to tackle a localized issue without getting in the way.

A trench drain (or channel drain), on the other hand, is the heavy-duty workhorse. It's the long channel that spans a wide area, like the entire cook line, catching water, grease, and food debris from multiple points at once. It’s all about high-volume capture across a broad surface.

Point Drains and Floor Sinks: The Specialists

Point drains are the most common type you’ll encounter. A floor sink is a specific, heavy-duty version of a point drain—it's essentially an open basin set into the floor to receive waste lines from equipment like dishwashers, three-compartment sinks, and walk-in coolers. This design creates the mandatory "air gap" that prevents dirty water from ever backing up into your clean equipment.

Standard point drains, often called area drains, are simpler and primarily drain the surrounding floor. You'll typically find them in prep areas or storerooms that get regular wash-downs but don't face a constant deluge of water. For a deeper dive, our guide on the role of a stainless steel floor sink explains their application in more detail.

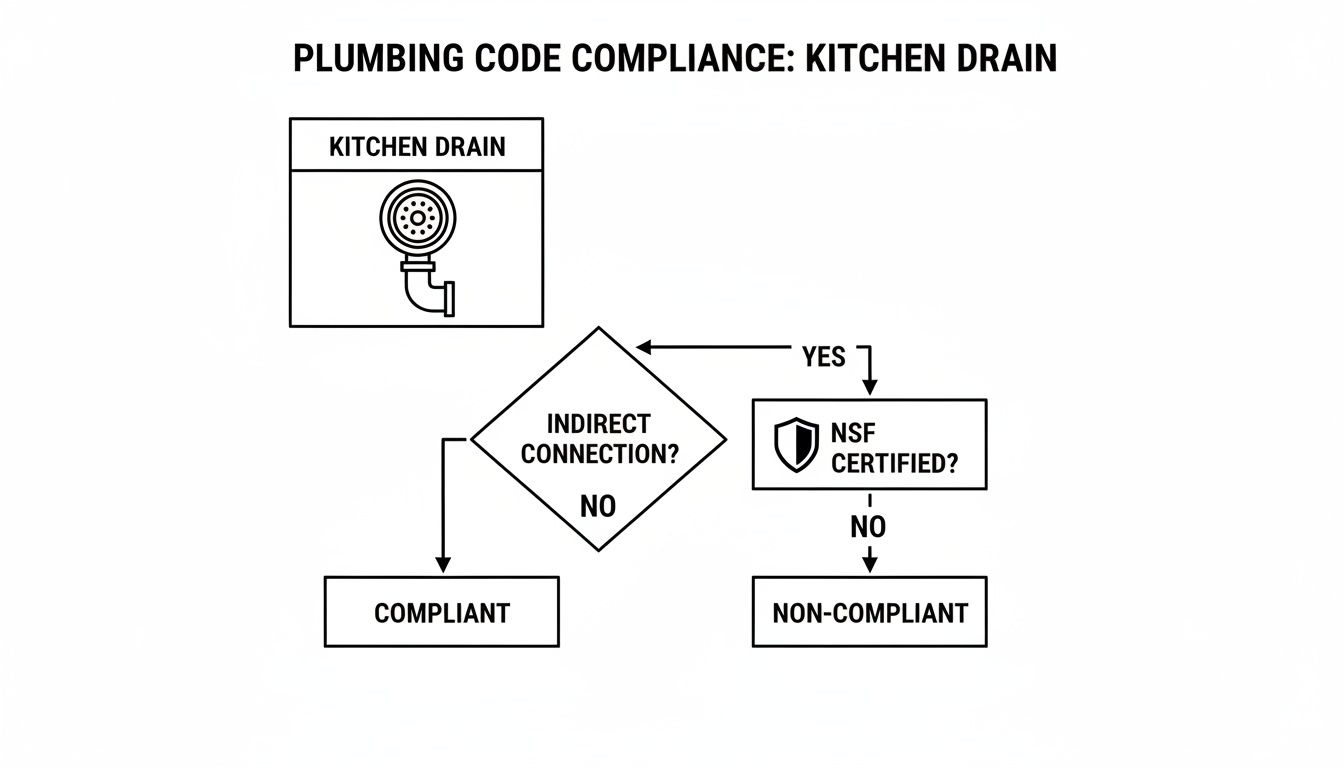

This decision-making process is critical for compliance. The flowchart below breaks down how to think about any drain, centering on the two most important factors: connection type and official certification.

As you can see, the path to a compliant drain starts with two simple questions. Does it need an indirect connection (a must for most food equipment)? And is it NSF-certified to meet sanitation standards?

Trench Drains: The Workhorses

When you're dealing with high-spill, high-traffic zones, a trench drain is almost always the better choice. Their biggest advantage is their ability to intercept a ton of water and slop before it has a chance to spread across the floor and become a slipping hazard.

They are essential in areas like:

- Cook Lines: This is ground zero for spills from stock pots, fryers, and kettles. A trench drain corrals the mess, keeping the floor much safer for a busy kitchen crew.

- Dish Pits: Between pre-rinse sprayers and commercial dish machines, the volume of water is massive. A trench drain is non-negotiable here to prevent flooding.

- Breweries and Beverage Stations: These zones see frequent cleaning and the occasional high-volume spill (think a dropped keg). A channel drain handles it all with ease.

To make the best decision for your space, it helps to compare these two main options side-by-side.

Comparison of Common Commercial Kitchen Drain Types

| Feature | Point Drains (Floor Sinks) | Trench Drains (Channel Drains) |

|---|---|---|

| Best For | Localized drainage, equipment connections (indirect), smaller areas. | High-volume water removal, large areas, linear capture (cook lines, dish pits). |

| Installation | Simpler and less disruptive. Requires a four-way slope in the floor towards the drain. | More complex and requires a one- or two-way slope along the channel's length. |

| Cost | Lower initial cost for the drain itself, but may require more drains to cover a large area. | Higher initial cost per foot, but can be more cost-effective for large, wet zones. |

| Maintenance | Strainer baskets are smaller and may need more frequent cleaning to prevent clogs. | Larger gratings and sediment baskets can hold more debris, often requiring less frequent cleaning. |

| Safety | Less effective at preventing the spread of large spills across the floor. | Excellent for containing spills and water, significantly reducing slip-and-fall hazards. |

Ultimately, most commercial kitchens need a smart combination of both types. Point drains handle the dedicated equipment tasks, while trench drains protect your busiest and wettest work zones.

Materials Matter: Durability vs. Hygiene

The material your drains are made of is just as crucial as their type. This choice directly affects your budget, long-term durability, and how easy it is to keep your kitchen sanitary.

- Cast Iron: The old-school, heavy-duty option. It’s tough and relatively cheap upfront, but it's prone to rust and corrosion over time. This creates rough, pitted surfaces where bacteria can thrive.

- Stainless Steel (304 Grade): This is the modern industry standard for food service. It has fantastic corrosion resistance and provides a smooth, non-porous surface that’s easy to clean and sanitize.

- Stainless Steel (316 Grade): This is the premium, top-tier choice. Grade 316 includes an element called molybdenum, which gives it superior resistance to harsh sanitizing chemicals, salts, and acids. If your kitchen uses aggressive cleaners or deals with high-salinity waste, this is the best long-term investment.

Don’t underestimate the budget impact. For a new restaurant build-out or a major renovation, the drainage system can easily account for 3–5% of the entire mechanical and plumbing budget. Driven by stricter health codes, the market for hygienic materials is booming. One industry analysis projected that the global market for stainless steel floor drains alone would reach $1.64 billion by 2025, a clear sign that operators are prioritizing cleanability and durability.

Mastering Slope, Sizing, and Grease Management

Getting your floor drains right is about more than just picking the right hardware. It’s about understanding the physics of your kitchen floor. Think of proper slope and effective grease management as two sides of the same coin—they have to work together perfectly to keep water and waste flowing out, not backing up. Mess this up, and you’re looking at failed inspections, dangerous working conditions, and plumbing disasters waiting to happen.

Imagine your kitchen floor is a waterslide for wastewater. If it’s too flat, the water just sits there, creating a murky, stagnant mess. In a real kitchen, this means puddles that breed bacteria, stink up the place, and create a massive slip-and-fall risk for your staff. This is exactly why health inspectors are so strict about it.

The Golden Rule of Floor Slope

The gold standard for floor slope in any commercial kitchen is a minimum of a 1/4-inch drop for every one foot of horizontal run. It’s the magic number. This angle is just enough to let gravity do its job, pulling water and small bits of debris toward the drain, but it’s not so steep that it feels awkward or unsafe to work on.

This gentle decline guarantees that when you hose down the floors at the end of a long shift, all that water has a clear path to the exit. It’s a simple concept, but it's absolutely non-negotiable for passing inspections and keeping your team safe.

The Critical Role of Grease Management

If the floor slope is all about moving the water, then grease management is about protecting your pipes from what's in that water. Fats, oils, and grease—or FOG, as it’s known in the industry—are public enemy number one for plumbing systems. When hot, liquid grease from a fryer or a grill hits the cold water in your drain lines, it solidifies almost instantly. Layer by layer, it builds up into a blockage that can become as hard as concrete.

This is precisely why any drain that takes on waste from grease-producing equipment must route through a grease interceptor (you probably know it as a grease trap). This piece of equipment has one job: to separate the FOG from the wastewater before it ever gets a chance to enter the city sewer system.

Neglecting grease management doesn't just put your restaurant's plumbing at risk; it can cause massive blockages in the municipal sewer system, leading to sewage backups and environmental hazards. The fines for such an incident can be astronomical.

Understanding Grease Interceptor Types

Not all grease traps are created equal. The right size and type for your kitchen depend entirely on the volume of grease you’re producing. Your choice will typically come down to one of two main categories:

- Hydromechanical Grease Interceptors (HGIs): These are the smaller, often stainless steel units you might see tucked under a three-compartment sink. They’re designed for lower-grease applications and use a system of baffles to slow down the water, giving grease time to float to the top and solids a chance to sink.

- Gravity Grease Interceptors (GGIs): These are the heavy-hitters—massive tanks, often holding 1,000 gallons or more, that are usually buried underground just outside the building. Any full-service restaurant running multiple fryers, grills, and woks will almost certainly need a GGI to handle the sheer volume of FOG they generate daily.

Picking the right size isn’t a guessing game. It’s a specific calculation based on your kitchen's size, seating capacity, menu, and the number of fixtures draining into it. To get this right, check out our guide on grease trap sizing for the formulas and factors you need to consider. Proper sizing is the key to an efficient system that keeps you compliant with local health and environmental codes.

What's Next for Kitchen Drainage Technology?

Meeting today's commercial kitchen floor drain requirements is one thing, but just ticking the boxes on current codes won't keep you ahead of the game. The smartest operators are already looking to the future, investing in tech that turns drainage from a simple utility into an active, data-driven system. This isn't just a futuristic idea; it's the next logical step in building a kitchen that’s truly efficient and resilient.

These new advancements go way beyond the basic job of getting water off the floor. We're talking about smart drainage systems designed to catch problems before they can shut you down for the night. Imagine a drain that senses a clog forming and shoots you an alert days before it turns into a full-blown emergency.

Smart Drains and Predictive Maintenance

The biggest leap forward in drainage tech is the use of sensors and data. Smart drain systems are now being built with sensors that constantly track water flow rates. If that flow slows down even a little bit—a classic early sign of a grease clog or debris backup—the system can send a notification right to a manager's phone or a central building management dashboard.

The payoff here is huge. Instead of frantically calling an emergency plumber for a costly after-hours visit to fix a catastrophic backup, you can tackle the issue proactively during scheduled downtime. It’s the difference between a quick, preventative fix and a full-blown operational crisis.

The whole point of smart drainage is to eliminate surprises. By giving you real-time data, these systems let you shift from a reactive maintenance model to a predictive one, saving thousands in emergency repair costs and lost revenue.

The Evolution of High-Performance Materials

It's not all about digital tech; material science is also pushing things forward. While stainless steel is still the workhorse of the industry, manufacturers are now cooking up new alloys and finishes designed specifically for the brutal environment of a commercial kitchen. These materials are built to be even tougher against the harsh sanitizers and cleaning chemicals needed to keep foodborne pathogens at bay.

These next-gen materials offer some serious advantages:

- Easier to Clean: The surfaces are smoother and less porous, which makes it much harder for bacteria and biofilms to get a foothold. This means your team can get everything truly sanitary, faster.

- Less Water Wasted: Since these surfaces are easier to clean, staff can achieve the same level of sanitation using less water and fewer chemicals, which is a big win for your sustainability goals and your utility bills.

- Built to Last: Advanced materials provide even better resistance to corrosion and the thermal shock from boiling liquids, which extends the life of your entire drainage system.

This trend toward smarter, tougher components is a big deal in the market. Industry analysts are seeing a steady rise in sensor-equipped systems, and in some kitchens, real-time monitoring has already cut down maintenance calls by double-digit percentages. The global market for commercial floor drains is expected to push past $4 billion in the next few years, with these smart and high-performance products taking a bigger and bigger slice.

You can learn more about these commercial floor drain market trends to see what they mean for your business. Getting on board with these tools now is a strategic move that sets your operation up for the future.

Keeping Your Drains Flowing: An Essential Maintenance Checklist

Getting your commercial kitchen drains installed correctly is a huge win, but that's just the starting line. The real marathon is keeping them working perfectly day in and day out, and that all comes down to consistent maintenance. Think of it like this: a little preventative care for your kitchen’s plumbing can save you from the nightmare of a total system failure—the kind that shuts you down, costs you a fortune, and has you frantically calling a plumber at peak hours.

This checklist breaks down the critical tasks into simple daily, weekly, and monthly habits. Stick to this schedule, and you’ll keep your drains clear, stay on the right side of the health inspector, and protect your investment. It’s a straightforward game plan for making sure your drainage system works as hard as your crew.

Daily Drain Maintenance Tasks

These are the non-negotiables. Make them a core part of your closing routine. It only takes a few minutes, but it's your absolute best defense against clogs, backups, and nasty odors.

- Empty Every Strainer Basket: At the end of each shift, pull out all the strainer baskets from your floor sinks and channel drains. Get them completely empty, then give them a good scrub with a stiff brush and hot, soapy water to get all the gunk and grease off.

- Flush Drains with Hot Water: Once the strainers are clean and back in place, pour a few gallons of very hot water down each drain. This simple step helps melt and wash away any fresh grease before it has a chance to cool, harden, and create a blockage in the P-trap.

Weekly and Monthly Routines

Deeper cleaning tasks are for tackling the gunk that a daily hot water rinse just can't handle. Putting these on the calendar is key to the long-term health of your plumbing.

- Weekly Deep Clean: Once a week, treat your pipes with an approved enzymatic drain cleaner. These products are fantastic because they use beneficial bacteria to literally "eat" the organic grease and food particles without using harsh chemicals that can damage your plumbing.

- Monthly Grease Trap Check: If you have smaller, indoor grease interceptors, you need to check the FOG (fats, oils, grease) levels every month. A good rule of thumb is if the top layer of grease and solids takes up 25% or more of the interceptor's total liquid depth, it’s time to call in a professional to pump it out.

A well-maintained drain is an invisible one—it does its job without causing odors, backups, or safety hazards. Neglect, however, quickly turns it into the most noticeable and problematic feature in your kitchen.

Troubleshooting Common Drain Problems

Even with the best maintenance plan, things can still go wrong. The trick is knowing how to spot the issue and, more importantly, when it's time to put down the plunger and call a pro.

Problem: Slow Drains

- DIY Fix: Nine times out of ten, a slow drain is just a simple clog in the P-trap. After making sure there's no debris on the surface, a good commercial-grade plunger or a plumber's snake can often do the trick.

- When to Call a Pro: If plunging doesn't work or the water backs up right away, you've got a bigger problem. The clog is likely much deeper in the line and will probably require professional hydro-jetting to clear it.

Problem: Foul Odors

- DIY Fix: The most common culprit is a dry P-trap. That U-shaped pipe is designed to hold a water seal that blocks sewer gas. If it dries out, the smell comes right up. Pouring a gallon or two of water down the drain usually refills the trap and solves the problem. Regular enzymatic cleaning will also help by killing off odor-causing bacteria.

- When to Call a Pro: If the smell sticks around after you’ve refilled the trap and cleaned the drain, you could be looking at a clogged vent pipe or a more serious issue in the main sewer line. That's a definite job for a professional.

Proper drain care is a critical piece of your kitchen's overall health. To see how this fits into the bigger picture, our guide on commercial kitchen equipment maintenance offers a more complete view of operational upkeep. And for those really tough clogs, understanding the many benefits of professional drain cleaning makes a strong case for why calling an expert is often the smartest and most cost-effective move.

Frequently Asked Questions

When you're trying to get a commercial kitchen up and running, the details around floor drains can be a real headache. Let's tackle some of the most common questions we get from restaurant owners to clear up the confusion.

How Many Drains Does My Kitchen Need?

There’s no single, magic number here. The right amount of drains really depends on your kitchen’s size, layout, and the specific equipment you're running. Codes typically demand a drain within a certain distance of any fixture that kicks out waste. More importantly, any area that gets a regular hosing down—think cook lines and dish pits—needs its own effective drainage.

A good rule of thumb is to put drains at every low point in the floor and near any major source of water or grease. The main goal is simple: make sure water has nowhere to pool.

Think of drains as emergency exits for water. You need enough of them, placed in all the right spots, so water always has a quick and easy escape route. This mindset is the key to meeting commercial kitchen floor drain requirements and keeping your team safe.

Can I Use PVC Drains Instead of Stainless Steel?

While you see PVC all the time in home plumbing, it's a definite no-go for most parts of a commercial kitchen. The biggest issue is heat. A sudden dump of boiling water from a pasta cooker or hot oil from a fryer can make PVC pipes warp, crack, or even melt over time.

Beyond that, PVC is also more porous than stainless steel and scratches easily. Those tiny crevices become breeding grounds for bacteria. That's why health inspectors will almost always insist on the smooth, non-porous, and heat-resistant surface of stainless steel—it's just cleaner, safer, and far more durable for a food environment.

What Is the Difference Between a Floor Drain and a Floor Sink?

This one trips a lot of people up, but it's pretty straightforward once you get it. A "floor drain" is the general term for any drain opening in the floor, like a standard area drain or a long channel drain. Its only job is to get rid of water that's on the floor surface.

A floor sink, on the other hand, is a different beast entirely. It's an open basin set into the floor, designed to catch wastewater indirectly from equipment like dishwashers, ice machines, or three-compartment sinks. This indirect connection creates an "air gap"—a physical space that makes it impossible for dirty drain water to back up and contaminate your clean equipment. It's a non-negotiable health code requirement.

Getting the drainage right from day one is one of the most important parts of any new kitchen build or major renovation. At Encore Seattle Restaurant Equipment, we've seen it all and can help you pick the right drains, grease traps, and sinks to satisfy every code. We help restaurant owners and chefs discover the latest news and exclusive deals on restaurant equipment and supplies. Check out our huge inventory of new and used equipment at https://encoreseattle.com and build a kitchen that’s safe, compliant, and ready for service.