Finding the Best Commercial Refrigerators for Your Kitchen

Share

Finding the best commercial refrigerators isn't about chasing one top-rated model. It’s about finding the right cooling solution for your specific business. What works for a high-volume restaurant will be completely wrong for a small café or a busy food truck. Getting this decision right from the get-go is one of the most important investments you'll make in your kitchen's future. Stay informed about the latest industry trends and exclusive deals to ensure you're making the smartest choice for your restaurant equipment and supplies.

How to Choose the Right Commercial Refrigerator

Think of your commercial refrigerator as a key member of your kitchen team, not just a piece of metal. Each type is built for a specific job, and if you "hire" the right one, your kitchen will run like a well-oiled machine, your ingredients will stay fresh and safe, and your profits will be protected.

A bad choice can cause chaos during a dinner rush, lead to thousands of dollars in spoiled food, or send your utility bills through the roof. On the other hand, the perfect refrigerator just works, seamlessly supporting your staff and safeguarding your inventory. Before we get into the nitty-gritty of BTUs and refrigerants, let's start with the basics: understanding the main types of units and what they're built to do.

Matching Refrigerator Type to Business Needs

Every food business operates differently. A packed restaurant needs quick access to prepped ingredients line-side. A catering business needs to store massive amounts of food for a weekend event. Figuring out your primary need is the first step to narrowing down the options.

You'll generally come across five main categories:

- Reach-In Refrigerators: The classic workhorse. These are found in almost every kitchen and are perfect for holding ingredients you need to grab throughout the day.

- Walk-In Coolers: This is your bulk storage warehouse. If you buy ingredients in large quantities, a walk-in is an absolute necessity.

- Undercounter Units: These are the ultimate space-savers. They tuck neatly under counters at bars, in food trucks, or at specific prep stations to keep essentials within arm's reach.

- Prep Tables: Part refrigerator, part workspace. These units are designed for assembly-line tasks like making salads, sandwiches, or pizzas, keeping all your cold ingredients right where you need them.

- Merchandisers: These are your silent salespeople. With their glass doors, they’re designed to display drinks, sandwiches, and other grab-and-go items to entice customers.

Selecting the right unit is less about the appliance and more about the application. A caterer trying to work exclusively out of an undercounter unit will struggle just as much as a small café paying to run a half-empty walk-in.

To help you get started, here’s a quick breakdown of which units fit best with different types of businesses.

Quick Guide to Refrigerator Types

Match the right refrigerator to your business type to quickly identify your best options.

| Refrigerator Type | Ideal For | Primary Benefit |

|---|---|---|

| Reach-In | Restaurants, Cafes, Bakeries | Versatile, everyday ingredient access |

| Walk-In | High-volume Restaurants, Caterers, Institutions | Bulk inventory storage & organization |

| Undercounter | Bars, Food Trucks, Coffee Shops | Space-saving, point-of-use cooling |

| Prep Table | Pizzerias, Sandwich Shops, Salad Bars | Streamlined food assembly & workflow |

| Merchandiser | Cafes, C-Stores, Delis | Impulse sales & product visibility |

This table should give you a solid starting point for figuring out which category makes the most sense for your day-to-day operations.

Why the Right Size and Type Matter

Picking the right style and dimensions is the bedrock of an efficient kitchen. A refrigerator that's too big is a massive waste of energy and precious floor space. One that's too small will be overstuffed, leading to poor airflow, inconsistent temperatures, and serious food safety risks.

You absolutely have to get this right. For a step-by-step process on how to measure your space and calculate the capacity you truly need, check out our guide on selecting the right commercial refrigerator size. Nailing this first step ensures your investment starts paying for itself immediately.

A Breakdown of Commercial Refrigerator Types

Picking the right commercial refrigerator isn't just about finding a box that keeps things cold. Every unit is a specialist, built for a specific job in your kitchen's ecosystem. Think of your kitchen like a sports team—you need the right player in the right position to win a busy service.

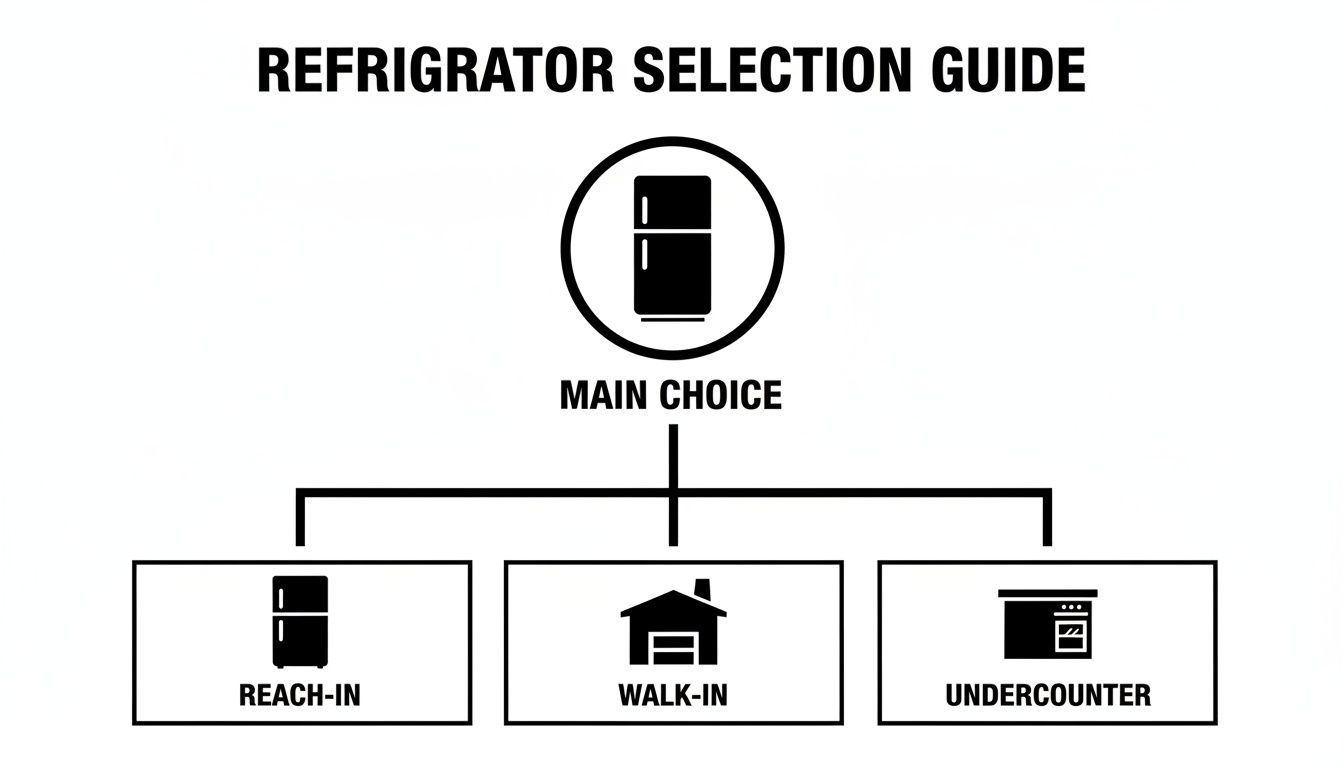

This diagram helps simplify that first big decision, showing how your main choice splits into different categories.

As you can see, the path forward really depends on how much you need to store and how your team needs to access it. Let's dig into what makes each type tick.

Reach-In Refrigerators: The Front-Line Soldiers

Reach-in refrigerators are the workhorses of almost every professional kitchen. These are your front-line soldiers, positioned right on the prep or cook line so chefs can grab what they need in the middle of a chaotic service. Their upright design with multiple shelves makes it easy to keep everything organized, from prepped veggies to sauces, all just an arm's reach away.

These units are built to take a beating. They have tough doors and powerful compressors that can get the temperature back down quickly, even when being opened constantly. Whether you go for a one, two, or three-door model, the mission is the same: keep essential ingredients close, cold, and ready for battle.

Walk-In Coolers: Your Central Warehouse

If reach-ins are your soldiers on the line, think of the walk-in cooler as your central warehouse. These are room-sized units designed for holding bulk inventory—everything from cases of produce to massive containers of stock. A well-organized walk-in is the absolute backbone of any high-volume restaurant, making sure you have enough product to get through a busy week without daily deliveries.

Smart shelving and a clear organizational system inside a walk-in are non-negotiable. It’s what prevents inventory loss, bolsters food safety, and makes taking inventory less of a nightmare. It's a big investment, for sure, but if you buy ingredients in bulk, it's a necessity for controlling costs and keeping service running smoothly.

Undercounter and Worktop Models: Efficiency Hubs

In a kitchen where every square foot counts, undercounter and worktop refrigerators are the ultimate efficiency hubs. These compact units slide right under countertops, giving you cold storage without eating up precious workspace. They’re perfect for dedicated stations, like a salad prep area, behind the bar, or tucked into a food truck.

Worktop models push this idea even further by adding a durable stainless steel top that serves as a prep surface. This two-in-one functionality is a lifesaver in tight spaces, letting you get more done in a smaller footprint.

Prep Tables: The Specialized Workstations

For kitchens built around an assembly line—think sandwich shops, pizzerias, or salad bars—refrigerated prep tables are the specialized workstations. They combine an undercounter fridge with a refrigerated rail on top, designed to hold pans of ingredients. This setup keeps all your meats, cheeses, veggies, and dressings chilled and organized right where you build the final product.

This design is all about speed and safety. It makes the workflow dramatically faster, cuts down on the risk of cross-contamination, and keeps ingredients at safe temperatures. Keeping an eye on industry trends is key, as innovative options like refrigerated food lockers are also popping up, creating new possibilities for modern delivery and pickup services.

Merchandisers: The Silent Salespeople

Finally, we have the merchandisers—your silent salespeople. With their glass doors and bright interior lights, these refrigerators are designed to do one thing: show off your products and trigger impulse buys. You’ll see them in cafes, convenience stores, and delis, filled with bottled drinks, pre-made sandwiches, and grab-and-go snacks.

The key to a good merchandiser is visibility. An attractive, well-lit display can significantly boost sales of high-margin items, making it an investment that directly contributes to your bottom line.

These units do more than just cool; they are an active part of your marketing. A great merchandiser not only holds the perfect temperature but also makes your products look too good to pass up.

Key Features to Evaluate Before You Buy

Alright, let's get into the nitty-gritty. Choosing the right commercial refrigerator goes way beyond the sticker price. You're really looking at the unit's DNA—the technical details that dictate how well it performs day in and day out, how much it costs to run, and how long it'll last. Think of it as managing your kitchen's most valuable real estate; every square inch counts, and every decision hits your budget.

We're about to demystify the jargon. I’ll translate terms like compressor types, refrigerants, and defrost cycles into practical knowledge you can actually use to make a smarter investment for your business.

Capacity and Footprint: The Kitchen Real Estate Game

First things first: how much cold storage do you actually need, and how much physical space can you give up for it? Capacity, measured in cubic feet, tells you how much you can cram inside. The footprint is the unit's external dimensions—how much floor space it will occupy.

Getting this balance right is non-negotiable. A fridge that's too small forces you to overstock it, which is a recipe for disaster. It blocks airflow and creates dangerous temperature pockets where food can spoil. On the flip side, a unit that’s too big for your inventory is just a power-hungry box, wasting electricity cooling empty space and hogging floor area you could use for something else.

Your goal is to find that sweet spot: maximum storage within the smallest possible footprint. Always, always measure your intended location—including doorways and hallways—before you even start looking at models.

Energy Efficiency: A Direct Return on Your Investment

Energy efficiency isn't just some green buzzword; it's a direct investment that pays you back every single month on your utility bill. A model with an ENERGY STAR certification can be up to 40% more energy-efficient than a standard unit. Over its lifespan, that adds up to hundreds, sometimes thousands, of dollars in savings.

Here’s what to look for:

- LED Lighting: It generates far less heat than old-school fluorescent bulbs, which means the compressor doesn't have to work as hard to keep things cool.

- High-Quality Insulation: Better insulation, like dense polyurethane foam, means the unit holds its temperature without constantly kicking on. Less run time equals lower bills.

- Self-Closing Doors: This simple feature is a lifesaver in a chaotic kitchen. It prevents doors from being left ajar—one of the biggest energy-wasters out there.

Making a smart choice here dramatically lowers your total cost of ownership. If you want to dive deeper, you can learn more about how to choose energy-efficient commercial refrigerators and see just how much you can save.

The Compressor: The Heart of Your Refrigerator

The compressor is the engine of your refrigeration system. It's the workhorse that circulates refrigerant to pull heat out of the box. Where this engine is placed—either on the top or the bottom—makes a huge difference depending on your kitchen's environment.

Top-Mount Compressors

A top-mount compressor is a great fit for cooler, less greasy kitchens, like a bakery or a quiet café. It pulls in cleaner air from above the floor and pushes hot air up and away. This design helps keep the coils from getting clogged with all the dust and gunk that inevitably collects on a kitchen floor.

Bottom-Mount Compressors

This is the go-to for most hot, high-volume commercial kitchens. A bottom-mount compressor draws in cooler air from floor level, which means it doesn't have to struggle as much in a hot room. As a bonus, it raises the bottom shelves, making it a bit easier for staff to grab items without bending all the way down.

The demand for more efficient systems is fueling massive growth in this market. The global commercial refrigeration market hit USD 85.6 billion in 2024 and is on track to reach a staggering USD 161 billion by 2034. This boom is driven by businesses like yours upgrading to models that save on operational costs and meet new environmental standards.

Refrigerant and Defrost Cycles

Finally, let’s talk about two critical features that are easy to overlook: the refrigerant type and the defrost method. These affect everything from your environmental footprint and maintenance schedule to the quality of your stored food.

Today, the industry standard is R290 refrigerant, a natural, non-toxic hydrocarbon. It has a nearly non-existent Global Warming Potential (GWP), making it an eco-friendly choice that also happens to be more energy-efficient than older refrigerants.

Defrost cycles are essential for preventing ice buildup on the evaporator coils, which can kill your fridge's performance. You have two main options:

- Automatic Defrost: The unit uses a timer and a heating element to melt away ice on a regular schedule. It's incredibly convenient, but the heating cycle can cause minor temperature swings inside the cabinet.

- Manual Defrost: This requires you to empty the unit and shut it down to let the ice melt. It's more work, no doubt, but it provides rock-solid temperature stability, which is crucial for very sensitive products.

Navigating Your Budget: New vs. Used Equipment

One of the biggest hurdles for any operator is figuring out how to get the right commercial refrigerator without torching your budget. This brings up the age-old debate: do you spring for a brand-new unit, or go with a certified used model? There’s no single right answer here—it all comes down to your available cash, how much risk you're willing to take, and your long-term vision.

A new unit is a direct investment in reliability and the latest tech. You're getting the most energy-efficient models, which means lower utility bills from day one. Plus, it comes with a full manufacturer's warranty, giving you peace of mind and protecting you from surprise repair bills. For an established restaurant looking to upgrade, that security is often worth the higher upfront cost.

On the other hand, a certified used refrigerator can be an incredibly smart buy, especially if you're just starting out or expanding. It lets you get your hands on a high-quality, durable piece of equipment from a top brand for a fraction of the price. That frees up critical cash for inventory, marketing, or anything else you need to get off the ground.

The Case for Buying New Equipment

Choosing a new commercial refrigerator is a lot like buying a new car. You get that factory-fresh performance right out of the box and the assurance of a solid warranty. This is the best route for operators who can't afford downtime and want to keep unexpected maintenance costs off their plate for the first few years.

Here’s why buying new makes sense:

- Maximum Energy Efficiency: New models, especially those with an ENERGY STAR rating, are built to the latest standards. They can literally save you hundreds of dollars a year on your power bill.

- Full Warranty Coverage: A manufacturer's warranty is your safety net. It covers parts and labor for a specified time, protecting your investment from defects or early breakdowns.

- The Latest Technology: You get access to all the modern bells and whistles, like precise digital temperature controls, eco-friendly R290 refrigerant, and better insulation.

This option is a perfect fit for businesses that have the capital for the initial investment and want a dependable, set-it-and-forget-it solution.

The Strategic Value of Used Equipment

Going with used equipment isn't about buying someone else's problems—it's a strategic play for savvy, budget-conscious owners. The key is to find a professionally refurbished, cleaned, and tested unit from a trusted source. For many, this is the smartest way to make every dollar count.

A well-maintained, certified used refrigerator from a reputable dealer can provide 80% of the lifespan of a new unit for as little as 50% of the cost. That trade-off can mean the difference between a new café getting the gear they need or compromising their financial footing.

Of course, you have to do your homework. To make sure you’re getting a good deal, you need to know what to look for. Our deep-dive guide on buying used restaurant equipment gives you a complete checklist of what to inspect and the right questions to ask before you sign on the dotted line.

Financing and Leasing Your Equipment

Beyond just buying new or used, there's a third path that many operators overlook: financing or leasing. Think of it not as a last resort, but as a strategic financial tool. This approach lets you get the exact equipment you need—new or used—while keeping your working capital in your pocket.

Instead of taking a massive cash hit all at once, you make predictable monthly payments. This keeps your funds free for payroll, inventory, and other day-to-day expenses. When you’re mapping out your budget, it’s worth exploring different options like leasing versus buying commercial equipment. Spreading out the cost this way makes top-tier equipment accessible to just about any business, helping you build the kitchen you need to thrive.

Installation and Maintenance for Peak Performance

Buying one of the best commercial refrigerators is a big step, but your job isn't done when it rolls off the delivery truck. Getting the installation right and sticking to a simple maintenance routine are what will truly determine its performance, efficiency, and how long it lasts. It's like buying a great set of chef's knives; you still have to sharpen them to keep them at their best.

If you skip these steps, you're setting yourself up for headaches—think unexpected breakdowns during the Friday night rush, escalating energy bills, and a unit that dies years before its time. A little proactive care, on the other hand, turns that metal box into a reliable workhorse for your kitchen. This is how you protect your investment and make sure it works as hard as you do.

A Solid Foundation: The Installation Checklist

A flawless installation is the first and most critical step toward a long, trouble-free life for your equipment. Honestly, a surprising number of performance issues I see in the field trace right back to a rushed or sloppy setup. Before you even think about plugging it in, run through this quick checklist.

-

Let It Breathe: Commercial refrigerators generate a lot of heat, and they need space to vent it. Make sure you leave at least 3-4 inches of clearance around the top, back, and sides. Shoving it right up against a wall traps hot air, which forces the compressor to work itself to death and sends your utility bills soaring.

-

Get It Level: A wobbly, unlevel refrigerator is a bigger problem than it seems. It makes the doors hang crooked, creating tiny gaps that leak cold air and make the unit run constantly. Use a level to get it perfectly balanced; this also ensures the door's self-closing mechanism actually works as intended.

-

Check the Juice: Don’t just find the nearest outlet. These are powerful machines. Double-check the manufacturer's specs and plug it into a dedicated circuit with the proper voltage and amperage. Overloading a circuit isn't just bad for the compressor—it's a major fire hazard.

Building a Simple Preventative Maintenance Routine

You don't need to be a refrigeration technician to keep your unit humming. A simple, consistent routine is the single best way to prevent expensive emergency calls and get the most life out of your machine. We're talking about a few minutes a month, not a major time commitment.

Think of preventative maintenance as an operational investment, not an expense. A few minutes of cleaning each month can easily prevent a catastrophic failure that could shut your kitchen down for a day.

Try to work these simple tasks into your weekly or bi-weekly cleaning schedule:

- Clean the Condenser Coils: These coils are magnets for all the dust, grease, and grime floating around a kitchen. When they get clogged, they can't release heat, so the compressor has to work much harder. A quick pass with a stiff brush or vacuum once a month can cut energy use by up to 10% and prevent a burnout.

- Inspect and Clean Door Gaskets: The rubber seal around the door is your frontline defense against wasted energy. Look for cracks or tears and wipe them down weekly to get rid of food gunk. A tight seal keeps the cold in and your money in your pocket.

- Wipe Down the Interior: Clean up spills immediately with mild soap and water. This is basic food safety, but it also prevents mold, nasty odors, and corrosion that can damage the interior of the unit over time.

- Glance at the Thermometer: Make it a daily habit. If you notice the temperature creeping up or fluctuating wildly, it’s an early warning sign. Catching a problem early gives you time to get it fixed before you lose a walk-in full of product.

Your Final Decision-Making Checklist

Alright, let's bring it all together. Picking a commercial refrigerator is a huge decision, and with so much on the line, it's easy to feel stuck. But you don't have to be.

Think of this as your final walkthrough. We’ve covered a ton of ground, and this checklist pulls it all into a simple, step-by-step process. Follow these steps, and you’ll be able to choose a refrigerator that’s not just a piece of equipment, but a true workhorse for your kitchen.

Step 1: Assess Your Kitchen's Reality

Before you even glance at a product page, you need to get real about your own space. Your kitchen’s layout, your menu, and your team’s daily dance are the true blueprints for the right refrigerator.

- Measure Everything: I mean everything. Grab a tape measure and get the exact dimensions for the spot where the unit will live. Don't forget doorways and tight corners it has to pass through. You absolutely need at least 3-4 inches of breathing room around the unit for ventilation.

- Analyze Your Menu: What are you serving? A menu heavy on fresh produce demands different storage than one built around frozen goods. This will tell you if you need a giant walk-in for bulk items, a reach-in right on the line, or a specialized prep table.

- Map Your Workflow: Watch your crew during a busy service. Where are the logjams? A well-placed undercounter unit can eliminate wasted steps and speed up service, making a huge difference when you're in the weeds.

Step 2: Define Your Financial Game Plan

Now it's time to talk money. Let's line up your kitchen's needs with what your wallet can handle. Knowing your financial boundaries and options is what turns a purchase into a smart, sustainable investment.

Figure out your absolute maximum upfront budget, but also look at all your options. A used unit might seem like a bargain, but will it cost you more in energy bills and repairs down the road? A new one costs more now, but the warranty and energy savings could make it cheaper in the long run. Don’t dismiss financing—it can be a great way to get the right unit now while protecting your cash flow.

Step 3: Compare Features and Long-Term Value

With your needs defined and your budget set, you can finally start shopping. This is where you dig into the details and focus on what provides real value over the life of the machine.

The smartest purchase isn’t always the cheapest one. It’s the one that delivers the best performance, efficiency, and reliability for the lowest total cost of ownership over many years of service.

Start comparing models head-to-head. Look for that ENERGY STAR certification, decide if a top-mount or bottom-mount compressor makes more sense for your kitchen, and prioritize units that use eco-friendly R290 refrigerant. These aren't just specs on a sheet; they directly affect your monthly utility bills and how often you'll be calling a repair technician.

Finally, think past the purchase. Have a solid plan for delivery and installation, and commit to a basic maintenance routine. A little proactive care goes a long way, ensuring your new refrigerator will be a reliable partner for years, protecting both your food and your profits.

Frequently Asked Questions

When you're in the weeds running a kitchen, you've got questions about your gear. It's only natural. Getting straight answers about commercial refrigeration helps you work smarter and protect the thousands of dollars you've invested in your equipment. Let's tackle some of the most common things we hear from chefs and owners.

What Is the Difference Between a Top Mount and Bottom Mount Compressor?

The location of the compressor—the heart of your refrigerator—really matters, and the right choice depends entirely on your kitchen environment.

A top-mount compressor is perfect for kitchens that stay relatively cool and clean, like a pastry station or a quiet café. Because heat rises, the compressor pushes hot air up and away from the unit. It also avoids sucking in all the dust and grime that settles on the floor.

On the other hand, a bottom-mount compressor is built for the chaos of a hot line. It pulls in cooler air from near the floor, so it doesn't have to fight as hard in a sweltering kitchen. Plus, the coils are way easier to get to for a quick cleaning, which is a huge bonus.

How Often Should My Commercial Refrigerator Be Professionally Serviced?

Your daily wipe-downs and weekly deep cleans are critical, but they aren't a substitute for a pro's eye. You should plan on having your commercial refrigerators professionally serviced at least twice a year.

Think of it like a regular check-up for your most valuable player. A technician can catch things you'd never notice—like a slow refrigerant leak or a fraying wire—before they shut you down in the middle of a Saturday night rush.

This kind of preventative care is one of the smartest things you can do for your equipment's lifespan. A well-maintained unit runs more efficiently, saving you a bundle on electricity and last-minute emergency repair calls.

What Type of Refrigerator Is Best for a Food Truck?

In a food truck, space is everything, and your equipment has to be tough enough to handle life on the road. For this, undercounter and worktop refrigerators are almost always the answer.

These units are the ultimate multitaskers. You get critical cold storage tucked neatly under a durable prep surface, which is a game-changer when you're working in tight quarters. When you're shopping, make sure you look for models designed for mobile use—they’ll have a sturdier build, reinforced parts, and strong door latches that won't fly open when you hit a pothole.

Ready to find the right refrigeration for your kitchen? The team at Encore Seattle Restaurant Equipment has been outfitting businesses in the Pacific Northwest and Alaska since 1990. We help restaurant owners and chefs discover the latest news and exclusive deals on restaurant equipment and supplies. Check out our huge selection of new and used equipment today at https://encoreseattle.com.