A Chef's Guide to Buying Used Restaurant Equipment

Share

Let's be honest, fitting out a commercial kitchen can feel like writing a check with an endless number of zeros. But seasoned chefs and smart restaurant owners have a secret weapon: the used equipment market. This isn't just about saving a few bucks; it's a strategic play to build a more resilient, better-equipped kitchen from day one. By smartly redirecting those massive savings, you can fuel other critical parts of your business, like marketing or staffing, turning a huge expense into a real competitive edge. To stay ahead, savvy owners are always on the lookout for industry news and exclusive deals on equipment and supplies.

The Savvy Chef's Strategy for Kitchen Savings

There's a common misconception that "used" automatically means "worn out." More often than not, it actually means "gently used" by a restaurant that unfortunately had to close its doors or decided to upgrade.

This reality opens up a world of opportunity. You can get your hands on top-tier, durable brands—the kind of workhorses built to withstand the nightly grind of a busy kitchen—that might be completely out of reach if you were buying new. It’s a powerful financial move that frees up a ton of cash flow right when you need it most, allowing you to stay informed about the latest industry trends without being financially constrained.

A Real-World Success Story

Think about a startup café owner trying to make a name for herself in a packed downtown market. Instead of saddling her new business with massive debt for shiny, new gear, she decided to go the used route. She found a high-end espresso machine, a commercial convection oven, and top-notch refrigeration, all from a bistro that had recently closed.

The final tally? She kitted out her entire kitchen for over 60% less than the sticker price for new equipment. That wasn't just a small win; it was a total game-changer. The capital she saved was immediately poured back into a strong local marketing push and premium initial inventory, helping her build a loyal customer base right out of the gate.

This is a perfect example of a core principle successful restaurateurs live by: every dollar saved on equipment is a dollar you can invest in growth, marketing, and creating an unforgettable customer experience.

Why the Used Market Is Booming

This isn't some niche hack; it’s a major trend shaping the industry. The global market for used restaurant equipment is growing fast, fueled by operators keeping a close eye on their bottom line and the unfortunate reality of high turnover in the food business.

In fact, its value is projected to climb from USD 6.34 billion to USD 9.14 billion between 2024 and 2029. This explosive growth proves a major shift in thinking, where smart, practical investments are winning out. You can dig deeper into these trends on The Business Research Company's website.

Tapping into the used market is about building a better kitchen for less. It gives you the power to:

- Acquire Premium Brands: Score equipment from trusted names known for performance and longevity without the eye-watering price tag.

- Maximize Your Budget: Make your startup or renovation funds go way further, freeing up money for other essentials.

- Reduce Financial Risk: Lower your initial debt, which creates a much more stable financial foundation for your restaurant’s future.

At the end of the day, buying used isn't a compromise. It’s a massive opportunity to use the market to your advantage and make intelligent investments that will pay off for years to come.

Where to Hunt for Quality Used Kitchen Gear

Finding the right equipment starts with knowing where to look. Your success in buying used hinges on tapping into the right channels, each with its own set of rules and rewards. It's about more than just a quick online search; you need a strategy for finding the gems, vetting sellers, and knowing when to walk away. Of course, before you even start hunting, you need a clear shopping list. If you're not sure where to begin, this essential coffee shop equipment list can be a great reference point.

The digital world offers a massive marketplace, but you have to keep a sharp eye out. Platforms like Facebook Marketplace and Craigslist are absolutely packed with listings from private sellers. You can find some incredible deals this way, but you have to proceed with caution. Always do your homework by researching the seller and demanding detailed photos and, if possible, a video of the equipment running.

Navigating Online Marketplaces Like a Pro

When you're scrolling through online listings, a few red flags should immediately jump out at you. Be wary of vague descriptions, stock photos instead of pictures of the actual item, or sellers who get cagey when you ask specific questions about the equipment's history. These are all warning signs.

A good seller will be an open book, ready to give you all the information you need to feel confident in your purchase. And remember, an in-person inspection is non-negotiable for any big-ticket item. If the seller won't agree to it, it’s time to move on.

Expert Tip: Never take a seller's description at face value. Ask for the model and serial number right away. A quick search will tell you the unit's age, its original specs, and any common maintenance problems, which gives you some serious leverage when you start negotiating.

The Thrill of the Auction House

Local restaurant auctions are another fantastic place to find high-quality, pre-owned gear. These events usually pop up when a restaurant closes and liquidates its assets, meaning you can find an entire kitchen's worth of equipment all in one spot. It's a sad reality that as many as 61% of independent restaurants don't make it past their first three years, which means there’s a steady stream of well-maintained equipment hitting the auction block.

The key to winning at an auction is preparation. Get there early to inspect the lots you’re interested in. Test what you can, look for obvious wear and tear, and set a hard budget for every single item. It's way too easy to get swept up in a bidding war, but a smart buyer knows their limit and sticks to it.

Here’s a quick game plan for auction day:

- Make a List: Know precisely what you need—and its specs—before you even walk in the door.

- Know the New Price: Research what the item costs new. This helps you set a realistic bidding ceiling.

- Set Your Budget: Decide on your absolute maximum bid for each piece and don't go a penny over.

- Factor in the Extras: Don't forget to account for the buyer's premium (a percentage tacked onto your winning bid) and the cost of hauling it all away.

The Advantage of Specialized Dealers

If you're looking for a bit more security, specialized used equipment dealers are the gold standard. These businesses buy, inspect, and often refurbish equipment before putting it up for sale. The prices might be a little higher than what you’d find in a private sale, but the benefits are huge.

Dealers provide a level of assurance you just won't get anywhere else. Many offer limited warranties, which is a world away from the "as-is" gamble of auctions and private sales. When a dealer offers a 30- or 90-day warranty, they're showing they have confidence in their refurbishment work. That peace of mind, especially for critical equipment like your walk-in cooler or convection oven, is often well worth the slightly higher price tag. Reputable dealers can also be a source for exclusive deals and industry news.

Tapping Into Your Professional Network

Finally, never underestimate the power of your local chef community. Some of the best deals I've ever seen were never advertised to the public. They happen through word-of-mouth in private Facebook groups or at industry meetups.

Start talking to your peers. Let people know what you're looking for. You might just connect with another chef who's upgrading their kitchen and would rather sell their old gear to a trusted colleague. This insider track can lead to some incredibly well-maintained equipment at a fantastic price.

Your Ultimate Pre-Purchase Inspection Checklist

This is where the rubber meets the road. A thorough, hands-on inspection is what separates a fantastic deal from a future financial headache. It’s absolutely non-negotiable when you’re buying used.

Think of yourself as a detective. Every scratch, strange noise, and missing screw tells a story about the equipment's past life and its likely future. Your job is to uncover that story before any money changes hands. Going in with a plan gives you the confidence to spot hidden issues and save yourself from a costly mistake.

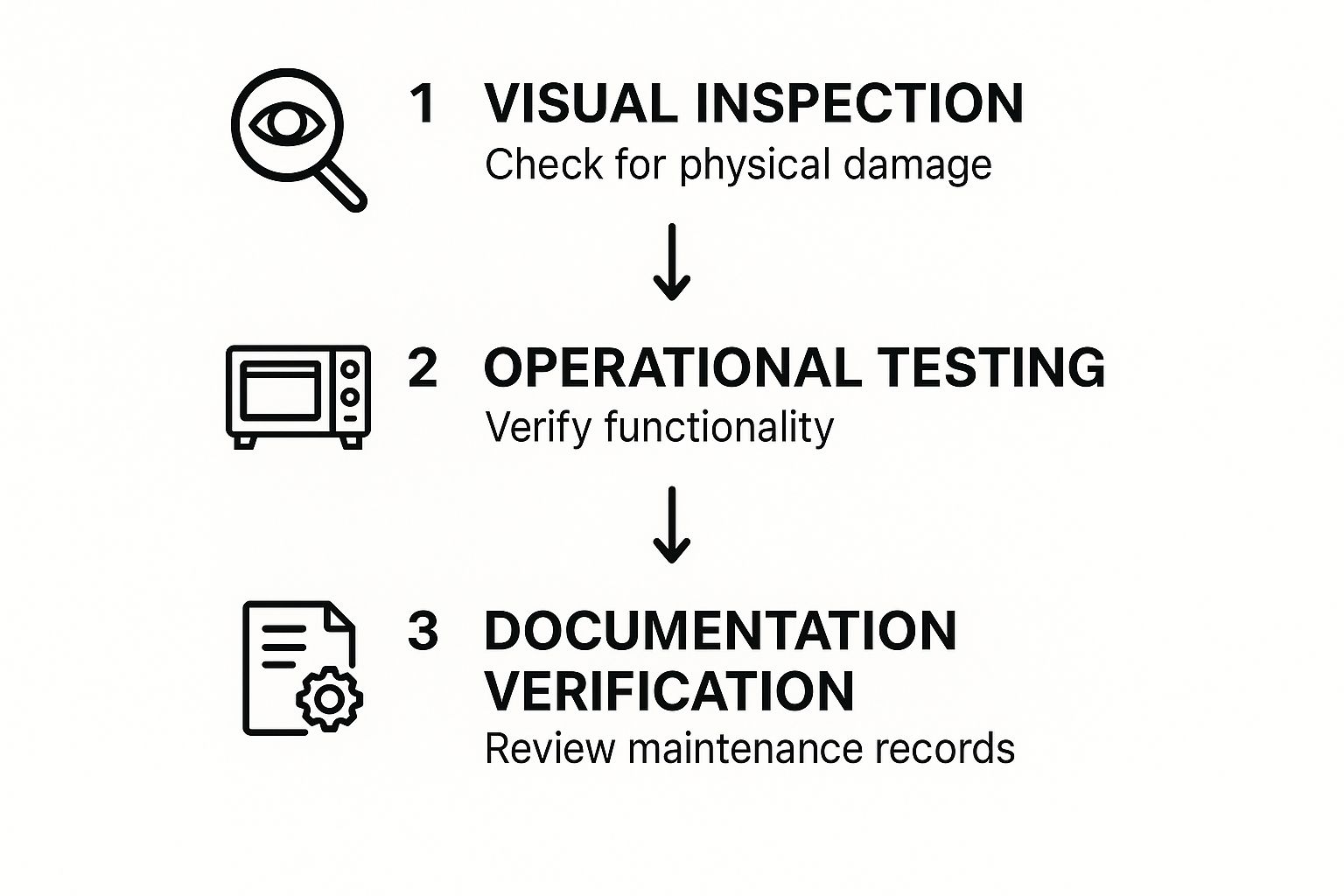

The following process offers a structured approach to your inspection, breaking it down into three core phases.

This visual guide shows a logical progression: start with a broad visual assessment, then move to functional tests, and finally, review any documentation to get a complete picture of the equipment's condition.

Inspecting Refrigeration Units

For any kitchen, refrigeration is the heart of the operation. A failing cooler or freezer means spoiled inventory and lost profits, so this inspection is critical. Don't just open the door and check if it feels cold; you need to dig deeper.

Start with the compressor—the unit's engine. Does it kick on and off at regular intervals, or is it running constantly? A compressor that never shuts off is a massive red flag, suggesting it’s struggling to hold temperature. Listen for loud clanking or grinding noises, which often signal an imminent failure.

Next, check the gaskets and seals around the doors. They should be flexible and create a tight seal. Brittle, cracked, or moldy gaskets will need immediate replacement, an added cost you have to factor into your offer.

Here are the key checkpoints for any refrigeration unit:

- Temperature Accuracy: Bring a reliable thermometer. Place it inside, shut the door for 20-30 minutes, and see if the reading matches the unit's thermostat.

- Coil Condition: Look at the condenser and evaporator coils. Are they caked in dust and grease? Poorly maintained coils force the compressor to work harder, shortening its lifespan.

- Physical Integrity: Check for rust, especially at the bottom where moisture collects. Dents on the outside might seem cosmetic, but a significant impact could have damaged internal components.

Pro Tip: Bring a small, powerful magnet. Run it along the stainless steel surfaces, especially near the base and corners. If the magnet sticks, it might be detecting Bondo or another filler used to cover up serious rust damage hiding beneath a patch job.

Evaluating the Cooking Line

Cooking equipment is the biggest slice of the used market, which isn’t surprising given its central role in any kitchen. When you're looking at ranges, ovens, and fryers, your focus should be on heat consistency and structural integrity.

For a gas range, fire up every single burner. The flame should be a steady blue with a small yellow tip. A large, lazy yellow flame points to an air mixture problem that needs servicing.

With convection ovens, the fan is everything. Does it spin freely and quietly? Any rattling or scraping sounds could mean the motor bearings are shot. One of the worst and most expensive problems is a cracked heat exchanger. While it can be tough to spot, look for any visible cracks inside the oven cavity or signs of soot around the burner compartment.

Warewashing Equipment Inspection

A commercial dishwasher is a workhorse, but the combination of high heat, water pressure, and chemicals means it can wear out fast without proper maintenance. When inspecting one, the motor should be your primary concern.

Listen carefully as it runs through a cycle. A low, consistent hum is good; a high-pitched whine or a clattering sound spells trouble for the motor or wash pump. Check all spray arms to make sure the nozzles are clear and that they spin freely—clogged nozzles mean poor cleaning.

Also, inspect the interior for lime and scale buildup. Heavy scaling is a dead giveaway that the previous owner didn't descale the unit, which can lead to clogged lines and heating element failure down the road.

Before finalizing any purchase, it's wise to evaluate the equipment's potential for future issues and know your options for reliable restaurant equipment repair.

Deciding between used and new equipment involves weighing several factors, from upfront cost to long-term reliability. The right choice depends entirely on your budget, risk tolerance, and business needs.

Here’s a table to help you compare the key considerations side-by-side:

Used vs New Equipment Purchase Considerations

| Factor | Used Equipment | New Equipment |

|---|---|---|

| Upfront Cost | Significantly lower, typically 30-70% less than new. | Full retail price; a major capital expense. |

| Depreciation | Much slower depreciation as the initial drop has already occurred. | Depreciates quickly, especially in the first year. |

| Warranty | Rarely includes a warranty, sold "as-is." | Comes with a manufacturer's warranty for parts and labor. |

| Reliability | Variable; depends on past usage, brand, and maintenance. | High reliability with no prior wear and tear. |

| Availability | Immediately available for pickup or delivery. | May involve lead times for shipping or custom orders. |

| Energy Efficiency | Older models are often less efficient, leading to higher utility bills. | Modern units are built to current energy standards. |

| Repair History | Often unknown, potential for hidden issues. | No repair history; brand new components. |

Ultimately, a brand-new machine offers peace of mind with a warranty, while used equipment provides an opportunity for significant savings if you perform a thorough inspection and choose wisely.

For a complete overview of what to look for across all kitchen areas, our https://encoreseattle.com/blogs/seattle-restaurant-equipment/commercial-kitchen-equipment-checklist is an invaluable resource.

The All-Important Electrical Check

No matter the equipment, a basic electrical check is essential. Look closely at the power cord and plug for any fraying, cracking, or signs of melting. Damaged cords are a serious fire hazard and must be replaced immediately.

If you're comfortable and know how to do it safely, bring a multimeter. You can use it to test for continuity and verify that electrical components are getting the correct voltage. This simple step can uncover hidden electrical faults that a power-on test might miss, saving you from a dangerous and expensive surprise later. A little diligence here makes all the difference.

How to Negotiate Your Best Price

Finding the right piece of used equipment is half the battle. Getting it for the right price? That’s where the real win is. Negotiation isn’t just about haggling; it's a strategic conversation where what you know matters just as much as what you say. A smart approach can turn a good deal into a great one.

The homework you did during your inspection is about to pay off big time. Every single flaw you spotted—that worn-out gasket, a rattling fan motor, a patch of surface rust—is now a point of leverage. This isn't about being nit-picky; it's about being honest about the total cost you're about to inherit.

Turn Your Inspection Findings into Leverage

When it's time to make an offer, don't just pull a number out of thin air. You need to back it up. Frame your offer around the specific issues you found, showing the seller you're a serious buyer who has done their due diligence.

A real-world conversation might go something like this: "The unit seems solid, but I did notice the door gaskets are shot. It's going to cost me about $150 for a new set, not to mention my time to install them. With that in mind, I can offer you $800 cash today."

See the difference? This approach is transparent, fair, and incredibly difficult to argue against. You've anchored the entire negotiation in cold, hard facts.

By connecting your offer directly to specific, provable issues, you change the dynamic. It’s no longer just about price—it’s about the equipment's actual condition. This makes your offer far more credible and persuasive.

Master the Art of the Bundle Deal

Sellers, especially those closing down a restaurant, are often motivated by one thing above all else: convenience. Their main goal is to clear out the space quickly with as few headaches as possible. This is a massive opportunity for you.

Let's say you came for a convection oven, but you spot a couple of stainless steel prep tables and some wire shelving you could also use. Don't negotiate for each piece individually. Propose a bundle.

An offer like, "Look, I'll take the oven, both of those prep tables, and that wire rack off your hands right now for one price," is music to a seller's ears.

They're often willing to offer a much bigger discount on a package deal because it saves them the time and effort of dealing with multiple buyers. For them, it's more cash and less hassle, all in one go. It’s a classic win-win that experienced buyers lean on all the time.

Understand the Seller’s Motivation

Every seller is in a different situation, and if you can figure out why they're selling, you gain a serious advantage. Is it a dealer with a packed warehouse, or a frantic owner who needs to be out by Friday?

- Liquidation Sales: In a liquidation, time is the enemy. The seller is almost always up against a hard deadline and is highly motivated to move inventory. You can be more aggressive with your offers here because their main objective is to clear the floor.

- Upgrading Owners: A chef who's just swapping out an old model for a new one isn't in a rush. They can afford to wait for the right price. In this case, your negotiation should be less about speed and more about the equipment's fair market value and condition.

- Dealers: A used equipment dealer lives and breathes this stuff. They know the market, and lowball offers will just get you laughed out of the warehouse. The best approach is to be respectful, lean on your detailed inspection notes, and look for bundling opportunities. Knowing what you might need down the road is key; having a complete restaurant kitchen equipment list handy can help you spot those package deals.

Managing Logistics and Installation Like a Pro

You’ve found the perfect piece of equipment and negotiated a great price. It feels like the hard part is over, but don’t celebrate just yet. Getting that heavy, often awkward gear from the seller to your kitchen and installed correctly is a huge hurdle that can trip up even seasoned operators.

This final stretch is about more than just finding a truck. Commercial kitchen equipment is a beast—it’s heavy, oddly shaped, and surprisingly fragile. I’ve seen deals go south fast because a multi-hundred-pound convection oven was dropped or a delicate compressor got rattled into oblivion during transit. Suddenly, that bargain becomes a very expensive paperweight.

This is where you seriously consider calling in the pros. For the heavy lifting and careful placement of your investment, it's often worth looking into specialized commercial moving services. These teams show up with the right tools—pallet jacks, lift gates, furniture dollies—and the know-how to maneuver your gear without damaging it or your property.

Pre-Installation Checks You Cannot Skip

Before that equipment is even loaded onto the truck, you need to pull out your tape measure and get familiar with your local building codes. The absolute worst time to find out your new six-burner range needs a different gas line is when it’s already sitting in the middle of your kitchen floor.

I once heard about a chef who got an incredible deal on a top-of-the-line ventilation hood at an auction. He was thrilled. He arranged for delivery, and the crew brought it in, only for him to discover it was three inches too tall to clear a major ceiling joist. That one oversight cost him thousands in unexpected structural work, completely erasing his initial savings.

Don't let this be you. Measure your doorways, hallways, and the final installation spot. Then, do it again. Make sure you account for clearance space for ventilation and maintenance access.

Utility Hookups and Code Compliance

Beyond just fitting in the space, you have to be certain your building can actually power the thing. This part is non-negotiable and requires a bit of homework. I recommend making a simple checklist for every major piece you buy.

- Electrical Specs: Does it need a 110V, 208V, or 240V outlet? Is it single-phase or three-phase power? A mismatch here can mean calling in an electrician for expensive rewiring.

- Gas Connections: What kind of gas does it take—natural or propane? And what size is the connection line? Your building's gas infrastructure has to be able to handle the BTU load safely.

- Plumbing and Drainage: For anything that uses water, like dishwashers, ice machines, or steamers, you need to map out where your water lines and floor drains are. Check that the connections are accessible and compliant with local health codes, especially for things like backflow prevention.

This level of detail is becoming more important every day. The used restaurant equipment market is growing fast—it’s projected to jump from USD 7.7 billion in 2025 to over USD 15.3 billion by 2035. As more kitchens opt for used gear, mastering these logistical details gives you a real edge.

When it's time for the final hookup, always bring in a qualified technician. They know the local codes inside and out, can perform a final safety check, and will make sure everything is calibrated to run perfectly from the start. It’s a small price to pay to protect your investment and ensure your kitchen runs safely and efficiently.

Common Questions on Buying Used Equipment

Even with the best game plan, jumping into the used equipment market can leave you with some nagging last-minute questions. That's a good thing—it means you're thinking like a smart business owner. Keeping informed about industry trends and the latest news will help you navigate this process with confidence.

I've been in this business a long time, and the same few concerns always pop up. Let's walk through them so you can move forward with the confidence you need to score a great deal.

Can I Get a Warranty on Used Restaurant Equipment?

This is probably the number one question I hear, and the answer really comes down to where you're buying.

If you’re picking up a fryer from another restaurant that’s closing down or scrolling through Facebook Marketplace, it’s almost certainly going to be "as-is." That means what you see is what you get, no take-backs.

Reputable used equipment dealers, on the other hand, are a different animal. Many of us stand behind the gear we sell and offer warranties—usually for 30 to 90 days—that cover critical parts and labor. A dealer willing to offer a warranty is putting their reputation on the line, showing they’re confident in their refurbishment process. For a piece of equipment that's the lifeblood of your kitchen, like a walk-in cooler, that peace of mind is worth every penny.

What Are the Best Brands to Buy Used?

When you’re buying used, a trusted brand name isn’t a luxury; it’s a necessity. You need equipment built like a tank, but just as importantly, you need to know you can find parts for it down the road.

Stick with the tried-and-true industry workhorses. I’m talking about brands like:

- Hobart for mixers and dish machines

- Vulcan for your ranges and ovens

- True for rock-solid refrigeration

- Rational for combi ovens

These guys build equipment to withstand the daily grind of a commercial kitchen. Plus, they have massive service networks. That means when something eventually breaks—and it will—you can find a tech who knows the machine and can actually get the parts. A cheap, off-brand piece might look good on paper, but it becomes a very expensive paperweight when you can't fix it. For a deeper look at sourcing reliable pieces, you can find valuable insights on finding used restaurant equipment in Seattle and apply those same principles no matter where you are.

A well-known brand name isn't just about prestige; it's a practical insurance policy. It ensures your equipment is serviceable, which is a critical factor for the long-term health of your kitchen operations.

How Do I Know if the Price Is Fair?

Figuring out a fair price takes a bit of legwork, but it saves you from overpaying. A solid rule of thumb is that a well-maintained piece of used equipment should go for about 40-60% of its current new price. Of course, that number will fluctuate based on its age, condition, and brand recognition.

Before you even think about making an offer, do your research. Search the model number online. See what other dealers are listing it for. Check out completed listings on auction sites to see what similar units actually sold for.

This gives you a realistic price range to work with. And don't forget to mentally subtract the cost of getting it to your restaurant and any immediate repairs you know it's going to need.

Is It Better to Buy Refurbished or As-Is?

This one really boils down to your tolerance for risk versus your budget.

Refurbished equipment from a dealer has been put through its paces. It's been inspected, deep-cleaned, and any shot components have been replaced by a professional. Yes, it costs more upfront, but the risk is significantly lower, and as we discussed, it often comes with a warranty.

"As-is" equipment from an auction or a private seller is your cheapest route, but you're buying all of its problems, too. If you’re a pro at fixing equipment yourself (or have a tech on speed dial), you can find some incredible bargains. For most restaurant owners, though, refurbished is the smarter, safer bet—especially for anything that could shut down your entire line if it fails.

At Encore Seattle Restaurant Equipment, we believe outfitting your kitchen shouldn't break the bank. We provide chefs and restaurateurs with access to premium new and used equipment, expert advice, and flexible financing to help you build the kitchen of your dreams on a budget that makes sense. We also help restaurant owners and chefs discover the latest news and exclusive deals on restaurant equipment and supplies. Discover our inventory and see how we can help your business thrive by visiting us at https://encoreseattle.com.