A Complete Guide to the Size of Under Counter Fridge

Share

When you're fitting out a commercial kitchen, every inch of space is prime real estate. Undercounter refrigerators are designed to slide perfectly under standard countertops, which generally means they stand between 34 to 36 inches high. The width is where you'll see the most variety, with common sizes spanning 24 to 60 inches to accommodate single, double, or even triple-door units.

Decoding Standard Undercounter Fridge Sizes

Picking the right undercounter fridge goes way beyond just adding more cold storage. It's a key decision that can make or break your kitchen's workflow. Think of these units not just as appliances, but as foundational building blocks for a more productive, efficient kitchen. Their dimensions aren't random; they're meticulously engineered to create a seamless, modular workspace.

This thoughtful design is what allows you to tuck a unit right under a prep station or service counter. You gain crucial refrigerated storage without sacrificing an inch of your valuable work surface. Our goal is to help restaurant owners and chefs stay informed about industry trends, and that starts with cutting through the technical jargon to give you a practical feel for how these numbers translate to a real-world kitchen.

Why Standard Dimensions Matter

In a high-pressure kitchen, consistency is everything. Standardized equipment sizes make planning your layout a thousand times easier. When your fridge is built to a common height, it aligns perfectly with your other gear, creating a smooth, ergonomic line for your staff. No more awkward gaps or uneven surfaces to slow down the rush.

Across the foodservice industry, undercounter fridges have settled into a few dominant footprints. In North America and Europe, you’ll find most units fall between 24 and 60 inches wide. The 48-inch and 60-inch two- and three-door models are especially popular on busy restaurant lines.

Standard heights almost always hover around 34–36 inches, a perfect match for typical worktops. This lets the refrigerator pull double duty as extra counter space when things get tight. Depths usually stick between 24–32 inches, which is shallow enough to meet most ADA and corridor clearance rules while still being deep enough to hold full-size sheet pans.

A Quick Look at Common Sizes

To help you get started, let’s break down the typical dimensions you’ll see when you're shopping around. Knowing these ranges will help you measure your space with confidence and choose a unit that fits like a glove.

- Height: The sweet spot for most units is between 34 and 36 inches (roughly 864-914 mm). This ensures they slip right under a standard 36-inch high commercial countertop.

- Width: This is the most variable dimension. You’ll find models at 24", 36", 48", 60", and even 72" (approx. 610-1829 mm). A compact, single-door unit is often 24 inches, while a 60-inch model might have two doors and a bank of drawers.

- Depth: Most undercounter fridges are between 24 and 32 inches deep (approx. 610-813 mm). This keeps them flush with your countertops, so they won't stick out and obstruct busy walkways.

For a deeper dive into how these sizes translate to different kitchen setups, you can explore more about commercial refrigerator sizes.

To make things even clearer, here’s a quick reference table summarizing the key dimensions.

Quick Guide to Standard Undercounter Fridge Sizes

This table breaks down the most common external dimensions for commercial undercounter refrigerators, giving you a baseline for planning your space.

| Dimension | Common Range (Inches) | Common Range (Millimeters) | Key Consideration |

|---|---|---|---|

| Height | 34" – 36" | 864 – 914 mm | Designed to fit under standard 36-inch high countertops. |

| Width | 24" – 72" | 610 – 1829 mm | Varies by capacity and number of doors/drawers. |

| Depth | 24" – 32" | 610 – 813 mm | Ensures the unit sits flush with surrounding cabinetry. |

These standard sizes are the foundation, but the right choice always comes down to your specific operational needs. By matching these dimensions to your available space, you can make sure your new equipment boosts your kitchen's productivity from day one.

Why Ventilation Space Is Non-Negotiable

Ever seen your kitchen staff during a full-blown dinner rush? An undercounter fridge needs to breathe just like they do. Squeezing a unit into a cabinet with no airflow is a recipe for disaster—it's inefficient, stressful, and leads straight to burnout. Honestly, overlooking ventilation is one of the most common and costly mistakes I see people make.

When a refrigerator can't get rid of the hot air its compressor churns out, it has to work overtime just to keep things cold. This constant strain doesn't just send your energy bills through the roof; it puts massive pressure on all the critical parts and drastically shortens the lifespan of your investment. It’s a fast track to those dreaded mid-service emergency repair calls that were completely avoidable.

The good news? Preventing this is simple. It all boils down to understanding how your specific unit is designed to cool itself.

Front-Breathing vs. Rear-Breathing Models

Think of a refrigerator's ventilation system like its lungs. Where those lungs are located dictates exactly how and where you can install it. Every commercial undercounter fridge is either a front-breathing or rear-breathing model.

-

Front-Breathing Units: These are the superstars of built-in kitchen design. Their intake and exhaust vents are right on the front grille, usually just below the door. This smart setup lets them pull in cool air and push out hot air entirely from the front, meaning you can slide them right in between other equipment or flush against a back wall. No side or rear clearance needed.

-

Rear-Breathing Units: These models have their cooling coils and vents on the back. To get rid of heat, they rely on having open space behind and around the unit. While they're often a bit friendlier on the wallet, you absolutely cannot box them into tight cabinetry without leaving some serious breathing room.

Picking the right one is crucial. A front-breathing unit offers total flexibility, making it perfect for a packed bar station or a tight prep line where every inch is prime real estate. A rear-breathing model, on the other hand, demands careful planning to give it the space it needs to do its job.

Key Takeaway: Proper airflow is the single most important factor for an undercounter fridge's performance and longevity. Front-breathing models are built for zero-clearance installations, while rear-breathing units need plenty of space to avoid overheating and failure.

Calculating Your Total Installation Footprint

Once you know which type of ventilation your unit has, you have to add its required clearance to your measurements. This "breathing room" is not optional—it's a critical part of the fridge's true footprint.

For any rear-breathing model, the manufacturer’s spec sheet is your bible. If you can't find it, a safe rule of thumb is to plan for:

- 1-2 inches (25-50 mm) of space on both sides.

- 3-4 inches (75-100 mm) of clearance at the back.

This air gap is what allows the compressor to shed heat effectively so the unit can run without struggling. Forgetting to factor in this space is just asking for a fridge that runs hot, eats up electricity, and dies an early death.

Proper equipment spacing is foundational to a well-run kitchen. For a broader look at this topic, you can learn more about general commercial kitchen ventilation requirements. Respecting these clearances ensures your equipment works the way it was designed to, protecting your investment and keeping your ingredients perfectly chilled.

Your Practical Measurement Checklist Before Buying

There's nothing worse than the delivery truck showing up with your shiny new undercounter fridge, only for it to not fit. It’s a completely preventable headache, but one that can halt your workflow, waste precious time, and cause a world of frustration. To sidestep this nightmare, you need a solid measurement plan that goes way beyond just the basic width, height, and depth of the opening.

Think of this as your pre-flight check before investing in a key piece of equipment. A few extra minutes with a tape measure now will save you from days of installation delays and the pain of a return. This checklist will walk you through every critical point, from the delivery route to hidden gotchas, making sure your installation goes off without a hitch.

Step 1: Measure the Core Space Accurately

First things first, let's nail down the dimensions of the space where the fridge will live. Don't just take one measurement and call it good—commercial kitchens, especially in older buildings, are famous for not being perfectly square.

- Measure Width in Three Places: Check the width at the very top, the middle, and the bottom of the opening. Always, always use the smallest measurement of the three. Even a quarter-inch difference can be the reason a unit won't slide in.

- Measure Height Twice: In the same way, measure the height from the floor to the underside of the counter on both the left and right sides. Again, stick with the shortest measurement. Uneven floors can throw off your vertical space more than you'd think.

- Measure Depth Carefully: Check the depth from the back wall to the front edge of the neighbouring cabinets. Be sure to account for any plumbing or electrical conduits running along the back wall that might eat into your usable depth.

Step 2: Account for Hidden Obstacles

Now, it’s time to play detective. The most common installation problems pop up from things that are easy to miss on a quick first glance. These hidden obstacles can completely torpedo your plans if you aren't looking for them.

A perfect fit on paper means nothing if you can't physically get the unit into the building. Always check your delivery path—doorways, tight corners, and stairwells—before you even click "buy." An extra inch of clearance can be the difference between a smooth delivery and a logistical nightmare.

Keep a sharp eye out for these potential roadblocks:

- Plumbing and Gas Lines: Are there any water lines, drain pipes, or gas connections running along the floor or snaking up the back wall? Measure their exact position to ensure they won't clash with the fridge's body or feet.

- Electrical Outlets: Pinpoint the exact location of the power outlet. The fridge’s cord needs to reach it easily without being stretched taut or crushed against the wall. Double-check that the outlet type (a NEMA 5-15R is standard) and voltage match what your new unit requires.

- Baseboards and Trim: That decorative molding along the floor or trim around the cabinet opening can steal precious fractions of an inch. Make sure your measurements are taken from the narrowest points, inside any trim.

Step 3: Plan the Delivery Path

Finally, you need to map out the fridge’s entire journey, from the delivery truck's ramp to its final home under the counter. This is the step everyone forgets—until the delivery crew is stuck in a hallway.

Measure the width of every single doorway, hallway, and tight corner on the path. Now, compare those numbers to the crated dimensions of the fridge, which you can find on the spec sheet. The crated size is always bigger than the unit itself, and it’s the number that really matters for getting it through the door.

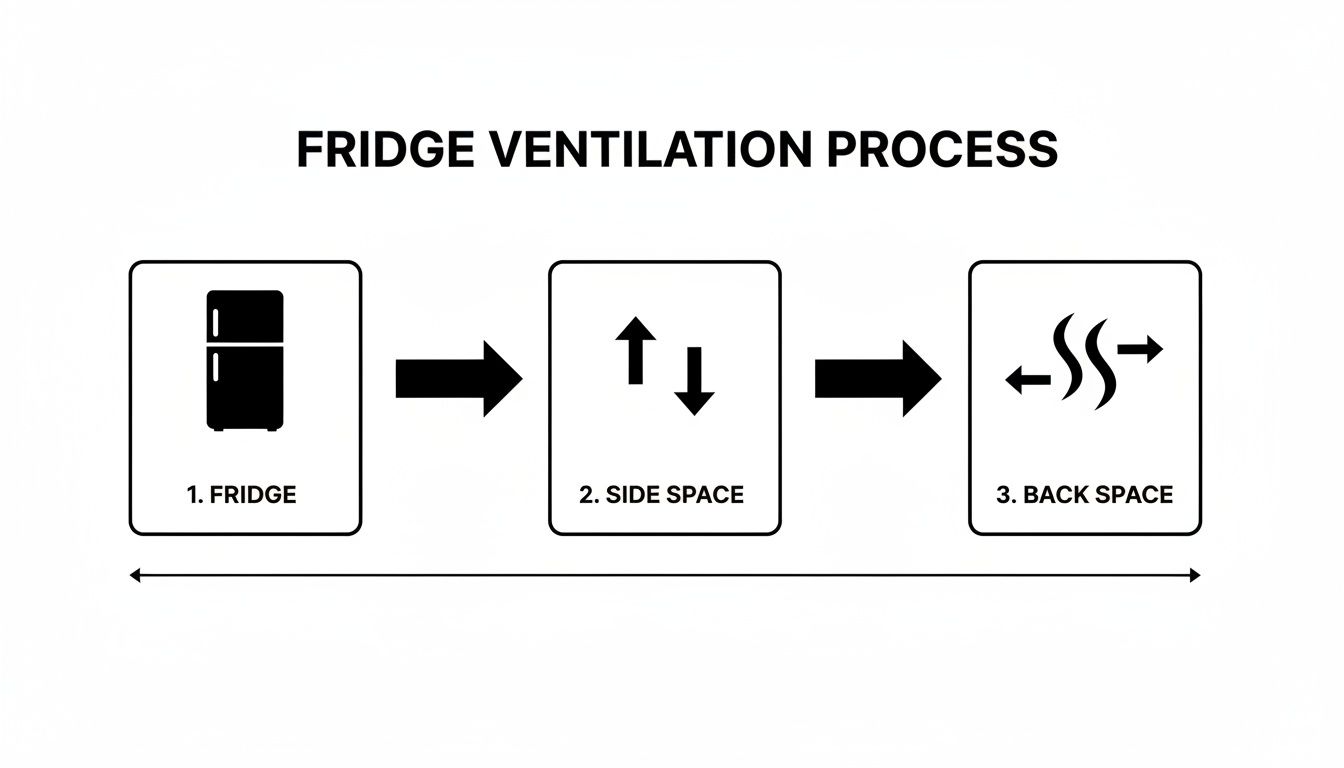

Once the unit is in place, you also have to think about the space around it for proper airflow, as this diagram shows.

This just drives home the point that after making room for the fridge itself, you still have to factor in that all-important side and back clearance. For rear-breathing models, giving the unit room to breathe isn't just a suggestion—it's critical for it to work properly.

Matching Fridge Size to Your Kitchen's Workflow

Finding the perfect undercounter fridge isn't just about what fits into a gap in your cabinetry—it's about what fits into your kitchen's rhythm. A unit that’s too small will create frustrating bottlenecks, while one that’s poorly configured will absolutely slow down your team. True efficiency comes from matching the fridge’s dimensions and features directly to the specific tasks happening at that station.

Think of your kitchen as a finely tuned machine, where each piece of equipment is a critical gear. The goal is to pick a gear that meshes perfectly with the others, turning smoothly to keep the whole operation moving. A mismatched undercounter fridge is like a gear with the wrong teeth; it causes friction, stalls progress, and ultimately disrupts your entire workflow.

This decision is more than a simple purchase; it's a strategic investment in how well your business runs. For operators choosing the right size and configuration, global data shows a direct link between capacity planning, revenue, and compliance. The commercial undercounter refrigeration market is projected to grow from USD 11,402.25 million in 2024 to USD 15,014.58 million by 2032. This growth is happening because these units let kitchens pack more essential cold storage into the same linear footage of a cook line—a massive advantage in high-cost real estate markets. You can discover more insights about this growing market and how it's shaping modern kitchen design.

Choosing the right unit means understanding the unique demands of your specific operation. Let's break down some common scenarios.

Undercounter Fridge Sizing Recommendations by Use Case

The table below offers a quick guide to help you match the right fridge to your business needs, ensuring you get the features that will actually help your staff, not hinder them.

| Business Type | Recommended Width (Inches) | Key Features | Primary Use |

|---|---|---|---|

| High-Volume Bar | 24 to 48 | Glass doors, adjustable shelving, LED lighting | Quick access to bottles, mixers, and garnishes |

| Busy Café | 24 | Solid door, durable top, proximity to espresso machine | Storing milk, cream, and alternative dairy products |

| Sandwich/Salad Prep | 48 to 60 | Drawers for food pans, combination door/drawer models | Organized access to portioned prep ingredients |

| Pizza Prep Line | 60 to 72 | Integrated refrigerated pan rail on top, bulk storage below | Holding toppings at arm's reach and storing dough/cheese |

| Catering/Flex Kitchen | 48 | Heavy-duty casters for mobility, solid doors | Mobile cold holding for prepped sheet pans and bulk items |

Ultimately, the best choice aligns perfectly with the day-to-day tasks your team performs, turning a simple appliance into a cornerstone of your kitchen's efficiency.

Sizing for High-Volume Bars and Cafés

For a bustling bar, speed and visibility are everything. Bartenders need to grab bottles, garnishes, and mixers without missing a beat. The right fridge here is all about rapid access.

- Recommended Size: A 24 to 48-inch width is usually the sweet spot. A single-door 24-inch model is great for smaller stations, while a two-door 48-inch unit can easily serve a busy main bar.

- Key Features: Glass doors are non-negotiable. They let staff see what they need before opening the door, cutting down on search time and keeping service flowing. Look for adjustable shelving to handle all your different bottle heights.

A café has similar needs but for a different inventory. Baristas need milk, cream, and oat milk right now. A 24-inch solid door unit is typically perfect, tucked right beside the espresso machine to minimize steps and keep the drink line moving.

Recommendations for Sandwich Shops and Prep Lines

In a sandwich or salad prep station, organization is the name of the game. It’s less about seeing everything at once and more about having prepped ingredients perfectly sorted and within arm's reach.

Drawers are the unsung heroes of the prep line. They transform a standard undercounter fridge into a highly organized cold station, allowing cooks to pull exactly what they need without rummaging through a crowded shelf. This simple feature can dramatically increase speed and reduce food waste.

For these spots, drawers are almost always better than doors. They let you neatly organize portioned ingredients in food pans, which cuts down on cross-contamination and makes inventory checks a breeze.

- Recommended Size: A 48 to 60-inch model gives you the space you need for a good variety of ingredients. A 60-inch unit might even have a combination of doors and drawers, giving you bulk storage on one side and organized pans on the other.

- Key Features: Consider refrigerated prep tables that have integrated pan rails on top with refrigerated storage below. Solid doors or drawers are best here to maintain consistent temperatures, since they aren't opened nearly as often as a bar fridge.

Specialized Units for Pizza and Catering Operations

Pizza prep lines have their own unique needs. The whole workflow centers on a specific set of toppings that have to be held at safe temperatures. A refrigerated pizza prep table is the purpose-built solution, combining a workspace with specialized cold storage.

These units are sized based on their pan capacity—that is, how many standard food pans they can hold in the refrigerated rail. The undercounter section provides bulk storage for dough, cheese, and sauce. A 60 to 72-inch model is a common sight in high-volume pizzerias.

Catering businesses, on the other hand, need flexibility above all else. An undercounter unit on casters becomes a mobile cold-holding station that can be rolled wherever it’s needed most. A 48-inch solid door model is a versatile workhorse for holding sheet pans of prepped food before it goes out the door.

By choosing the right size of under counter fridge for your specific workflow, you're not just buying an appliance; you're investing in a more efficient, less stressful, and more profitable operation.

Why Bother With an Undercounter Fridge? It's All About Strategy.

In any commercial kitchen, profitability is a game of inches. Real estate isn't getting any cheaper, and kitchens are getting smaller and smarter. Every square foot has to earn its keep. This is where undercounter refrigeration has gone from a nice-to-have appliance to a core piece of modern kitchen design.

These compact units aren't just for convenience anymore; they're a strategic investment. Picking the right size of under counter fridge is a serious business decision that hits your workflow, food safety, and ultimately, your bottom line. It’s about squeezing every last drop of efficiency out of the space you already have.

More Than Just a Cold Box

Think of an undercounter fridge as a way to break up your cold storage and put it right where the action is. Instead of your line cooks constantly trekking back and forth to the big walk-in, ingredients are right at their fingertips—under the prep counter, on the cook line, or beneath the bar. It sounds like a small change, but the ripple effect is huge. It slashes ticket times and speeds up service.

This idea of strategic placement is exactly why these units are booming. The global undercounter refrigerator market was valued at around USD 3.42 billion in 2024, with most of that demand coming from restaurants, bars, and cafes. The trend is especially big in North America and Europe, where you have a ton of restaurants packed together and tough food safety regulations that encourage keeping ingredients close to where they're used. If you're curious about the data, you can learn more about the undercounter refrigerator market findings.

An undercounter fridge isn't just about saving space; it's about saving steps. In a busy kitchen, saved steps translate directly into faster service, less staff fatigue, and higher table turnover—all of which boost profitability.

The right-sized unit lets your team work smarter, not harder. A fridge dedicated to a salad station can get rid of a major bottleneck. A glass-door model at the bar helps a bartender find what they need in a split second. This is how you get a real, tangible edge over the competition.

A Smart Investment in Efficiency

Yes, there's an upfront cost to a commercial undercounter fridge, but you're really investing in long-term efficiency and a more resilient operation. When you smooth out the flow of your kitchen, you cut down on waste, make your dishes more consistent, and create a much less chaotic workplace for your staff. And this focus on efficiency doesn't just stop at the kitchen door.

For businesses that distribute appliances, like Encore Seattle, getting the right equipment to the right place on time is everything. Their entire operation relies on a solid understanding logistics management principles. It’s what ensures a restaurant gets its new fridge without a hitch, keeping the whole foodservice supply chain moving.

When you start looking at your undercounter fridge as a strategic tool, the investment makes perfect sense. It’s not just a box that keeps things cold. It’s a workflow optimizer, a space saver, and a key ingredient for building a leaner, more profitable restaurant in a tough market.

Finding Your Perfect Fit with Encore Seattle

Okay, you've got the essentials down. We’ve covered everything from standard dimensions and why ventilation is so important, to a measurement checklist and how to match a unit to your kitchen's unique workflow. Getting the right size of under counter fridge isn't just a purchase; it's a direct investment in your daily efficiency and future success.

Here at Encore Seattle, we’ve been helping businesses in the Pacific Northwest make that investment with confidence since 1990. We know the ins and outs of what local restaurants, bars, and cafés need to thrive, and we're here to help you discover exclusive deals on the restaurant equipment and supplies that drive your business.

Partnering with a Local Expert

Our team can offer real, hands-on advice that’s specific to your operation, making sure the unit you get is the right tool for the job. We're not just here to move boxes; we're here to build partnerships that help you grow. Our experts can walk you through different models, like the ones in our guide on the Atosa undercounter refrigerator, and help you find what truly works for your space and budget.

Choosing the right equipment partner is as crucial as selecting the equipment itself. A local supplier with industry expertise can offer invaluable guidance, from initial selection to installation and beyond, ensuring you get the most from your investment.

Feel free to give us a call with any questions or swing by our showroom in Seattle’s Sodo District to see the units for yourself. We can also show you how our flexible financing options can make that much-needed kitchen upgrade happen without breaking the bank. Let's find you the perfect undercounter fridge—one that will be a workhorse for your business for years to come, backed by people who know their stuff.

Common Questions We Get About Undercounter Fridges

Even with all the specs laid out, there are always a few lingering questions that pop up just before you pull the trigger on a new unit. These are the practical, real-world details that can make or break an installation. Getting these right is often the final piece of the puzzle.

Think of this as the last-minute gut check. We'll walk through the common "what ifs" and "should Is" that operators ask us all the time, from mobility to the classic doors vs. drawers debate.

How Do Casters Affect Fridge Height?

This is a big one, and it’s an easy detail to miss. If you want your undercounter unit to be mobile, you’ll be adding casters (wheels), and that’s going to lift the whole thing up. You can typically expect casters to add anywhere from 2 to 4 inches to the total height.

That might not sound like much, but it’s a deal-breaker if you’re trying to slide it under a standard 36-inch countertop. A fridge that's 34 inches tall on its legs won't fit once you add 3-inch casters. Always, always check the spec sheet for the "height on casters" measurement and measure your counter clearance before you buy.

Glass Doors vs. Solid Doors: What's the Energy Difference?

The choice between glass and solid doors is more than just about looks—it directly hits your utility bill. Solid doors are the clear winner for energy efficiency. They’re packed with insulation and do a much better job of holding a consistent temperature, which is why they’re the standard for back-of-house prep lines where temperature stability is everything.

Glass doors look great and are fantastic for letting staff quickly see what's inside, especially at a busy bar. But that convenience comes at a cost. Glass just isn't a great insulator, so the compressor has to kick on more often to keep things cool. Over time, that adds up on your energy bill, particularly if the door is being opened constantly.

Our Take: It's a classic trade-off. Weigh the operational need for visibility (glass) against long-term energy savings and rock-solid temperature control (solid). For storing ingredients, solid is almost always the smarter move. For front-of-house or high-speed bar service, the visibility of glass often justifies the extra running cost.

When Should I Choose Drawers Instead of Doors?

Drawers are all about workflow and speed, especially on a busy prep line. You should go with drawers when a specific station is all about assembly—think sandwiches, salads, or pizzas. They’re designed to hold standard food pans, giving your cooks immediate, organized access to prepped ingredients.

Instead of a cook opening a door and rummaging around on a shelf, they just pull a drawer and grab what they need. This setup is a massive time-saver, keeps the line moving, and helps you keep a close eye on inventory. While a standard door gives you more flexibility for storing bulky items, nothing beats the efficiency of drawers for high-volume, repetitive prep tasks.

Ready to find the undercounter fridge that truly fits your space and workflow? The experts at Encore Seattle Restaurant Equipment have spent decades helping kitchens in the Pacific Northwest find the right gear. We’re here to give you personalized advice, keep you informed on the latest industry trends, and provide competitive pricing to help your business thrive.

Explore our collection and find the perfect fit for your operation at https://encoreseattle.com.