Boost Your Pizzeria with a Pizza Dough Roller Machine

Share

Imagine your pizzeria on a Friday night. The tickets are piling up, and the whole operation grinds to a halt at the very first step: hand-stretching the dough. This is the exact moment a pizza dough roller machine goes from a "nice-to-have" to an absolute necessity, turning a production bottleneck into a smooth, efficient workflow. Stay informed about industry trends and discover exclusive deals on essential equipment like this to keep your kitchen ahead of the curve.

Why a Dough Roller Is Your Pizzeria's Secret Weapon

Think of a pizza dough roller as your most reliable, consistent, and tireless kitchen hand. It’s an investment in control. This machine takes one of the most physically demanding and repetitive jobs in the kitchen and automates it, making sure every single pizza base comes out exactly how you want it, every single time. As industry trends move towards greater efficiency, savvy restaurant owners and chefs are turning to automation to gain a competitive edge.

When you hand off the manual labor of stretching dough, you immediately gain three huge advantages: speed, consistency, and a break on labor costs. This isn't just about making dough faster; it's about making your entire kitchen run better.

The Power of Automation and Consistency

At its core, a dough roller is a powered rolling pin, but it works with a level of precision that no person can maintain for an entire shift. It gently flattens and stretches dough balls into perfectly uniform circles or sheets, getting rid of all the little inconsistencies that happen when people get tired.

This kind of consistency means every pizza cooks evenly, has the same bite, and lives up to the standard your customers expect. It also frees up your skilled kitchen crew from a tedious job, letting them focus on what really matters—crafting perfect topping combinations and ensuring quality. You end up with a happier team and a better pizza.

You can see the impact of this kind of efficiency across the entire food industry. The global market for dough equipment, which includes these rollers, was valued at a massive USD 228.96 billion in 2024. This isn't just a random number; it's a key industry trend that shows how much businesses are relying on automation. North America alone accounts for over 35% of that market. For a restaurant owner in a busy spot like Seattle, a dough roller can cut prep time by as much as 50% compared to doing it all by hand. That's a serious edge during the dinner rush. You can dig deeper into these trends on Congruence Market Insights.

Scaling Your Operations Effortlessly

It doesn't matter if you're running a food truck, a catering business, or a full-scale restaurant—you have to be able to scale up when demand hits. A pizza dough roller is exactly what lets you meet that demand without sacrificing quality or scrambling to hire more people just to prep dough.

A dough roller removes the single biggest bottleneck in pizza production. It empowers your business to handle a sudden rush of orders with ease, turning what could be a crisis into a major moneymaker.

With one of these machines, you can:

- Boost Output: Start churning out hundreds of perfectly consistent pizza bases every hour, easily keeping pace with even the craziest dinner rush.

- Cut Down on Food Waste: Uniform dough thickness means no more burnt edges or soggy centers, which saves you money on ingredients.

- Simplify Training: A new hire can learn to use a roller in just a few minutes. Compare that to the weeks it takes to get someone truly good at hand-stretching.

Choosing The Right Type Of Dough Roller

Picking the right pizza dough roller machine isn't about finding the "best" one, but the best one for you. It's a decision that needs to match the unique rhythm of your kitchen. Think of it like a chef choosing a knife—what works for a delicate task is different from what you need for heavy-duty prep. The right roller depends on your daily volume, how much counter space you have, and the kind of pizza you're famous for.

Let's break down the main types of dough rollers out there. Each is built to solve a specific problem, whether it's cranking out pies during a crazy dinner rush or fitting neatly into a tight food truck kitchen. Understanding the core differences will help you pick a machine that truly works for you, not against you.

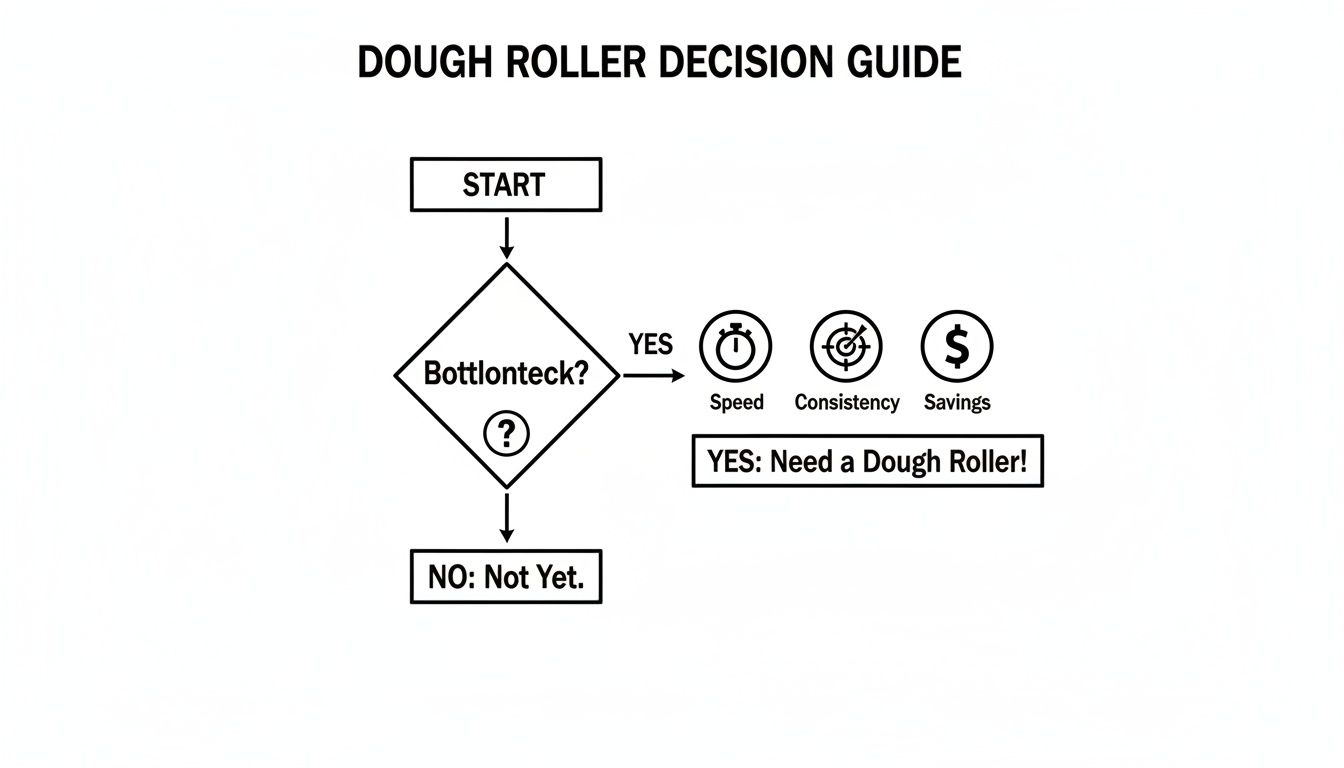

This flowchart can help you think through whether a roller is the right move to tackle speed, consistency, or cost issues in your kitchen.

As you can see, if you're hitting a wall with production, a dough roller is a direct solution for getting orders out faster, ensuring every pizza is the same, and saving money in the long run.

To make the choice even clearer, let's compare the main types side-by-side.

Comparing Pizza Dough Roller Machines

This table gives you a quick snapshot of the main types of pizza dough rollers, helping you see at a glance which one might be the best fit for your kitchen's needs, output, and layout.

| Machine Type | Best For | Key Feature | Average Output (Pizzas/Hour) | Space Requirement |

|---|---|---|---|---|

| Single-Pass Roller | Low-volume cafes, food trucks, flatbreads | Simple, one-motion flattening for ovals/rectangles | 50-75 | Minimal |

| Double-Pass Roller | High-volume pizzerias, consistent round crusts | Two-step process for perfectly round bases | 200-250 | Moderate |

Ultimately, the choice comes down to volume and shape. If you need speed and perfect circles for a classic pizza menu, the double-pass is your go-to. For more varied shapes or lower volume, the single-pass is an efficient, space-saving option.

Single-Pass Dough Rollers

The single-pass dough roller is the sprinter of the kitchen. It uses one set of rollers to flatten a dough ball in a single, quick motion, usually resulting in an oval or rectangular sheet. The design is simple, efficient, and super easy for any staff member to learn.

These machines are a perfect match for:

- Lower-volume spots: Think cafes, small bakeries, or restaurants where pizza is just one part of a larger menu.

- Other doughs: They're great for focaccia, flatbreads, or calzones where a perfect circle isn't necessary.

- Tight spaces: Their smaller footprint makes them ideal for crowded prep areas or food trucks.

Double-Pass Dough Rollers

For any serious, high-volume pizzeria, the double-pass machine is the undisputed champion. It has two sets of rollers, usually set at a 90-degree angle. The dough goes through the first set, gets flattened, then is fed through the second set to produce a perfectly round, consistent base in just a few seconds.

This is the machine you need when your main goal is cranking out pies as fast as possible without losing quality. A busy pizzeria can easily produce up to 250 pizza bases per hour with a double-pass roller—something a team of chefs couldn't hope to match by hand. That's the kind of power that gets you through the Friday night rush without breaking a sweat.

A double-pass roller is more than just a piece of equipment; it's a production engine. It automates the sheeting process to give you the same crust every single time, which is key for consistent cooking and predictable food costs.

Material and Construction Considerations

Beyond the roller type, you have to look at what the machine is made of. The materials directly affect how well it performs and how long it will last in a demanding kitchen. Pay close attention to the rollers themselves.

- Stainless Steel Rollers: These are built to last. They're tough, easy to sanitize, and won't rust or corrode. For a busy kitchen that prioritizes food safety and durability, this is the gold standard.

- Synthetic Rollers: Often made from a non-stick resin, these rollers are designed to keep dough from sticking. This means you can use less flour, which is a big help when working with delicate or high-hydration doughs.

The body of the machine should be just as tough, usually made from heavy-duty stainless steel that can take a beating. Don't forget that a great roller needs a great workspace. To create the most efficient pizza station, check out our guide on choosing the best Atosa pizza prep table to complete your setup.

Calculating Your Return on Investment

Let's move past the features and specs for a moment and talk about what really matters to your business: the bottom line. A pizza dough roller machine isn't just another line item on your expense sheet; it's a strategic investment that actively generates revenue. When you start thinking of it that way, the financial upside of automating your dough prep becomes crystal clear. For chefs and restaurant owners tracking the latest industry news, understanding the ROI of new equipment is paramount.

Figuring out its return on investment (ROI) doesn't have to be a complicated spreadsheet exercise. By looking at a few key areas, you can build a simple but powerful case for how this machine pays for itself, often much faster than you’d expect.

The Three Pillars of Dough Roller ROI

The financial magic of a pizza dough roller really boils down to three things: saving on labor, making more money, and wasting less food. Each one of these directly fattens up your profit margin. Let's break down how this plays out in a real pizzeria.

First up, direct labor savings. Hand-stretching dough is slow, physically tough work that requires a skilled touch. When you automate this step, you free up your most valuable people to focus on higher-value tasks like saucing, topping, baking, and making sure every pizza that goes out is perfect.

A mid-range dough sheeter can plow through about 100kg of dough per hour. Compare that to the 20kg a skilled employee might get through manually. That's a five-fold jump in productivity from one machine.

This efficiency means you’re either spending less on wages or you’re able to move that labor to where it counts—improving service speed and keeping customers happy.

Boosting Revenue During Peak Hours

Next, let's talk about increased production capacity, because that directly ties to your revenue. Think about a Friday night dinner rush. How many potential sales have you lost simply because the kitchen couldn't stretch dough fast enough? A dough roller completely eliminates that bottleneck.

When you can crank out hundreds of consistent pizza bases per hour, you can serve more customers, slash wait times, and truly maximize your earnings when you're busiest. Just imagine being able to sell an extra 10 pizzas during a peak weekend shift. That adds up to a serious, easily measurable revenue boost over the course of a month.

This is more important than ever. The global dough sheeters industry, valued at USD 2.5 billion in 2023, is booming as restaurant owners scramble for efficiency to fight rising costs. Here in the U.S., which accounts for 23.5% of that market, automating your dough prep can cut manual labor by 60%. That’s a game-changer when you're staring down 10-15% annual foodservice inflation. You can dig into more of this data over at Dataintelo.com.

Reducing Waste and Improving Consistency

Finally, a dough roller dramatically cuts down on food waste. Inconsistent hand-stretching inevitably leads to thin spots that burn and thick spots that are undercooked, which means pizzas end up in the trash. A machine, on the other hand, gives you a perfectly uniform base every single time.

This consistency delivers a few key benefits:

- Predictable Cook Times: Every pizza bakes evenly, guaranteeing a great product for your customers.

- Lower Ingredient Costs: Fewer screw-ups mean less wasted dough, sauce, cheese, and toppings.

- Standardized Portions: You get precise control over your food costs, which is absolutely vital for profitability.

Thinking about the long-term financial benefits is the right approach. It’s similar to how you might weigh the pros and cons of cabinet refacing vs refinishing for a kitchen project—you’re balancing the upfront cost against the long-term savings and value it brings.

And the benefits go beyond just the numbers. You’re also removing a physically draining task from your kitchen, which boosts staff morale and reduces the risk of repetitive strain injuries. This lets your talented chefs save their energy and creativity for what they do best, elevating your entire menu and cementing your reputation for quality.

Mastering Your Machine for the Perfect Crust

Getting the most out of your pizza dough roller machine is about more than just reading the manual. It's about developing a feel for how your dough interacts with the equipment. This is your hands-on guide to mastering that process, so you can turn out an incredible, artisan-quality crust every single time.

We'll walk through the pro tips that seasoned chefs swear by, starting with the most critical step: prepping the dough before it even sees the rollers. Things like temperature and proofing time aren't just minor details—they're the entire foundation of your final product. Stay informed about these best practices to get the most from your restaurant equipment and supplies.

Preparing Your Dough for Success

The path to a perfect crust starts long before you hit the 'on' switch. Seriously, the condition of your dough is the single most important factor in how well the machine will work for you. Think of it this way: the roller is just a tool, but your dough is the canvas. A cold, stiff dough is going to fight the machine every step of the way, which can lead to tears or a tough, overworked texture.

For the best results, your dough needs to be cool but not ice-cold, and properly proofed. This ensures it's relaxed and pliable, ready to be shaped without putting up a fight. Rushing this stage is a rookie mistake that even the most expensive machine can't fix.

"A dough roller is just a powered rolling pin. Just like the rolling pin in your kitchen. Just like the one your grandma uses to make pizza...if you're looking for a crackery thin pizza of uniform thickness...then a dough roller is your best bet."

This gem from pizza expert Alberto DeCicco really hits the nail on the head. The machine is a tool for precision, but it can only work with dough that's ready for it. A good rule of thumb is to let your dough rest for at least 30 minutes after balling to let the gluten relax.

Dialing in the Perfect Thickness

One of the biggest wins of using a dough roller is the dead-on consistency. This isn't just for looks; it means every single pizza cooks evenly from edge to center. Getting comfortable with the adjustment settings is how you'll unlock the ability to offer a whole range of pizza styles.

Here's a quick cheat sheet for different crusts:

- Thin Neapolitan-Style: For that delicate, crispy-chewy crust, you need a very thin setting. But don't go straight for the thinnest gap. Start wider for the first pass to gently flatten the dough, then narrow the gap for a second pass. This avoids shocking and tearing the dough.

- Classic New York-Style: This calls for a base that's thin in the middle with that iconic, chewy cornicione. Roll the dough to a medium thickness, leaving a slightly thicker border that you can then shape by hand right before you add the toppings.

- Hearty Deep-Dish or Pan Pizza: For these brawny styles, you need a thicker base. A single, slower pass through the rollers on a wider setting will give you a uniform sheet that can handle heavy toppings and a longer bake.

Debunking the "Dough Killer" Myth

You'll sometimes hear purists claim that rollers "kill" the dough, smashing all the delicate air pockets and ruining the gluten structure. While that might have been true with old-school machines and bad technique, modern dough rollers are designed to be much gentler.

The secret is to work in stages. Instead of trying to force a thick dough ball through the thinnest setting in one go, use multiple passes. Start with a wide gap and then progressively make it narrower. This method coaxes the gluten to stretch naturally, preserving those crucial air bubbles that create a light, airy crumb. A well-operated machine doesn't crush the dough; it persuades it into shape.

Quick Troubleshooting for Common Issues

Even with perfect prep, things can go sideways. Here are some quick fixes for the most common headaches you and your kitchen crew might run into.

1. Dough Sticking to the Rollers

- The Cause: Your dough is probably too wet, too warm, or you just need more flour.

- The Fix: Make sure your dough is properly chilled. Give the dough ball and the rollers a light dusting of flour before each pass. If it keeps sticking, your dough recipe might have too much hydration for machine rolling.

2. Uneven or Weird Shapes

- The Cause: The dough ball wasn't perfectly round to begin with, or it was fed into the machine crooked.

- The Fix: Always start with a nicely rounded, centered dough ball. Feed it straight into the rollers so it flattens out evenly. If you're using a double-pass roller, that 90-degree turn between passes is non-negotiable for getting a round crust.

3. Dough Tearing During Rolling

- The Cause: The dough is too cold and tight, or you're getting impatient and trying to thin it out too fast.

- The Fix: Let your dough temper for a few minutes to make it more pliable. And always, always use a gradual, multi-pass approach, reducing the roller gap a little at a time. Trying to rush it is the number one cause of torn dough.

Essential Maintenance and Safety Practices

Think of your pizza dough roller machine as a key player on your kitchen team. Just like any star performer, it needs the right care to keep delivering consistent, high-quality results day in and day out. If you neglect it, you're not just risking a breakdown; you're putting food safety, your staff, and your profits on the line.

Let's walk through the essential cleaning routines and safety rules that will protect your investment and your crew. Getting this right means your machine will run like a dream for years, churning out those perfect pizza bases your customers crave. Keep an eye out for exclusive deals on maintenance supplies to keep your restaurant equipment in top condition.

Your Routine Maintenance Checklist

The secret to a long-lasting machine isn't some complicated trick—it's consistency. By breaking down your maintenance into simple daily, weekly, and monthly tasks, you make it manageable and stop small problems from turning into massive headaches. Staying ahead of issues is always cheaper than fixing them.

For a broader look at keeping all your gear in top shape, check out our complete guide on commercial kitchen equipment maintenance.

Daily Tasks (End of Shift):

- Power Down and Unplug: This is non-negotiable. Before any cleaning starts, make sure the machine is completely disconnected from the power source.

- Scrape and Brush Rollers: Grab a soft, food-safe brush or a plastic scraper and get all that dough residue off. If it dries on there, it'll cause sticking and can even damage the rollers over time.

- Wipe Down Surfaces: With a damp cloth and a mild, food-grade sanitizer, wipe down the entire exterior, especially any surface the dough touches.

Weekly Tasks:

- Deep Clean Removable Parts: Take off any guards, trays, or scrapers that are meant to be removed. Wash them thoroughly, following the manufacturer’s guide.

- Inspect Belts and Gears: Give the drive belts a quick look. Are there any signs of fraying or wear? Is the tension right? Also, listen for any weird grinding noises when it's running.

Monthly Tasks:

- Lubricate Moving Parts: Some models need a little lubrication to keep things moving smoothly. If yours does, apply a food-grade lubricant to the specific points mentioned in the manual.

- Check Electrical Components: Do a quick visual check of the power cord and plug. You're looking for any fraying, cracking, or damage.

A clean machine is a food-safe machine. Proper sanitation isn't just about passing health inspections; it’s about preventing cross-contamination and protecting both your customers and your hard-earned reputation.

Prioritizing Staff Safety and Training

A powerful machine demands a well-trained operator—it's as simple as that. You can't just point someone to the machine and hope for the best. Proper training is the foundation of a safe, efficient kitchen, and every single person who uses the dough roller needs to know it inside and out.

Modern machines come with some great safety features built right in. Make sure your team understands what they are, where they are, and why they're so important.

- Finger Guards: These are the physical shields that keep hands far away from the rollers. They should never, ever be removed or messed with.

- Emergency Stop Button: This is your big red panic button. Every team member should know exactly where it is and be trained to hit it instantly if anything goes wrong.

- Proper Feeding Technique: Show your staff the right way to feed dough into the machine. No forcing it, and definitely no using random objects to push the dough through.

This commitment to reliable equipment is a huge deal across the industry. The global market for bakery processing equipment hit USD 14.81 billion in 2024 and is expected to climb to USD 28.38 billion by 2034, all because kitchens need that consistency and quality. With pizza sales through delivery apps jumping 18% year-over-year, dependable machines like dough rollers are more critical than ever. You can dive deeper into these market trends over at Precedence Research.

How to Purchase and Finance Your New Equipment

Deciding to bring a pizza dough roller into your kitchen is a big move—one that can seriously boost your efficiency. Let's walk through how to make that happen, from picking the right machine to figuring out how to pay for it without tying up your cash. This is where restaurant owners and chefs can discover exclusive deals and the latest news on equipment that drives their business forward.

The first step is moving from online research to seeing the real thing. Reading spec sheets is one thing, but getting your hands on the equipment is a whole different story. That’s the advantage of working with a local supplier like Encore Seattle. You can swing by our Seattle showroom, check out different models, feel the build quality, and ask our team how a particular machine will actually work in your kitchen.

Finding the Right Partner and Equipment

Who you buy from is just as crucial as what you buy. You need a partner who gets the daily grind of the restaurant business and offers more than just a piece of equipment in a box. Here at Encore Seattle, our team knows these machines inside and out. We’ll help you find the perfect new or used model based on your pizzeria's volume, space, and budget.

We'll help you nail down the important details:

- Production Volume: We’ll match your busiest rush with a machine that won’t break a sweat, ensuring you can keep up with orders.

- Kitchen Footprint: Our team will help you find a model that slots right into your prep line without creating a new traffic jam.

- Budget and Goals: Whether you need a top-of-the-line workhorse or a budget-friendly used model, we have options that fit your financial game plan.

Flexible Financing to Preserve Your Cash Flow

A big equipment purchase shouldn’t mean emptying your bank account. Financing is a fantastic tool that lets you get the equipment you need right now, paying for it over time with predictable monthly payments. This keeps your cash free for essentials like payroll, inventory, and keeping the lights on.

Financing transforms a large capital expense into a predictable operational cost, making it easier to manage your budget while immediately benefiting from the new equipment's productivity.

There are a few ways to fund new equipment. When thinking about how to pay for your dough roller, options like a What Is Merchant Cash Advance can give you quick access to capital. We also offer solutions designed specifically for the food service world. To get a better handle on what might work for you, check out our guide to restaurant equipment financing. Our goal is to make your investment smart and straightforward.

FAQs: What to Know Before You Buy a Dough Roller

It's smart to have a few questions before you bring a new piece of gear into your kitchen. Let's walk through some of the most common things we hear from restaurant owners about pizza dough roller machines. My goal is to clear up any doubts so you can feel 100% confident in your decision.

Will a Dough Roller Ruin My Crust?

This is the big one, the number one fear for any serious pizza maker. It’s a totally valid concern. The old myth is that rollers smash the dough, killing all those beautiful air pockets you worked so hard to ferment, leaving you with a dense, cracker-like crust.

While that can happen if you're careless, it’s easily avoided with the right technique. The secret is to think in multiple passes. Never try to flatten a dough ball on the thinnest setting in one shot. Instead, you gently coax the dough into shape by running it through two or three times, slightly narrowing the roller gap with each pass. This persuades the dough to stretch without destroying its internal structure. Done right, you get a beautifully consistent and tender crust every single time, especially for thin and crispy pies.

Can These Machines Handle Tricky Doughs?

They sure can. Modern dough rollers, especially the ones with non-stick synthetic rollers, are built to be versatile. They're actually a huge help with doughs that are a pain to work with by hand.

- High-Hydration Doughs: You know the kind—wet, sticky, and a nightmare to hand-stretch. A roller with synthetic drums makes quick work of them, often with less dusting flour needed to prevent sticking.

- Gluten-Free Doughs: These doughs have no gluten structure to give them stretch, so they tear easily by hand. A roller applies gentle, even pressure to flatten them into a perfect base without ripping them to shreds.

What's the Real Difference Between a Dough Roller and a Sheeter?

Good question. You'll hear the terms thrown around interchangeably, but there is a technical difference. A dough sheeter is usually a much larger machine with a conveyor belt, designed to create huge, continuous sheets of dough for industrial bakeries. A pizza dough roller is basically a compact, specialized sheeter made for one job: turning individual dough balls into round pizza bases, fast.

For just about any pizzeria, food truck, or restaurant kitchen, the "dough roller" is the tool you're actually looking for.

How Much Training Will My Staff Need?

This is one of the best parts—they’re incredibly simple to use. You can get a brand new employee up to speed on the basics in less than 15 minutes.

The learning curve is minimal. Staff quickly learn how to feed the dough, adjust thickness, and follow safety protocols, making it one of the easiest machines in the kitchen to master.

Your training just needs to hit three key points: how to prep the dough for rolling, the multi-pass technique we talked about, and (most importantly) safety. Make sure every single person knows where the finger guards and emergency stop button are and that they are never, ever to be bypassed. With a few minutes of clear instruction, your team can be using it safely and cranking out perfect pizza bases from day one.

Ready to break through your production bottleneck and get more pizzas out the door? The team at Encore Seattle Restaurant Equipment is here to help you find the perfect pizza dough roller for your kitchen and your budget. Check out our selection of new and used equipment online or stop by our Seattle showroom to see these machines for yourself. Discover your ideal dough roller today!