Your Guide to the Atosa Pizza Prep Table

Share

An Atosa pizza prep table isn't just another piece of stainless steel in your kitchen. It's the command center, the very heart of a high-volume pizzeria where refrigerated storage and a dedicated workspace come together. These units are built from the ground up for speed and food safety, letting your crew pump out consistently great pizzas, even when the tickets are flying. Stay informed with our guides and discover exclusive deals on top-tier restaurant equipment and supplies to keep your kitchen ahead of industry trends.

Why Top Pizzerias Choose Atosa Prep Tables

In a slammed pizzeria, every second counts. Every inch of counter space is prime real estate. During a chaotic dinner rush, you need a workflow that's not just fast, but smooth and repeatable. Your team is juggling dozens of fresh ingredients, all needing to be held at a precise, food-safe temperature, while also building pizzas at breakneck speed. This is exactly where an Atosa pizza prep table stops being an expense and starts being a strategic investment.

This piece of equipment is the central hub for pizza making. It’s not just a surface to work on; it's a fully integrated system designed to crush the bottlenecks that slow down service and hurt quality. By combining an efficient workspace with powerful, easy-to-reach refrigeration, it solves the core problems of a high-output kitchen.

The Engine of an Efficient Kitchen

Think of an Atosa prep table as the engine driving your pizza line. Its main job is to bring order to the chaos of creation. Instead of your cooks darting back and forth between a walk-in and a separate prep counter, every single thing they need is right there in one station. This smart design pays off in some huge ways:

- Boosted Speed and Output: When every topping is chilled and within arm's reach, the time it takes to build a pizza drops dramatically. This means your crew can push out more orders during peak hours, which translates directly to more revenue.

- Unwavering Consistency: An organized station makes it easy for your staff to follow recipes to the letter. Every pizza gets made to the same high standard, every single time.

- Enhanced Food Safety: The built-in refrigeration keeps sensitive ingredients like cheese, pepperoni, and fresh veggies out of the temperature danger zone. This is non-negotiable for meeting health codes and serving a safe product.

- Improved Kitchen Morale: A well-designed workspace means less running around and less stress for your team. A happier crew is a more productive crew.

The demand for this kind of efficiency is exploding. The global market for pizza prep tables is expected to grow from USD 1.2 billion in 2023 to a staggering USD 2.3 billion by 2032. That growth is fueled by one thing: the absolute need for hygienic and productive gear in modern kitchens. This trend makes it crystal clear just how vital these units have become.

A Smart Investment in Your Success

Top pizzerias pick Atosa for the same reason a high-tech workshop carefully considers its layout after understanding workbenches with integrated storage—it’s all about workflow and efficiency. Investing in an Atosa unit is a deliberate decision to sharpen your kitchen's operations.

Ultimately, it’s about creating an environment where your team can truly shine, ensuring every pizza that goes out the door reflects your commitment to quality and speed. That's how you turn a first-time customer into a regular for life.

What Makes Atosa Pizza Prep Tables Tick?

When you’re looking at a piece of kitchen equipment, it’s easy to see the surface. But to really understand what makes an Atosa pizza prep table a solid investment, you have to look deeper. It’s not just a refrigerated cabinet with a cutting board on top; it's a purpose-built workstation where every single feature is designed to make your pizza line faster, smoother, and more efficient.

The first thing you'll probably notice is the heavy-duty stainless steel build, both inside and out. This isn't just for show. In a busy kitchen, that steel is your best defense against dents, dings, and the general chaos of a dinner rush. Plus, it's a breeze to wipe down, which is a must for keeping your health inspector happy.

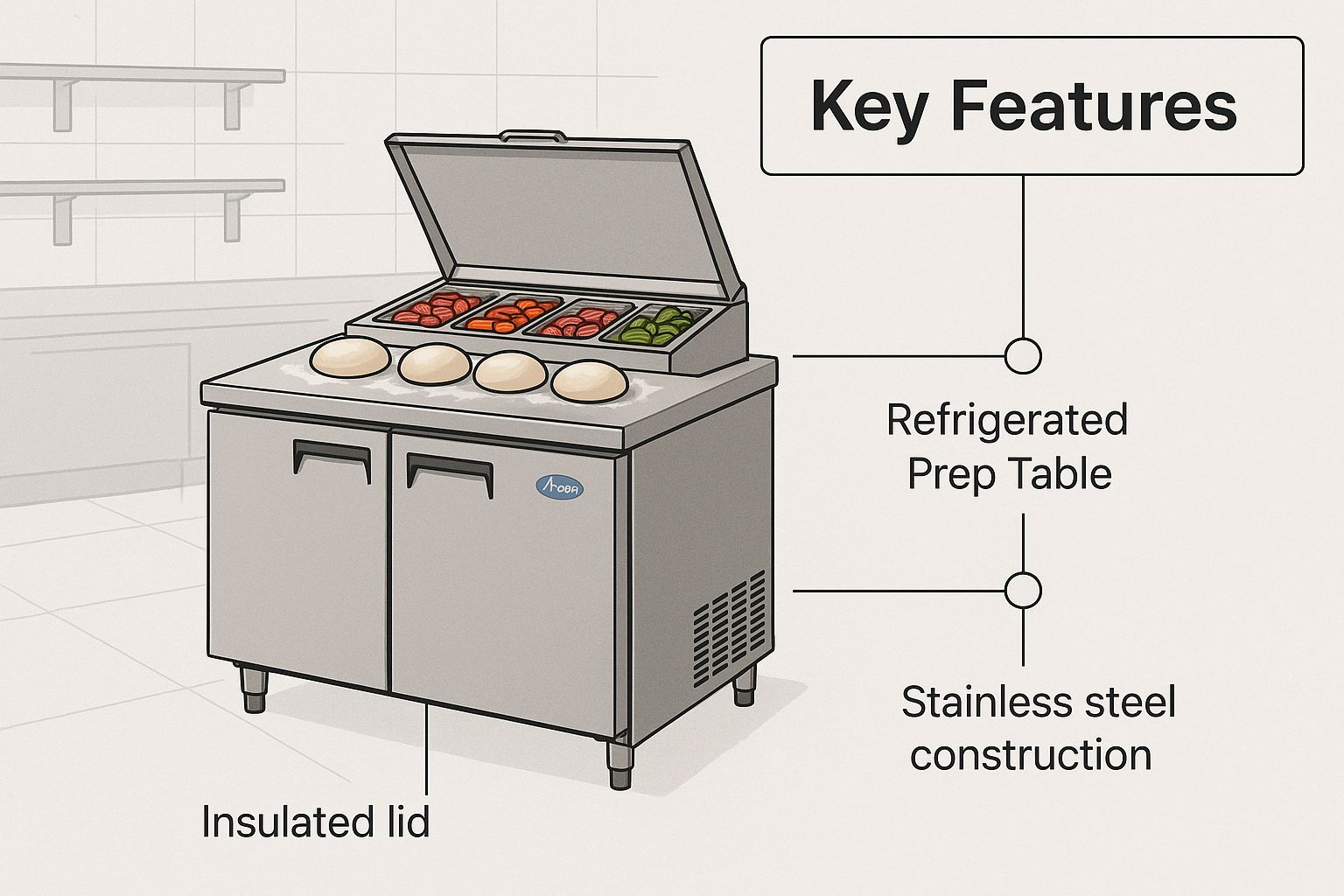

This image really breaks down the core components that make these tables such a workhorse.

As you can see, it's the combination of tough construction, smart cooling, and thoughtful design that makes it a practical powerhouse for any pizzeria.

The Core of Its Performance

Digging a bit deeper, the design choices are all about practical performance. The entire unit is packed with high-density, eco-friendly polyurethane foam insulation. This is a huge deal for two reasons: first, it keeps the cold air locked in for better food safety, and second, it makes the table way more energy-efficient. When cold air doesn't escape, the compressor runs less, and that means lower electricity bills for you.

Then there’s the refrigeration system itself. Atosa tables are engineered to hold a rock-steady temperature between 34°F and 40°F. This isn't just a suggestion; it's a critical range that keeps your cheese, meats, and veggies fresh and safely out of the "danger zone." It’s a key part of protecting both your food quality and your customers.

“The true value of a great prep table isn’t just in its ability to keep things cold, but in how it maintains that temperature consistently during the chaos of a dinner rush. That’s where reliability is truly tested.”

This consistency comes from a forced-air system that blows cold air evenly through the storage cabinet and up into the topping rail. Even when your crew is constantly opening the doors, the system snaps back to its set temperature quickly, ensuring everything stays properly chilled.

Smart Features That Make Life Easier

Beyond the heavy-duty basics, Atosa tables are loaded with features that are genuinely designed to help your team. These are the little details that can make a huge difference in speed and organization when the orders are flying in.

Here’s a quick rundown of some of the standout features and how they help your day-to-day operations.

| Feature | Description | Primary Benefit |

|---|---|---|

| Stainless Steel Construction | The interior and exterior are built with durable, corrosion-resistant stainless steel. | Withstands heavy use in a commercial kitchen and makes cleaning simple. |

| Forced-Air Refrigeration | A powerful system that circulates cold air evenly throughout the unit. | Ensures consistent temperatures for superior food safety and quick recovery. |

| Self-Closing Doors | Doors automatically swing shut but also have a stay-open feature for easy loading. | Prevents energy waste and temperature fluctuations from doors left ajar. |

| Adjustable Shelving | Heavy-duty, PVC-coated wire shelves that can be moved to different heights. | Provides flexible storage for organizing dough boxes, sauces, and backups. |

| Digital Temperature Control | An easy-to-read digital display for monitoring and adjusting temperatures. | Allows for precise control, taking the guesswork out of food safety. |

| Air Curtain System | Creates a "curtain" of cold air over the topping rail when the lid is open. | Keeps ingredients fresh and chilled for longer, reducing food waste. |

These aren't just bullet points on a sales sheet; they are practical solutions to real-world kitchen problems that improve workflow and efficiency.

The Genius of the Air Curtain System

One of the cleverest features is the "air curtain" system for the topping rail. Picture it as an invisible shield of cold air. When you lift the insulated lid during service, this system pushes a continuous stream of cold air directly over the tops of your ingredient pans.

This current acts like a barrier, stopping the warm kitchen air from settling on your toppings. What does that mean for you? Your pepperoni, onions, and cheese stay crisp, fresh, and properly chilled for hours, even during the busiest Friday night. It’s a game-changer for maintaining quality and cutting down on food waste.

Every single element, from the steel shell to the intelligent airflow, is there to help your pizzeria run better. It's a cohesive system designed for durability, efficiency, and real-world use, making it a reliable partner in your kitchen's success.

How to Choose the Right Atosa Model

Picking the right Atosa pizza prep table is a make-or-break decision for your kitchen. This isn't just about finding a spot for a new piece of stainless steel; it's about investing in the very engine of your pizza line. Get it right, and your workflow will be smooth and efficient. Get it wrong, and you’re signing up for constant bottlenecks and frustration during the dinner rush.

Think of it like choosing a delivery vehicle. A small local shop might only need a nimble scooter to handle a few dozen orders a night. But a high-volume hub? They need a fleet of vans to keep pace. It’s the same logic here. The compact 44-inch Atosa is a fantastic fit for a small takeout joint, while a sprawling restaurant with a huge menu will need the massive 93-inch model to survive Friday night.

This piece of equipment is the cornerstone of your kitchen. In the U.S., the pizza industry is a beast, with over 74,000 pizzerias pulling in around $50.1 billion in 2024. For these businesses, the prep table is a non-negotiable investment. In fact, more than 36% of operators rely on them for their combination of organized refrigeration and assembly space. You can dig into the 2025 pizza industry trends to see just how critical the right gear is.

Sizing Up Your Needs

First things first: be honest about your space and your volume. Don't eyeball it. Grab a tape measure and map out your available footprint, making sure to leave enough room for staff to move and for the unit to breathe.

-

The Compact Powerhouse (44-inch Model): This is your go-to when every inch counts. It’s perfect for food trucks, cozy cafes that happen to serve pizza, or takeout-only spots. You'll have enough pan space for the classics—pepperoni, mushrooms, cheese—without sacrificing your entire prep line.

-

The All-Rounder (67-inch Model): For most growing pizzerias, this is the sweet spot. It gives you a serious boost in cold storage and pan capacity, opening the door for a more diverse menu. If you're slinging specialty pies with a dozen different toppings, this size offers the flexibility you need without demanding a massive amount of floor space.

-

The High-Capacity Commander (93-inch Model): This beast is built for war. High-volume restaurants, large-scale catering operations, and pizzerias inside busy venues need this kind of firepower. The huge work surface and massive topping capacity let multiple chefs build pies at once, keeping hundreds of pizzas flying out of the kitchen during peak hours.

Technical Choices That Matter

Beyond pure size, you need to think about the compressor. Where it’s located might seem like a small detail, but it has a big impact on maintenance and your kitchen's layout.

Choosing the right equipment from the start prevents costly operational headaches later. A comprehensive commercial kitchen equipment checklist can guide you through these crucial decisions, ensuring you account for details like compressor placement and ventilation needs.

Understanding this one technical difference will help you make a much smarter long-term investment.

Rear-Mounted vs Side-Mounted Compressors

Let’s break this down. The compressor is the engine of your prep table. Its location determines how you access it for service and how it gets rid of heat.

| Compressor Type | Best For | Key Advantage | Potential Drawback |

|---|---|---|---|

| Rear-Mounted | Kitchens with ample depth. | Creates a sleeker, uninterrupted front profile. | Needs more clearance from the wall for proper airflow. |

| Side-Mounted | Kitchens with limited depth. | Easier to access for cleaning and maintenance without moving the unit. | Adds to the overall width of the unit, taking up more horizontal space. |

For most standard kitchen layouts, a rear-mounted compressor works just fine, as long as you can leave a few inches of breathing room behind it. But if you know your table is going to be wedged tightly between other equipment, the side-mounted model is the only way to go. Its placement ensures the compressor can breathe, preventing it from overheating—a leading cause of equipment failure. It’s a simple choice that can add years to the life of your Atosa prep table.

Getting Your New Table Set Up Right

You've just unboxed your new Atosa pizza prep table. It's a great moment, but what you do next is crucial. Proper setup isn't just about finding a plug; it's about laying the foundation for years of reliable, efficient service. Get it right now, and you'll save yourself a lot of headaches later.

We've seen it all, and these are the real-world steps that'll get your new kitchen workhorse started on the right foot.

Before you even think about electricity, think about logistics. The path from the delivery truck to its final home in your kitchen needs a solid plan. It's a classic mistake: a beautiful new unit stuck in a hallway because nobody measured the door frames. Grab a tape measure, check the unit's dimensions, and walk the entire route.

Finding the Perfect Spot: Pre-Installation Checks

Okay, so you've confirmed the table will actually fit through the door. Now, where do you put it? This decision is bigger than it seems, as it directly affects how well the unit runs and how long it lasts.

First, look down. A fully loaded prep table is seriously heavy. Your floor needs to be perfectly level and strong enough to handle the weight day in and day out. If the floor is uneven, the whole frame can twist, causing doors to hang crooked. That means bad seals, wasted energy, and a compressor that never gets a break.

Next, give it some breathing room. The refrigeration system needs air to work properly. Shoving it flush against a wall is like asking your compressor to run a marathon in a winter coat. It’s going to overheat and wear out fast. Atosa's official recommendation is a minimum of 4-6 inches of clearance around the back and sides. This space is non-negotiable.

Think of it this way: Proper ventilation isn't just a friendly suggestion. It's the single best thing you can do to keep your table cooling efficiently and avoid an emergency service call. Give it space to breathe, and it will give you a longer, healthier service life.

The Power-Up and Calibration Sequence

With your table perfectly placed and ready to go, it’s time to power it on. But hold on—don't start throwing in your pepperoni and cheese just yet. There's a right way to do this.

Follow this simple start-up sequence:

- Let It Settle: After all that moving and jostling, the compressor oil and refrigerant need to settle back into place. Let the unit sit, completely unplugged, for at least an hour. This is a critical step!

- Plug It In: Connect the unit directly to its own dedicated circuit. Seriously, never use an extension cord. They can cause voltage drops that can fry your compressor over time.

- Set the Temp: Fire it up and use the digital controller to set your target temperature. For most pizza prep, that's somewhere between 34°F and 40°F.

- The Empty Cool-Down: Let the unit run completely empty for at least 2-3 hours. You want to see it hit your set temperature and hold it steady. This is your first and most important test of the refrigeration system.

Setting Up Your Ingredient Pans for Success

Once the table is holding a stable temperature, it's time for the pans. How you organize them actually matters for cooling efficiency. It makes sense to put your most-used items, like cheese and sauce, right where they're easiest to grab.

The biggest mistake we see? Overfilled pans. When you mound ingredients high above the rim, you're lifting them right out of the cold air stream. This is a food safety gamble. Keep your toppings level with the pan's edge to ensure they stay in that critical "cold zone," keeping everything fresh and safe.

Taking the time to follow these setup steps will help you sidestep the common pitfalls that can trip up a new Atosa pizza prep table before it even gets through its first service.

A Practical Guide to Cleaning and Maintenance

Your Atosa pizza prep table is a serious piece of kit and the heart of your kitchen's workflow. Protecting that investment isn't about complicated procedures; it’s about building a simple, consistent routine. Think of it as preventative care for your most valuable player on the line. Just a few minutes each day, and a little more once a month, will keep it humming along for years, ensuring top-notch food safety and keeping your energy bills in check.

This guide breaks down the essential tasks into a simple schedule. Follow these steps, and you’ll sidestep the most common equipment failures and keep your unit running as smoothly as the day you unboxed it.

Daily Habits for Peak Performance

The secret to long-term health for your prep table is all about those quick, daily habits. These tasks take just a few minutes at the end of a shift but make a world of difference in stopping grime from building up and keeping everything food-safe.

- Wipe Down All Surfaces: Grab a food-safe cleaner and a soft cloth to clean the stainless steel exterior and interior, the cutting board, and the entire ingredient rail. This stops food debris from sticking around where it can grow bacteria.

- Clean the Door Gaskets: Crumbs, sauce, and other bits of food love to get stuck in the door seals (gaskets), preventing them from closing tightly. This makes the compressor work overtime. A quick wipe-down ensures a good seal, which saves energy and keeps the cold air where it belongs.

A leaky door seal is like leaving a window open with the AC blasting. The system is constantly fighting a losing battle, which means higher energy costs and a lot of unnecessary strain on the compressor.

While keeping your Atosa table spotless is key, it's just one part of the bigger picture. Overall restaurant hygiene, including smart pest management, is crucial for your reputation and health inspections. To learn more, check out this excellent guide to fly control for restaurants.

Weekly and Monthly Deep Cleaning

Daily wipe-downs are your first line of defense, but some parts of the unit need more focused attention on a regular basis. These weekly and monthly jobs keep the core systems of your Atosa pizza prep table in prime condition.

- Weekly Tasks: Pull out all the ingredient pans and give them and the entire topping rail a thorough cleaning. This is also a perfect time to check that the shelving inside the refrigerated cabinet is clean and sitting securely.

- Monthly Tasks: Here’s the big one: cleaning the condenser coil. Over time, this part gets clogged with a nasty mix of dust, grease, and flour, which completely chokes off the airflow.

The Lungs of Your Refrigeration System

The best way to think of the condenser coil is as the lungs of your prep table. Its whole job is to push heat out of the refrigeration system. When it’s caked in grime, it simply can't "breathe" properly. This forces the unit to work way harder to stay cool, kicking off a whole chain of problems:

- Higher Energy Bills: A compressor that’s struggling is a compressor that’s guzzling electricity.

- Poor Cooling Performance: You might find the table can’t hold a food-safe temperature, especially during a busy rush.

- Costly Breakdowns: Overheating is the number one cause of compressor failure, and that’s a very expensive repair.

Cleaning the coil is easy. First, always unplug the unit. Then, just use a stiff-bristled brush to loosen the gunk and a vacuum to suck away all the dust and debris from the fins. Seriously, doing this one thing every month can prevent the vast majority of service calls. For more maintenance tips that apply to similar equipment, our guide on the Atosa sandwich prep table has some great insights.

Simple Troubleshooting for Common Issues

Even with a perfect maintenance schedule, you might run into a small problem here and there. Before you pick up the phone to call a technician, run through this quick checklist if you notice things like temperature swings.

- Check the Power: Is the unit plugged in all the way? Is it on a dedicated outlet?

- Verify Door Seals: Are the doors swinging shut completely, with nothing blocking them?

- Confirm Airflow: Does the unit have enough breathing room? It needs at least 4-6 inches of clearance all around for proper ventilation.

- Inspect the Condenser Coil: Take a look. Is it clean and free of blockages?

More often than not, one of these simple fixes will solve the problem, saving you the money and downtime of a service visit. A proactive approach to cleaning is the best way to protect your investment and ensure your Atosa pizza prep table remains a dependable workhorse for years to come.

How Atosa Stacks Up in a Crowded Market

When you're shopping for an Atosa pizza prep table, you’re stepping into a packed marketplace. You’ve got the heavy hitters, the budget-friendly newcomers, and everything in between. So, where does Atosa fit? It’s not about being the cheapest or the most decked-out unit on the block; it's about hitting that perfect middle ground of performance, reliability, and price.

A good way to think about the commercial refrigeration world is to compare it to the car market. You have brands like True Manufacturing, which are the luxury sedans of the industry—unbeatable build quality, the latest features, and a price tag that reflects it. On the flip side, you have various budget brands that are like basic economy cars. They'll get you from A to B, but you might be sacrificing some long-term reliability and efficiency.

Atosa plants its flag firmly in the dependable, hardworking pickup truck category. It gives you the solid performance and durability you need to get through a busy Friday night without the sticker shock of a premium brand. This makes it a fantastic choice for independent pizzerias, food trucks, and growing restaurants.

Finding That Value Sweet Spot

The commercial kitchen equipment space is no joke. For pizza prep tables, you’ve got major players like True Manufacturing, Turbo Air Inc., Beverage-Air, and Hoshizaki Corporation all competing on everything from a cool new feature to their warranty and service. The market is sliced and diced by unit type, what it’s made of, and the tech inside. If you want to dive deep into the industry stats, you can check out the full market report.

Atosa carves out its space by zeroing in on what most kitchen operators actually need. While some competitors might boast about smart controls you'll never use or complex cooling systems, Atosa sticks to the fundamentals—like high-grade stainless steel and dependable, easily serviced components.

Atosa’s philosophy is pretty straightforward: build durable, efficient equipment that offers incredible value. It’s for the restaurant owner who needs a machine that’s going to show up and work hard, day in and day out.

This focus means you get a prep table that holds its temperature, comes with a strong warranty, and does it all at a price that won’t break your budget. The real win isn't just the upfront cost, but the total cost of owning it over its life. If you're looking for that same practical value in other coolers, our guide on the Atosa freezer shows how the brand delivers quality and affordability across their lineup.

Atosa Pizza Prep Tables vs Competitors

So, how does Atosa really compare when you put it side-by-side with other brands? Here’s a quick look at the major players and where they stand.

| Brand | Key Value Proposition | Typical Price Point | Standard Warranty |

|---|---|---|---|

| Atosa | Best All-Around Value Excellent balance of performance, durability, and affordability. | $$ | 2-Year Parts & Labor, 5-Year Compressor |

| True | Premium Performance Known for top-tier build quality and long-term reliability. | $$$$ | 3-Year Parts & Labor, 7-Year Compressor |

| Turbo Air | Energy Efficiency Focus Strong emphasis on innovative, energy-saving technology. | $$$ | 3-Year Parts & Labor, 7-Year Compressor |

| Budget Brands | Lowest Initial Cost Focused on being the most affordable option on the market. | $ | Varies, often 1-Year Parts & Labor |

Ultimately, Atosa isn't trying to be the flashiest unit on the market. It thrives by offering a dependable, no-nonsense solution. It’s the smart, practical choice for operators who need a workhorse that can keep up with their business without requiring a huge upfront investment.

Got Questions About Atosa Pizza Prep Tables? We've Got Answers.

When you're investing in new kitchen equipment, you're bound to have a few questions. It's only natural. To save you some time, we've put together answers to the most common things chefs and pizzeria owners ask about Atosa pizza prep tables. We're here to help restaurant owners and chefs like you discover exclusive deals and stay informed about the latest news in restaurant equipment and supplies.

What's the Best Temperature to Set It At?

You'll want to keep your Atosa prep table running between 34°F and 40°F. This is the sweet spot for food safety. It keeps all your crucial toppings—cheese, pepperoni, fresh veggies—well out of the temperature "danger zone," ensuring everything stays fresh and safe for your customers.

How Good Is the Atosa Warranty?

Atosa provides a really solid warranty, which speaks volumes about how they build their gear. You get a two-year parts and labor warranty right out of the box, which handles any manufacturing issues.

On top of that, they cover the heart of the machine—the compressor—with a separate five-year warranty. That kind of long-term coverage on the most important component shows they're confident in their product's reliability and gives you great peace of mind.

How Much Space Does It Need to Breathe?

Good question. Proper airflow is non-negotiable for keeping the refrigeration system happy. You need to leave at least 4-6 inches of clear space around the back and sides of the unit. Think of it as giving the machine room to breathe. If you block that airflow, you risk overheating the compressor, which can lead to a costly failure down the road.

Is It Okay to Use an Extension Cord?

Definitely not. Never plug your Atosa prep table into an extension cord. These are powerful commercial units that draw a lot of electricity. An extension cord simply can't handle the load safely and can cause a voltage drop, which is a surefire way to burn out the compressor. Always plug it directly into its own dedicated wall outlet. No exceptions.

Ready to bring this level of performance and reliability into your kitchen? At Encore Seattle Restaurant Equipment, we have a great selection of Atosa models ready to go. Take a look at our inventory and find the perfect prep table for your pizzeria at https://encoreseattle.com.