Expert Guide to Choosing a Modular Ice Machine

Share

As a restaurant owner or chef, staying ahead of industry trends and sourcing the best equipment is vital. This guide not only helps you choose the ideal modular ice machine but also connects you with the latest news and exclusive deals on restaurant equipment and supplies.

Choosing The Right Modular Ice Machine Quickly

When you’re under the pump and need a machine that won’t quit, focus on three essentials: production capacity, footprint, and energy use. These quick checks get you down to a handful of contenders in no time.

Think of these factors as your compass—pointing you straight toward models that match your busiest shifts without wasting space or power.

- Production Capacity: Hit peak service smoothly, without renting extra coolers.

- Footprint: Slide under counters or stack heads when back-of-house real estate is tight.

- Energy Use: Shrink monthly bills and tap into utility rebates.

- Maintenance Ease: Choose designs with front-access panels and simple sanitation hookups.

Key Factors Explained

Before you bolt anything down, here’s a snapshot of why each point matters:

Key Factors for Selecting a Modular Ice Machine

| Factor | Why It Matters |

|---|---|

| Production Capacity | Meet your busiest hour without running out of ice |

| Footprint | Fit machines into narrow service lines or leverage vertical space |

| Energy Efficiency | Lower utility bills and become eligible for rebates |

| Maintenance Ease | Cut cleaning time with accessible water lines and wipe-down surfaces |

Use this overview to weight each decision and narrow your shortlist before diving into specs.

Venue Scenarios In Action

Different venues demand different setups. Here’s how numbers play out on the floor:

- Boutique Bar: 200 lb/day output with a 300 lb bin keeps cocktails moving during happy hour.

- Casual Café: 400 lb/day head and 500 lb storage tackle weekend brunch rushes.

- Banquet Hall: 1,000+ lb/day remote-head system and large off-peak ice bank for back-to-back events.

Of course, numbers are just the start. Double-check your water supply, drainage plan and ENERGY STAR rating (see ENERGY STAR for details) before you sign off.

By zeroing in on capacity, size and efficiency first, you turn a jumble of specs into a straight-ahead shortlist—one that keeps pace with your service today and scales with you tomorrow.

Understanding Market Impact Of Modular Ice Machines

Think of modular ice machines like a stack of Lego bricks: you snap on just the right number of modules to hit your production target. This setup trims upfront costs and keeps you from paying for ice you won’t use.

Different sectors drive the need for varying ice outputs. A small café might run 500 lb/day, while a big hotel easily tops 2,000 lb/day.

Geography plays a role, too. North America commands about 37–38% of the global ice maker market, thanks to large chains and fine-tuned operations. Meanwhile, Asia-Pacific leads in growth as new restaurants and hotels come online.

Growth Drivers And Use Cases

Some businesses plug in extra heads when demand spikes. Imagine a ski lodge adding modules for a busy winter weekend—downtime drops by as much as 25% during rush periods.

- Small Café: Runs a 300 lb head on weekdays, scaling up to 600 lb for weekend brunch.

- Hotel: Uses 4 modular heads feeding a 1,500 lb bin to cover banquet events.

- Healthcare Facility: Swaps in flake-ice heads during flu season to preserve samples.

Recent research shows modular machines are pushing capacity growth in foodservice and hospitality. The global ice maker market sits between USD 3.5–5.3 billion, with North America holding 37–38% share and Asia-Pacific racing ahead in expansion forecasts. Dive deeper into the numbers at Strategic Market Research.

Market Size Comparison For Ice Maker Segments

Here’s how the total ice maker market compares to its modular subsegment:

| Segment | Market Value (USD Billion) | Forecast CAGR (%) |

|---|---|---|

| Total Ice Maker Market | 4.5 | 4.0% |

| Modular Ice Machines Subsegment | 1.2 | 6.5% |

Notice how the modular segment is growing at roughly twice the rate of the overall market.

Regional Adoption Patterns

Different regions lean on module layouts that match local needs:

- North America: Uses stackable heads to boost capacity without expanding footprints.

- Europe: Chooses nugget ice modules for the booming craft-cocktail scene.

- Asia-Pacific: Favors large remote heads paired with high-capacity bins to serve new venues.

This flexibility means operators can redeploy modules across sites, shifting gear for seasonal peaks or major events.

Case Study Example

A popular Seattle café began with a single 400 lb head but added three more modules for summer festivals. Output jumped 300%, and the owner reports an 18% drop in per-pound production costs.

They eased cash flow by phasing purchases with Encore Seattle’s financing options, spreading investment over two fiscal years.

Operational Benefits Summary

- Improved Uptime: Service one module while the rest keep running.

- Budget Flexibility: Stagger capital expenses as you add modules.

- Scalable Energy Savings: Phase in energy-efficient models to tap rebates and lower utility bills.

Use these insights to build a modular ice strategy that fits your venue, budget, and growth plans. Next up, we’ll explore ice types and capacities for various operations.

Comparing Ice Types Capacities And Applications

Choosing between cube, flake, nugget or crystal ice is more than just a matter of preference. The decision shapes everything from a chilled cocktail’s pace to a seafood platter’s freshness. Let’s break down what each style delivers.

Ice Textures And Service Patterns

Cube ice offers those classic square or rectangular blocks. They melt slowly, making them the go-to for cocktails and long pours.

Flake ice falls apart at a gentle touch. It wraps around fish, produce and even lab samples, keeping them cold without damaging delicate flesh.

- Nugget ice is soft and slightly chewy, perfect for soda fountains, iced coffee counters and self-serve stations.

- Crystal ice takes on round or diamond shapes. It’s slow to dilute and shines under glassware—ideal for high-end bars and photo-ready presentations.

Capacity Ranges And Module Pairing

Most modular ice machine heads produce between 50–200 kg per day. Pair them with remote storage bins and you can push that output much higher—up to 500 kg daily in busy venues.

Below is a quick guide to daily output and where each ice type fits best.

Ice Types Capacities and Ideal Uses

| Ice Type | Daily Capacity (kg) | Ideal Use |

|---|---|---|

| Cube Ice | 50–200 | Cocktails and long drinks |

| Flake Ice | 60–300 | Seafood displays and chilling |

| Nugget Ice | 80–250 | Soda fountains and chewable drinks |

| Crystal Ice | 40–150 | Upscale bars and premium presentation |

This table helps you match production capacity to your busiest service windows.

Storage And Sanitation Practices

Ice is only as good as the bin it lives in. A warm, bacteria-rich environment will turn clear cubes cloudy fast.

- Rotate stock every night to avoid thaw-refreeze cycles.

- Wipe down bins weekly with an NSF-approved sanitizer.

- Keep bin temps just above 0 °C to prevent clumping.

Tip: Align your ice type with your menu focus to ensure texture and capacity work in harmony.

On the business side, modular machines represent a substantial slice of the commercial ice category. Analysts peg the segment at roughly USD 1.2 billion, with a 6.5% CAGR across bars, quick-service outlets and healthcare facilities. Learn more in the commercial modular ice maker market report

Combining Ice Types For Versatility

Running two styles at once is more common than you might think. For example, a cocktail bar can serve neat whiskey over cubes while offering nugget ice at the soda station.

- Dual-head setups let teams switch textures without swapping machines.

- Assign one remote bin to flake ice for prep and another for front-of-house service.

- Separate heads simplify cleaning when moving between ice varieties.

Key Takeaways On Ice Selection

- Match ice shape to drink or dish for best texture and performance.

- Size your head and bin to cover peak service without overproducing.

- Stick to a strict rotation and cleaning schedule to keep ice clear.

- Plan modular upgrades so you can add capacity or new ice types later.

Use these points to zero in on the modular ice solution that keeps your service flowing, glass after glass.

Water Quality And Ice Taste

The purest ice starts with good water. Hard minerals, chlorine and sediment all influence clarity and taste.

- Fit a sediment pre-filter to cut down on scale inside your machine.

- Add an activated carbon filter to strip chlorine and off-flavors from your ice.

Clean water not only delights guests—it prolongs equipment life and lowers repair costs.

In the next section, we'll cover sizing calculations and site requirements to make sure your new ice system fits seamlessly into your kitchen workflow.

Sizing And Installation Requirements

Every successful ice program starts with sizing. First, tally your expected guest counts, typical drink pours and busiest service periods. That gives you a clear picture of peak hourly output and daily totals.

Then run a quick three-step formula:

- Estimate Daily Demand by multiplying total covers by average ice use per cover.

- Add an Ice Loss Buffer of 20% to cover melting and waste.

- Select a machine head with at least 10% more capacity than your adjusted total.

Think of it like sizing a fuel tank: you want enough reserve to cruise through rush hours without running dry. Once capacity is set, you can move on to footprint planning and utility hookups before placing your order.

Installation Footprint Essentials

Plan for airflow and maintenance access:

- Side & Rear Clearances: Minimum 2 inches on each side.

- Top Clearance: At least 6 inches above the unit.

- Water Supply: Maintain a steady 20 psi at peak flow.

- Drain Slope: Ensure a 1/4 inch drop per foot.

Keep filters and shut-off valves within 24 inches of the front panel. A simple plumbing diagram will help your installer visualize water inlets and waste lines.

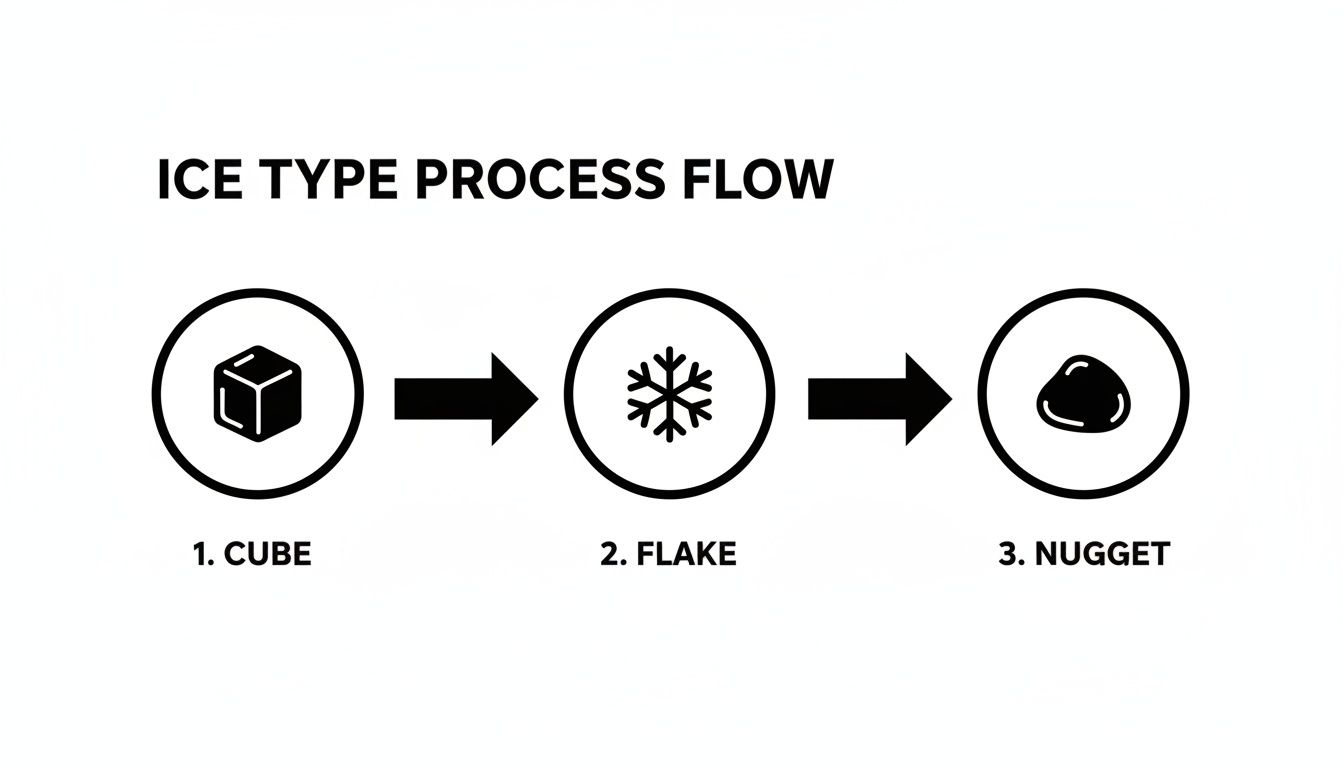

Here’s a process flow infographic illustrating how different ice types progress through modular production.

This graphic highlights the journey from cube to flake to nugget—showing why cube ice holds its shape longest and flake ice melts fastest.

Electrical And Plumbing Requirements

Before installation, verify these key specs:

- Match your electrical voltage to the machine’s rating on a dedicated circuit.

- Confirm NSF-compliant water filtration and cleaning hookups.

- Align drain lines with the correct slope and trap installation.

For tips on choosing the right bin, check out our guide on ice storage bins.

A properly sized machine and planned footprint reduce installation delays by over 30%, says our service manager.

Installation Key Takeaways

Accurate sizing plus clearances mapped out up front means fewer surprises on install day. You’ll hit the ground running with reliable output and simpler upkeep.

Sample Sizing Calculation

Consider a restaurant serving 120 guests on its busiest night, each using 0.8 lbs of ice:

- Base demand: 96 lbs

- With a 20% buffer: 115 lbs

- Choose a machine head rated for 125 lbs daily

Tips for final checks:

- Factor in seasonal spikes like holidays.

- Always confirm specs with a qualified installer.

- Document clearances and utility locations for future upgrades.

One Seattle coffee shop saved $2,000 and avoided a three-day delay simply by verifying footprint and plumbing before installation. With a clear plan, you’ll keep ice flowing and service smooth.

Evaluating Energy Usage And Maintenance Schedules

Operational costs can chip away at your profits faster than you’d expect. Every watt your ice machine draws and every service call you schedule shows up on your bottom line.

Newer refrigerants paired with connected smart controls behave like cruise control for ice production. They throttle back power use, manage defrost cycles on their own and keep everything humming without constant human input.

Energy and refrigerant upgrades are shaking up the modular ice machine market. In fact, Hoshizaki has announced that in 2025 they’ll swap HFCs for natural refrigerants and build IoT energy-saving controls right into their modular lines, slashing greenhouse gas equivalents per kilogram of ice by double-digit percentages. Learn more about these findings.

Energy efficiency improvements don’t just look good on paper—they cut costs from day one and boost resale value down the road.

- Up to 20% reduction in power draw through IoT-driven load management

- Automated defrost cycles that cut manual intervention by 50%

- Compliance with emerging low-GWP refrigerant regulations

- Remote monitoring dashboards that alert you to service needs

Energy Metrics Comparison

A quick look at kWh per 100 kg of ice shows where the real savings live:

| Refrigerant Type | kWh per 100 kg Ice | GWP Reduction |

|---|---|---|

| HFC Model (2018) | 45 kWh | Baseline |

| Natural Refrigerant | 38 kWh | 15% |

| Hybrid Control Model | 40 kWh | 10% |

These figures make it clear: natural refrigerants and smart controls drive energy use down with every batch.

Real World Case Studies

Places that switch to modern modular heads with remote diagnostics often see dramatic results. One bar in Portland, for instance, cut service calls by 40% and added nearly two years to its ice machine’s lifespan.

Remote alerts are like having a technician on call 24/7—it flags small issues before they turn into late-night service emergencies.

Maintenance Calendar And Cleaning Procedures

A simple, repeatable schedule keeps your ice maker in peak condition and prevents unexpected downtime.

- Daily: Inspect water lines and drains for clogs

- Weekly: Sanitize the ice bin and wipe down the evaporator plate

- Monthly: Swap out filters and check refrigerant tubing

- Quarterly: Test the defrost cycle and verify sensor readings

- Annually: Bring in a certified tech for a full preventive tune-up

For detailed cleaning steps, check out our guide on ice machine cleaners and sanitizers.

Troubleshooting Tips

Even with a solid maintenance plan, hiccups happen. Catching them early keeps small glitches from snowballing into big headaches.

- Ice output tanks? Check filter pressure and clear any sediment in pre-filters

- Strange rattles or hums? Tighten loose panels and inspect fan motors

- Temperature errors persist? You might have a refrigerant leak—schedule a check right away

- No ice discharge? Flush the inlet tubing with warm water to clear blockages

“Remote diagnostics turned maintenance from a guessing game into a clear checklist,” says one Seattle chef.

Routine upkeep paired with smart energy controls keeps your modular ice machine running smoothly and lets your team focus on serving guests. By blending connected features with a straightforward maintenance calendar, you’ll maximize uptime without overburdening your staff.

In our next section, we’ll guide you through financing, warranty options, and a decision checklist that seals the deal.

Exploring Financing, Warranties, and Decision Checklist

When you’re budgeting for a modular ice machine, the sticker price is just the opening chapter of your story. You’ll also want to weigh payment structures, manufacturer incentives, and ongoing expenses to get a clear picture of your total outlay.

Financing comes in several flavors—each can be tailored to your restaurant’s cash flow and seasonal demands:

- Leasing spreads the cost over multiple years, keeping monthly payments modest.

- Equipment Loans give you full ownership upfront, with a set interest rate.

- Deferred Payment Plans let you buy now and start payments after a short grace period.

- Vendor Financing often bundles promotional rates or service agreements with the purchase.

Comparing Lease Versus Purchase

Leasing shifts your spend from capex to opex, freeing up working capital for other priorities. Buying with a loan, on the other hand, adds an asset to your balance sheet and builds equity over time. Of course, considerations like buyout fees, residual values, and tax treatments will vary depending on which path you choose.

“Choosing the right payment plan is about balancing immediate budget needs with long-term asset goals,” says one finance manager with years in the hospitality sector.

Unlocking Rebates And Incentives

Energy rebates can make a real dent in your upfront costs—some programs cover 10–30% of the price on ENERGY STAR® certified machines. In Washington state, utilities like Puget Sound Energy run additional incentive programs that reward ultra-efficient models.

- Investigate federal tax credits for high-efficiency equipment.

- Browse state and utility rebate portals to see what’s available in your area.

- Partner with vendors who guide you through the rebate application process.

These savings directly improve your return on investment and shrink your total cost of ownership.

Warranty Tiers And Service Plans

A solid warranty is your safety net when uptime is critical. Most manufacturers start with a 12-month parts-and-labor guarantee. If you want extra peace of mind, extended coverage can stretch from 36–60 months—often in exchange for annual service agreements.

| Warranty Level | Coverage Term | Key Features |

|---|---|---|

| Standard | 12 months | Parts and labor on defects |

| Gold | 24 months | Includes select wear components |

| Platinum | 36–60 months | Priority service and discounts |

Service plans typically bundle scheduled inspections, priority dispatch, and spare-parts discounts. These add-ons help maintain optimal performance under heavy use.

Decision Checklist

- Pin down your budget for both upfront costs and monthly outlays.

- Calculate total cost of ownership—factor in energy, maintenance, and potential downtime.

- Research manufacturer reputation and local service responsiveness.

- Verify rebate and incentive eligibility by region and model.

- Scrutinize warranty details and any optional service agreements.

- Align payment schedules with your cash-flow cycles.

This checklist ensures you cover every financial angle before making a final call.

Negotiation Best Practices

- Ask for volume discounts if you’re ordering multiple units or combining equipment buys.

- Request extended warranty coverage and service credits as part of the deal.

- Secure a guaranteed response time for service calls to minimize costly downtime.

Effective negotiation not only lowers costs today but protects your ROI throughout the machine’s lifespan.

For a deeper dive into loan structures and leasing solutions, check out our guide on Restaurant Equipment Financing.

Always document all agreed terms in writing before you sign on the dotted line.

FAQ

Calculating Capacity Needs

When sizing your modular ice machine, think of your busiest hour like a restaurant’s peak dinner service. Tally guest covers and average ice usage per order to establish both daily totals and that critical one-hour output. This buffer ensures you never run dry when demand spikes.

Cleaning and Sanitation

Routine sanitizing protects both ice quality and customer health. A quick rinse and wipe-down every 24 hours keeps bacteria at bay, while a full system purge and filter swap each month tackles deeper buildup. Simple, consistent care pays dividends in reliability.

Refrigerant Selection and Efficiency

Your choice of refrigerant affects power bills and your carbon footprint. Natural options such as R290 can trim energy use by 10–15% compared to legacy HFC units. Before deciding, run sample calculations and compare:

- Global Warming Potential (GWP) rating

- Energy use in kWh per 100 kg of ice

Financing and Lease Options

Cash flow matters—especially for small operations like food trucks. Many opt for tiered leases over 36 months, spreading payments evenly so the budget stays focused on ingredients and marketing. Some plans even bundle service support, reducing surprise expenses.

Expert Tips

Preventive maintenance keeps you ahead of breakdowns. Weekly drain checks and quarterly gasket inspections often stop small issues before they grow.

“A well-timed sanitation cycle can extend equipment life by up to 20%,” says a Seattle kitchen manager.

Key Refrigerant Stats

| Refrigerant Type | GWP Rating | Energy Use (kWh/100 kg Ice) |

|---|---|---|

| HFC | 1,430 | 45 |

| Natural (R290) | 3 | 38 |

| Hybrid Control | 150 | 40 |

Quick Decision Checklist

- Confirm capacity matches your peak-hour ice demand

- Schedule daily rinses and monthly deep cleans

- Compare refrigerant costs, incentives, and GWP scores

- Align lease or loan terms with your revenue cycle

Monthly inspections—like clearing condenser coils and testing fan motors—help maintain airflow and steady output. Follow these steps, and you’ll choose the right modular ice machine without the guesswork.

Stay informed about industry trends, restaurant equipment insights, and exclusive supplier deals—subscribe to our newsletter for real-time updates and special offers.

Ready to upgrade your ice service? Contact Encore Seattle Restaurant Equipment for personalized recommendations.