A Guide to Ice Machine Cleaners and Sanitizers

Share

Ice is food. That’s not just an industry saying; it's a fact backed by the FDA. Because of this, using dedicated ice machine cleaners and sanitizers isn't just a good idea—it's an absolute necessity for getting rid of the dangerous biofilm, slime, and scale buildup that a simple wipe-down always leaves behind. Stay informed about the latest trends and best practices to keep your kitchen compliant and your customers safe.

Why Your Ice Machine Needs More Than Just a Wipe Down

Think about that humming ice machine in the corner of your kitchen. It's easy to see it as just another utility, but it's one of the most frequently overlooked pieces of equipment and, frankly, a hotbed for health code violations. Health inspectors never forget what many operators do: every single cube of ice that machine produces is food. It has to meet the exact same safety standards as the steak on the grill or the lettuce in the salad.

The inside of an ice machine is dark, damp, and constantly has fluctuating temperatures. It's practically a perfect incubator for microorganisms. If you don't have a dedicated cleaning and sanitizing protocol, you're essentially rolling out the welcome mat for some serious trouble.

The Hidden Dangers in Your Ice Bin

This goes way beyond cloudy ice or an "off" taste. A neglected machine becomes a factory for contaminants that can put your customers' health and your business's future on the line.

- Biofilm and Slime: You can't always see it, but you can sometimes feel it. This slimy layer is a colony of bacteria clinging to surfaces inside your machine. It not only ruins the taste and smell of your ice but also serves as a protective shield for dangerous pathogens.

- Harmful Bacteria: It's not a scare tactic; it's a documented risk. Contaminated ice has been directly linked to outbreaks of Listeria, Salmonella, and E. coli. An incident like that can lead to severe illness, massive lawsuits, and a hit to your reputation that you might never recover from.

- Mold and Yeast: Airborne spores are everywhere, and they love settling in the moist environment of an ice machine. This leads to that tell-tale black or pink mold growth. Serving ice from a moldy machine is a one-way ticket to a failed health inspection.

A failed health inspection due to a dirty ice machine isn't just a slap on the wrist. It’s a public mark against your name that can destroy customer trust in an instant. The cost of a proper cleaner and sanitizer is pocket change compared to the fines and lost revenue.

Let me paint a picture for you. A bartender, rushing during a busy service, scoops ice from a bin where an invisible layer of biofilm has formed. That contamination is now in the customer's drink. A few days later, a case of foodborne illness is traced directly back to your establishment. This is why it's not enough to just clean the equipment; your team has to understand the "why." This is where comprehensive https://encoreseattle.com/blogs/seattle-restaurant-equipment/restaurant-food-safety-training becomes so critical. It empowers your staff to be the first line of defense, shifting your operation from reactive cleaning to a proactive culture of safety where every ice cube is guaranteed to be as safe as it is cold.

Choosing the Right Cleaning Products for Your Machine

Walking into a supply closet and facing a wall of chemicals can feel overwhelming. I've been there. Grab the wrong bottle, and you're not just wasting money—you could be actively damaging expensive components inside your ice machine, leading to some truly painful repair bills. This is your no-nonsense guide to picking the right ice machine cleaners and sanitizers every single time.

Getting this right is a cornerstone of protecting your equipment, your staff, and ultimately, your customers. It all starts with understanding one fundamental difference that trips up way too many operators.

Cleaners vs. Sanitizers: The Critical Distinction

People throw the terms "cleaner" and "sanitizer" around like they're the same thing. In food service, they absolutely are not. They are two different tools for two very different jobs, and you need both. More importantly, you have to use them in the right order.

Think of it this way:

-

Ice Machine Cleaners are all about descaling. Their main job is to break down and remove the mineral buildup—that chalky, white residue also known as scale or limescale—that hard water leaves behind. If you let that stuff build up, it will clog water lines, choke off ice production, and force your machine to work itself to death.

-

Ice Machine Sanitizers have one purpose: to kill the nasty stuff. We're talking bacteria, mold, viruses, and all the other invisible threats. Sanitizing is what gets rid of the slime and biofilm that can lead to serious foodborne illnesses.

You must always clean first, then sanitize. A sanitizer can't do its job if it's trying to kill germs through a layer of mineral scale and grime. The cleaner clears the battlefield so the sanitizer can actually work.

To make this crystal clear, here’s a simple breakdown of what sets them apart.

Cleaner vs. Sanitizer: What Your Ice Machine Needs

| Attribute | Ice Machine Cleaner | Ice Machine Sanitizer |

|---|---|---|

| Purpose | Removes mineral scale, limescale, and slime buildup. | Kills harmful microorganisms like bacteria, mold, and viruses. |

| Chemical Type | Typically a food-grade acid (phosphoric, citric). | Usually a quaternary ammonium compound or chlorine-based solution. |

| Application Frequency | Every 3-6 months, depending on water hardness. | Every 2-4 weeks, or as required by local health codes. |

Remember, these products work as a team. Using one without the other leaves the job half-done, which isn't good enough when it comes to food safety.

How to Read the Label and Make the Right Choice

When you’re looking at different quality cleaning supplies, the label is your best friend. A quick scan for a couple of key identifiers will tell you if you have a safe and effective product.

For Cleaners: Look for "Nickel-Safe"

This is a big one. A lot of high-end commercial ice machines have nickel-plated evaporators. If you use a harsh, generic acid cleaner on these surfaces, it can strip that plating right off, causing permanent, expensive damage. Always, and I mean always, check your machine's manual. If it calls for it, make sure the cleaner you buy is specifically labeled as nickel-safe. This tiny detail can save you from a multi-thousand-dollar mistake.

For Sanitizers: Look for an EPA Registration Number

Any sanitizer worth its salt (and sold legally in the U.S.) will have an EPA (Environmental Protection Agency) registration number printed clearly on the label. This is your proof that the product has been scientifically tested and verified to kill what it says it kills. If there's no EPA number on the bottle, put it back on the shelf. Don't even think about using it in your ice machine.

Key Takeaway: Choosing the right chemicals isn't just a maintenance chore; it's a critical control point in your food safety program. Using an unapproved product can lead to instant health code violations and, worse, put your customers' health on the line.

The demand for commercial ice makers is only getting bigger, showing just how vital they are in the foodservice and hospitality worlds. The global market was valued at USD 3.02 billion in 2024 and is on track to hit USD 3.82 billion by 2032. That growth highlights a huge industry focus on hygiene, making the proper use of cleaners and sanitizers absolutely non-negotiable for keeping customer trust.

Your Hands-On Guide to a Spotless Ice Machine

Alright, let's get down to business. A truly clean, food-safe ice machine doesn't happen by accident. It's the result of a deliberate, systematic process. This isn't just a quick spray-and-wipe; it’s a detailed procedure that protects both your expensive equipment and, more importantly, your customers.

I'm going to walk you through the entire cleaning and sanitizing cycle, from start to finish. I'll even throw in some pro tips I've picked up over the years to make sure no hidden slime or scale gets left behind.

Getting Started The Right Way

Before a single drop of cleaner even touches the machine, safety has to be your first priority. This is completely non-negotiable. It protects your staff, and it protects the machine itself.

- Kill the Power and Water: The very first thing you do is unplug the ice machine from the wall outlet. Then, find the main water supply line that feeds it and shut it off. You should never clean a piece of equipment that's still live.

- Gear Up: Grab your personal protective equipment (PPE). At a minimum, this means waterproof gloves and safety goggles. Ice machine cleaners and sanitizers are powerful chemicals, and an accidental splash can cause some serious skin or eye irritation.

- Empty Everything Out: Get every last cube of ice out of the bin. All of it gets discarded—don't even think about trying to save it. If the machine needs cleaning, you have to assume the ice is contaminated. While you're at it, take a quick look at the drain to make sure it's clear and not backing up.

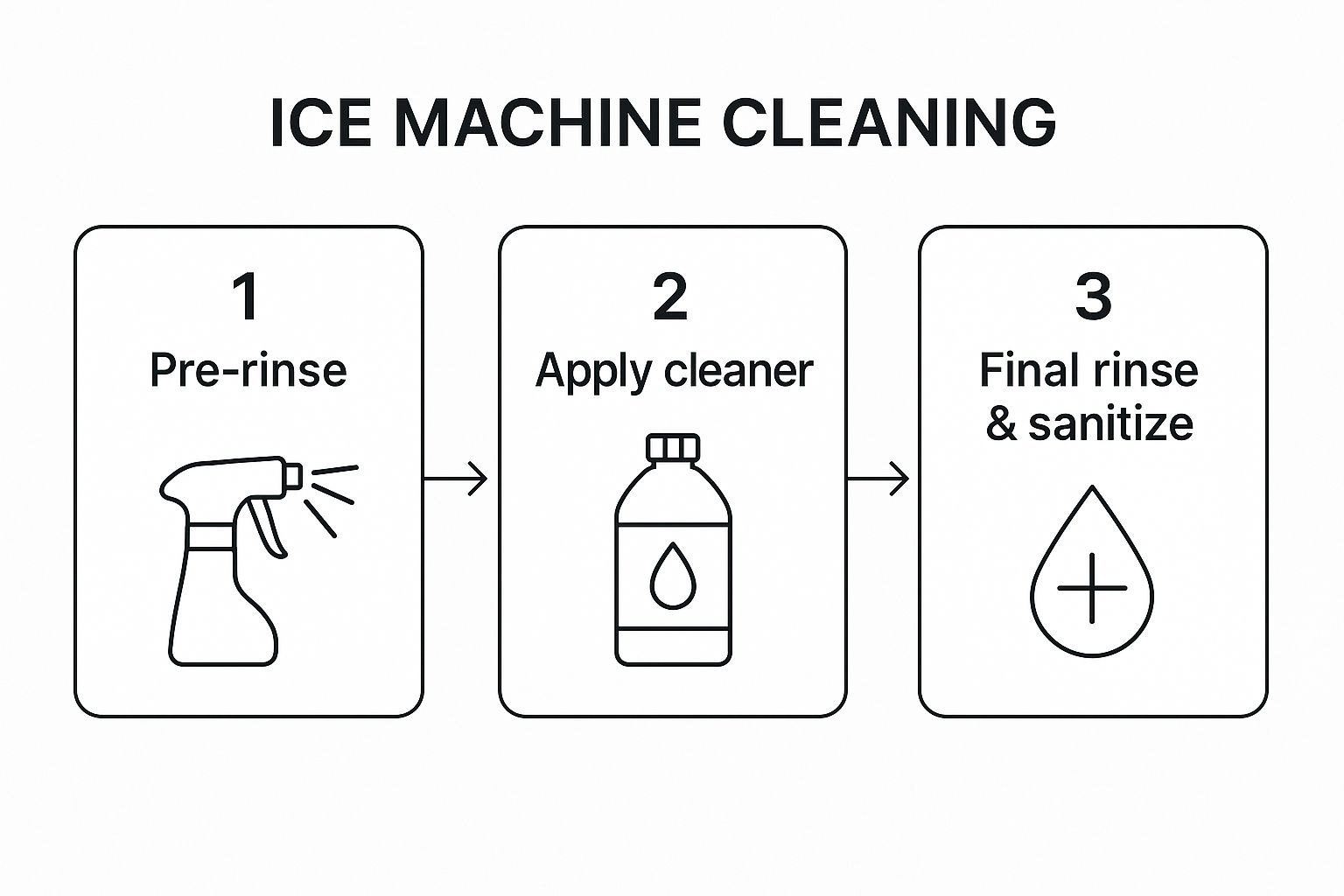

This visual breaks down the core workflow into its three essential stages.

It’s a great reminder that cleaning and sanitizing are two separate but equally important actions. One simply doesn't work without the other.

The Cleaning Cycle: Tackling Scale and Slime

Now that the machine is prepped and safe, you can get into the deep clean. The whole point here is to physically remove the mineral deposits (scale) and that nasty biofilm (slime) from all the internal components.

You'll need to take out the key parts first. Your machine's manual is your best friend here—it'll show you exactly how to remove components like the water curtain, distribution tube, and water trough. These are the parts that see constant water flow, making them magnets for buildup.

Next, mix your ice machine cleaner with warm water, following the manufacturer's directions to the letter. Submerge the parts you just removed into this solution. Using a soft-bristle brush (never, ever use steel wool or an abrasive pad), gently scrub down every surface. A technician I know keeps a small, soft-bristle bottle brush in his kit just for getting inside tubes and tight corners where slime loves to hide.

Pro Tip: While those parts are soaking, take your bucket of cleaning solution and scrub the inside of the machine itself. Give extra attention to the evaporator plate—that's where the ice actually forms—and the walls of the food zone. A thorough scrubbing here is what gets rid of the scale that chokes your ice production.

Once everything is visibly clean, rinse all the parts and the machine's interior with fresh, clean water. This step is absolutely critical. You have to get every trace of the cleaning chemical off before moving on.

The Sanitizing Cycle: The Final Food-Safety Step

Cleaning got rid of the gunk you can see. Sanitizing is what kills the invisible threats like bacteria and mold. This is the final, non-skippable step that makes your ice genuinely safe to serve.

Start by mixing your EPA-registered ice machine sanitizer with water. Again, follow the product's dilution ratio precisely. Reassemble the machine with the clean, well-rinsed parts.

Now it's time to circulate the sanitizer. Go ahead and restore the power and water, then start the machine's "Clean" or "Wash" cycle. When the machine prompts you (and your manual will tell you when), pour the sanitizing solution directly into the water trough. The machine will take over from there, circulating the sanitizer over all the internal components and reaching places you could never get to by hand.

After the cycle is finished, just let the components air dry. Do not rinse the sanitizer off unless the product label specifically tells you to. That thin residual film of sanitizer is what provides ongoing protection against new growth.

Finally, let the machine run through two full ice-making harvest cycles, and be sure to throw away all the ice it produces. This is just to flush any last remnants of the solution from the lines. Following these guidelines is a core part of effective commercial kitchen equipment maintenance that keeps your operation compliant and your customers safe. Now, your machine is officially ready for service.

Building a Cleaning Schedule That Health Inspectors Love

Cleaning your ice machine once in a blue moon just isn't going to cut it. To keep your operation compliant and, more importantly, your customers safe, you need consistency. The difference between a well-run kitchen and one constantly sweating inspections is a proactive, documented cleaning system.

This isn't about guesswork. Building a solid schedule means looking at your unique situation—how hard your machine works every day, the quality of your local water, and what the health department demands. These factors will tell you exactly how often to break out the ice machine cleaners and sanitizers.

Setting Your Cleaning Cadence

A truly effective cleaning calendar is layered. Think of it as a series of small, manageable tasks that prevent bigger problems down the road. By breaking down your schedule, you ensure nothing gets missed and those big deep-cleaning jobs feel less like a massive chore.

A great place to start is to map out daily, weekly, and monthly (or quarterly) responsibilities.

- Daily Checks: These are your quick, five-minute wins. A simple wipe-down of the exterior, the door handle, and the scoop makes a huge difference. Crucially, make sure that scoop lives in its proper holder—never in the ice. It’s a tiny habit that stops cross-contamination in its tracks.

- Weekly Sanitization: This is where you tackle the ice bin and any parts you can easily remove. Slime and biofilm can build up surprisingly fast, especially in a busy kitchen, and a weekly sanitizing run is often the bare minimum to meet health codes.

- Deep Cleaning & Descaling: This is the full works, running a complete cycle with both cleaner and sanitizer. For most establishments, this needs to happen every 3-6 months. But if your area has hard water, you'll likely need to descale more often to fight off the mineral buildup that can kill your machine.

A cleaning log isn't just for you—it's your proof for the health inspector. When they show up unannounced, a detailed log shows you’re on top of your game and serious about food safety. It demonstrates diligence and a real commitment to doing things right.

The market for countertop ice makers is exploding, projected to jump from USD 2.85 billion in 2024 to USD 5.15 billion by 2035. This trend shows just how important accessible ice production has become, and with it, the absolute necessity of solid cleaning routines to prevent contamination, no matter the size of the machine.

A solid schedule is a cornerstone of your food safety plan. If you're looking to build out a more comprehensive system, our guide on what HACCP is and why it matters for food safety is a great resource. To really integrate your ice machine care into your overall workflow and keep things running smoothly, check out these best practices to master equipment maintenance scheduling.

Common Cleaning Mistakes and How to Avoid Them

Even with the best intentions, kitchen crews can slip into bad habits that put food safety at risk or, worse, damage the ice machine itself. Knowing what not to do is just as critical as following the right steps. Let's walk through some of the most common mistakes I’ve seen out in the field and how you can avoid them for good.

First and foremost, never, ever reach for household bleach. I can't stress this enough. It might seem like a quick and cheap way to sanitize, but it's a disaster waiting to happen for your ice machine. Bleach will eat away at plastic components, making them brittle, and it corrodes metal parts over time. The biggest risk? If you don't rinse it out perfectly—and I mean perfectly—toxic residues can end up in your customers' drinks.

Overlooking the Small Details

It’s easy to get tunnel vision and focus only on the inside of the machine. But what about the parts your team touches all day long? These little oversights can quickly turn into major contamination hotspots.

- Forgetting the Scoop: Think about it—the ice scoop is handled constantly. If it isn't being cleaned and sanitized just as often as the bin, you're basically putting germs right back into your fresh ice with every single scoop.

- Neglecting the Bin Door: The handle and the gaskets around the door are total magnets for bacteria. A quick, thorough wipe-down should be a mandatory part of your closing duties. No exceptions.

My rule of thumb is simple: if it touches the ice, or if a hand that touches the ice touches it, treat it like a critical food-contact surface.

Rushing the Process

I get it. Kitchens are chaotic, and time is always in short supply. But cutting corners when you're cleaning the ice machine is a gamble that never pays off. There are two areas where I see this happen most often, and both have serious consequences.

The first is skimping on the rinse cycle. After you’ve used ice machine cleaners to dissolve all that scale and mineral buildup, you have to rinse every single surface thoroughly. Any cleaner left behind will immediately neutralize the sanitizer you use next, making it completely useless. It's like trying to sanitize a dirty countertop—it just doesn't work.

Don’t fall into the trap of thinking cleaners and sanitizers are interchangeable. Cleaners remove the gunk. Sanitizers kill the germs. If you skip the rinse between them, you're only doing half the job and leaving the door wide open for microbial growth.

The second shortcut is forgetting about the water filter. That little filter is your machine's first line of defense, catching sediment and minerals before they ever get inside. When it gets clogged, not only does it force your machine to work harder, but the filter itself can become a breeding ground for bacteria. Every drop of water passing through gets contaminated. Stick to the manufacturer's schedule for checking and changing it. It's a small task that prevents massive headaches down the road.

What's Next for Ice Machine Maintenance?

The restaurant world never stands still, and the technology we use to keep our kitchens safe and running smoothly is evolving right alongside it. When it comes to taking care of your ice machine, the future is all about smarter, more efficient solutions. We're seeing a clear move away from the harsh, old-school chemicals of the past.

This shift is happening for a good reason. More and more, owners and chefs are looking for cleaning solutions that are effective but also non-toxic and eco-friendly. They want ice machine cleaners and sanitizers that are safe for staff, customers, and the environment. The great news is that modern products can deliver a deep clean without leaving aggressive chemical residues behind.

Smarter Tech, Cleaner Ice

It’s not just about the cleaning chemicals, either. The machines themselves are getting a serious upgrade. New technologies are emerging that take a lot of the manual labor out of the cleaning process, which means more consistent, reliable hygiene.

- Automated Cleaning Systems: Think of it as a "set it and forget it" feature. Many new ice machines have self-cleaning cycles you can program to run automatically. These systems do the heavy lifting, circulating cleaners and sanitizers through the machine's guts, saving your team a ton of time and minimizing the risk of someone forgetting a step.

- Next-Gen Filtration: High-end water filtration is quickly becoming standard. By catching minerals and other gunk before the water even hits the machine, these advanced filters dramatically slow down the buildup of scale and slime. This means you can go much longer between deep cleanings.

This move toward greener, more efficient cleaning isn't just a niche trend. The global market for dry ice cleaning machines, which was valued at around USD 250 million in 2023, is projected to double by 2032. That kind of growth shows a massive industry-wide push for methods that don't produce chemical waste. You can find more details on this shift to sustainable cleaning tech in market reports from DataIntelo.

Adopting these newer technologies isn't just about following the latest trend. It’s a smart investment. You're cutting down on labor costs in the long run and showing your customers that you're serious about both safety and sustainability. In today's world, that's a message that really resonates.

Your Top Ice Machine Cleaning Questions, Answered

Even with the best maintenance schedule, questions always come up. I get calls about this all the time from kitchen managers and restaurant owners. Let's tackle some of the most common ones I hear about using ice machine cleaners and sanitizers.

How Often Should I Really Be Cleaning My Ice Machine?

The manufacturer's manual will likely say to do a full professional-level cleaning every six months. That means a complete takedown, descaling the entire system, and running a full sanitizing cycle. Honestly, that's the absolute minimum.

Think of it as a starting point. You'll need to clean it more often—maybe every three or four months—if you're dealing with any of these real-world conditions:

- Heavy Use: A packed bar or a high-volume restaurant is going to work its machine much harder.

- Hard Water: If your local water is loaded with minerals, scale will build up much, much faster. This is a huge issue in many regions.

- Your Kitchen's Air: A kitchen with a lot of yeast in the air, like a pizzeria, brewery, or bakery, is the perfect breeding ground for slime.

Can I Just Use Vinegar to Clean It?

I hear this one a lot, and the answer is a hard no. It might seem like a good "natural" way to descale, but vinegar is just not strong enough to cut through the heavy mineral deposits that build up in a commercial unit. You'll be wasting your time.

The bigger issue is safety and compliance. DIY solutions are not EPA-registered sanitizers. That means they won't kill dangerous pathogens like Listeria or E. coli. Using them puts your health inspection score and your customers' safety on the line.

A quick tip from experience: Using unapproved chemicals like vinegar or bleach can instantly void your machine's warranty. That attempt to save a few bucks on cleaner could end up costing you thousands in repairs. Stick with the pros and use a nickel-safe cleaner designed for ice machines.

What Are the Telltale Signs an Ice Machine Is Dirty?

Your machine will absolutely let you know when it needs help. If you see any of these red flags, don't wait for your next scheduled cleaning—act immediately.

- The ice looks bad. It's cloudy, smaller than usual, or coming out in weird shapes.

- Production has slowed way down, or the harvest cycle is taking forever.

- You can see it. Look for any visible slime, mold (often looks like black or pink spots), or a crusty white or gray scale buildup.

- The ice tastes or smells funny. If you get any hint of a musty odor or an "off" taste, that's a major warning sign.

Ready to maintain a pristine, compliant, and efficient ice machine? Encore Seattle Restaurant Equipment offers a full range of professional-grade ice machine cleaners and sanitizers to protect your investment and keep your customers safe. Explore our selection for exclusive deals on the restaurant equipment and supplies you need to stay ahead. Get the right products for your kitchen today at https://encoreseattle.com.