Restaurant Food Safety Training: Essential Tips for Success

Share

Restaurant food safety training is what separates a thriving kitchen from a potential disaster. It's the bedrock of any serious food business, teaching your team the right way to handle, prep, and store food to keep customers safe. Staying informed about industry trends and having the right restaurant equipment and supplies are just as crucial.

This isn't just about satisfying the health department. It's a promise you make to every guest who walks through your door, ensuring the quality and safety of every plate you serve. From mastering personal hygiene to preventing cross-contamination, this is mission-critical stuff for restaurant owners and chefs looking to succeed.

Building Your Food Safety Foundation

Great food starts with great safety. Think of your food safety program as your restaurant's immune system—it's your most important defense. Going beyond just checking a legal box, you're building a culture where safety is second nature. This foundation protects your customers, your reputation, and your bottom line, whether you're a tiny coffee shop or a multi-location enterprise.

The hard truth? Too many businesses treat this training as a one-and-done task. The 2024 Global Food Safety Training Survey found that while most restaurants do train their staff, many are just hitting the bare minimum instead of aiming for real excellence. This highlights a huge opportunity in our industry: to move from simple compliance to creating programs that actually change behavior on the floor. Learn more about these food safety training findings to see where you stand.

Pillars of an Effective Training Plan

To build a program that genuinely sticks, you have to nail a few core concepts. These are the non-negotiables that form the backbone of any curriculum designed to keep both your staff and your diners safe. Get these right, and you're well on your way.

Here's a quick-reference table that breaks down the absolute essentials for any modern food safety program.

Core Components of a Modern Restaurant Food Safety Program

| Training Area | Key Topics | Why It Matters |

|---|---|---|

| Personal Hygiene | Handwashing protocols, proper attire, illness policies, glove use, avoiding bad habits (e.g., touching face/hair). | Prevents the direct transfer of pathogens from staff to food. It's the first and most critical line of defense. |

| Temperature Control | The "Temperature Danger Zone" (41°F to 135°F), proper cooking/cooling/reheating temps, thermometer calibration. | Bacteria thrive in the danger zone. Strict temperature control is the only way to stop their growth and prevent illness. |

| Cross-Contamination | Color-coded equipment (cutting boards, knives), separate prep areas for raw vs. ready-to-eat, proper food storage order. | Stops harmful bacteria from traveling from raw meats or contaminated surfaces to food that's ready to be served. |

| Allergen Management | Identifying the 9 major allergens, preventing cross-contact during prep, clear communication with guests and staff. | Food allergies can be life-threatening. Proper training protects guests and prevents serious liability issues for your business. |

Getting these four areas right is fundamental to running a safe and successful kitchen.

A well-trained team is your first line of defense against foodborne illness. Investing in their education isn't an expense; it's an investment in your restaurant's longevity and success.

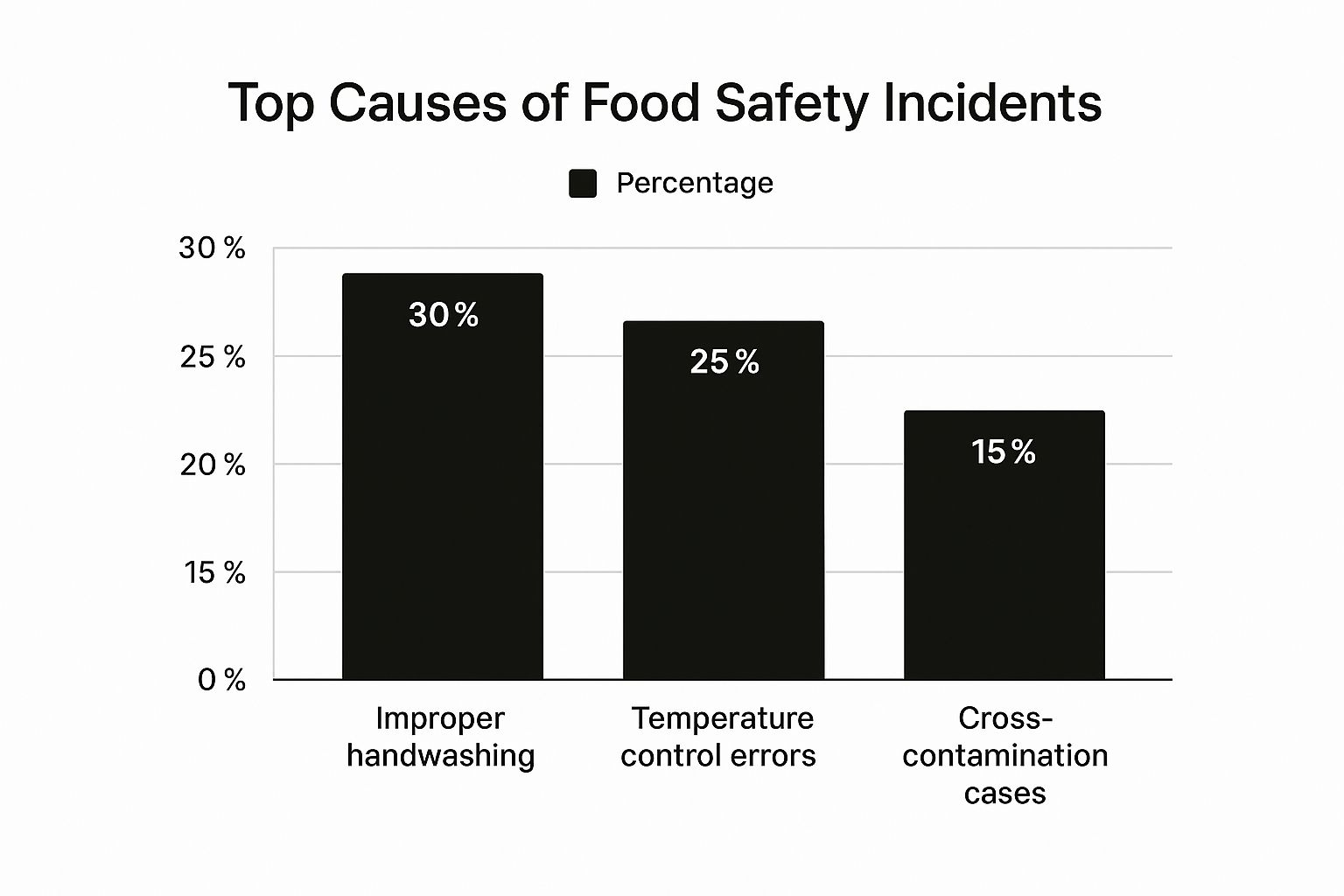

This chart really drives home where the biggest risks lie, and consequently, where your training needs to be sharpest.

As you can see, the most basic mistakes are often the most common culprits. This isn't about complex science; it's about drilling the fundamentals until they become instinct.

Tailoring Training to Your Operation

A generic, one-size-fits-all training video isn't going to cut it. The day-to-day risks in a bustling burger joint are completely different from those in an upscale sushi restaurant. Your training has to reflect the reality of your kitchen, your menu, and your team's roles.

For instance, a bakery's program will need a heavy focus on preventing cross-contact with allergens like nuts and dairy. A steakhouse, on the other hand, will need to double down on correct cooking temperatures and preventing raw meat contamination.

This is where a structured system like HACCP comes in. It helps you pinpoint the specific hazards tied to your menu and build targeted controls for them. If you're not familiar with it, check out our guide on what HACCP food safety is to see how you can apply its principles. By tailoring the training, you make it relevant, memorable, and far more effective for everyone on your team.

Designing Training Your Staff Will Remember

Let's be honest. Nobody remembers the dusty training binder or the hour-long, monotone video everyone tunes out after five minutes. If your food safety training feels like a chore, your staff will treat it like one. To create a program that actually sticks—and more importantly, changes behavior on the floor—you need a much more thoughtful approach that respects how people actually learn.

The secret is to blend different methods to keep the material fresh and engaging. People retain information far better when they can see it, hear it, and do it. This means moving past passive learning and creating an interactive environment where safety principles truly come to life. Savvy restaurant owners know that staying current with industry trends includes innovative training techniques.

Mixing Up Your Training Methods

A dynamic training program layers multiple teaching styles to hammer home the key concepts. Instead of just leaning on one method, try combining several to connect with everyone on your team.

A program that really works often includes a mix of:

- Hands-On Demos: Show, don't just tell. Demonstrate the right way to calibrate a thermometer or the proper handwashing technique—right there at the sink.

- Interactive Quizzes: Use short, simple quizzes to check for understanding. You can even make them fun and competitive to turn learning into a low-stakes game.

- Quick Pre-Shift Huddles: Take five minutes before service to focus on a single food safety topic. This could be a quick reminder about allergen protocols or checking sanitizer concentrations.

- Real-World Scenarios: Pose "what if" situations. Ask your team, "A customer tells you they have a severe shellfish allergy after their food has been fired. What are the exact steps you take, right now?"

This multi-faceted approach ensures the information isn't just heard once and forgotten; it's reinforced daily in practical, memorable ways. If you're looking to build out a more structured program, it's worth exploring some expert online course design strategies to get more ideas.

The goal isn't just to teach the rules, but to build muscle memory. When safe practices are repeated through different formats, they become instinctual, even during the chaos of a Saturday night rush.

Making Training Relevant to Each Role

One of the biggest mistakes I see is delivering the same generic training to everyone. A dishwasher, a line cook, and a server face entirely different food safety risks and responsibilities. When you tailor the content to each specific role, it becomes immediately relevant and far more impactful.

For instance, your training plan could be broken down like this:

For Line Cooks:

- A heavy focus on preventing cross-contamination between raw and ready-to-eat foods.

- Drilling down on precise cooking temperatures and proper cooling procedures for batch-prepped items.

- Role-playing how to handle allergen tickets and communicate clearly with the front-of-house.

For Dishwashers:

- Emphasize correct sanitizer concentrations and water temperatures for the dish machine.

- Train on proper storage of clean dishes and glassware to prevent re-contamination.

- Cover safe chemical handling and storage procedures—this is crucial.

For Servers and Bartenders:

- Train them to recognize symptoms of allergic reactions and the protocol for responding.

- Focus on personal hygiene, like never touching the rim of a glass.

- Cover safe ice handling and garnish preparation.

When your team sees exactly how the training applies to their daily tasks, they are so much more likely to buy in and remember what you've taught them.

Scheduling for Maximum Impact

How and when you schedule your food safety training is just as important as the content itself. Pulling your entire team off the floor for a four-hour session is a nightmare for service and a terrible way to learn. Information overload is real, and you can bet that retention drops off a cliff after the first hour.

A much better strategy is "microlearning"—breaking down complex topics into short, digestible sessions that fit into the daily workflow.

Consider these scheduling tips:

- Integrate Training into Onboarding: Food safety needs to be a core part of a new hire's first few days. Don't let them touch food until they've mastered the absolute basics.

- Use Pre-Shift Meetings: As I mentioned, these five-to-ten-minute huddles are perfect for quick refreshers and reinforcing a single, timely topic.

- Schedule Monthly Focus Topics: Dedicate each month to a specific area of food safety, like allergen awareness in May or temperature control in July. This keeps the learning continuous without ever feeling overwhelming.

This approach respects your team's time and your operational needs. It weaves training into your restaurant's culture, making it a consistent, manageable habit rather than a disruptive, one-off event.

How Management Shapes a Safety Culture

You can have the best food safety training program in the world, but it all falls apart without leadership buy-in. A restaurant's commitment to safety lives and dies with its managers. When leadership doesn't just talk the talk but actively walks the walk, that's when you build a real, lasting safety culture.

It's about making food safety a core value, not just a checkbox for the health inspector. When the people in charge lead the charge, the message is loud and clear: cutting corners is never an option.

Leading by Example Every Single Day

Make no mistake, your team is always watching. They see what you prioritize during a chaotic dinner rush and what you let slide when you're slammed. The real training happens in those unscripted, high-pressure moments.

To lead by example, you need to be the most diligent person in the kitchen. Are you the first to wash your hands when you step on the line? Do you instinctively reach for a fresh spoon to taste a sauce? These small, consistent acts set the standard for everyone else.

Here’s how you can put this into practice:

- Walk the Floor Daily: Start and end every shift with a quick walkthrough. Check cooler temps, look for properly dated labels, and make sure cleaning supplies are where they should be. This shows you're paying attention.

- Coach in the Moment: If you see a line cook about to use the same tongs for raw chicken and ready-to-eat garnishes, don’t wait for their annual review. Step in, correct it calmly, and explain why it matters. This is a powerful teaching opportunity.

- Show Up for Training: When you sit in on food safety sessions with your crew, it demonstrates that the material is vital for everyone, no matter their title.

Weave Safety into Your Operations

For a team to take food safety seriously, it has to be part of the restaurant's DNA. It needs to be a key factor in how you hire, review performance, and reward your people. It should carry the same weight as ticket times and food costs.

A global food industry survey confirms this. A staggering 88% of respondents said management support was the key to delivering training that creates real, consistent, safe behaviors. The biggest benefits they reported weren't just fewer safety incidents, but a stronger overall culture and better product quality. You can discover more insights on management's role in food safety training and see the full impact for yourself.

A policy tucked away in a binder is just paper. A standard that is constantly coached, upheld, and celebrated by management becomes a shared value. Your active, visible involvement is the most powerful tool you have.

This kind of integration is a cornerstone of effective restaurant operation management. It’s all about building systems where doing things the safe way is the natural, easy way.

Make Safety a Constant Conversation

So, how do you keep food safety front and center when you're in the weeds? You talk about it. All the time. Not by nagging, but by making it a routine part of your daily communication.

- The "Safety Minute": Add a quick 60-second safety topic to your pre-shift meetings. "Alright team, a quick reminder: let's be militant about swapping out our sanitizer buckets every two hours today. Who's got point on that?"

- Safety in Reviews: Make food safety a standard discussion point in every performance review. Acknowledge the team members who are setting a great example and create a clear improvement plan for those who are struggling.

- Celebrate the "Good Catches": Did a server notice a delivery was temping in the danger zone? Did a prep cook flag a cross-contamination risk? Praise them publicly. This shows you value their vigilance and encourages others to speak up.

By making safety a visible and vocal priority, you empower your team to take ownership. They'll shift from just following the rules to actively protecting your customers, your reputation, and your business. That's the difference between a compliant kitchen and a truly committed one.

From Theory to the Trenches: Making Food Safety an Ingrained Habit

We’ve all seen it happen. You spend hours training a new line cook, they ace the quiz, and then, during a chaotic Friday night rush, you see them use the same tongs for raw chicken and cooked steak. It's a gut-wrenching moment.

The hard truth is that classroom knowledge can disappear the second the pressure is on. This is where we bridge the critical gap between what your team knows and what they actually do when the tickets are flying and the kitchen is in the weeds.

Passing a test is just the beginning. A telling study on food safety training revealed something many of us have suspected: while formal training improved employee knowledge, it didn't automatically translate to better, safer habits on the floor. For restaurant food safety training to actually stick, it needs constant, practical reinforcement until it becomes pure muscle memory. You can dive into the study's findings here to see just how important this is.

The goal isn't just memorization. It’s about embedding food safety so deeply into your daily operations that the right way becomes the only way, no matter how crazy the service gets.

Design a Kitchen Where Safety Is the Default

The most effective way to build habits is to make the safe choice the easiest choice. Your kitchen's environment—and the restaurant equipment and supplies you choose—should be designed to do the heavy lifting for you, using visual cues as silent, constant guides.

Here’s how to put that into practice:

- Color-Code Everything: This is a non-negotiable in my book. Use red cutting boards and knives only for raw meat, green for produce, and yellow for poultry. It's a simple, visual system that makes cross-contamination glaringly obvious and much harder to do by accident.

- Make Checklists Unavoidable: Don't bury your temperature logs on a clipboard in the back office. Post them right on the cooler doors. Integrate them into the official opening and closing checklists so they become a mandatory part of the routine.

- Use Smarter Signage: Go beyond the standard "Wash Hands" sign. Put up clear, picture-based instructions for proper handwashing right above the sink. Inside the walk-in, post a visual guide showing the correct top-to-bottom storage order (ready-to-eat on top, raw poultry on the bottom).

These environmental nudges make safe practices feel natural and automatic. They create a clear path for your staff to follow, turning conscious effort into unconscious competence.

Your job is to make it easy to do things right and hard to do them wrong. Let your kitchen’s layout and tools be a constant reinforcement of your training.

Practice, Practice, and Peer Power

There's a world of difference between reading about a critical food safety protocol and actually executing it under pressure. You have to create low-stakes opportunities for your team to put their knowledge into action.

A "buddy system" works wonders, especially for new hires. Partner them with a seasoned pro—someone who not only knows their station but truly lives your safety culture. This mentor can offer immediate, on-the-spot corrections and answer the "dumb" questions a new person might be too nervous to ask a chef. It fast-tracks learning and builds accountability from day one.

You should also run quick, practical drills before a shift. Think of them as fire drills for food safety:

- "Table 5 just told us they have a severe nut allergy, and their ticket is already firing. Walk me through our protocol, step-by-step. Go!"

- "The Sysco driver just dropped a case of chicken that’s temping at 50°F. What is the very first thing you do?"

These scenarios build muscle memory for crisis moments. When a real emergency hits, your team won't freeze up—they'll instinctively fall back on the habits they've already practiced.

Weave Safety Into Your Daily Rituals

Finally, habits are forged through repetition. To make your restaurant food safety training last, you must weave reminders into the daily rhythm of your kitchen.

Start by implementing these simple rituals:

- The 60-Second Safety Huddle: Before every service, take one minute to spotlight a single safety topic. It could be a quick reminder to check sanitizer concentration or a call-out to double-check dates on prepped items.

- Catch Them Doing It Right: When you see a cook change their gloves after handling raw beef without being told, praise them publicly. A simple, "Hey, great job on the glove change, thank you," reinforces that behavior for everyone within earshot.

- Quick End-of-Shift Debrief: During your closing meeting, take a moment to talk about any safety wins or near-misses from the shift. This creates a culture of shared responsibility and constant improvement.

By making these small but consistent actions part of your culture, you turn food safety from a boring training topic into a living, breathing daily habit. This is how you build a crew that isn't just certified, but truly committed.

Using Technology for Smarter Food Safety

Let's be honest: messy paper logs and manual checklists are relics of the past. In a modern kitchen, relying on them is not just inefficient, it’s a risk. Technology gives us powerful ways to simplify food safety management, cut down on human error, and gather data that actually makes our operations better. This shift lets your team get back to focusing on what matters most: creating incredible food.

When you bring digital tools into your restaurant for food safety training and daily checks, health inspections become far less daunting. Day-to-day tasks get done faster and more accurately. Think of the right tech—from automated sensors to simple apps—as a constant, vigilant partner in your kitchen. Discovering the latest news on restaurant equipment can give you an edge.

Automating Critical Control Points

One of the biggest wins technology offers is automated monitoring. We’ve all seen it: manual temperature logs are riddled with problems. Numbers get penciled in from memory, checks are missed during a chaotic dinner rush, and readings can be inconsistent. All of this creates dangerous gaps in your safety net.

Automated temperature sensors completely change the game. These small, wireless devices sit inside your refrigerators and walk-in coolers, tracking temperatures 24/7. If a cooler door is left open or a freezer starts to fail, you get an instant alert on your phone. This simple step can prevent thousands of dollars in spoiled inventory and guarantees your food is always held safely. It's a cornerstone of effective what is cold chain management, the system designed to protect food from the moment it leaves the supplier until it reaches the customer.

By automating these routine checks, you move food safety from a reactive, memory-based chore to a proactive, data-driven system. It's all about catching problems before they have a chance to start.

Digital Checklists and Training Records

The days of chasing down training certificates and filing them in a dusty binder are over. Modern software and apps are built to put all your food safety management tasks under one digital roof. This makes staying compliant and holding people accountable so much easier.

Here’s how these systems help:

- Effortless Daily Logs: Staff can fly through opening and closing checklists on a tablet or phone. This covers everything from checking sanitizer levels to verifying equipment is clean and food is stored correctly.

- Centralized Training Records: You can finally keep a clean record of every employee's food safety certifications and their expiration dates. The best part? The system can automatically ping you when someone's certificate is about to expire.

- Built-in Corrective Actions: If a checklist item fails—say, a dishwasher isn't getting hot enough—the app can require the employee to log what they did to fix it. This creates a perfect digital paper trail for health inspectors.

- Data That Tells a Story: Over time, all this information starts to reveal patterns. Is one specific cooler always causing trouble? Does the morning shift consistently miss the same checklist item? These insights show you exactly where to focus your training and maintenance efforts.

The Future of Food Safety Training

Technology isn't just for daily monitoring; it's also revolutionizing how we train our teams. Hands-on practice in the kitchen will always be vital, of course. But new tools are making restaurant food safety training more sticky and effective.

Online modules let new hires learn at their own pace, and interactive simulations can test their knowledge in realistic scenarios without any real-world risk. For a glimpse into what's next, you can explore immersive learning with AR/VR for truly engaging skill development. Imagine a brand-new cook practicing how to handle raw chicken in a virtual kitchen, where mistakes provide instant feedback without wasting product or creating an actual hazard. This is where we're headed.

By bringing these tools into your operation, you’re not just checking a compliance box. You're investing in a smarter, safer, and more efficient future for your restaurant.

Frequently Asked Food Safety Questions

No matter how buttoned-up your training plan is, questions will always come up. It's just the nature of the beast. Running a food safety program means you're constantly juggling specific regulations, team personalities, and trying to get ahead of problems before they start.

Let’s tackle some of the most common questions I hear from chefs and owners. Think of this as your quick-reference guide for those moments you need a straight answer, fast.

How Often Does My Staff Need Retraining?

This is a big one, and the answer isn't as simple as "once a year." While a formal certification like ServSafe is good for five years, real-world food safety knowledge isn't a one-and-done deal. The lessons from a single class can fade surprisingly fast in the daily chaos of a busy kitchen.

A much better strategy is to create a rhythm of continuous learning. It looks something like this:

- Formal Annual Refresher: Get everyone together once a year for a comprehensive course. This sets a strong baseline and ensures everyone is up-to-date on the latest rules.

- Quick Monthly Huddles: Pick one topic—say, allergen handling or proper cooling—and dedicate 10 minutes to it during a pre-shift meeting each month. It keeps safety top of mind.

- In-the-Moment Coaching: This is where the magic happens. When you see a mistake, you correct it right then and there. This immediate, gentle correction is often the most effective training you can do.

When you treat food safety like an ongoing conversation instead of a one-time event, you start building habits that actually stick.

What Is the Difference Between a Food Handler and a Food Manager Certification?

Getting this right is crucial for compliance. The names sound similar, but they're for completely different roles and cover vastly different material.

| Certification | Who Needs It? | What It Covers |

|---|---|---|

| Food Handler | The frontline crew—line cooks, prep staff, servers, bussers. Pretty much anyone who touches food. | The essentials: personal hygiene, basic temperature control, and how to prevent cross-contamination. |

| Food Manager | The person in charge (PIC) on every shift. This is your manager, chef, or lead line cook. | The big picture stuff: in-depth knowledge of the entire flow of food, HACCP plans, and managing the restaurant's overall safety program. |

The easiest way to think about it is that the food handler card ensures your team knows what to do. The food manager certification ensures your leaders know why they’re doing it and how to oversee the whole system.

I see so many operators make the mistake of thinking one certified manager is enough. Check your local health code—most require a Certified Food Protection Manager to be on-site during all hours of operation. This means you absolutely need to have multiple certified leaders on your team.

How Do I Handle Employees Who Resist the Training?

Pushback from staff can be maddening, but it’s rarely about them wanting to be unsafe. Resistance usually signals a breakdown somewhere else. Often, it's because they don't grasp the "why" behind a rule, or they find the training itself to be a boring, irrelevant chore.

First, make it personal. Explain how these practices aren't just about protecting customers; they're about protecting the staff, too. Nobody wants to get themselves or their work family sick.

Then, you have to make the training engaging. Ditch the dry lectures. Talk about real-life scenarios from your own kitchen. Instead of just stating, "store raw chicken on the bottom shelf," paint a picture of what happens when it drips onto the produce drawer below. When people understand the real, tangible consequences of their actions, the buy-in happens almost automatically.

At Encore Seattle Restaurant Equipment, we help restaurant owners and chefs discover the latest news and exclusive deals on restaurant equipment and supplies. We know that great training needs to be backed up by great equipment. It's hard to follow the rules without the right tools. From NSF-certified prep tables that make cleaning a breeze to high-tech refrigeration that maintains perfect temperatures, we've got the gear that turns your safety plan into a reality. Check out our inventory and find exclusive deals to build a safer kitchen at https://encoreseattle.com.