Your Complete Guide to the Commercial Ventless Hood

Share

A commercial ventless hood is a self-contained kitchen ventilation system that scrubs cooking fumes through a series of filters and then returns the clean air right back into the room. This clever design means you don't need to install expensive external ductwork, making it a game-changer for kitchens where traditional vented hoods just aren't an option. For restaurant owners and chefs, understanding this technology is key to discovering new opportunities and exclusive deals on essential equipment.

How a Commercial Ventless Hood Actually Works

Think about clearing smoke from a room. You could open a window to let it all out—that’s basically what a traditional vented hood does. But what if you could use a high-powered, self-contained air purifier to trap the smoke, grease, and smells, then release fresh air back into the same space? That's the principle behind a ventless hood.

Instead of punching a massive hole through a wall or roof, this technology creates a closed-loop system. It captures cooking exhaust, puts it through a rigorous cleaning process, and recirculates it. It’s an elegant solution that offers incredible flexibility for kitchen design, a key industry trend for modern food service operations.

The Multi-Stage Filtration Process

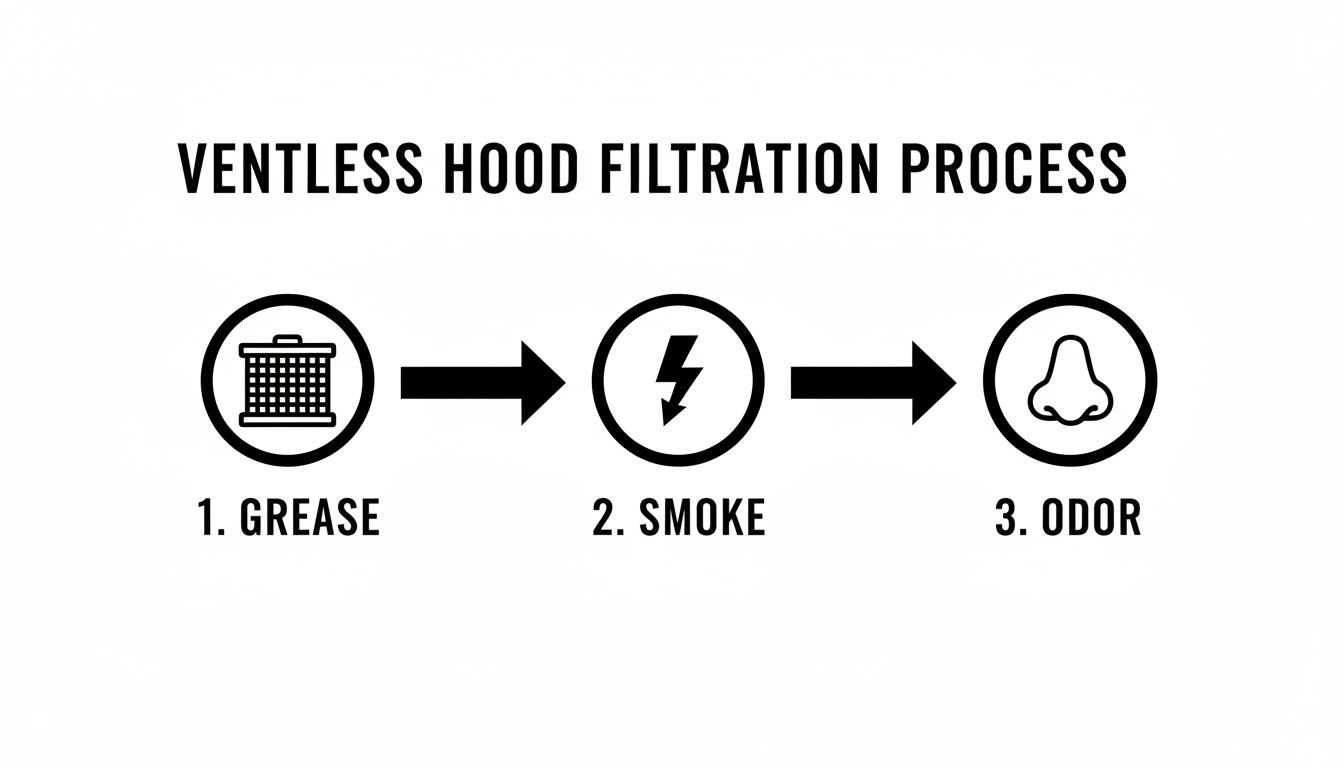

The real magic happens inside the hood's filtration system. It's not just one filter, but a sequence of them designed to tackle different contaminants one by one. Each stage is a specialist, targeting everything from heavy, greasy vapor down to the tiniest smoke and odor particles. This step-by-step approach is what ensures the air coming out is clean and safe to breathe.

You can think of the advanced filtration in ventless hoods as being similar to other dedicated air purification systems, but built to withstand the much harsher environment of a commercial kitchen.

The process usually unfolds in three key stages:

- Grease Removal: First up is a stainless steel baffle filter. As air gets sucked into the hood, it's forced to make a few sharp turns. The heavier grease particles can't keep up, so they slam into the metal baffles and drip down into a collection tray for easy disposal.

- Smoke Particle Capture: With the heavy grease gone, the air moves on to the next stage, which is all about smoke. This is often handled by an electrostatic precipitator that uses an electric charge to grab tiny particles out of the air, or a series of very fine mesh or HEPA-style filters that trap them.

- Odor Elimination: The final step is an activated charcoal (or carbon) filter. This material is incredibly porous, and those millions of tiny pores act like a sponge, absorbing smelly molecules and other volatile organic compounds (VOCs) before the purified air is pushed back into the kitchen.

This diagram gives you a clear visual of how these stages work together.

It’s this methodical, multi-stage cleaning that allows a ventless system to perform so well without needing to vent outside.

The Rise of Ductless Technology

Ventless hoods are fundamentally changing how restaurant professionals think about kitchen ventilation, especially in tricky spaces like food trucks, historic buildings, or strip malls. The numbers back this up. In 2024, the global Commercial Kitchen Fume Hoods Market was valued at a whopping USD 2.66 billion.

Even more telling, the ductless segment is projected to grow at a CAGR of 6.71% from 2025 to 2032. This industry trend is driven by the fact that over 80% of commercial kitchens are now adopting advanced filtration to meet tougher safety and air quality standards.

This technology opens up a world of possibilities, empowering chefs and restaurateurs to build kitchens in places that would have been impossible just a decade ago. If you want to explore all the options out there, our guide on commercial kitchen ventilation systems is a great place to start.

Choosing Between Vented and Ventless Hoods

Trying to decide between a traditional vented hood and a modern commercial ventless hood isn't about finding a single "best" answer. It's about choosing the right piece of restaurant equipment for the job. The best choice is the one that fits your kitchen's unique layout, your menu, and your budget.

For a massive, brand-new restaurant kitchen that’s going to be running multiple gas-fired appliances at full blast, a heavy-duty vented system is a logical, necessary investment. But for a growing slice of the food service world, the ventless hood is more than just an alternative—it’s the key that unlocks their entire business concept.

When Does a Ventless Hood Make Sense?

Let's look past a generic pros-and-cons list and dive into real-world situations where a ventless system isn't just a good idea, it's a total game-changer. These examples show how building limitations, startup costs, and menu types all play a huge role in the decision for savvy restaurant owners.

-

The Historic Building Café: You've found the perfect spot for a cozy coffee shop in a beautiful historic district. The catch? Preservation codes mean you can't just punch a giant hole through that 100-year-old brick for ductwork. A ventless hood lets you bring in electric ovens and panini presses, turning an otherwise impossible location into a thriving business.

-

The Mobile Food Truck: Life in a food truck is all about being nimble. A ventless system is a self-contained powerhouse that doesn't need to be physically tied to a building's exterior. It’s the perfect setup for serving crowds at festivals, office parks, or catered events, all while staying on the right side of the health department.

-

The Pop-Up Ghost Kitchen: The ghost kitchen model is built on speed and low overhead. When you're leasing a spot in a shared commissary or a warehouse, major construction is usually off the table. A ventless hood is essentially a plug-and-play solution, getting your kitchen up and running in a matter of days instead of weeks. If a better location comes along, you can pack up and move without losing a massive investment in ductwork.

To help you see the differences side-by-side, here’s a quick comparison.

Comparing Vented and Ventless Commercial Hoods

This table breaks down the key features of each system to help you decide which one truly fits your kitchen's needs, budget, and physical location.

| Feature | Vented Hood (Type I) | Commercial Ventless Hood (Type II) |

|---|---|---|

| Installation | Complex and expensive; requires ductwork, roof penetration, and make-up air unit. | Simple and fast; requires only an electrical connection. |

| Ideal For | High-volume grease producers like charbroilers, grills, and gas ranges. | Electric equipment like ovens, fryers, griddles, and panini presses. |

| Location Flexibility | Limited to spaces where external venting is possible. | Can be installed almost anywhere, including basements, historic buildings, and food trucks. |

| Upfront Cost | High. Can range from $15,000 to $50,000 including installation. | Moderate. Significantly lower upfront cost with minimal installation fees. |

| Operating Cost | Lower filter costs, but higher energy bills due to HVAC strain. | Higher filter replacement costs, but lower energy bills as it recirculates conditioned air. |

| Permitting | Extensive permitting process involving building, mechanical, and fire codes. | Streamlined permitting process, often simpler and faster. |

| Maintenance | Regular professional duct cleaning is required to prevent fire hazards. | Routine filter cleaning and replacement, typically handled in-house. |

Ultimately, the choice comes down to a few core questions about your business and your space.

Key Factors in Your Decision

To make the right call, you need to weigh these critical factors. Your answers will point you clearly in one direction or the other.

Installation Costs and Complexity

A traditional vented hood has a lot of hidden costs. You aren't just buying the steel canopy; you’re paying for a labyrinth of expensive ductwork, cutting and sealing a hole in your roof, and installing a make-up air unit to replace the air being pumped outside. All that labor and material can easily add $15,000 to $50,000 to your project budget.

On the flip side, a commercial ventless hood wipes out nearly all of those extra expenses. The main costs are the unit itself and a simple electrical hookup, which dramatically slashes your upfront investment and gets you operational much faster.

Long-Term Operational Expenses

While a vented hood seems cheaper to run day-to-day (it's just a fan, right?), it’s constantly sucking the heated or cooled air right out of your kitchen. This makes your HVAC system work much harder to keep the temperature stable, driving up utility bills. Some studies show this can spike HVAC energy use by as much as 30%.

A ventless hood, however, cleans and recirculates that same air, keeping your climate control costs in check. The main ongoing expense is replacing the filters, which is a predictable line item you can easily budget for.

Building Constraints and Menu

Finally, take a hard look at your physical space and your menu. If you're in a high-rise, a basement, or any building where running ductwork is a non-starter, the ventless hood is your answer. It's also the clear winner if your menu relies on electric equipment like fryers, ovens, or flat-top griddles.

However, if your signature dishes come off a high-heat, gas-powered charbroiler or grill, you're in vented hood territory. For that kind of heavy-duty grease and smoke production, a traditional Type I vented hood is non-negotiable for safety and code compliance.

Getting the Go-Ahead: Navigating Codes and Permits for Your Ventless Hood

Getting the green light from local inspectors for your commercial ventless hood can feel a bit daunting, but it’s honestly much simpler than you might think. Unlike traditional vented systems that require knocking holes in your roof and running complicated ductwork, the path for a ventless hood is usually more direct. The key for any restaurant owner is knowing the rules before you spend a dime.

The most important thing to remember is that all regulations are local. National standards set the baseline for safety, but your city’s health and fire departments always have the final word. Talking to them early on is the single best move you can make.

What Those Safety Acronyms Actually Mean

When you're looking at spec sheets for restaurant equipment, you'll see a jumble of acronyms like UL, NSF, and NFPA. These aren't just random letters; they're your proof that the equipment is up to snuff. They tell inspectors the unit has been put through its paces for safety and sanitation.

- UL (Underwriters Laboratories): This is the big one for safety. For ventless hoods, you need to see UL 710B, which is the standard specifically for recirculating systems. It means the hood has proven its filtration works and comes with a built-in fire suppression system.

- NSF (National Sanitation Foundation): This sticker is all about hygiene. It certifies that the hood is built with materials and a design that’s easy to clean and won't trap bacteria—a must for any commercial kitchen.

- NFPA 96 (National Fire Protection Association): This is the go-to standard for fire protection in commercial kitchens. A compliant ventless hood is designed to meet these tough fire safety rules, which is why that integrated fire suppression system is so crucial.

Think of these certifications as non-negotiable. They give officials confidence that your equipment can safely handle the heat, grease, and daily grind of a professional kitchen. For a more detailed look, check out our guide on commercial kitchen ventilation requirements.

The Golden Rule: Always Check Locally First

Even if a hood is plastered with every certification under the sun, never assume it’s automatically approved for your specific spot. The rules can be surprisingly different from one town to the next. What's perfectly fine in Seattle might not fly in a neighboring county.

Before you even think about buying, make two phone calls: one to your local health department and another to the fire marshal. Have the spec sheet for the commercial ventless hood you're considering ready, and ask them to confirm it's good to go for what you plan to cook.

This one step saves you from massive headaches, like buying an expensive piece of equipment you can't use or facing unexpected modification costs after it's already installed. It’s the surest way to a smooth inspection without any delays.

The push for compliant ventilation is a huge deal in the restaurant world. Strict regulations mean that over 90% of commercial kitchens in the U.S. now list ventilation as a top compliance priority. This industry trend has only grown with the rise of ghost kitchens, where ventless hoods have enabled 70% more setups in non-traditional spaces, often without needing major permits. Discover more insights about the kitchen hood market from Future Market Insights to see how these trends are shaping the industry.

Unlocking New Kitchen Possibilities with a Ventless Hood

A commercial ventless hood isn't just another piece of restaurant equipment—it's often the key that unlocks a new business venture. It has the power to turn spaces you'd never think could house a kitchen into profitable operations. This technology gives entrepreneurs the freedom to get creative, opening up revenue streams in places where a traditional, ducted ventilation system would be a deal-breaker.

Let's look at some real-world examples where a ventless hood wasn't just helpful; it was the hero of the entire operation.

Think about that food truck you see with a long line during the downtown lunch rush. Inside, the chef is frying and grilling away, but there's no giant, noisy exhaust fan hanging off the side. How? The entire business model is built around a self-contained ventless hood. It handles all the air purification on its own, untethering the kitchen from a fixed building. It’s the solution that makes mobility possible, letting the owner follow the crowds from business parks to weekend festivals without compromising their menu or safety codes.

The Historic Cafe and the Mall Kiosk

Now, let's picture a quaint coffee shop inside a beautiful historic building. The owners dream of serving hot breakfast sandwiches alongside their coffee, but the building's preservation rules are strict. Drilling massive holes through century-old brick for ductwork? Absolutely not. A traditional vented hood is off the table.

This is where a commercial ventless hood saves the day. By installing one over their electric panini presses and small convection ovens, they brought their food menu to life. They got their kitchen up and running in a protected space, dodged invasive construction, and secured a prime location that their competitors couldn't even consider.

Or what about a pop-up food stall inside a busy airport, stadium, or shopping mall? These spots come with a built-in audience but also iron-clad rules against permanent changes to the structure.

A ventless system provides the ultimate plug-and-play solution. You can set it up quickly for a seasonal event or a short-term lease and have a professional-grade kitchen environment ready to go. When the event is over or you find a better location, you can pack it all up and move without leaving a huge investment in ductwork behind in the walls.

These aren't just hypotheticals. They represent a real shift in how foodservice businesses can think and operate. When you can bypass the headache and cost of traditional ventilation, it completely changes the game for entrepreneurs who need to start lean and stay agile.

The Financial and Strategic Advantage

This kind of flexibility is a lifeline, especially for new businesses. Ventless systems are a perfect fit for ghost kitchens, tiny cafés, and food trucks, whether you're in a dense urban neighborhood like Seattle's Sodo District or running a pop-up in a remote location.

Let's talk numbers. A staggering 40% of commercial failures are linked to high overhead costs. Ventless hoods, with their energy-efficient designs, tackle this problem head-on. They can slash initial installation expenses by 50-70% compared to a ducted system.

It's no surprise that in the U.S. and Europe, where over 60% of new food businesses are small-format, the adoption of this technology has jumped by 25% since 2020. You can explore more of these commercial ventless cooking equipment market trends to see the full picture.

Ultimately, these stories all point to one powerful truth: a commercial ventless hood solves critical problems, turning limitations into opportunities. It lets you build your business where your customers are, not just where the building lets you, opening up entirely new paths to success.

Understanding the True Cost and Savings

When you're building out a kitchen, every dollar matters. So, let’s get right to it and break down the real numbers behind a commercial ventless hood. It’s not just about the sticker price; it’s about the massive savings and exclusive deals you unlock from day one and for years to come.

The initial cost of the ventless unit itself can look pretty similar to a traditional vented hood, and that's where some people get stuck. But that's only seeing a tiny piece of the financial puzzle. The real story is in everything you don't have to pay for.

Escaping High Installation Costs

With a traditional ducted system, buying the hood is just the start of the spending. The installation is where your budget can truly get out of hand, fast. You’re not just hanging some metal; you’re funding a full-blown construction project.

Think about what's involved with a standard hood:

- Expensive Ductwork: You're paying for custom fabrication and the labor to run heavy metal ducts all the way through your building. It adds up quickly.

- Roof or Wall Penetration: This isn't a DIY job. You need specialists to cut a massive, perfectly sealed hole in your building's structure, which can easily cost thousands.

- Make-Up Air (MUA) Systems: This is a big one. For all the air a vented hood pumps outside, a pricey MUA system has to bring treated air back in. It's a huge, often overlooked expense.

A commercial ventless hood lets you skip all of that. Installation is a world of difference: place the unit, plug it in, and get the fire suppression system charged. That's it. This alone can slash your total upfront investment by 50% to 70% compared to a fully installed vented system.

The bottom line is simple. With a ventless hood, you sidestep tens of thousands of dollars in construction, labor, and supplemental equipment costs. This frees up crucial capital that can be invested back into other areas of your business.

Calculating Your Long-Term Value

The savings don’t stop after installation. A ventless hood keeps delivering value by chipping away at your daily operating costs, and the biggest win here is on your energy bills. Since the system cleans and recirculates the air you've already paid to heat or cool, your HVAC system doesn't have to fight to keep the kitchen comfortable.

This efficiency is a game-changer. A traditional hood is like an open window, constantly sucking out conditioned air and forcing your HVAC to run nonstop, inflating your utility bills. By keeping that air inside, a ventless system can lower your kitchen's energy use by as much as 30%.

The main ongoing expense for a ventless unit is replacing the filters, which is a predictable and easy-to-budget cost. When you're weighing the total investment, checking a comprehensive restaurant equipment financing guide can really help put these long-term savings into perspective and show how manageable the purchase can be.

When you add it all up, the combined savings on installation and energy create a powerful return on investment. A ventless hood doesn't just make it possible to cook anywhere; it actively helps pay for itself by cutting your overhead, month after month.

Keeping Your Ventless Hood in Prime Condition

A commercial ventless hood is a serious workhorse, but its entire performance really boils down to consistent maintenance. A clean hood isn't just about efficiency—it's about safety, compliance, and getting the most life out of your restaurant equipment. Let things slide, and you're looking at poor air quality, fire risks, and some seriously expensive repairs down the line.

The good news is, keeping your system in top shape doesn't have to be a huge ordeal. By building a simple routine for your kitchen staff, you can protect your equipment and make sure it's working perfectly, shift after shift. This is the smartest way to guarantee your hood is actually doing its job: purifying the air, killing odors, and preventing fires.

Your Essential Maintenance Checklist

Instead of thinking of maintenance as one giant chore, break it down. Daily, weekly, and monthly tasks are much easier for your team to manage. A predictable schedule is the secret to a ventilation system you can always count on.

Daily Tasks (5 Minutes)

- Wipe Down Surfaces: At the end of the day, give all the stainless steel surfaces—inside and out—a quick wipe with a food-safe degreaser. This stops grease from baking on and keeps the kitchen looking sharp.

- Empty Grease Tray: Slide out the grease collection tray and empty it. A quick wash with hot, soapy water is all it takes to get it ready for the next service.

Weekly Tasks (15-20 Minutes)

- Clean Baffle Filters: Pop out the reusable metal baffle filters. Most can go right through a commercial dishwasher, or you can soak them in a degreasing solution. Clean filters are absolutely essential for good airflow and grabbing grease effectively.

Letting filter maintenance slide is one of the biggest mistakes a chef can make. Clogged filters make the fan motor work overtime, which kills efficiency and can lead to a breakdown. Worse, greasy filters are a massive fire hazard waiting to happen.

Monthly and Long-Term Upkeep

While your daily and weekly cleanings cover the front lines, some jobs are for the long haul. These deeper-clean tasks are what keep your commercial ventless hood at peak performance, ensuring it’s capturing smoke and odors, not just the heavy grease.

The most important long-term job is swapping out the disposable filters that do the fine-particle and odor removal. How often you do this depends entirely on what you’re cooking and how much of it.

- Pre-Filters: If your unit has them, check these monthly. When they look dirty, it's time for a new one.

- Activated Carbon Filters: These are your secret weapon against odors. For a typical kitchen, plan on replacing them every three to six months. If you’re doing a lot of high-volume frying, you’ll likely need to do it more frequently.

Luckily, many modern ventless hoods have indicator lights that take the guesswork out of it, telling you exactly when a filter needs changing. To see how this fits into the bigger picture, check out our complete guide to commercial kitchen equipment maintenance. A solid plan keeps the whole kitchen running like a well-oiled machine.

Frequently Asked Questions

Even after you get the basics down, a few practical questions always pop up when you're getting serious about a commercial ventless hood. Let's tackle some of the most common ones we hear from chefs and restaurant owners to help you iron out those final details.

Can I Use a Ventless Hood with My Gas Charbroiler?

This is a hard no, and it’s the single most important safety rule to burn into your memory. Commercial ventless hoods are specifically engineered and UL-listed for use with electric cooking equipment only.

Gas appliances kick out dangerous byproducts like carbon monoxide that a ventless system simply isn't built to handle. Attempting to pair them is not only a major fire hazard but also an instant code violation that will shut you down. Always, always match the hood to the equipment type specified by the manufacturer and your local health department.

How Often Will I Need to Replace the Filters?

There’s no magic number here—it really depends on what you’re cooking and how much of it. A high-volume fryer station will clog up filters way faster than a panini press used a few times a day.

That said, here’s a solid rule of thumb to start with:

- Metal Baffle Filters: These are your first line of defense and are meant to be reused. Plan on cleaning them daily or, at the very least, weekly. The good news is most are dishwasher-safe.

- Disposable Pre-Filters: For units that have them, a busy kitchen should expect to swap these out about once a month.

- Activated Carbon Filters: These are the workhorses for odor control. You'll likely need to replace them every three to six months.

Thankfully, many newer models have an indicator light that tells you when a filter is due for a change, which takes out all the guesswork. Sticking to a schedule is non-negotiable for keeping the air clean and the unit running efficiently.

The fastest way to kill your ventless hood's performance is to ignore the filters. Once they're clogged, the fan has to work overtime, air capture plummets, and you risk burning out the motor.

Is a Ventless Hood as Good as a Vented Hood?

This is like asking if a sports car is "better" than a pickup truck. It's not about which one is superior overall, but which one is the right tool for the job. For its intended purpose—pulling grease, smoke, and smells from approved electric appliances—a quality commercial ventless hood is incredibly effective. Its filtration system is designed to meet tough air quality standards.

But is it a direct replacement for a big Type I vented system in a kitchen cranking out food with a full gas cookline? No. The right choice always comes down to your menu, your restaurant equipment, and the limitations of your building.

Will a Ventless Hood Make My Kitchen Hotter?

This is a common misconception. It's true that a ventless hood sends filtered air back into the room instead of outside. But what people forget is that a traditional hood is constantly sucking out the conditioned air you’ve already paid to heat or cool.

The actual impact on room temperature is pretty minimal. In fact, any minor heat it recirculates is often completely balanced out by the energy your HVAC system saves by not having to fight to replace all that air being exhausted outside.

Ready to discover the latest deals and stay informed on industry trends for restaurant equipment? The experts at Encore Seattle Restaurant Equipment can walk you through the options and find the perfect fit for your kitchen's unique setup. Visit us online or stop by our Seattle showroom to get started.