Your Guide to Commercial Blast Chillers

Share

Think of a commercial blast chiller as a time machine for food temperature. It's a specialized piece of refrigeration equipment designed to do one thing exceptionally well: take hot food and make it cold, fast. By rapidly dropping the temperature, it zips food straight through the bacterial "danger zone" in a matter of minutes, not hours. This isn't just about cooling; it's about preserving the quality, texture, and flavor of your food in a way that standard refrigerators simply can't match.

The Secret to Better Food Safety and Quality

Picture a beautiful prime rib, just pulled from the oven. If you leave it on the counter to cool, it's going to spend a long, slow time sitting in what food safety experts call the "danger zone"—that temperature range between 40°F and 140°F. This is the perfect breeding ground for bacteria, and it also allows moisture to evaporate, drying out the final product. It’s a food safety gamble that also hurts the quality of your dish.

Now, let's change the scene. Instead of the countertop, that same prime rib goes into a blast chiller. In as little as 90 minutes, its internal temperature drops all the way down to a perfectly safe 38°F. That’s the magic of a blast chiller. It’s not just about refrigeration; it’s about speed.

A New Standard for Kitchen Operations

This rapid cooling process completely changes the game for a professional kitchen. It’s more than just a fancy fridge; it's an active food preservation system that directly impacts your efficiency, your food costs, and even your reputation. Being able to cool food this quickly gives you an incredible amount of control over your inventory and prep schedule.

A commercial blast chiller is quickly becoming a non-negotiable tool for any serious culinary operation.

- Elevating Food Safety: It's the most reliable way to meet HACCP standards, slashing the time food spends in the danger zone.

- Improving Operational Efficiency: Imagine making huge batches of sauces, soups, or stocks during a slow period. You can chill them perfectly, store them, and then reheat them days later with virtually no loss in quality. This is how smart kitchens get ahead.

- Enhancing Culinary Quality: Fast chilling prevents large ice crystals from forming inside the food. Those ice crystals are what destroy the cell structure, leading to a mushy texture and loss of flavor. Blast chilling keeps everything just as the chef intended.

The shift from slow, passive cooling to active, rapid chilling is at the heart of modern kitchen management. It opens the door to better planning, less waste, and a consistently excellent product for your customers.

This piece of equipment acts as a critical link in your kitchen’s safety chain, protecting ingredients from the moment they’re cooked until they’re ready to be served. These principles are a huge part of proper food handling, a topic we dive into in our guide on what is cold chain management. Bringing a blast chiller into your kitchen is a foundational step toward a safer, more efficient, and higher-quality operation.

How a Commercial Blast Chiller Actually Works

Ever seen a convection oven? Imagine one that works in reverse. Instead of blasting hot air to cook food, a blast chiller uses powerful fans to circulate intensely cold air, literally stripping the heat away from food in a fraction of the time a normal freezer would take.

It's this aggressive cooling that makes all the difference. When you put hot food into a regular freezer, it cools down slowly. This slow, passive process gives large, jagged ice crystals time to form inside the food, and those crystals shred the food's cellular walls. The result? When you thaw it out, you're left with a mushy, watery product that has lost much of its original flavor and nutrients.

A blast chiller changes the game entirely. By forcing the temperature down so rapidly, it prevents those large, destructive ice crystals from ever forming. Instead, you get tiny micro-crystals that leave the food's structure intact. This is the secret to preserving the original texture, moisture, and taste. A delicate piece of fish or a rich, hearty stew will emerge from the blast chiller tasting just as incredible as it did the moment it finished cooking.

Understanding Chilling Cycles

Blast chillers aren't just on-or-off machines; they're sophisticated pieces of equipment with different cycles tailored to different kinds of food. Knowing when to use each one is the key to unlocking the full potential of your unit and guaranteeing top-notch quality and safety.

The two main cycles you'll work with are:

- Soft Chilling: This is the more gentle approach, perfect for delicate, thin, or low-density foods. We're talking about things like fish fillets, rice, custards, mousses, and fresh vegetables. The air temperature is kept just above freezing (around 32°F or 0°C) to cool the food down quickly without freezing the surface and ruining its fragile texture.

- Hard Chilling (or Shock Freezing): This is the powerhouse setting. It's designed for dense, thick, or high-fat foods that take a long time to cool—think large roasts, thick stews, rich sauces, and multi-layered dishes like lasagna. The hard chill cycle plunges the air temperature as low as -40°F (-40°C) to pull heat from the very core of the food, getting it through the bacterial "danger zone" in record time.

The ability to switch between a gentle cool-down and an intense freeze is what makes a blast chiller so versatile. It gives chefs precise control over the preservation process, ensuring every component of a dish maintains its intended quality from preparation to service.

This technology is a cornerstone of modern food safety, primarily because it rapidly moves food through the temperature "danger zone" (5°C to 63°C) where bacteria thrive. It's no surprise the global blast chillers market, valued at around USD 286 million in 2025, is expected to jump to nearly USD 484 million by 2032. Reach-in models are poised to command a dominant 40% market share, proving just how essential they've become in professional kitchens. For a deeper dive into these trends, you can find more data at Coherent Market Insights.

What Can a Blast Chiller Actually Do for Your Restaurant?

Sure, the food safety perks of a blast chiller are a huge deal, but that's just scratching the surface. The real magic happens when you see how this single piece of equipment impacts your bottom line, streamlines your kitchen, and elevates the quality of every single plate that goes out. Think of it less as an appliance and more as a strategic investment that pays you back in multiple ways.

By giving you precise control over the cooling process, a blast chiller brings a new level of calm and predictability to the often chaotic restaurant environment. Let's break down the four biggest advantages that make this machine a game-changer for any modern kitchen.

Enhanced Food Safety and HACCP Compliance

Keeping your customers safe isn't just about following the rules—it's about earning their trust. A commercial blast chiller is your best bet for making good on that promise. It powers food through the temperature "danger zone" (from 140°F down to 40°F) well within the timeframes required by health departments. This is a critical control point for any serious HACCP plan.

This incredibly fast cooling process slams the brakes on the growth of nasty bacteria like Salmonella and Listeria. Because the process is so consistent and verifiable, you can easily document your cooling procedures for health inspectors, ensuring you're always compliant and protecting your hard-earned reputation.

Drastic Reduction in Food Waste

Food waste is like watching profits go straight into the bin. A blast chiller fights this problem head-on by dramatically extending the shelf life of everything from prepped ingredients to cooked dishes. By chilling food this quickly, you lock in its quality, allowing you to store it safely for days without sacrificing taste or texture.

This opens up a world of possibilities for repurposing food that would otherwise be thrown out. For example:

- Soups and Sauces: Cook huge batches during downtime, chill them, and have them ready to go all week.

- Cooked Meats: Chill leftover roast chicken or prime rib to use in sandwiches, salads, or daily specials.

- Vegetables: Blanch and blast-chill vegetables to preserve their vibrant color and nutrients, making them perfect for quick service.

Putting these simple practices into play can make a massive difference. For more ideas, check out our guide on reducing food waste in restaurants.

Improved Operational Efficiency

What if you could prep for a slammed Saturday night without the usual last-minute scramble? That’s what a blast chiller enables through a "cook-chill" system. Your team can prepare complex dishes, sauces, and components in large quantities when things are slow. Once cooked, everything is blast-chilled and stored, ready to be reheated and served the moment an order hits the ticket rail.

This completely changes how a kitchen operates. It levels out the intense peaks and valleys of service, massively reduces stress on your line cooks, and guarantees consistency even when you’re in the weeds. Your kitchen becomes a calmer, more organized, and far more productive place to work.

A blast chiller doesn't just cool food; it restructures your entire kitchen workflow. It shifts your team from reactive cooking to proactive preparation, giving you a powerful competitive advantage.

Superior Food Quality

At the end of the day, people come back for great food. This is where a blast chiller truly proves its worth. Traditional cooling methods create large ice crystals that shred the cellular structure of food, turning it mushy and bland. Blast chilling creates tiny micro-crystals, preserving the original texture, flavor, and nutrients of your ingredients.

Meats stay tender and juicy, vegetables keep their snap, and delicate sauces maintain their perfect, smooth consistency. The dish you serve on Thursday tastes just as amazing as it did when it was first cooked on Monday. This level of consistency is what builds a loyal following. It's no wonder the global commercial blast chiller market, valued at USD 1.5 billion in 2024, is expected to surge to USD 2.8 billion by 2033. You can read more about this market's impressive growth on Verified Market Reports.

Choosing the Right Blast Chiller for Your Kitchen

Picking out the right commercial blast chiller isn't a simple "add to cart" decision. The machine that’s a perfect fit for a massive catering operation would be a complete waste of space and money in a small bakery. On the flip side, a tiny model would create a serious bottleneck in a bustling restaurant kitchen. Getting this right means taking a hard look at your own operation—what you cook, how much you cook, and the space you're working with.

Think of it like buying a car. You wouldn't get a semi-truck to run errands around town, and you wouldn't try to haul lumber in a two-seater convertible. Your blast chiller has to be just as suited to its job. Before you even start looking at models, you need to understand your production volume, the kind of food you’re making, and the physical layout of your kitchen.

Assessing Your Kitchen’s Needs

The first thing to pin down is your daily output. How much food are you actually trying to chill, and how fast do you need it done? The key spec to look for here is the chilling capacity, which is usually measured in kilograms (kg) per cycle. This number tells you the max weight of food the machine can bring down from hot (say, 90°C) to a safe, cold temperature (like 3°C) in a standard 90-minute cycle.

To figure out the capacity you need, ask yourself these questions:

- Production Volume: Are we talking about a few pans of soup, or are you prepping for a 200-person wedding?

- Menu Type: Dense foods like a big roast or a deep pot of chili will take a lot more chilling power than delicate items like fish or pastries.

- Workflow: Do you plan on doing all your cooking and chilling in one big batch before service, or do you need to be able to chill things on the fly all day long?

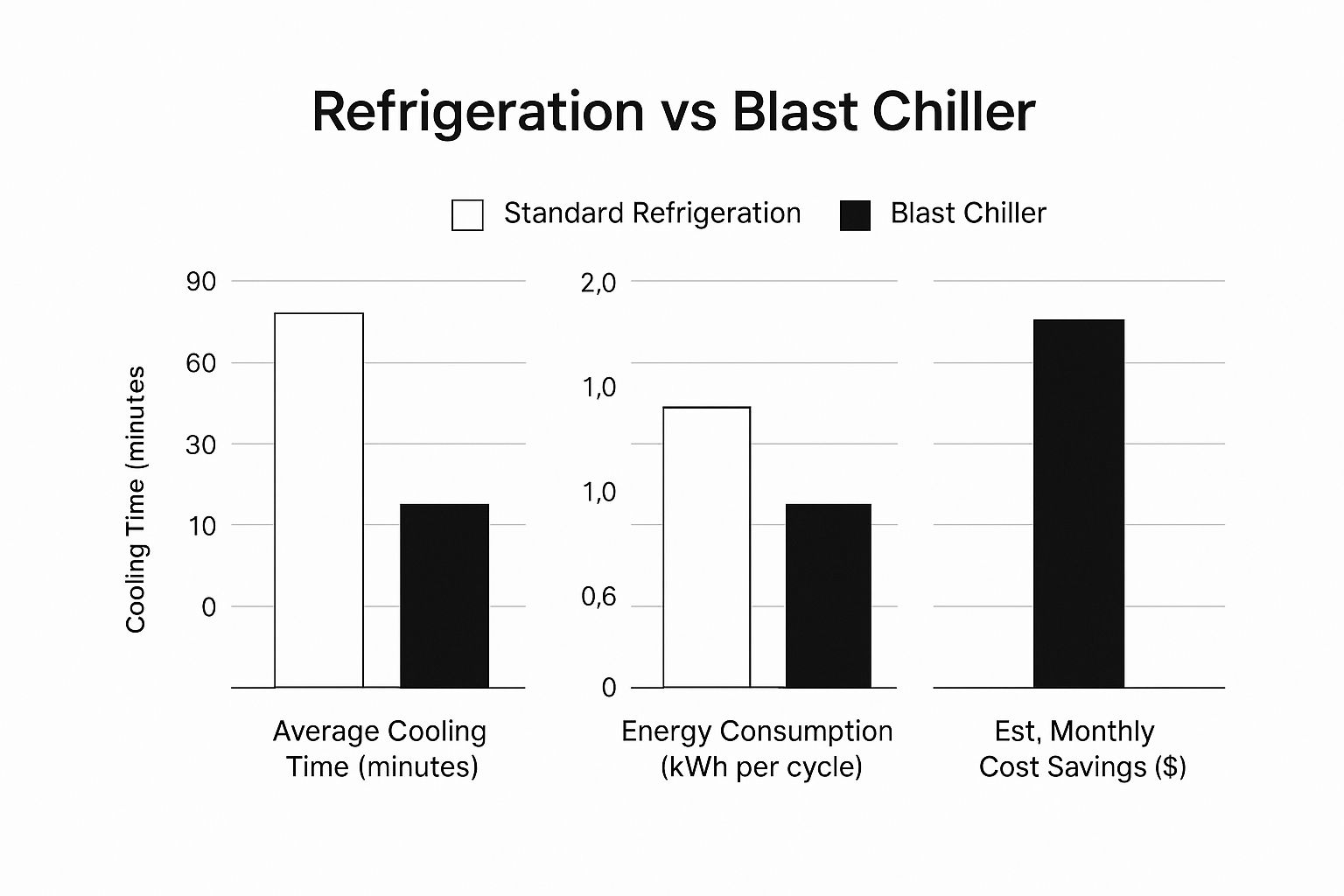

This simple breakdown shows just how different a blast chiller is from a standard fridge, not just in performance but also in what it costs to run over time.

It’s clear that while the initial price tag is higher, the savings you'll see in energy and efficiency down the road are substantial.

Matching the Model to Your Operation

Once you’ve got a solid idea of your capacity needs, you can start looking at the different types of blast chillers out there. Each one is built for a different kind of kitchen and a different way of working.

The physical footprint of a blast chiller is just as important as its chilling power. Choosing a unit that fits seamlessly into your kitchen's flow is crucial for maximizing its efficiency and usability.

- Countertop Blast Chillers: These small, mighty units are a lifesaver for kitchens tight on space—think small cafes, bakeries, or dedicated pastry stations. You get all the benefits of rapid chilling without having to rearrange your entire kitchen. The market for these compact models is actually booming, with an estimated value of USD 1.2 billion in 2025 expected to grow to USD 1.64 billion by 2035, largely because they're perfect for city restaurants and pop-ups. You can find more details on the rise of countertop models on futuremarketinsights.com.

- Reach-In Models: This is the workhorse you’ll see in most medium to large restaurants. It looks a lot like a standard upright fridge, but inside it's packed with the powerful fans and refrigeration components needed to chill food fast.

- Roll-In or Pass-Through Units: For the real heavy-hitters like big hotels, hospitals, and catering companies, these are the only way to go. You can roll an entire speed rack loaded with food straight from the oven into the chiller. It’s an incredible time-saver that cuts down on food handling and labor.

Choosing the right features can feel overwhelming, so let's break down what different types of kitchens should be looking for.

Commercial Blast Chiller Feature Comparison

| Feature | Small Cafe / Bakery | Mid-Sized Restaurant | Large Catering Operation |

|---|---|---|---|

| Capacity | Low (5-15 kg per cycle) | Medium (20-50 kg per cycle) | High (100+ kg per cycle) |

| Footprint | Compact, countertop model | Upright reach-in | Large roll-in or pass-through |

| Primary Use | Pastries, sauces, small batches | Prepping sauces, proteins, batch cooking | High-volume meal prep, cook-chill systems |

| Key Feature | Space-saving design, simple controls | Versatility, multiple probe sensors | Speed rack compatibility, advanced programming |

| Energy Efficiency | Important for low overheads | Crucial for managing daily operational costs | Essential for large-scale cost control |

This table should give you a good starting point for matching a unit's capabilities with the reality of your kitchen's day-to-day demands. Remember, the goal is to find a machine that not only meets your current needs but also gives you a little room to grow.

Best Practices for Using and Maintaining Your Equipment

Simply having a commercial blast chiller in your kitchen is one thing, but really making it work for you is another. To truly get your money's worth, you have to approach it with the same care and attention to detail you give your recipes. Mastering its day-to-day use and sticking to a maintenance routine is the only way to guarantee it runs efficiently, keeps your food safe, and avoids those dreaded, costly breakdowns.

I like to think of it like a high-performance sports car; you can't just floor it all the time and forget about oil changes. It needs the right handling and regular tune-ups to perform. For your blast chiller, proper technique is the "handling," and consistent maintenance is the "tune-up." Skimp on either, and you'll end up with unevenly chilled food, sky-high energy bills, and a much shorter lifespan for the machine.

Optimizing Your Daily Workflow

Weaving your blast chiller into your kitchen’s rhythm is all about building good habits. The goal is a smooth cook-chill process where every batch is cooled safely and evenly, locking in the quality and flavor you worked so hard to create.

- Load Smart, Not Full: This is a big one. You have to resist the urge to cram the unit full. Always leave at least 2-3 inches of breathing room between pans so that frigid air can get everywhere it needs to. An overloaded chiller has to work overtime and ends up with dangerous warm spots where bacteria can take hold.

- Use the Right Cycle: Don't just set it to the most powerful option and walk away. That "soft chill" cycle is there for a reason—it’s perfect for delicate items like fish, pastries, and vegetables, preventing ice crystals from ruining their texture. Save the "hard chill" or shock-freezing function for the dense stuff, like big roasts or a deep pot of stew.

- Probe Placement is Key: The temperature probe is your eyes and ears inside the food. You absolutely have to place it correctly. Stick it deep into the thickest part of the largest item in the batch, making sure it isn't touching a bone or the pan itself. An accurate reading is non-negotiable for food safety.

When you get this right, the blast chiller becomes the reliable heart of your kitchen's prep cycle. It stops being just a cold box and transforms into a strategic tool for managing your workflow and maintaining quality.

Creating a Simple Maintenance Schedule

Getting ahead of problems is always cheaper and less stressful than reacting to them. A straightforward maintenance schedule will keep your commercial blast chiller in peak condition without eating up too much of your team's time. A simple routine is the bedrock of any well-run kitchen.

For a deeper dive, check out our complete guide on commercial kitchen equipment maintenance for more detailed tips.

Daily Checks (Less than 5 minutes):

- Wipe down the interior walls, shelves, and floor.

- Clean and sanitize the temperature probe after every single use.

- Make sure there's no debris or food scraps inside the unit.

Weekly Tasks (Around 15 minutes):

- Give the door gaskets a quick inspection. Look for any cracks or tears where cold air could be escaping.

- Pop out the air filters or grilles and wash them, following the manufacturer’s guide.

Monthly Responsibilities (30-45 minutes):

- This is crucial: carefully clean the condenser coils. When they get clogged with dust and grease, the compressor has to work much harder, wasting energy and heading for an early grave.

- Check and clear out the drain lines to prevent clogs and nasty water backup.

Following these simple steps protects your investment and makes sure your blast chiller stays a dependable workhorse for years to come.

Blast Chiller FAQs: Your Questions Answered

Even after you're sold on the benefits, dropping a significant investment on a new piece of kitchen equipment naturally comes with a few lingering questions. Getting straight answers is the only way to feel confident about bringing a commercial blast chiller into your workflow.

Let's dive into some of the most common questions we hear from chefs and operators just like you.

How Is It Different From My Regular Freezer?

This is probably the number one question we get. It all comes down to speed and purpose. Your standard freezer is a storage locker. It’s designed to keep frozen food frozen, slowly bringing room-temperature items down over many, many hours.

A commercial blast chiller, however, is an active cooling process machine. It's not for long-term storage. It uses powerful fans to blast frigid air over food, forcing its temperature down with incredible speed. This rapid cooling preserves the food's texture and, most importantly, gets it through the bacterial danger zone in a flash.

Think of it like this: a freezer is a parking garage for your food. A blast chiller is the high-speed on-ramp that gets it safely up to speed before it parks.

So, can you actually freeze food with it? You bet. Most blast chillers have a "shock freezing" or "hard chill" cycle designed for just that. This process plummets food temperatures to -18°C (-0.4°F) or below, creating tiny ice micro-crystals. This is a game-changer because these small crystals cause far less damage to the food's cell structure compared to the large, jagged crystals that form during slow freezing.

What About Installation and Food Safety Rules?

Okay, so it’s a powerful machine. Is it a nightmare to install and maintain? Not at all.

Installation is pretty straightforward and similar to any other commercial refrigeration unit you’d buy. It just needs its own dedicated electrical circuit and enough space around it for good ventilation so the compressor doesn't have to work overtime.

Day-to-day upkeep is also quite simple. We're talking basic, routine tasks:

- Wipe down the interior and temperature probes daily.

- Check the door seals weekly to make sure you aren't losing cold air.

- Clean the condenser coils once a month to keep it running at peak performance.

And how does this fit into HACCP and food safety inspections? It's your single best tool for compliance. Food safety plans have strict rules about cooling hot food through the "danger zone" (from 63°C down to 5°C) within a specific window of time. A blast chiller is the only piece of gear that can guarantee this happens quickly and consistently every single time, making it an easily documented and reliable part of your safety protocol.

Ready to see what a blast chiller can do for your kitchen's safety, efficiency, and food quality? Explore a wide selection of top-tier commercial blast chillers at Encore Seattle Restaurant Equipment. Our team is here to help you find the perfect unit to fit your operation and your budget. Stay informed about the latest industry trends, exclusive deals, and essential news on restaurant equipment and supplies to give your business a competitive edge.

Discover the ideal blast chiller for your business at encoreseattle.com