Top Restaurant Equipment and Design for Success

Share

Defining the best restaurant equipment and design is about so much more than just splurging on shiny, expensive gear. It’s about the thoughtful marriage of a smart, workflow-focused layout with durable, high-performance equipment. When you get this combination right, you create a powerful system that drives speed, improves safety, and genuinely boosts staff morale. Staying informed about industry trends and exclusive deals on restaurant equipment and supplies is key to making the smartest investments.

Think of it as building the perfect engine for your restaurant.

Building Your Kitchen's Foundation for Success

Your kitchen is the heart of your entire operation, and it directly dictates everything from ticket times to your profit margins. A poorly designed kitchen with the wrong equipment is like an engine that’s constantly misfiring—it creates friction, wastes fuel, and is guaranteed to break down right in the middle of a dinner rush.

But a well-planned space? That’s a finely tuned, high-performance machine.

The right design erases bottlenecks and allows your team to move with a clear sense of purpose. Every single piece of equipment, from the six-burner range to the walk-in, has its place in a carefully choreographed dance. When it all works together, the results are powerful and immediate.

The Impact of Smart Design Choices

Great design isn't just another line item on your budget; it's a direct investment in your restaurant's long-term profitability. By starting with a layout that actually supports your menu and your unique style of service, you’re building a solid foundation for success. This approach thinks through the entire journey of an ingredient—from the delivery truck to the final plate—and cuts out wasted steps and physical strain on your crew.

A kitchen built on the best restaurant equipment and design principles pays off in several huge ways:

- Increased Speed and Efficiency: An optimized layout means chefs can get more done, faster. This translates directly to shorter ticket times and happier guests.

- Enhanced Safety and Morale: A logical, uncluttered workspace doesn't just reduce the risk of slips and burns; it lowers stress and makes for a much more positive and productive environment.

- Reduced Operational Costs: Choosing energy-efficient appliances and designing a flow that prevents cross-contamination can slash your utility bills and minimize food waste.

- Greater Consistency: When the kitchen runs like a well-oiled machine, the quality and consistency of every dish that leaves the pass goes way up, building a rock-solid reputation.

A thoughtfully designed kitchen is your restaurant's unsung hero. It's the silent partner working behind the scenes to make every service a success, directly impacting everything from staff retention to guest loyalty.

So what does it take to create this kind of high-performance kitchen? It’s a combination of smart planning, the right equipment, and a deep understanding of your operational needs.

Core Elements of a High-Performance Kitchen

| Pillar | Primary Goal | Impact on Your Restaurant |

|---|---|---|

| Workflow-Driven Layout | To create a logical flow for staff and ingredients. | Reduces chaos, speeds up ticket times, and minimizes accidents. |

| Durable Equipment | To withstand the demands of a commercial kitchen. | Lowers repair costs, ensures reliability during peak hours. |

| Ergonomic Design | To reduce physical strain on the kitchen staff. | Improves morale, increases productivity, and lowers injury risk. |

| Code Compliance | To meet all local health and safety regulations. | Avoids fines, ensures a safe environment, and protects your license. |

Ultimately, these pillars work together to create a space that doesn’t just function—it excels.

Assembling Your Kitchen Blueprint

Building this engine requires a solid plan. Before you even think about picking out a single piece of equipment, you have to get crystal clear on your menu's demands and your service goals.

Are you running a high-volume, fast-casual joint or a fine-dining spot where every dish is a work of art? The answer to that question will shape both your layout and the specific tools you need to execute.

To get started, the first step is always to map out every single piece you'll need. For a detailed breakdown, our complete guide on creating a comprehensive restaurant kitchen equipment list is the perfect place to begin. Think of this list as your blueprint—it’s what ensures you build a kitchen that’s not just functional, but truly foundational to your long-term success.

Designing a Smarter Commercial kitchen Layout

Think of your commercial kitchen layout as the silent partner in your restaurant's success. A bad one causes chaos—think constant traffic jams, lagging ticket times, and a frustrated crew. You can have the best equipment money can buy, but if the flow is broken, it's all for nothing. A great layout, on the other hand, is like a perfectly choreographed dance where every step is planned and every movement has a purpose.

Getting that choreography right starts with your menu and service style. The needs of a high-volume ghost kitchen are worlds apart from an intimate fine-dining spot. The real goal is to design a space that cuts out wasted steps, slashes the risk of accidents, and keeps your kitchen humming, even when you're slammed on a Saturday night.

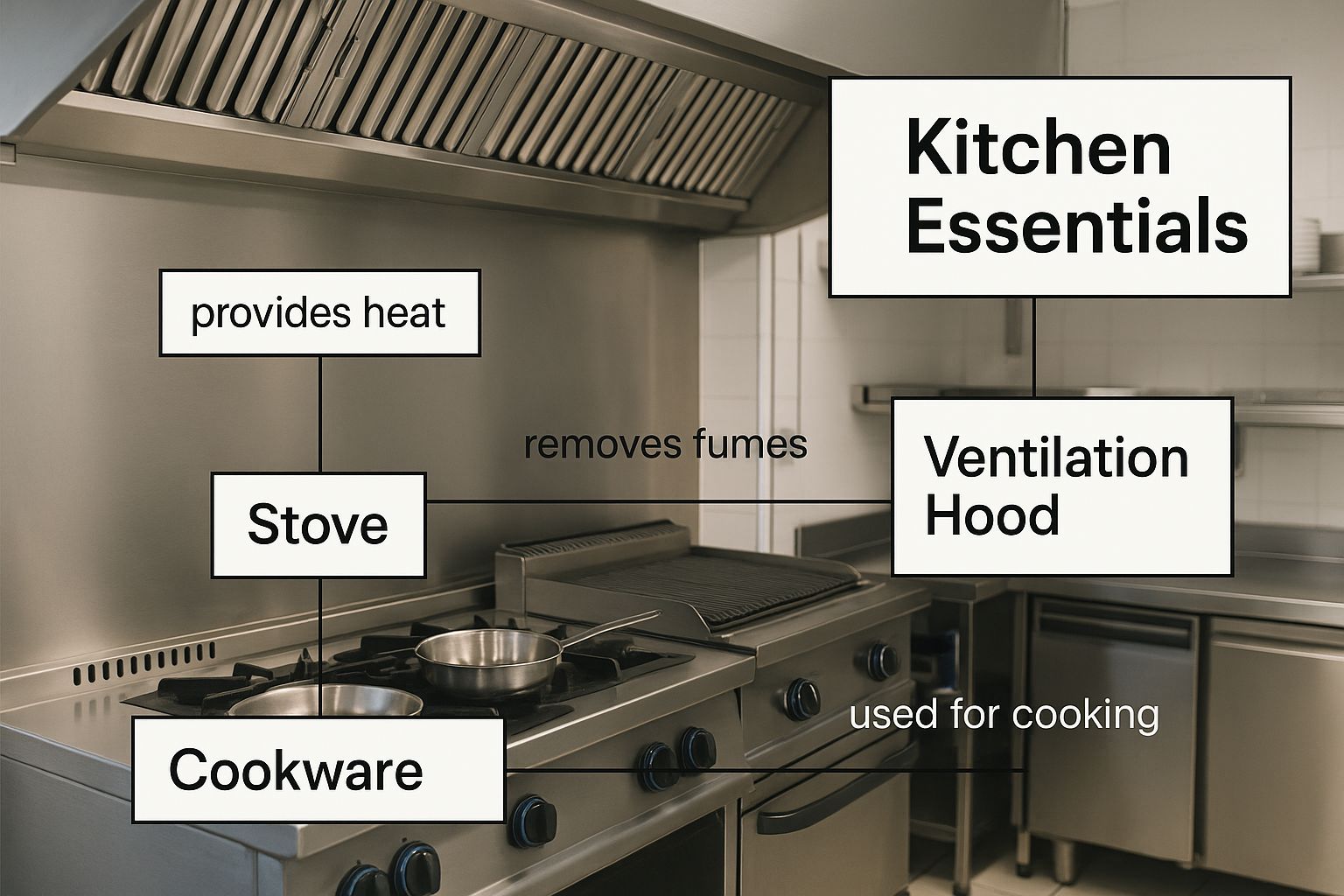

This infographic breaks down some of the core equipment that needs a strategic home in any effective layout.

As you can see, where you put these essentials is just as critical as what you buy.

From Triangles to Modern Work Zones

For years, the old-school "kitchen work triangle"—linking the sink, fridge, and stove—was the go-to design rule. It’s a simple idea, but frankly, it’s outdated for the fast-paced, complex world of a modern commercial kitchen. These days, we think in terms of work zones or stations. It's just a more practical and efficient way to operate.

A work zone is simply a dedicated area where a specific task gets done from start to finish. This approach organizes your kitchen into logical hubs of activity.

- Receiving and Storage: This is your inventory's first stop. It needs to be right by the delivery entrance, with your dry storage, walk-in coolers, and freezers close at hand.

- Food Prep: Here’s where the magic starts—washing, chopping, and portioning raw ingredients. This zone demands prep tables, sinks, and quick access to refrigeration.

- The Cooking Line: The heart of the operation. This is home to your ranges, ovens, fryers, and grills. It's all about heat, speed, and execution.

- Service & Pass: The final stop before food hits the table. You'll find plating areas and heat lamps here, and it has to connect seamlessly to both the cooking line and the front-of-house.

- Sanitation (The Pit): Home to dish machines, three-compartment sinks, and drying racks. To avoid cross-contamination, this area needs to be kept separate from your food prep zones.

Organizing your kitchen into these dedicated zones creates clear pathways for your team, which means fewer collisions and less confusion. This modern approach to layout is a cornerstone of efficient https://encoreseattle.com/blogs/seattle-restaurant-equipment/commercial-kitchen-design-layout.

Choosing the Right Layout for Your Concept

A few tried-and-true layouts serve as great starting points. The trick is picking the one that actually matches how your restaurant works day-to-day.

- Assembly Line Layout: This is perfect for businesses with a linear workflow, like a busy pizzeria or a sandwich shop. Stations are arranged in sequence, moving the product from one step to the next. It’s all about maximizing speed and consistency.

- Island Layout: This design puts a central block of cooking equipment right in the middle, with other zones built around the perimeter. It’s fantastic for communication and works well in kitchens where multiple chefs are collaborating.

- Zone-Style Layout: A really versatile option that creates separate stations for different parts of the menu (think a dedicated grill station, fry station, and salad station). This is ideal for restaurants with diverse menus because it lets specialists focus on their craft without getting in each other's way.

When you're designing a complex kitchen, you have to think about how all the different systems—plumbing, electrical, ventilation—will fit together without clashing. To see how the pros solve these puzzles, check out these real-world clash detection and coordination case studies. At the end of the day, the best layout is the one that feels intuitive to your team, making their jobs easier and more productive.

How to Select the Right Commercial Kitchen Equipment

Think of outfitting your commercial kitchen like casting the perfect team for a championship run. Every single piece, from that six-burner range to the walk-in freezer, has a critical role to play. They all need to be top performers, working in sync to handle the crushing pressure of a dinner rush. Investing smartly here isn't about grabbing the fanciest brand names; it's about picking tools that are built to last, run efficiently, and are a perfect match for your specific menu and workflow.

This whole selection process is fundamental to achieving the best restaurant equipment and design. Why? Because the right gear directly impacts your kitchen's speed, the consistency of your dishes, and ultimately, your bottom line. A dependable oven or an energy-sipping freezer can be the unsung hero that separates a smooth, profitable service from a night of pure, costly chaos.

It’s no surprise that the market for this equipment is huge and getting bigger. The global food service equipment market was pegged at around USD 39 billion in 2024 and is on track to blow past USD 58 billion by 2030. This boom is fueled by major shifts in how people dine, like the explosion in takeout and fast-casual, which demand kitchens that are leaner and meaner than ever before. This trend just underscores how vital it is for restaurant owners to invest in equipment that can keep up with the pace.

Key Factors for Smart Equipment Investment

Before you even think about adding an item to your cart, you need a solid game plan. Looking past the initial price tag is the secret to choosing equipment that delivers real value for years, not just short-term headaches. Consider it a pre-purchase inspection to make sure you’re bringing home a workhorse, not a lemon.

Here are the non-negotiables you should be looking at:

- Energy Efficiency: Always look for the ENERGY STAR® logo. These certified machines can be 15-30% more energy-efficient than their standard counterparts, which translates directly into hefty savings on your utility bills month after month.

- Material and Durability: There's a reason stainless steel is the king of the kitchen—it’s tough, non-porous, and a breeze to sanitize. But not all steel is created equal. Pay attention to the grade; Type 304 stainless steel, for example, offers fantastic corrosion resistance, making it the perfect choice for most kitchen environments.

- Ease of Maintenance: Sooner or later, every piece of equipment needs a little TLC. Go for models known for having easily accessible components and a rock-solid reputation. Scour reviews and, better yet, talk to other chefs and owners to find out how simple a machine is to clean and get repaired.

- Functionality and Size: This is all about fit. Does the equipment actually fit in your space, and does it fit your menu? A gigantic convection oven is completely useless if it creates a bottleneck in your kitchen's flow or if you really only need a smaller, more versatile model for what you cook.

Smart Investments in Core Kitchen Categories

You can really break down your kitchen's needs into four foundational pillars. If you focus your budget and attention here, you’ll build a solid operational base. For a truly granular look at every last item you might need, our in-depth commercial kitchen equipment checklist is the perfect guide.

1. Cooking Equipment

This is the heart and soul of your operation. The choices you make here should be a direct reflection of what’s on your menu. A classic steakhouse is going to pour its money into high-octane grills and broilers, while a bakery will be looking for best-in-class convection ovens and proofing cabinets. The key is to avoid overbuying. Get the equipment you need for 80% of your menu, not for that one obscure dish you might run as a special twice a year.

2. Refrigeration

When it comes to food safety and managing inventory, solid refrigeration is absolutely non-negotiable. Invest in reliable walk-in coolers, reach-in freezers, and handy under-counter units. Keep an eye out for models with heavy-duty compressors and precise digital temperature controls. A single failure in this department can easily cost you thousands of dollars in spoiled product overnight.

Think of your refrigeration units as the silent guardians of your inventory. Investing in quality here protects your ingredients, ensures food safety, and prevents the catastrophic financial loss that comes from spoilage.

3. Food Preparation

A smooth service always starts with efficient prep work. Commercial mixers, food processors, slicers, and sturdy stainless steel work tables are the essential tools of the trade. Your goal here is to pick equipment that cuts down on labor and guarantees consistency, whether it's for perfectly thin-sliced onions or dough that's been mixed to perfection every single time.

4. Sanitation and Storage

A clean and organized kitchen isn't just a pleasant place to work—it's a safe and efficient one. A three-compartment sink is a must for washing dishes by hand, and a high-temp commercial dishwasher is a game-changer, capable of sanitizing hundreds of dishes an hour. Pair this with NSF-certified shelving to keep all your dry goods, tools, and clean wares neatly organized and safely off the floor, which will keep the health inspector happy.

The Future of Kitchens: Smart and Sustainable Tech

The commercial kitchen is changing, and fast. For years, "the best" equipment and design simply meant heavy-duty stainless steel and a layout that made sense. But that's no longer the whole story. Today, the real innovation is happening at the intersection of two powerful trends: smart, connected technology and a serious commitment to sustainability. These aren't just bells and whistles; they're fundamental upgrades that make kitchens more efficient, less wasteful, and ultimately, more profitable.

Think of it this way: smart tech gives your equipment a brain. We're seeing more and more appliances connected through the Internet of Things (IoT), creating a network where your ovens, fryers, and refrigerators can talk to you—and each other. This isn't some far-off concept; it's practical, powerful, and already here.

The Rise of Intelligent Appliances

Smart equipment gives you a level of control and foresight that was impossible a decade ago. Imagine your walk-in freezer sending an alert to your phone because the temperature is creeping into the danger zone, letting you save thousands of dollars in spoiled inventory. Or picture your convection oven diagnosing a failing fan motor and scheduling its own service call before it dies in the middle of a Saturday night dinner rush.

This connected ecosystem offers some huge advantages:

- Predictive Maintenance: Onboard sensors keep an eye on equipment health, flagging potential problems before they turn into catastrophic failures.

- Remote Monitoring: You can check equipment status, tweak temperatures, and even preheat ovens from your phone, whether you're at home or running errands.

- Data-Driven Insights: These appliances track everything from energy consumption to performance cycles, giving you hard data to make smarter decisions about your workflow and menu.

Adopting smart technology is like hiring a vigilant assistant for every piece of equipment in your kitchen. It's about preventing problems instead of just reacting to them, which is a game-changer for operational reliability and cost control.

This shift is part of a much bigger movement. The global restaurant equipment market is set to explode, growing from USD 4.8 billion in 2025 to a projected USD 10.2 billion by 2035. This growth isn't just about replacing old gear; it's driven by a demand for smarter, more energy-efficient equipment that streamlines the entire kitchen.

Embracing Sustainable and Cost-Saving Technology

Right alongside smart tech, sustainability has become a cornerstone of modern kitchen design. And let's be clear: investing in eco-friendly equipment isn't just about feeling good. It's one of the smartest financial moves you can make, with a fantastic return on investment.

High-efficiency equipment is engineered to do more with less. Take ENERGY STAR® certified appliances, for example. They can use up to 30% less energy than standard models, which translates directly into lower utility bills month after month.

This goes for cooking, too. Induction cooktops are a perfect example, transferring heat directly to the pan with up to 90% efficiency. Compare that to a traditional gas range, which wastes most of its heat into the air and operates at around 40% efficiency. This means faster cook times, a cooler kitchen, and a much more comfortable environment for your staff. To get ahead of the curve, it's also worth looking into things like commercial LED lighting upgrades, which cut down your energy footprint even further.

Other technologies making a real impact include high-efficiency dishwashers that can slash your water consumption by thousands of gallons a year and ventless cooking equipment that eliminates the need for massive, expensive hood systems. By weaving these smart and sustainable solutions into your design, you're not just building a kitchen for the future—you're building a more resilient and profitable one today.

Weaving Your Equipment and Layout into a Cohesive Workflow

Nailing the perfect commercial kitchen layout is a huge step, but it's only half the journey. If you take all that amazing, high-end equipment you've selected and just drop it into the wrong spots, you're setting your team up for failure. It’s like having a championship sports team but putting every player in the wrong position—the talent is there, but the execution will be a mess.

The real magic happens when your physical space and your tools are in perfect sync. You want to create a logical, intuitive path that food and staff follow, from the receiving dock all the way to the pass. Getting this integration right is what separates a good kitchen from a great one, directly impacting speed, safety, and your team's sanity.

Strategic Placement is Everything

Every single piece of equipment has a "right" home. Putting it there can make a night-and-day difference in how your kitchen runs. This isn't about aesthetics; it’s about pure, simple ergonomics and common sense. Smart placement cuts down on wasted steps, which saves time and, ultimately, money.

Here are a few golden rules I've seen work time and time again:

- Keep Hot and Cold Apart: This is non-negotiable. Never, ever place your coolers or freezers right next to your ovens, fryers, or ranges. Your refrigeration will be forced to work overtime, fighting a constant battle against the heat. This is a massive energy drain and a surefire way to burn out your compressors.

- Shrink the "Travel Triangle": Think about the path your cooks travel. Key prep stations should be located logically between storage and the main cooking line. For example, a garde manger station needs its own under-counter or reach-in cooler right there, so your salad cook isn't constantly running to the walk-in for ingredients.

- Group by Function: This just makes sense. The ice machine should be near the beverage station. The commercial dishwasher needs to be right next to where the dirty dishes are dropped off. When you group related tasks together, you create zones that even brand-new staff can pick up on quickly.

A well-integrated kitchen helps your team operate on muscle memory. When everything is exactly where it should be, the work becomes fluid and instinctual, helping to get plates out faster and keeping stress levels down during a chaotic service.

Don't Forget the Unseen Infrastructure

Beyond where you place the big-ticket items, you have to think about the kitchen's central nervous system: the electrical, plumbing, and ventilation. This is where meticulous planning pays off big time. Trying to add a new gas line or floor drain after the fact isn't just a headache—it's incredibly expensive.

The industry itself is pouring more money into this crucial foundation. The market for commercial cooking equipment manufacturing in the U.S. was already sitting at about USD 6.4 billion in 2024 and is on track to hit USD 6.7 billion in 2025. This isn't just about shiny new ovens; a lot of that investment is going into the essential systems that make them run. You can see more on the growth of the commercial cooking equipment market on ibisworld.com.

Before you sign off on any layout, you absolutely must map out these connections:

- Electrical Needs: Power-hungry beasts like combi ovens and big electric fryers demand specific voltage and dedicated circuits. Bring in an electrician early to map everything out and make sure your panel can handle the load without tripping breakers mid-service.

- Plumbing and Gas Lines: Every sink, dishwasher, and steam table needs water and a drain. Gas-powered equipment needs professionally installed lines. These have to be planned to the inch to line up perfectly with your equipment specs.

- Ventilation: Your hood system is one of the most important—and most regulated—pieces of your kitchen. It has to be sized and installed correctly over your cookline to pull heat, smoke, and grease out of the air. A properly ventilated kitchen is a safe, comfortable, and compliant kitchen.

Finding Exclusive Deals and Navigating Regulations

Getting your kitchen set up is a two-pronged effort that goes way beyond just picking out shiny new equipment. On one hand, you have to be a savvy shopper, sniffing out the best deals to protect your budget. On the other, you need to become an expert on the maze of health codes and safety standards that govern every inch of your space. Nail both, and you’re setting yourself up for success from the get-go.

Think of regulations as the non-negotiable rulebook for your kitchen. Trying to sidestep them is a recipe for disaster—we're talking hefty fines, failed inspections, and even forced shutdowns. Before you even think about swiping a credit card for a new range, you need a rock-solid understanding of what your local health department, fire marshal, and ADA guidelines demand.

Staying Compliant and Passing Inspections

It’s the small misses that cause the biggest headaches down the line. A simple oversight, like buying shelving that isn't NSF-certified or not leaving enough space between your fryer and the wall, can bring your opening plans to a screeching halt. Passing that first critical inspection is all about careful planning and a serious eye for detail.

Here’s a practical checklist to keep you on the straight and narrow:

- Go Local First: National standards are a good starting point, but your city or county health department has the final word. Always start with their specific codebook.

- Check for Certifications: Look for the right acronyms. Every piece of equipment should have its credentials, like NSF for sanitation and UL for electrical safety.

- Nail Your Ventilation: Your commercial hood is one of the most scrutinized parts of your kitchen. It has to be the right size, installed perfectly, and meet strict fire codes. No exceptions.

- Mind the Gaps: Pay close attention to the required clearances around cooking equipment and in walkways. This is crucial for both fire safety and making sure your kitchen is accessible.

Navigating regulations isn't just about ticking boxes on a form. It's about building a kitchen that's fundamentally safe and smart—a space that protects your staff, your customers, and the business you've worked so hard to build.

Sourcing Equipment and Finding the Best Deals

Once you've got the rules down, it’s time to hunt for value. Knowing where to look and when to buy can literally save you thousands of dollars, freeing up cash for other parts of your business. A great first step is to subscribe to industry newsletters and trade publications; they’re often the first to announce new products and exclusive supplier deals on restaurant equipment and supplies.

To really source like a pro, you have to think beyond a single supplier.

- Bundle and Bargain: If you're buying a whole kitchen's worth of equipment from one place, don't be shy about asking for a package deal. Most vendors will knock down the price to lock in a big sale.

- Buy Used, But Smart: You can find incredible bargains on pre-owned equipment, especially on bomb-proof items like stainless steel prep tables or heavy-duty ranges. Just make sure you’re buying from a reputable dealer who offers professionally refurbished gear with a warranty.

- Time Your Purchases: Keep an eye out for end-of-year sales, trade show specials, and model closeouts. Suppliers are always looking to clear out last year's inventory, and that’s your chance to swoop in for a deep discount.

When you blend smart sourcing with a solid grasp of regulations, you're not just building a well-designed kitchen. You're building one that's cost-effective, safe, and made to last.

A Few Common Questions We Hear

When you're designing a commercial kitchen, a lot of questions come up. It doesn't matter if you're a veteran chef opening your fifth spot or a first-timer just getting your feet wet—getting solid answers is key to making smart decisions that don't drain your bank account.

Let's dive into some of the most common questions we get from people in the industry.

How Much Space Does My Kitchen Really Need?

The old rule of thumb says your kitchen should take up about 25-35% of your restaurant's total space. But honestly, that's just a starting point. Think about it: a delivery-only ghost kitchen will naturally need a much bigger slice of the pie, while a fine dining restaurant with a huge seating area might be fine on the lower end of that scale.

Ultimately, the right size comes down to your menu, your service style, and how much storage you need. Always, always design for a smooth workflow first, not a magic number.

What's The One Piece of Equipment I Can't Skimp On?

Every kitchen has its own "must-haves," but if I had to pick one, it's top-notch commercial refrigeration. A cheap unit failing overnight can cost you thousands in spoiled food and shut you down completely. Your walk-in coolers and freezers are the unsung heroes protecting your inventory, keeping food safe, and guarding your profits.

Once your cold storage is solid, your main cooking line—your range, oven, or fryer—is the next critical piece. That's the heart of the whole operation.

Your refrigeration is the only thing in your kitchen that runs 24/7. Splurging on a durable, energy-efficient model isn't just about food safety; it's a long-term financial move that will save you a fortune on electricity bills.

Should I Buy New or Used Equipment?

Ah, the classic budget dilemma. The smartest move is usually a mix of both. For the really complex gear with lots of moving parts or sensitive electronics (think combi ovens or high-temp dishwashers), buying new with a warranty is almost always the way to go. It’s just not worth the headache.

On the other hand, you can get fantastic deals on used equipment for the simpler, sturdier stuff. Items like stainless steel prep tables, sinks, and even some beastly old gas ranges can be found refurbished from a good dealer for a fraction of the price, and they'll last for years.

How Do I Keep Up With The Latest Gear and Deals?

Staying in the loop is crucial for making the best restaurant equipment and design choices. A great way to discover the latest news and exclusive deals on restaurant equipment is by subscribing to industry newsletters and following the blogs of reputable suppliers. You'll find product reviews, get expert advice, and often be the first to know about sales or new releases. This helps you stay informed about industry trends, ensuring you're always making the smartest investment.

Ready to build a kitchen that truly works for you? The team at Encore Seattle Restaurant Equipment has been outfitting chefs and restaurateurs across the Pacific Northwest since 1990. Check out our huge selection of new and used equipment and get the expert support you deserve at https://encoreseattle.com.