What Is HACCP Food Safety Explained for Restaurants

Share

HACCP, which stands for Hazard Analysis and Critical Control Point, is a globally recognized system for making sure the food you serve is safe. Forget waiting for health inspectors to find problems; this is a proactive, science-driven approach that lets you get ahead of food safety issues.

Think of it as a pre-flight checklist for your kitchen. It’s all about identifying exactly where things could go wrong—from receiving to serving—and putting controls in place to stop disasters before they even start. By integrating this system, restaurant owners and chefs can not only ensure safety but also stay informed about industry trends that prioritize proactive management.

Why Smart Kitchens Run on HACCP Food Safety

For any chef or restaurant owner juggling a million things, HACCP isn't just another box to tick. It’s your operational playbook for food safety. Instead of scrambling when an inspector shows up unannounced, you’re in control. You have a system that protects your food from the moment a delivery truck backs up to your door to the second a beautiful plate lands on a customer's table.

This methodical approach completely shifts your focus from fixing mistakes to preventing them in the first place. It gives you a clear, logical framework to map out your entire food prep process and pinpoint the exact steps where hazards—like bacteria, cross-contamination with allergens, or even physical contaminants—could creep in.

Moving From Reactive To Proactive

Let's be honest, the old-school approach to food safety often felt like a guessing game. You'd do your best and hope for the best during spot-checks or end-product testing. The problem? That’s a reactive model. You only discover an issue after it’s already happened. HACCP flips that script entirely by building safety checks directly into your kitchen’s daily workflow.

It's all about switching from a "wait and see" mindset to one of constant prevention. The table below really highlights the difference in thinking.

HACCP A Proactive Safety Playbook

| Food Safety Approach | HACCP System (Proactive) | Traditional Inspections (Reactive) |

|---|---|---|

| Core Philosophy | Prevent hazards before they occur. | Find and correct problems after they exist. |

| Focus | The entire process, from supplier to customer. | The final product and a snapshot in time. |

| Timing of Control | Continuous monitoring at critical steps. | Sporadic checks during inspections. |

| Responsibility | Owned by the kitchen staff and management. | Driven by external inspectors. |

| Outcome | Consistent safety, reduced waste, improved efficiency. | Inconsistent results, potential for costly errors. |

As you can see, the HACCP system puts the power back in your hands. A proactive kitchen is a smart, efficient, and safe kitchen.

A robust HACCP plan is one of the smartest business decisions a restaurateur can make. It protects your customers, safeguards your reputation, and ultimately makes your entire kitchen more organized and efficient.

Building A Foundation Of Safety

Putting a solid HACCP plan in place means looking at your operation from every angle. It's not just about cooking temperatures; it’s about the whole environment. Things like proper staff training, equipment maintenance, and even diligent pest management are all part of the big picture. For example, maintaining a clean facility includes having plans for effective rodent control to prevent contamination.

When you adopt this global standard, you're doing more than just following the rules. You're making a long-term investment in your restaurant's brand and future success. It sends a clear message to your customers that you take quality seriously, building a level of trust that keeps them coming back. That commitment is what truly separates the good restaurants from the great ones.

Breaking Down the 7 Principles of HACCP

A strong HACCP plan isn't built on abstract rules; it's a practical system based on seven core principles. Think of them as a series of connected, logical steps that create a complete safety loop for everything that happens in your kitchen. This framework takes the vague goal of "keeping food safe" and turns it into a clear, manageable process your team can follow every single day.

To make this real, let's follow a case of raw chicken from the moment it arrives at your delivery dock to when it lands on a customer's plate. This journey will show you exactly how these principles work in a busy restaurant.

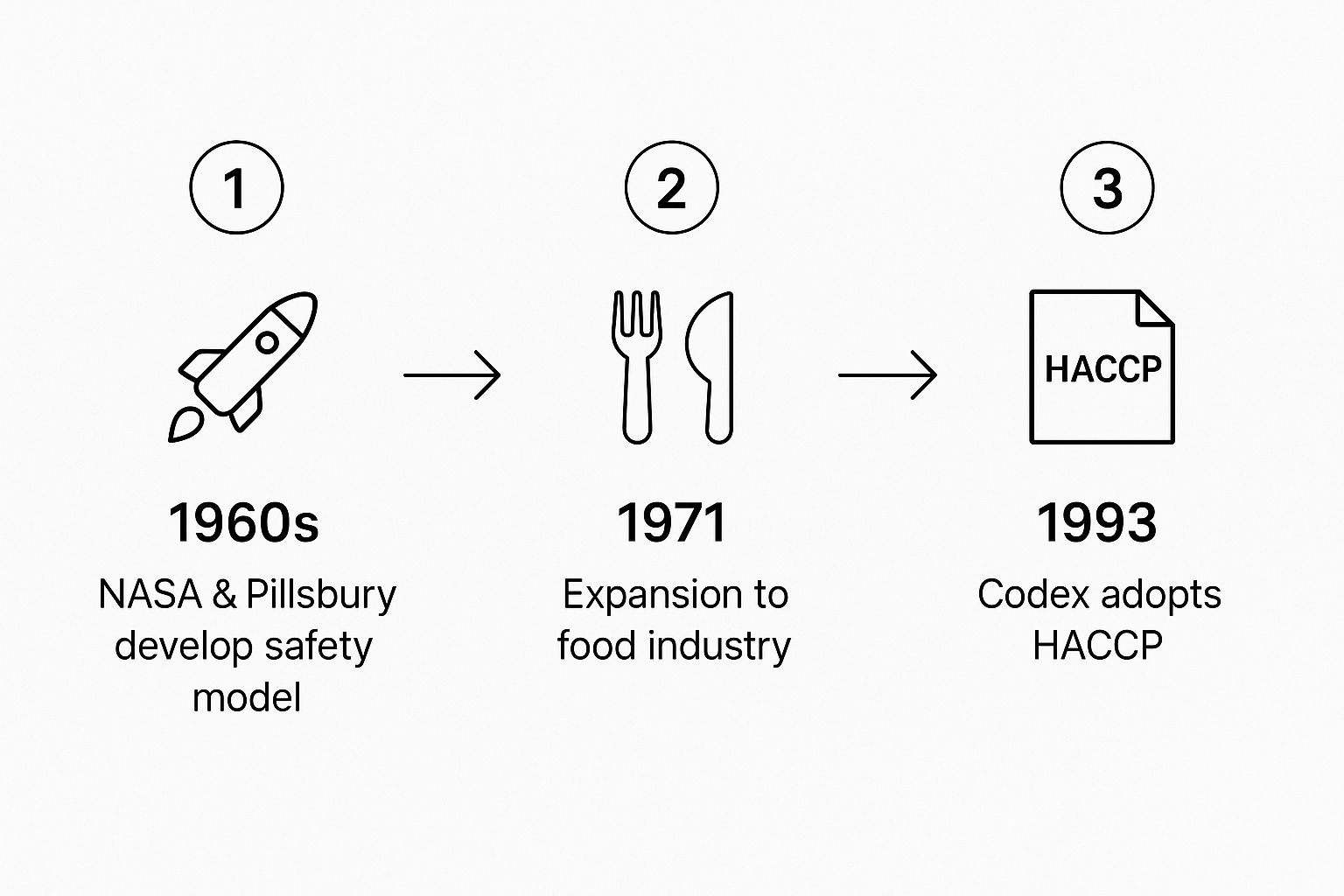

The infographic below shows just how far HACCP has come, evolving from a specialized tool for space missions into the global standard for food safety it is today.

This timeline highlights how effective HACCP is, leading to its adoption and endorsement by international food safety authorities worldwide.

Principle 1: Conduct a Hazard Analysis

This is where you put on your detective hat. The first move is to map out every single step in your food's journey and identify any potential food safety hazards. You're looking for where things could go wrong with biological, chemical, or physical contaminants.

For our chicken, the hazard analysis would flag points like these:

- Receiving: Biological hazard (Salmonella or Campylobacter on the raw chicken) or a physical hazard (like torn packaging).

- Storage: Biological hazard (bacteria multiplying if the cooler isn't cold enough).

- Preparation: Biological hazard (cross-contamination from raw chicken juices getting onto a ready-to-eat salad via a shared cutting board).

- Cooking: Biological hazard (pathogens surviving if the chicken isn’t cooked to a safe temperature).

- Holding: Biological hazard (bacteria growing if cooked chicken sits in the "danger zone" for too long before serving).

Principle 2: Find the Critical Control Points (CCPs)

After you've listed the potential dangers, you need to pinpoint the exact moments where you can step in to prevent, eliminate, or reduce that hazard to a safe level. These essential steps are your Critical Control Points, or CCPs.

Not every step is a CCP. A CCP is a kill-or-control point—a moment where, if you lose control, a health risk is likely to happen.

On our chicken's journey, the clear CCPs are:

- Storage: The temperature of your walk-in cooler.

- Cooking: The final internal temperature of the chicken.

- Holding: The temperature of the hot-holding station.

You might notice that prepping the chicken (cutting it) isn't a CCP for the chicken itself. Instead, that step is managed by good hygiene practices—what we call prerequisite programs—which are vital for preventing cross-contamination.

Principle 3: Set Critical Limits

For every CCP you've identified, you need to set clear, measurable rules that define what’s safe and what’s not. These are your critical limits. They have to be specific and based on science, leaving zero room for interpretation.

A critical limit is a non-negotiable target. It’s the minimum or maximum value you must hit at a CCP to control a hazard. Saying "cook chicken well" is useless. "Cook chicken to a minimum internal temperature of 165°F for 15 seconds" is a critical limit.

Applying this to our chicken CCPs:

- Storage CCP: The walk-in cooler must stay at 41°F or below.

- Cooking CCP: The chicken's internal temperature must hit at least 165°F.

- Holding CCP: Once cooked, the chicken must be held at 135°F or above.

Principle 4: Monitor Everything

How do you know if you're hitting your critical limits? You watch them. This principle is all about setting up a system to regularly observe and measure your CCPs. Monitoring is your early-warning system—it tells you if you're drifting off course so you can fix it before it becomes a real problem.

Good monitoring is consistent and written down. It answers four key questions:

- Who: A specific line cook is assigned to check temperatures.

- What: They measure the internal temperature of the thickest part of the chicken.

- How: They use a calibrated digital thermometer.

- When: They check every single batch of chicken cooked during their shift.

Principle 5: Plan Your Corrective Actions

Even in the best kitchens, things go wrong. A corrective action is your pre-planned response for when monitoring shows you've missed a critical limit. Deciding these actions ahead of time prevents panic and ensures everyone on your team reacts correctly and safely.

For instance, if the thermometer shows a chicken breast is only at 155°F, the corrective action is simple: put it back on the heat until it reaches 165°F, and make a note of it in the log.

Principle 6: Verify That Your Plan Works

Verification is like stepping back to double-check your work. It's the process of confirming that your whole HACCP system is actually doing its job. These are activities that prove your plan is scientifically sound, that your team is following it, and that it's effectively controlling the hazards you identified.

Verification could mean routinely calibrating your thermometers, having a manager review temperature logs each week, or even sending food out for occasional microbial testing.

Principle 7: Keep Good Records

If you didn't write it down, it didn't happen. The final principle is about documenting everything. Meticulous records are your proof that the system is functioning correctly, day in and day out.

This includes your hazard analysis, your CCPs and critical limits, all your monitoring logs, any corrective actions you took, and your verification activities. These documents are crucial not just for your own review, but for demonstrating compliance when a health inspector walks through the door.

The results of this kind of systematic control are huge; countries that mandate HACCP have seen some food contamination outbreaks drop by as much as 50%. By controlling hazards at these critical points, you're not just following rules—you're actively preventing foodborne illness. You can discover more insights about these food safety improvements and their global impact.

Your Step-By-Step HACCP Implementation Guide

It's one thing to understand the seven principles of HACCP, but it's another thing entirely to make them work in a bustling kitchen. Building your own plan from scratch can feel daunting, but it doesn't have to be. Think of this guide as your roadmap, breaking the process down into manageable steps that actually fit into your restaurant's daily grind.

The goal here is to get you from theory to action. We’ll focus on the practical tools—checklists, logs, and simple documentation—that will help you build a system that works for your menu, your team, and your kitchen.

Assemble Your HACCP Team

First things first: you need to put together a food safety team. This doesn't need to be a formal committee. In a smaller restaurant, it might just be you and your head chef. The important thing is to involve people who have real, hands-on knowledge of how your kitchen flows every single day, from receiving deliveries to plating the final dish.

This core group will take the lead on building the plan, rolling it out, and checking in on it down the road. Their combined experience is gold when it comes to spotting realistic hazards and creating control points that actually make sense for your operation.

Create a Detailed Food Flow Diagram

Before you can tackle hazards, you need a crystal-clear picture of how food moves through your kitchen. A food flow diagram is just a simple visual map that charts an ingredient’s journey from the delivery truck to the customer's plate. This isn't about abstract theory; it's about seeing how food safety plays out in your physical space.

Try it with a single menu item, like your signature burger patty:

- Receiving: Ground beef arrives from your supplier.

- Storage: The meat is immediately placed in the walk-in cooler.

- Preparation: It's portioned and formed into patties at a designated prep station.

- Cooking: The patty is cooked on the grill to a specific internal temperature.

- Assembly: The cooked patty is placed on a bun with toppings.

- Holding/Serving: The finished burger is served immediately or held under a heat lamp for a brief period.

Mapping this out for your most important menu items gives you a powerful visual. It makes spotting potential problems in the next step much, much easier.

The most effective HACCP plans are built on a deep understanding of a kitchen's unique processes. A detailed flow diagram is the foundation of that understanding, revealing every point where control is critical.

Use Practical Worksheets and Checklists

With your team and flow diagrams ready, you can get into the real work of implementing the HACCP principles. This is where practical tools like worksheets and checklists become your best friends, keeping everything organized and your documentation clean.

A simple hazard analysis worksheet helps you systematically go through each step in your flow diagram. Just create columns for the process step, potential hazards (biological, chemical, physical), why it’s a hazard, and what preventive measure you’ll use to control it.

As you implement your HACCP plan, you'll need a way to ensure everyone is sticking to the standards. You can lean on resources like audit and compliance checklist templates specifically for the food and beverage industry to make this part easier. These kinds of tools offer a ready-made format for everything from receiving logs to daily temperature checks.

Focus on Clear and Simple Documentation

The final piece of the puzzle is documentation. Your records are the proof that your system is working as intended. But this doesn’t mean you need to drown in binders full of complicated forms. Your paperwork should be as simple and straightforward as possible so your team will actually use it consistently.

Here are a few essential documents you’ll want to create and maintain:

- Temperature Logs: Simple daily sheets for fridges, freezers, and hot-holding units.

- Receiving Checklists: A quick form to verify that deliveries meet your safety criteria (e.g., proper temperature, no damaged boxes).

- Corrective Action Reports: A basic log for when a critical limit is missed, noting what went wrong and what was done to fix it.

By breaking down the implementation into these focused steps and using practical tools, you can build a solid HACCP system that protects your customers, empowers your staff, and ultimately strengthens your business.

Choosing Kitchen Equipment for HACCP Success

Your kitchen equipment isn't just a pile of stainless steel; it’s an active, working member of your food safety team. The real magic happens when you connect the seven principles of HACCP directly to the appliances you use every single day. The right gear doesn't just make life easier—it builds safety right into your workflow, automates compliance, and fortifies your most critical control points (CCPs).

When you start looking at equipment through a HACCP lens, your entire purchasing strategy changes. Suddenly, a commercial refrigerator with a built-in digital thermometer isn't just a nice feature. It’s an automated CCP monitor, logging data around the clock and screaming for your attention the second temperatures drift outside your critical limits. This is where you can find exclusive deals on the latest restaurant equipment and supplies designed for modern safety standards.

Equipment as Your First Line of Defense

Certain features on your equipment are designed to solve specific HACCP challenges. Think about cooling a huge batch of chili. Getting it through the temperature danger zone (135°F to 41°F) quickly is a classic—and very high-risk—CCP. A standard walk-in cooler just isn't built for that job; it can struggle, raising the air temperature and putting every other item in there at risk.

A blast chiller, on the other hand, is engineered for exactly this task. It plunges food temperatures down fast, guaranteeing you hit the strict cooling times required by the health department. This isn't just a fancy pastry gadget; it's a serious hazard control machine.

"Your equipment choices are a direct investment in your HACCP plan's success. A machine with built-in monitoring or easy-to-clean design isn't a cost—it's a safeguard that pays dividends in safety, efficiency, and peace of mind."

Prioritizing Sanitation and Design

Cross-contamination is one of the biggest headaches HACCP plans aim to cure. This is where the actual construction of your equipment becomes a huge factor. That’s why you should never compromise on NSF-certified equipment. It's a non-negotiable for any kitchen that takes safety seriously.

When you see that NSF mark, you know the equipment has passed rigorous testing for public health. These standards guarantee a few key things:

- Smooth Surfaces: The materials are non-porous, with no tiny cracks or crevices for bacteria to set up camp.

- Ease of Cleaning: The design allows for easy disassembly, so your team can get in there and sanitize every nook and cranny. No hidden gunk.

- No Harmful Chemicals: The materials are food-safe and won't leach anything nasty into your ingredients.

From your cutting boards to your big-ticket mixers, choosing NSF-certified gear is your best defense against biological and chemical hazards.

Smart Investments for Safer Operations

Modern kitchen technology offers some incredible tools to help with HACCP. Think about a deep fryer with automatic oil filtration versus a standard model. The self-filtering unit doesn't just save you money on oil; it helps control chemical hazards by keeping the oil from breaking down and going rancid. Staying informed about such industry trends in restaurant equipment can significantly enhance your safety protocols.

It's the same story with a combi oven. The ability to dial in precise temperature and humidity gives you complete command over your cooking CCPs. When you can absolutely guarantee a chicken breast hits the right internal temperature every single time, you've locked down one of the most important control points in your kitchen.

Making a comprehensive list can help you figure out where to invest. For a complete rundown of what you'll need, check out our commercial kitchen equipment checklist.

Comparing HACCP-Ready vs Standard Kitchen Equipment

See how specific equipment features directly support your HACCP plan, making compliance easier and more reliable.

| Equipment Type | HACCP-Supportive Feature | Benefit for Compliance |

|---|---|---|

| Refrigerator/Freezer | Digital thermostat with data logging and alarms | Automates monitoring of a critical control point (temperature), provides records for verification, and alerts staff to deviations. |

| Blast Chiller | Rapid, high-velocity cooling cycles | Ensures foods pass through the temperature danger zone within mandated time limits, controlling a major CCP for cooling. |

| Combi Oven | Precise temperature and humidity probe cooking | Guarantees consistent and accurate internal cooking temperatures are met, validating a critical kill step for pathogens. |

| Cutting Boards | Color-coded, non-porous material (NSF-certified) | Prevents cross-contamination (a key hazard) by segregating raw meats, poultry, and produce. Easy to clean and sanitize. |

| Vacuum Sealer | Airtight sealing and modified atmosphere packaging | Controls biological hazards by limiting oxygen, extending shelf life, and preventing cross-contamination during storage. |

In the end, every piece of equipment you buy should be judged on how well it supports your food safety system. When you see your appliances as strategic investments in compliance, you're not just buying tools—you're building a stronger, safer, and more successful restaurant from the ground up.

The Bottom-Line Benefits of a HACCP System

Let's be honest: when most people hear "HACCP," they think of passing health inspections. But that’s just scratching the surface. Treating a HACCP system as a business strategy rather than just a regulatory hurdle is a complete game-changer. It's an investment that pays real dividends in how you operate, how customers see you, and ultimately, your profitability.

The most immediate payoff? Building rock-solid trust with your guests. In a market where diners have endless choices, a reputation for impeccable safety is worth its weight in gold. When people know you’re serious about standards, they don't just come back—they become your biggest fans.

Drive Profitability and Reduce Waste

One of the biggest financial perks of a well-executed HACCP plan is a major drop in food waste. The whole system is built to flag problems before they escalate, whether it's checking delivery temperatures at the back door or making sure stock is rotated correctly. This proactive mindset stops expensive spoilage from ever eating into your profits.

Just think about it. When your walk-in cooler temps are logged and monitored like clockwork, you’re not just checking a box; you're preventing the potential loss of thousands of dollars in inventory. Nail your cooking temperatures every time, and you'll see less product get thrown out. These small, consistent wins stack up, leading to serious savings and healthier margins.

A strong HACCP plan transforms your kitchen from a place of potential risk into a hub of efficiency and quality control. It's a framework that directly supports your financial health by protecting your inventory, your customers, and your reputation.

This isn't just a hunch; the value is proven. A global survey of 116 food companies found that after implementing a formal food safety management system (FSMS) like HACCP, certification rates soared from 34.2% to 59.6%. Even more telling, measures of food safety culture and leadership jumped to over 80%. That shows a deep, company-wide commitment that customers can feel. If you want to dig into the numbers, you can read the full study on FSMS implementation benefits.

Streamline Operations and Protect Your Business

A clear HACCP plan is also one of the best training tools you can have. It gives your staff a clear playbook for every critical task, which cuts out the guesswork and empowers them to make the right call, every time. This structured approach makes training new hires a breeze and ensures everyone is on the same page about food safety.

On top of that, the detailed records you keep are your best defense. If a food safety issue ever comes up, your logs of temperatures, corrective actions, and verification checks are hard proof that you did everything right. This documentation is invaluable for limiting liability and protecting your business. It’s a proactive shield that also keeps your gear running smoothly, a topic we cover in our guide on how to master commercial kitchen equipment maintenance tips.

At the end of the day, building HACCP into the DNA of your restaurant sets you up for long-term success. It’s not just about compliance; it’s about excellence.

Common Questions About HACCP for Restaurant Owners

Even after you've got a handle on the seven principles, the real-world questions start popping up. It's totally normal. When you're trying to figure out how a food safety system like HACCP fits into your actual kitchen, concerns about cost, legal rules, and daily workflow are front and center. Let's tackle the questions we hear most often.

One of the biggest is, "Do I legally have to have a HACCP plan for my small restaurant?" The straight answer is: it depends. Regulations can vary quite a bit based on where you are and what you're serving. Some health departments require a full-blown HACCP plan for specific high-risk foods or processes (like sous vide or curing meats), but it's not always a blanket mandate for every cafe or diner.

But here’s the thing—just focusing on whether it's legally required is missing the bigger picture. Embracing the principles of HACCP is always a smart move. It becomes your best defense against liability and shows you're serious about protecting your guests.

Costs Versus Investment

"What's this going to cost me?" That's a fair and crucial question for any business owner. Getting a HACCP system up and running does have some initial costs. You might need to budget for staff training, maybe some new equipment like better digital thermometers, or even software to help you track everything.

It’s essential to see this as an investment, not just another expense on the books. The return you get over the long haul is huge. A solid HACCP system drastically cuts down on costly food waste, helps you avoid the devastating financial hit of a foodborne illness outbreak, and protects your reputation—which is priceless. Keeping an eye out for exclusive deals on essential restaurant supplies can help manage these initial costs effectively.

Understanding the Difference

A lot of chefs and managers ask, "How is HACCP different from my regular health inspection?" This is a key distinction. Think of a health inspection as a snapshot in time. It's a look at how your kitchen was doing on that one particular day, at that one particular moment.

Your HACCP plan, on the other hand, is the whole movie. It’s your own internal system, running 24/7 in the background to stop problems before they can even start. It puts you in the driver's seat of your food safety, which makes those health inspections feel more like a routine check-in than a high-stakes test. This proactive mindset also applies to other critical systems, like the ones covered in our guide to commercial kitchen ventilation requirements.

Think of a health inspection as a pop quiz. HACCP is the daily study habit that makes sure you’re always ready for it.

Finally, people want to know, "Can software help me manage my HACCP plan?" Absolutely, and it's a game-changer. Modern digital tools can take so much of the manual work off your plate. They can automate temperature logs, make record-keeping a breeze, and even send you alerts when something needs a corrective action. This makes your plan more efficient and less likely to fall victim to human error.

At Encore Seattle Restaurant Equipment, we help restaurant owners and chefs discover the latest news, trends, and exclusive deals on restaurant equipment and supplies. We provide the tools and expertise to build a kitchen that's not just efficient, but fundamentally safe. Discover equipment designed for HACCP compliance and operational excellence at https://encoreseattle.com.