What Is a Blast Freezer and Why Your Kitchen Needs One

Share

So, what exactly is a blast freezer? Think of it less as a typical freezer and more as a high-performance freezing machine. It’s a specialized piece of commercial restaurant equipment that uses powerful fans to blast frigid air across food, freezing it in a fraction of the time a standard freezer would take.

For chefs and restaurant owners running a professional kitchen, this isn't just a minor upgrade. It’s a complete game-changer for locking in freshness, preserving the delicate texture of ingredients, and holding onto nutritional value. Mastering this technology allows you to stay ahead of industry trends and elevate your culinary output.

Understanding the Power of Rapid Freezing

Here’s a simple analogy: imagine you have a wet dish. You could let it air-dry slowly, or you could hit it with a high-powered jet dryer. A blast freezer does for food what that jet dryer does for water—it removes heat with incredible speed and force. It’s an active, aggressive process, a world away from the passive cooling of a conventional freezer just sitting there, maintaining a cold environment.

This speed is critical for one key reason: ice crystals. When you freeze food slowly in a regular freezer, large, jagged ice crystals have time to form. These crystals act like tiny knives, piercing the cell walls of the food. You don’t see the damage until you thaw it, but the result is a mushy texture, a puddle of water on the plate (that’s called drip loss), and a noticeable drop in flavor.

Preserving Food at the Cellular Level

A blast freezer, sometimes called a shock freezer, sidesteps this damage completely. By forcing extremely cold air over food at high velocity, it plummets the core temperature so fast that only tiny, smooth ice crystals can form. These micro-crystals don't rupture the cell walls, leaving the food’s internal structure perfectly intact.

This means when you thaw a product that's been blast-frozen, it retains its:

- Original Texture: A delicate fish fillet stays firm, a berry remains plump and whole.

- Natural Flavor: The taste is locked in, preventing that bland, watery quality of poorly frozen food.

- Nutritional Value: Vitamins and minerals are far better preserved than with slow-freezing methods.

- Moisture Content: Products lose very little water, keeping them juicy and appealing.

In essence, blast freezing is like hitting the pause button on your food. It captures ingredients at their absolute peak of freshness, preserving that quality until the moment you need it—whether that's days, weeks, or months down the line.

A Strategic Tool for Modern Kitchens

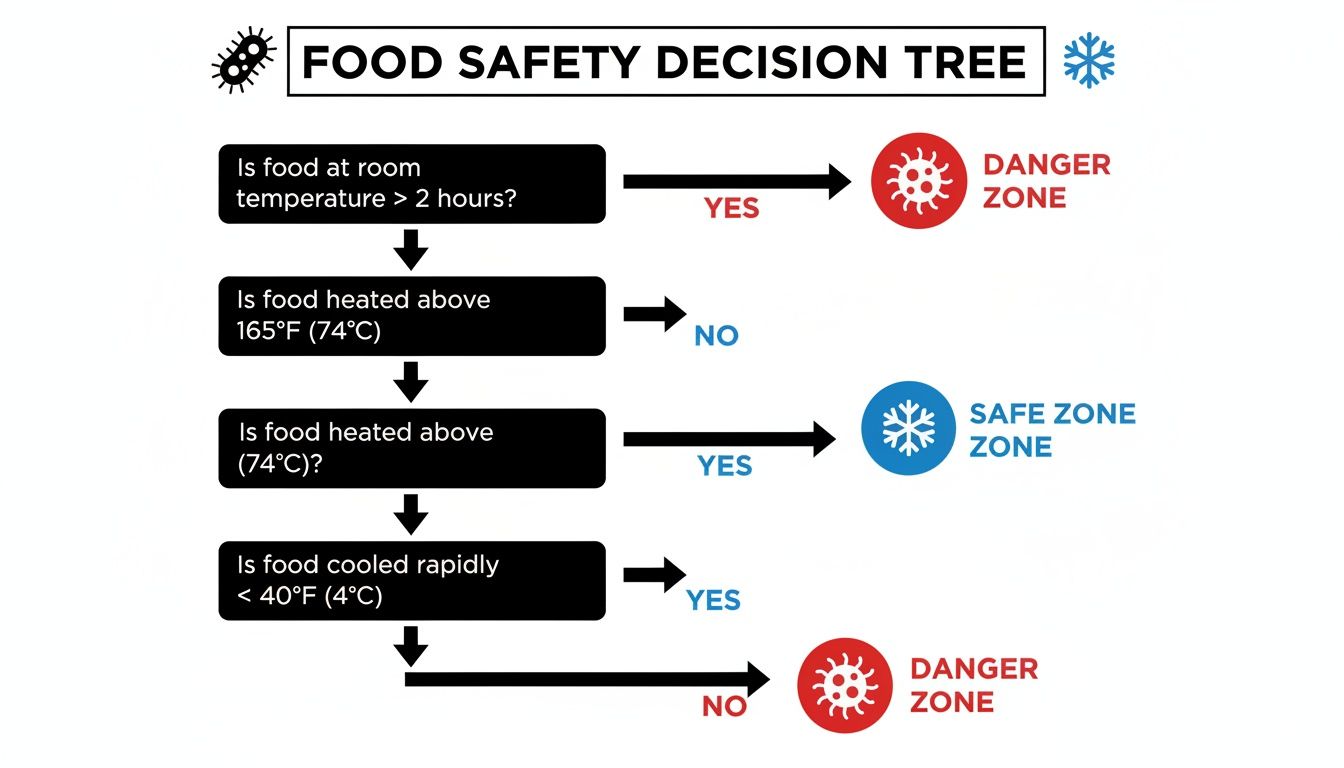

For chefs and restaurant operators, a blast freezer is about much more than just temperature control. It’s a strategic system that directly improves food quality, boosts kitchen efficiency, and enhances food safety. By getting ingredients through the temperature "danger zone" (where bacteria thrive) in minutes instead of hours, blast freezers offer an unmatched level of safety.

This technology allows kitchens to prep ingredients in large batches, reduce waste by preserving seasonal produce at its best, and ultimately serve a consistently excellent product. It turns freezing from a simple storage method into a precise, powerful culinary technique that savvy chefs are using to gain a competitive edge.

The Science Behind Rapid Freezing Technology

To really get what a blast freezer does, you have to look under the hood. It’s not just a beefed-up version of your walk-in; it's a completely different beast, engineered for one thing: aggressive, rapid heat removal. This incredible performance comes down to three core components working together like a well-oiled machine.

First, you have powerful high-velocity fans that whip up a storm of frigid air inside the cabinet. This isn't the gentle, passive cold of a standard freezer. It’s an active, forceful process that literally strips heat from the surface of the food.

Next up is the powerhouse duo: an oversized compressor and a super-efficient evaporator. Think of them as the engine. The compressor gets the refrigerant intensely cold, and the evaporator coils unleash that cold into the air being blasted by the fans. The whole system is built to take on a massive heat load, meaning it can handle hot food right out of the oven without breaking a sweat.

Conquering Critical Temperature Zones

This powerful combination lets a blast freezer fly through two critical temperature zones at lightning speed. In any professional kitchen, getting through these zones quickly isn't just a "nice-to-have"—it's a non-negotiable for food safety and quality.

-

The Bacterial 'Danger Zone' (40°F to 140°F): This is the temperature sweet spot where nasty bacteria like Salmonella and E. coli throw a party and multiply like crazy. A blast freezer crashes that party, moving food through this entire zone in minutes instead of hours. Microbial growth is stopped dead in its tracks.

-

The 'Crystal Formation Zone' (31°F to 25°F): When water freezes slowly, it forms large, jagged ice crystals. These crystals act like tiny knives, puncturing cell walls in the food. The result? A mushy, watery mess when you thaw it out. By racing through this zone, blast freezers only allow tiny micro-crystals to form, keeping the food’s cellular structure intact.

It’s this science that protects your craft. The flavor, the texture, and the quality you worked so hard to perfect get locked in, ready to shine on the plate.

Precision Engineering for Perfect Preservation

The whole process is a finely tuned operation. A blast freezer is an industrial-grade unit that circulates super-cooled air at high speeds, often hitting temperatures as low as -40°F. This speed is what drastically cuts down the time food spends in that zone where large, damaging ice crystals form. While the concept has been around since the early 20th century, it was Clarence Birdseye's work in the 1920s that paved the way for the modern machines we use today. You can learn more about how this technology evolved to preserve food quality on boudat-kar.com.

Getting this timing and temperature just right requires some sophisticated controls. Most units use probes to monitor the internal temperature of the food, automatically adjusting the cycle for a dense pot of chili versus a delicate tray of croissants. For a deeper look at the kind of automation that makes this precision possible, it's worth exploring how PLC process controls work.

Think of it this way: a standard freezer puts food into a cold room and waits. A blast freezer actively attacks the heat in the food, pulling it out with engineered force and precision.

Ultimately, this is the key difference. A blast freezer isn’t just about making things cold faster; it’s a controlled scientific process that protects the very molecular structure of your food. It delivers a superior product that a standard freezer just can't touch, helping you nail consistency, cut down on waste, and serve food that’s truly at its peak.

Blast Freezer vs. Blast Chiller vs. Standard Freezer

In any professional kitchen, knowing exactly what your equipment is designed for is non-negotiable. It's tempting to think of all cold storage as one big category, but blast freezers, blast chillers, and standard freezers are specialized tools, each with a distinct job. Getting them mixed up doesn't just slow down your workflow—it can mess with food safety and the quality of your final product.

Think of it like this: your standard commercial freezer is basically a holding pen. Its one and only job is to keep things that are already frozen at a steady, cold temperature, usually around 0°F (-18°C). It's built for long-term storage, not for actively pulling the heat out of a hot pan of food.

A blast chiller, on the other hand, is all about speed. Its mission is to get cooked food through the bacterial "danger zone" (that dreaded 140°F to 40°F window) as fast as possible, landing it at a safe refrigeration temp of about 37°F (3°C). This is your go-to for cooling a huge batch of chili or a pot of stock you'll need for service tomorrow. If you're looking for a deep dive on that process, our commercial blast chiller guide breaks it all down.

So, Where Does the Blast Freezer Fit In?

The blast freezer (sometimes called a shock freezer) takes things to a whole other level. It’s designed to freeze food solid, dropping the core temperature from hot or chilled all the way down to a frigid -18°F (-27°C), sometimes even colder, often in just a few hours. This is the powerhouse you rely on to perfectly preserve trays of delicate pastries, dozens of salmon fillets, or a haul of fresh berries at their peak.

The chart below gives you a great visual of why this speed is so critical. Moving food out of the temperature danger zone quickly is the key to stopping bacterial growth and locking in both flavor and texture.

This rapid-freezing technology is engineered to prevent the formation of large ice crystals, which are the enemy of food texture. When food freezes slowly, these large crystals form and rupture the cell walls, leading to that mushy, watery mess when thawed. Blast freezers blow past this critical 32°F to 14°F (0°C to -10°C) range so fast that only tiny micro-crystals can form, keeping the food's structure intact.

This isn't new tech, either. By the 1970s, this concept had scaled up to massive spiral freezers capable of processing 10-20 tons per hour, becoming a cornerstone for the commercial baking and poultry industries.

Commercial Cooling Equipment Compared

To really spell out the differences, it helps to see these three machines side-by-side. Each has a very specific role in a modern kitchen.

| Feature | Blast Freezer | Blast Chiller | Standard Freezer |

|---|---|---|---|

| Primary Function | To rapidly freeze hot or chilled food solid for preservation. | To rapidly cool hot food to safe refrigeration temperatures. | To hold and store food that is already frozen. |

| Typical Temp Range | -18°F to -40°F (-27°C to -40°C) | +37°F (+3°C) | 0°F to -10°F (-18°C to -23°C) |

| Process Speed | Extremely fast (e.g., 90 mins to 4 hours to freeze solid). | Very fast (e.g., 90 minutes to chill). | Slow and passive; not designed for rapid cooling. |

| Ideal Use Case | Long-term preservation, locking in freshness of seasonal items, prepping large batches of items like meatballs or lasagna. | Safely cooling cooked foods for next-day service, prepping soups and sauces, following HACCP plans. | Storing bulk goods like French fries, proteins, or vegetables that were delivered frozen. |

The main thing to remember is that these are not interchangeable. Trying to cool a hot stockpot in a standard freezer is not just a food safety nightmare; it also puts every other item in that freezer at risk by raising the ambient temperature. It also freezes the food so slowly that the quality is completely destroyed by ice crystals.

Ultimately, choosing the right machine depends entirely on your menu and workflow. A blast chiller is a must-have for cook-chill operations, a blast freezer is a strategic investment for managing inventory and preserving quality, and the standard freezer remains the unsung hero for everyday frozen storage.

The Strategic Benefits of a Blast Freezer

Thinking about a blast freezer as just another box that gets cold is a huge mistake. It's not just a piece of equipment; it's a strategic investment that can completely change how your kitchen runs, for the better. When you look past the technical specs, you find four core benefits that hit everything that matters: food safety, product quality, kitchen efficiency, and ultimately, your profits.

Think of it as the central hub for your entire food preservation strategy. It gives you an incredible amount of control over your inventory, your prep, and the final dish that lands on your customer's table.

Elevate Food Safety and HACCP Compliance

In a professional kitchen, food safety isn't just a priority—it's everything. A blast freezer is your single best tool for shoring up your safety protocols and making Hazard Analysis and Critical Control Points (HACCP) compliance almost second nature.

Its main job from a safety standpoint is to rocket food through the temperature "danger zone" (40°F to 140°F) at incredible speed. This rapid temperature drop stops harmful bacteria in their tracks, slashing the risk of foodborne illness. It ensures the food you serve is safe, day in and day out. This process is a critical part of modern cold chain management, a key industry trend for ensuring quality from supplier to table.

Preserve Superior Product Quality

Here's where the real magic happens. A blast freezer protects the very integrity of your food, right down to the cellular level. When you freeze something slowly, large, jagged ice crystals form, which shred and damage the food's cell walls. The result? A mushy, watery mess when it thaws.

Blast freezing, on the other hand, creates tiny micro-crystals that leave those cell walls intact. This small difference has a massive impact. Studies show that blast-frozen products can retain up to 5-10% more moisture when thawed compared to conventional freezing methods. For a beautiful piece of fish or a prime cut of steak, that means preserving the texture, flavor, and nutritional value you paid for.

A blast freezer essentially hits the "pause" button on peak freshness. It locks in the vibrant color of seasonal vegetables, the firm texture of a freshly caught fish, and the delicate crumb of a pastry, ensuring the product you serve is exactly as you intended.

Drive Unmatched Operational Efficiency

A blast freezer opens up a whole new world of efficiency by making advanced prep and batch cooking a practical reality. Your team can become incredibly productive during slower periods, which frees them up to focus on execution when the dinner rush hits.

Imagine your kitchen running this smoothly:

- Batch Cooking: You can knock out huge batches of sauces, soups, or lasagna during a quiet Tuesday morning, blast freeze them in perfect portions, and have them ready to go for a packed Saturday night.

- Advanced Prep: Portion out proteins, prepare complex dessert components, or process a huge delivery of seasonal produce when it's at its peak. You can preserve that quality for months, not just days.

- Reduced Labor Strain: With key items already prepped and frozen, your line cooks can assemble dishes faster and more consistently. That means less stress and fewer mistakes during the busiest hours.

This approach transforms your kitchen from a reactive, chaotic environment into a proactive, well-oiled machine.

Reduce Food Waste and Boost Profitability

Ultimately, all these advantages circle back to a healthier bottom line. By preserving food perfectly and allowing for smarter purchasing, a blast freezer becomes a powerful tool for financial control.

The most obvious impact is on food waste. Ingredients that might spoil in the walk-in can instead be blast frozen at their peak, extending their shelf life from a few days to several months. It also lets you take full advantage of bulk purchasing and seasonal deals, buying top-notch ingredients when they're cheapest. This strategy turns potential losses into future profit. To get the most out of these savings, it pays to look at your kitchen's total energy consumption; for example, enhancing commercial door energy efficiency is a smart way to keep temperatures stable and cut down on operating costs.

How to Choose the Right Blast Freezer

Investing in a blast freezer isn't like buying a standard fridge. It's a serious piece of equipment, and picking the right one means matching it directly to your kitchen's menu, workflow, and physical space. Get it right, and you’ll unlock huge gains in efficiency and food quality. Get it wrong, and you're stuck with an expensive, oversized (or undersized) box that doesn't pull its weight.

Think of this as your practical checklist for cutting through the sales pitches and focusing on what really matters. We’ll cover everything from capacity and power to controls and defrost systems, so you can choose a machine that works for you, not against you.

Evaluating Capacity and Footprint

First things first: how much food are you freezing, and where are you going to put the machine? The answer will guide you toward one of two main styles, each built for a different scale of operation.

-

Reach-In Models: These are the workhorses for most small-to-medium-sized restaurants. They look a lot like your typical upright freezer and are designed to hold standard hotel pans on shelves. If your space is tight and you're freezing regular, smaller batches, this is likely your best bet.

-

Roll-In Models: Built for serious volume. Think large-scale catering, big restaurants, or central production kitchens. These units are cavernous enough to fit an entire rolling pan rack, letting you move dozens of trays from the oven straight into the freezer without wasting a single motion.

Beyond the physical size, you need to look at the throughput—that’s the specific amount of food, in pounds, the unit can blast freeze in a single cycle. Be brutally honest about your busiest days. A machine that can’t keep up during a dinner rush is a bottleneck you can't afford.

Understanding Key Technical Specifications

Once you’ve got a size in mind, it’s time to get into the weeds. These are the non-negotiable tech specs that determine how well the freezer performs and if it will even work in your building.

A critical number is the temperature range. A solid blast freezer must hit at least -18°F (-27°C), but the real power players can plunge down to -40°F (-40°C). That extra cold isn't just for show—the lower the temperature, the faster the freeze, which means smaller ice crystals and better-preserved food.

Next, and this is a big one people often miss, is the power requirement.

-

Single-Phase Power: This is what most smaller commercial spaces and homes run on, typically 120V or 240V. Many reach-in models are designed for this.

-

Three-Phase Power: The industry standard for heavy-duty kitchen equipment. It delivers more stable, efficient power. Almost all roll-in models and even some larger reach-ins will demand a three-phase hookup.

Crucial Tip: Before you even think about adding a blast freezer to your cart, have an electrician verify your building’s electrical panel. Realizing you need a costly three-phase upgrade after the delivery truck has left is a nightmare scenario.

Demystifying Features and Controls

The specs tell you what a machine can do, but the features determine how easy it is to live with day-to-day. A simple, intuitive control panel can save your staff a world of headaches.

Look for digital displays with programmable cycles. This lets you create custom freezing programs for different items—a gentle freeze for delicate fish is very different from what you need for a dense pot of chili.

Another feature you can't ignore is the defrost type. An automatic defrost cycle is your best friend. It regularly melts any ice buildup on the internal coils, keeping the machine running efficiently with maximum airflow. Manual defrost units are cheaper upfront, but they require you to shut the whole thing down and chip away at ice, which means downtime and lost productivity.

When you're comparing models, it helps to see how they stack up against the broader world of commercial refrigeration. To get that bigger picture, take a look at our guide on the best commercial freezer options out there. Knowing what else is available helps confirm you're making the smartest choice for your kitchen.

Blast Freezer Specification Checklist

Making a final decision involves juggling a lot of details. This checklist breaks down the essential factors to compare when you're looking at different models from suppliers. Use it to ask the right questions and ensure you're getting a machine that fits your operation perfectly.

| Specification | What to Look For | Why It Matters |

|---|---|---|

| Capacity (lbs/kg) | The max weight of food it can freeze per cycle. | Must exceed your peak production needs to avoid bottlenecks. |

| Footprint (W x D x H) | The physical dimensions of the unit. | Has to fit in your kitchen layout with proper ventilation clearance. |

| Temperature Range | Minimum achievable temperature (e.g., -18°F to -40°F). | Lower temps mean faster freezing and higher quality preservation. |

| Power Requirements | Voltage (V) and Phase (1-phase vs. 3-phase). | Must match your building's electrical supply to avoid costly upgrades. |

| Compressor Power (HP) | Horsepower of the compressor. | A more powerful compressor recovers temperature faster after opening the door. |

| Control System | Digital vs. manual; programmable cycles. | Digital controls offer precision for different food types and simplify training. |

| Defrost Type | Automatic vs. manual. | Auto-defrost saves labor and prevents efficiency loss from ice buildup. |

| Airflow Design | Indirect vs. direct airflow. | Indirect airflow is gentler on delicate foods, preventing freezer burn. |

| Construction Material | Stainless steel grade (e.g., 304-grade). | Higher-grade steel resists corrosion and is easier to sanitize. |

| Refrigerant Type | R404A, R290 (propane), etc. | Newer, eco-friendly refrigerants like R290 can lower energy bills. |

By methodically going through this list for each potential blast freezer, you move from just buying a piece of equipment to making a strategic investment in your kitchen's future. It ensures the unit you choose is a powerful asset, not a logistical headache.

Figuring Out Your Return on Investment

A blast freezer is a serious piece of equipment, and it comes with a serious price tag. Like any big purchase for your kitchen, it has to earn its keep. It’s easy to get sticker shock, but you have to look at it as more than just an expense—it's an investment that can actively pay you back over time. Calculating the return on investment (ROI) means looking past the initial cost and figuring out exactly how this machine will save you money and, ultimately, make you more profitable.

To really see if it makes sense for your business, you need to break down the financial benefits into three main buckets. This isn't about wishful thinking; it's about taking a hard look at your current numbers and projecting real savings.

Quantifying the Tangible Savings

The most obvious and immediate payback comes from slashing your food waste. Anyone who runs a kitchen knows the sting of spoilage—that beautiful case of raspberries that went fuzzy overnight or the expensive fish that didn't move. A blast freezer lets you hit the pause button, preserving those ingredients at their absolute peak. Start by figuring out what you’re losing to spoilage each month. Even a modest reduction of 25-30% can mean thousands of dollars back in your pocket over a year.

Then, there's the power of smart buying. Your suppliers give you the best deals when ingredients are in season and plentiful. With a blast freezer, you can load up on cases of summer tomatoes or fresh-caught salmon when prices are rock bottom, preserve them perfectly, and feature them on your menu months later. This strategy gets you off the roller coaster of commodity pricing and lets you lock in lower food costs all year.

Think of a blast freezer as a financial tool. It lets you invest in your inventory when the price is right, turning your purchasing from a reactive, day-to-day task into a strategic advantage that pads the margin on every plate you sell.

Factoring in Labor Efficiency

The third piece of the ROI puzzle is labor. In any professional kitchen, time is your most precious and costly commodity. This is where batch production, made possible by a blast freezer, completely changes the game. Your crew can knock out time-consuming prep—think stocks, complex sauces, or perfectly portioned proteins—during quieter hours.

This directly impacts your bottom line in a few key ways:

- Reduced Overtime: A smoother, more predictable prep schedule means less frantic scrambling during the dinner rush and fewer hours on the clock.

- Increased Output: When your prep is streamlined, the same kitchen team can handle more volume without needing to bring on extra staff.

- Better Consistency: Batching ensures that every serving of that signature sauce is identical, cutting down on costly mistakes, re-fires, and comps.

When you start adding up the savings from less food waste, smarter purchasing, and more efficient labor, the initial cost of the freezer suddenly seems a lot less intimidating. The question quickly changes from, "Can I afford to buy a blast freezer?" to, "How much money am I losing every month by not having one?"

Frequently Asked Questions

Even after you get the rundown on what a blast freezer does, the practical questions always start to bubble up. Let's tackle some of the most common things chefs and restaurateurs ask, clearing up the details so you can feel confident about your next move.

How Much Does a Commercial Blast Freezer Cost?

There's a pretty wide price range, and it really comes down to size and power. You can find smaller, under-counter models starting around $4,000, which are great for tight spaces or smaller-batch work.

Most kitchens will be looking at mid-sized, reach-in units, and those typically run anywhere from $8,000 to $20,000. If you're running a high-volume production kitchen or commissary, the big roll-in or walk-in systems can easily climb past $25,000.

Just remember to factor in the "hidden" costs. You'll likely need a professional for installation and might even need to upgrade your electrical to handle the power draw, so keep that in mind when you're budgeting.

Can I Just Use a Blast Freezer as a Blast Chiller?

Technically, you could, but it’s like using a sledgehammer to tap in a nail. A blast freezer is a powerhouse designed to freeze food solid, fast. Using it for simple chilling is overkill and inefficient. Plus, it just doesn't have the delicate temperature controls that a dedicated blast chiller offers for getting food safely through the danger zone without freezing it.

If you know you need to do both, look into a combination blast chiller/freezer. These units are built for that exact kind of versatility, giving you both rapid chilling and deep-freezing capabilities in one machine. It's often the smartest investment for a multi-purpose kitchen.

What Kind of Maintenance Does a Blast Freezer Need?

Think of it like any other critical piece of kitchen equipment: consistent maintenance is non-negotiable. Keeping up with it protects your investment, prevents those dreaded emergency service calls, and keeps your energy bills from creeping up.

Here’s a simple routine to follow:

- Every Day: Give the interior and exterior surfaces a good wipe-down. Basic hygiene goes a long way.

- Every Week: Check the door gaskets. You're looking for any cracks or gaps where cold air might be escaping. A good seal is crucial.

- Routinely: Keep the condenser coils clean. They get clogged with dust and kitchen grease, which forces the machine to work harder.

Beyond that, getting a professional technician to come in once or twice a year is a smart move. They'll check refrigerant levels, test the fans, and make sure all the electrical components are in good shape, keeping your blast freezer running like a champ.

Ready to discover the latest deals on restaurant equipment and stay informed about industry trends? The team at Encore Seattle Restaurant Equipment lives and breathes this stuff. We can offer expert advice on all kinds of refrigeration solutions. Check out our selection and let's find the perfect fit for your operation.