Restaurant Health Inspection Checklist for 2025: 8 Key Tips

Share

Facing a health inspection can be one of the most stressful experiences for any restaurant owner, chef, or manager. It’s more than just a passing grade; it's a direct reflection of your commitment to customer safety, a validation of your operational standards, and a cornerstone of your brand's reputation. A single failed inspection can have immediate and long-lasting consequences, from fines and temporary closures to a significant loss of public trust. But what if you could transform that anxiety into a proactive strategy for operational excellence?

This guide is designed to do just that. We've compiled the ultimate restaurant health inspection checklist, breaking down the eight critical areas that inspectors scrutinize with a fine-toothed comb. Forget generic advice; each point is packed with actionable steps, common pitfalls to avoid, and practical implementation details. This isn't just about preparing for a one-time event. It's about embedding a culture of safety and quality into your daily operations.

By mastering the core areas-from Food Temperature Control to Facility Infrastructure-you won't just be ready for an inspector's visit at any moment. You will be actively running a safer, more efficient, and more successful restaurant every single day. Throughout this comprehensive checklist, we will also highlight industry trends and connect you with exclusive deals on the essential restaurant equipment and supplies you need to stay compliant and elevate your standards. Let's turn inspection-readiness into a powerful tool for building a better business.

1. Food Temperature Control and Monitoring

Maintaining precise food temperature is arguably the most critical component of any restaurant health inspection checklist. It's the frontline defense against foodborne illness, as bacteria like Salmonella and E. coli multiply rapidly in the temperature "danger zone" between 41°F (5°C) and 135°F (57°C). Health inspectors are trained to scrutinize temperature logs and take direct measurements, making this a high-stakes area where non-compliance can lead to immediate violations.

Proper control involves a consistent, facility-wide commitment to keeping cold foods truly cold and hot foods demonstrably hot. This extends beyond simple storage; it includes monitoring temperatures during receiving, preparation, holding, and serving. A single lapse can compromise an entire batch of food, risking customer health and your restaurant's reputation.

Why It's a Top Priority

Ignoring temperature protocols is a direct path to a failed inspection. Foods found in the danger zone for extended periods are considered adulterated and will likely need to be discarded, resulting in costly food waste and a significant demerit on your report.

Key Insight: Health inspectors view temperature control as a direct indicator of a kitchen's overall commitment to food safety. Consistent and accurate temperature logs signal a proactive, well-managed operation.

Successful implementation requires both the right tools and rigorous training. A key industry trend is the adoption of smart kitchen technology. For instance, after its 2015 E. coli outbreak, Chipotle invested heavily in enhanced temperature monitoring systems, incorporating digital sensors with real-time alerts to prevent future incidents. Similarly, McDonald's uses standardized hot-holding cabinets with built-in timers across its global locations to ensure consistent product safety.

Actionable Tips for Implementation

To ace this part of your inspection, integrate these practices into your daily operations:

- Use Designated Thermometers: Assign color-coded food thermometers for different food types (e.g., red for raw meat, green for produce) to prevent cross-contamination.

- Embrace Technology: Install digital temperature monitoring systems in walk-in coolers and freezers. These systems can send real-time alerts to managers' phones if temperatures deviate, allowing for immediate corrective action. This modern equipment is a game-changer for compliance.

- Calibrate, Calibrate, Calibrate: Train all kitchen staff on how to properly calibrate thermometers using both the ice-point (32°F or 0°C) and boiling-point methods. This should be done weekly.

- Maintain Diligent Logs: Place temperature logs directly on or near each piece of equipment. Staff should record temperatures at the beginning of each shift and every two to four hours thereafter.

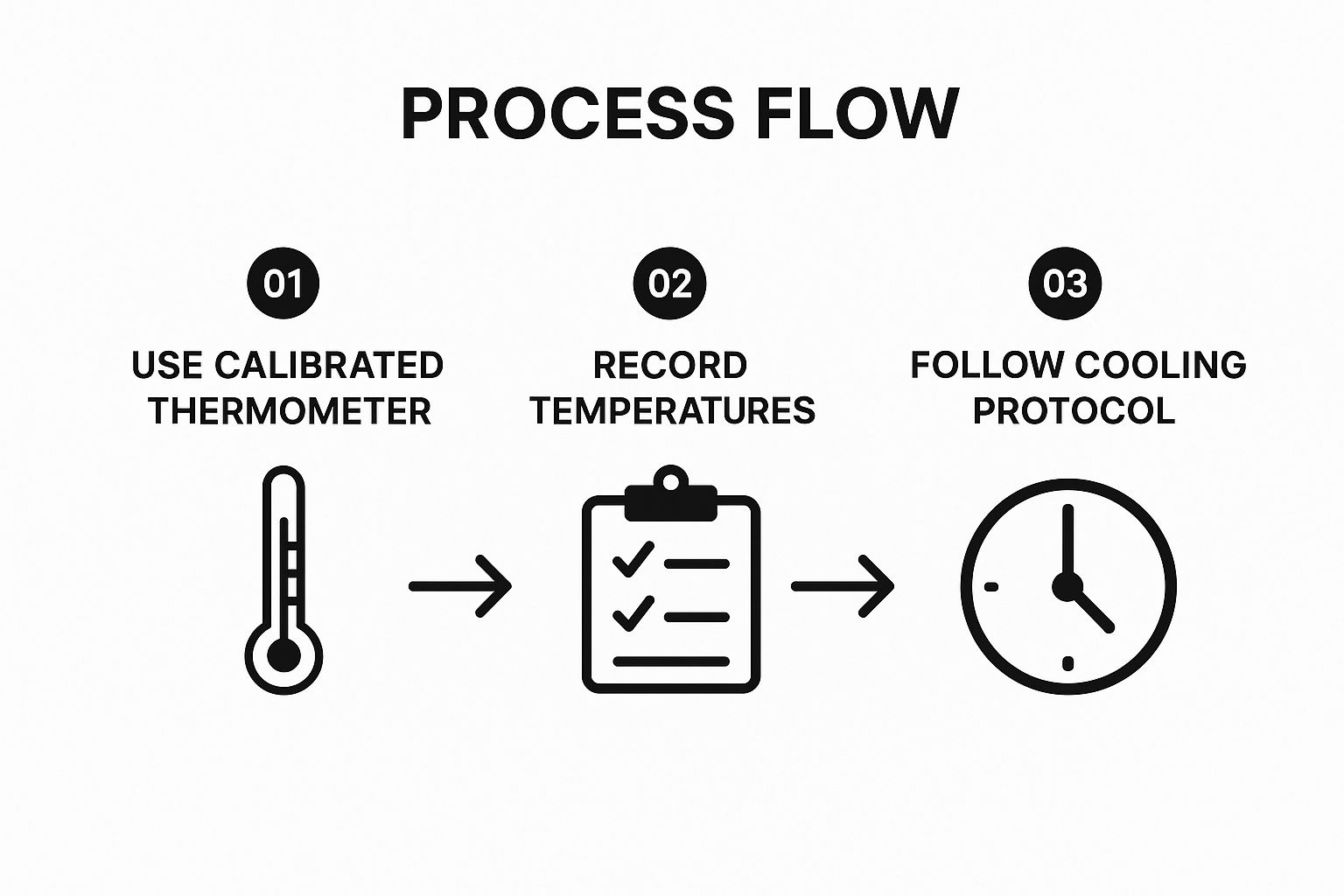

This infographic illustrates the fundamental three-step process for daily temperature management.

This simple yet crucial workflow, when followed consistently, creates an unbroken chain of documentation that proves due diligence to health inspectors.

For a deeper dive into proper thermometer usage and calibration techniques, the following video provides a helpful visual guide.

2. Cross-Contamination Prevention and Food Separation

A rigorous approach to preventing cross-contamination is a non-negotiable pillar of any successful restaurant health inspection checklist. This practice involves creating physical and procedural barriers to stop harmful bacteria, allergens, and other contaminants from transferring between foods, surfaces, and equipment. Inspectors will meticulously check storage arrangements, preparation workflows, and staff practices to ensure raw foods never compromise the safety of ready-to-eat (RTE) items.

The scope of cross-contamination goes beyond just raw meat juices. It includes allergens like peanuts touching a non-allergen dish, unwashed hands handling cooked food, or dirty utensils being reused. A single instance can lead to a foodborne illness outbreak, making this a critical point of evaluation during an inspection.

Why It's a Top Priority

Failing to control cross-contamination can result in severe violations, as it demonstrates a fundamental misunderstanding of food safety principles. An inspector observing an employee handle raw chicken and then assemble a salad without changing gloves or washing hands can lead to an immediate citation. These seemingly small errors have major consequences for public health and your establishment's score.

Key Insight: Health inspectors see cross-contamination prevention as a reflection of a kitchen's discipline and system-wide training. Proper separation of foods and equipment shows a deep, ingrained culture of safety, not just a last-minute effort to clean up.

Major brands have built their safety protocols around this principle. As an industry trend, many kitchens now employ a strict color-coding system for all food handling supplies. For example, Disney theme park kitchens use red equipment for raw proteins, green for produce, and white for RTE foods. Similarly, Panera Bread utilizes dedicated preparation areas and purple-handled utensils for its gluten-sensitive menu items, creating a clear visual system to protect guests with allergies. These industry-leading practices underscore the importance of systematic prevention.

Actionable Tips for Implementation

To ensure your kitchen passes this critical inspection point, embed the following habits into your daily routine:

- Master the Storage Hierarchy: Store foods in the walk-in cooler based on their final cooking temperature. Place RTE foods on the top shelf, followed by fish, whole cuts of beef and pork, ground meats, and finally, raw poultry on the bottom-most shelf.

- Implement Color-Coded Systems: Assign specific colors for cutting boards, knives, and tongs used for different food categories (e.g., red for raw meat, green for vegetables, yellow for raw poultry, blue for seafood). These supplies are an essential investment.

- Designate Prep Zones: If space allows, create physically separate areas for preparing raw proteins and RTE foods. If not, use time-based separation, thoroughly cleaning and sanitizing a surface after raw food prep before any RTE food touches it.

- Train on Proper Glove Use: Staff must be trained to change gloves between tasks, especially after handling raw meat, touching their face or clothing, or after handling money. Gloves are a barrier, not a replacement for handwashing.

3. Personal Hygiene and Handwashing Compliance

Beyond equipment and food storage, the human element is a critical focus of any restaurant health inspection checklist. Personal hygiene standards, especially proper handwashing, are the most effective methods for preventing the transmission of foodborne illnesses. Inspectors are trained to observe employee behavior, check the adequacy of handwashing stations, and scrutinize management policies regarding staff health and cleanliness.

A lapse in personal hygiene can contaminate otherwise safe food instantly. This category encompasses everything from handwashing protocols and glove use to employee illness policies, personal cleanliness, and appropriate attire like hair restraints. Ensuring compliance requires consistent training, accessible facilities, and a management culture that prioritizes safety over speed.

Why It's a Top Priority

Violations related to personal hygiene are often considered critical because they present a direct and immediate risk to public health. An inspector observing an employee handle raw chicken and then move to ready-to-eat produce without washing their hands can lead to a significant violation. These infractions signal systemic failures in training and oversight.

Key Insight: Health inspectors view employee hygiene practices as a direct reflection of a restaurant's food safety culture. Properly stocked handwashing stations and staff who follow protocols demonstrate a foundational commitment to preventing illness.

Many leading brands have built their reputation on stringent hygiene standards. In-N-Out Burger is known for its strict appearance standards, which include impeccable employee hygiene. As an industry-wide response to health concerns, many chains are now investing in touchless technology. For example, Starbucks implemented mandatory 20-second handwashing timers at all sinks to standardize its protocol after past norovirus concerns, reinforcing the importance of this simple yet vital task.

Actionable Tips for Implementation

To ensure your team meets and exceeds hygiene expectations, integrate these practices daily:

- Optimize Handwashing Stations: Position dedicated, fully stocked handwashing sinks within 20 feet of every food preparation area. Touchless faucets and soap dispensers are becoming the new standard for reducing cross-contamination.

- Implement Pre-Shift Checks: Create a daily hygiene checklist for managers to verify staff compliance before a shift begins. This includes clean uniforms, proper hair restraints, and trimmed fingernails.

- Reinforce with Visual Cues: Install clear handwashing reminder signs in multiple languages at all hand sinks. These visuals serve as constant, non-verbal reminders for all staff.

- Enforce a Clear Illness Policy: Create and enforce a policy that requires sick employees to stay home. Providing paid sick leave can reduce the financial pressure on employees to work while ill, a major food safety risk.

- Glove Use Protocol: Train staff that gloves are not a substitute for handwashing. They must wash hands before putting on new gloves and change gloves between tasks, especially when switching from raw to ready-to-eat foods.

4. Proper Cleaning and Sanitizing Procedures

A pristine appearance is not enough; health inspectors are laser-focused on the difference between "clean" and "sanitized." Effective cleaning and sanitizing procedures are a foundational element of any successful restaurant health inspection checklist. While cleaning removes visible food residue and dirt, sanitizing uses chemical or heat-based methods to reduce harmful microorganisms like Norovirus and Listeria to safe levels on food-contact surfaces, equipment, and utensils.

This distinction is non-negotiable in a commercial kitchen. An inspector will swab surfaces to test for pathogens and check the concentration of your sanitizing solutions. A failure in this area points to a systemic breakdown in food safety protocols and can lead to immediate critical violations, threatening both your score and public health.

Why It's a Top Priority

Cross-contamination from improperly sanitized surfaces is a leading cause of foodborne illness outbreaks. Inspectors will scrutinize your entire process, from the three-compartment sink setup to the wiping cloths used on prep tables. Inadequate procedures can contaminate otherwise safe food, leading to severe consequences for your customers and your business.

Key Insight: Health inspectors see your sanitizing practices as a direct reflection of your staff's training and management's oversight. Properly labeled and concentrated sanitizer buckets are a clear sign of an operation that takes food safety seriously.

Leading brands build their reputation on this principle. For instance, Chick-fil-A posts detailed, laminated cleaning schedules with clear sign-off sheets in all kitchen zones, ensuring accountability. Following a recent industry trend, many restaurants are now adopting eco-friendly, yet powerful, sanitizing supplies. Starbucks mandates its "clean, rinse, sanitize" protocol for all beverage equipment at least every four hours, a practice that safeguards against microbial growth in high-use machinery.

Actionable Tips for Implementation

To ensure your cleaning and sanitizing procedures exceed inspection standards, integrate these habits into your daily workflow:

- Test and Log Sanitizer Strength: Use chemical test strips to check the concentration of your sanitizer (e.g., chlorine, quaternary ammonia) every two to four hours, or whenever the water is changed. Log these readings to prove compliance.

- Use a Color-Coded System: Implement a color-coded system for wiping cloths and sanitizer buckets to prevent cross-contamination. For example, use red for raw meat areas, green for produce prep, and blue for front-of-house surfaces.

- Allow Proper Air-Drying: After sanitizing, allow equipment and surfaces to air dry completely. Wiping them with a cloth can reintroduce contaminants and negates the sanitizing step.

- Master the Three-Compartment Sink: Train staff on the correct sequence: wash in hot, soapy water (at least 110°F/43°C); rinse in clean, warm water; and sanitize with a properly concentrated solution for the required contact time. Investing in a high-temperature commercial dishwasher can also automate and guarantee this final step.

5. Pest Control and Prevention Program

An effective pest control program is a non-negotiable component of a passing restaurant health inspection checklist. Pests like rodents, cockroaches, and flies are not just a nuisance; they are vectors for disease, capable of contaminating food, surfaces, and equipment, which can lead to severe health code violations. Inspectors will actively search for signs of pest activity, including droppings, gnaw marks, nesting materials, and live or dead insects, making this a critical area of focus.

A modern approach, known as Integrated Pest Management (IPM), is the industry standard. It prioritizes prevention over reaction, focusing on eliminating the food, water, and shelter that pests need to survive. This includes maintaining the building's structural integrity, enforcing strict sanitation protocols, and working with licensed pest control professionals. A single sighting can trigger a cascade of scrutiny from an inspector.

Why It's a Top Priority

Evidence of a pest infestation is one of the fastest ways to fail an inspection, potentially leading to immediate closure. Beyond the regulatory consequences, a pest problem can irrevocably damage your restaurant's reputation and lead to significant financial loss from discarded food and property damage. Proactive prevention is far less costly than reactive extermination and brand recovery.

Key Insight: Health inspectors view pest control not just as extermination but as a reflection of your restaurant's overall sanitation and structural maintenance. A clean, well-sealed building is your first and best defense.

Major commercial pest control providers like Orkin and Terminix have developed specialized IPM programs for the foodservice industry. As a current industry trend, these programs now often include digital monitoring traps that provide real-time data on pest activity. Orkin's QualityPro program, used by chains like Applebee's and IHOP, combines routine inspections, structural recommendations, and detailed documentation. Similarly, Costco's food courts implement a comprehensive IPM that includes pheromone traps and sealed loading dock areas to prevent pest entry from the start.

Actionable Tips for Implementation

To ensure your establishment is pest-proof and ready for inspection, integrate these IPM practices:

- Seal All Entry Points: Regularly inspect the building's exterior. Install door sweeps to ensure no more than a 1/4-inch gap at the bottom of doors and seal any cracks or holes in walls and foundations.

- Eliminate Food and Water Sources: Store all dry goods in sealed, pest-proof containers made of hard plastic or metal, not their original cardboard or paper packaging. Clean drains daily with enzymatic cleaners to destroy fly breeding sites. These specialized supplies are crucial for prevention.

- Maintain Exterior Cleanliness: Keep dumpster areas clean, with lids tightly closed at all times. Position dumpsters at least 50 feet from building entrances and ensure the surrounding area is free of debris and standing water.

- Work with Professionals: Never use consumer-grade pesticides, as they can contaminate food and lead to pest resistance. Contract with a licensed commercial pest control operator who understands the specific challenges of a restaurant environment. For a systematic approach to identifying and addressing potential pest issues in your restaurant, refer to a comprehensive pest control inspection checklist.

6. Safe Food Sourcing and Storage

Food safety begins long before ingredients enter your kitchen. This critical component of a restaurant health inspection checklist covers the entire journey of your food, from verifying supplier credibility to implementing meticulous storage protocols. Inspectors will scrutinize your receiving process, supplier documentation, and storage organization to ensure every item is safe, from a reputable source, and handled correctly from the moment it arrives.

Proper sourcing and storage is a foundational practice that prevents contamination at the source. It requires a systematic approach to accepting deliveries, labeling, rotating stock, and organizing storage units to prevent cross-contamination and spoilage. A breakdown in this chain can introduce pathogens into your kitchen, compromising everything you do thereafter.

Why It's a Top Priority

Neglecting the "back-end" of your supply chain is a high-risk gamble. Using unapproved suppliers or having disorganized, improperly labeled storage can lead to critical violations. Inspectors may question the safety of any food without clear origin or date marking, potentially forcing you to discard large quantities of inventory and tarnishing your inspection score.

Key Insight: Inspectors view your supplier records and storage organization as a reflection of your restaurant's commitment to traceability and accountability. A well-documented supply chain and a meticulously organized walk-in signal a professionally managed and safe operation.

Leading brands demonstrate the importance of this process. An ongoing industry trend is hyper-transparency in sourcing. For example, Shake Shack's supply chain integrity is built on third-party audits of all its meat suppliers, while Sweetgreen transparently lists its farm partners and maintains extensive sourcing records. These practices build both consumer trust and a rock-solid defense during a health inspection.

Actionable Tips for Implementation

To ensure your sourcing and storage practices are inspection-ready, integrate these procedures into your daily workflow:

- Create a Standardized Receiving Checklist: Train all staff who accept deliveries to use a checklist that includes checking truck cleanliness, verifying temperatures of refrigerated and frozen goods, and inspecting for signs of damage or pests.

- Maintain a Master Supplier File: Keep an organized binder or digital file with current licenses, insurance certificates, and food safety audit reports for every supplier.

- Implement Strict FIFO: Use the "First-In, First-Out" method for all inventory. Dissolvable date labels are an excellent supply that simplifies this process, ensuring clear marking for prepared foods and opened ingredients.

- Organize for Safety: In all refrigerators, store raw proteins (like chicken and beef) on the lowest shelves, below ready-to-eat foods like produce and dairy, to prevent drips and cross-contamination. Learn more about how to optimize your setup with professional commercial kitchen storage solutions on encoreseattle.com.

- Reject Non-Compliant Deliveries: Empower your team to refuse any delivery that shows signs of temperature abuse (e.g., ice crystals on frozen items), has damaged packaging, or comes in cans that are dented, rusted, or swollen.

7. Employee Food Safety Training and Certification

An educated team is the foundation of a safe kitchen, making comprehensive employee training a non-negotiable part of any restaurant health inspection checklist. Inspectors don't just check your equipment; they observe your staff's actions and will often ask them questions to gauge their food safety knowledge. A team that lacks proper training is a significant liability, as human error is a primary cause of foodborne illness outbreaks.

Proper certification and ongoing training ensure that every team member, from the head chef to the newest dishwasher, understands and correctly implements critical food safety principles. This includes everything from handwashing protocols and cross-contamination prevention to understanding the nuances of food allergies. Many jurisdictions mandate that at least one Certified Food Protection Manager be on-site during all hours of operation, making this a critical compliance point.

Why It's a Top Priority

Insufficient training can lead to multiple, cascading violations during an inspection. If an inspector observes an employee improperly handling food or failing to answer basic safety questions, it signals a systemic failure in management's commitment to safety. This can result in significant penalties, mandatory re-training orders, and damage to your restaurant's reputation.

Key Insight: Health inspectors see a well-trained staff as the most reliable defense against food safety hazards. Documented, ongoing training demonstrates a proactive culture of safety that goes beyond simply meeting minimum requirements.

Leading brands recognize this as a core operational pillar. A major industry trend is the move toward digital, on-demand training platforms that allow for continuous learning and verification. After its 2015 food safety crisis, Chipotle mandated that 100% of its employees complete a food safety certification program. Similarly, Disney operates extensive internal training programs with custom curricula that often exceed local health department requirements, ensuring a consistent standard across its vast operations.

Actionable Tips for Implementation

To ensure your team is a food safety asset, not a liability, integrate these training practices:

- Schedule Manager Certification Early: Ensure your managers obtain their Food Protection Manager certification, such as the widely recognized ServSafe credential, well before opening a new restaurant or taking over an existing one.

- Implement Daily 'Huddles': Start each shift with a brief, two-to-three-minute food safety reminder. Focus on one specific topic, like proper glove use or checking sanitizer concentrations.

- Provide Multilingual Training: If you have a diverse team, provide training materials, posters, and instructions in employees' native languages to ensure full comprehension and retention. Look for restaurant supplies like posters and guides in multiple languages.

- Use Competency Checklists: Create and use checklists for each position that document specific safety skills. This provides tangible proof of training and helps identify knowledge gaps.

- Incorporate Scenario-Based Learning: During staff meetings, present real-world food safety scenarios (e.g., "What do you do if a refrigerator's temperature is 50°F?") to test critical thinking and reinforce protocols.

A strong training program often aligns with established food safety management systems. For those looking to implement a more advanced, preventative approach, it's beneficial to explore frameworks that are central to modern food safety. You can learn more about how HACCP food safety principles are integrated into restaurant operations, which provides a structured method for identifying and controlling potential hazards.

8. Facility Infrastructure and Equipment Maintenance

The physical condition of your building and the functionality of your equipment form the foundation of a safe food environment. This part of the restaurant health inspection checklist assesses everything from the structural integrity of walls and floors to the operational status of plumbing and ventilation. Inspectors verify that the physical plant is designed, built, and maintained to prevent contamination and support sanitary practices.

A well-maintained facility with properly functioning equipment is not just about aesthetics; it's a critical control point. Issues like cracked floor tiles, failing refrigeration units, or inadequate ventilation can directly lead to food contamination, pest infestations, and hazardous working conditions. Proactive maintenance ensures a safe space for both employees and guests.

Why It's a Top Priority

Neglecting infrastructure and equipment can result in a cascade of violations. A leaky pipe can lead to standing water, which attracts pests. A poorly ventilated kitchen can foster mold growth and create an unhealthy work environment. These issues are often considered core violations because they fundamentally compromise the restaurant's ability to operate safely and will be flagged immediately by an inspector.

Key Insight: Health inspectors view your facility's condition as a reflection of your operational standards. Well-maintained equipment and a clean, solid infrastructure signal a commitment to long-term safety and professionalism.

This principle is why global chains like McDonald's implement standardized facility designs across their 40,000+ locations, ensuring consistent infrastructure that meets or exceeds health codes. Following the latest industry trend, many new builds and renovations focus on energy-efficient and easy-to-clean equipment. Elite establishments like Eleven Madison Park have undergone complete infrastructure renovations, focusing on ventilation, plumbing, and seamless kitchen surfaces, to support their world-class food safety and quality standards.

Actionable Tips for Implementation

To ensure your facility and equipment pass inspection with flying colors, embed these practices into your maintenance schedule:

- Design for Cleanliness: Use non-porous, smooth, and easily cleanable surfaces for all walls, floors, and food-prep areas. Stainless steel equipment is ideal; avoid tiled surfaces with grout lines in prep zones, as they trap bacteria.

- Maintain Your Hoods: Schedule professional hood cleaning quarterly, or more frequently for high-volume frying operations. Clogged grease traps and filters are a major fire hazard and sanitation violation.

- Protect Your Water Supply: Test backflow prevention devices annually and keep detailed documentation for your inspector. This proves you are protecting the potable water supply from contamination.

- Keep Detailed Maintenance Logs: Create and maintain a logbook for all major equipment, documenting manufacturer-recommended service intervals, repairs, and preventive maintenance. This demonstrates due diligence to inspectors. For an in-depth guide, explore best practices for commercial kitchen equipment maintenance.

- Manage Air Quality and Climate: Proper ventilation is crucial for employee safety and preventing the buildup of grease and mold. For overall facility health and to ensure all systems contribute to operational excellence, consider integrating an essential commercial HVAC maintenance checklist into your routine.

Restaurant Health Inspection: 8-Point Compliance Comparison

| Food Safety Aspect | Implementation Complexity 🔄 | Resource Requirements ⚡ | Expected Outcomes 📊 | Ideal Use Cases 💡 | Key Advantages ⭐ |

|---|---|---|---|---|---|

| Food Temperature Control and Monitoring | Moderate: requires calibrated tools and records | Multiple thermometers, staff training, time for logging | High: reduces foodborne illness risk; documented compliance | All foodservice operations requiring strict temp control | Prevents bacterial growth; protects reputation |

| Cross-Contamination Prevention and Food Separation | Moderate-High: needs physical separation and protocols | Color-coded tools, extra storage space, ongoing staff training | High: reduces illness transmission and allergen exposure | Kitchens with high-risk foods or allergen-sensitive menus | Systematic workflows; allergen risk reduction |

| Personal Hygiene and Handwashing Compliance | Low-Moderate: simple protocols but needs strict enforcement | Handwashing stations, training, signage | High: reduces pathogen transmission by up to 50% | Food prep environments with high employee interaction | Most cost-effective intervention; builds trust |

| Proper Cleaning and Sanitizing Procedures | Moderate-High: multi-step process with chemical monitoring | Chemicals, test strips, time for cleaning cycles | Very High: eliminates 99.999% of bacteria; prevents biofilm | All foodservice facilities requiring sanitation compliance | Verifiable sanitation; extends equipment life |

| Pest Control and Prevention Program | Moderate: requires professional services and maintenance | Monthly pest control, building repairs, staff vigilance | High: prevents contamination and violations | Urban or high-risk pest environments | Protects reputation; reduces waste and damage |

| Safe Food Sourcing and Storage | Moderate: detailed recordkeeping and storage protocols | Documentation systems, storage space, trained staff | High: ensures traceability and reduces waste | Facilities needing supply chain control and traceability | Maintains quality; minimizes liability |

| Employee Food Safety Training and Certification | Moderate-High: requires certified managers, regular training | Training courses, documentation, ongoing refreshers | Very High: reduces illness, builds safety culture | All establishments with food handlers | Improves competency; lowers liability |

| Facility Infrastructure and Equipment Maintenance | High: requires capital investment and ongoing upkeep | Equipment, facility upgrades, preventive maintenance | Very High: supports all safety practices; prevents contamination | Restaurants needing consistent code compliance | Prevents contamination; reduces emergency repairs |

Equip Your Kitchen for Success and Safety

Navigating the complexities of a health inspection can feel like a high-stakes performance, but it doesn't have to be a source of anxiety. The detailed restaurant health inspection checklist we've explored is not merely a list of rules to follow; it's a blueprint for building a culture of excellence and safety that permeates every aspect of your operation. By moving from a reactive, pre-inspection scramble to a proactive, continuous system of compliance, you transform a potential vulnerability into one of your restaurant's greatest strengths.

This journey from basic compliance to operational mastery hinges on the eight core pillars we've discussed. From the scientific precision of Food Temperature Control to the diligent routines of Cleaning and Sanitizing Procedures, each element is interconnected. A lapse in one area, such as inadequate Employee Food Safety Training, can quickly undermine your best efforts in preventing cross-contamination or managing pest control. True readiness is achieved when these practices are no longer seen as separate tasks but as a unified system working in concert to protect your customers, your staff, and your brand's reputation.

From Checklist to Culture: Making Safety Second Nature

The ultimate goal is to embed these standards so deeply into your daily operations that they become second nature. Think of your health and safety protocols as the foundational recipe for your entire business. Just as you wouldn't compromise on a key ingredient in your signature dish, you cannot afford to compromise on food safety. This requires consistent reinforcement, visible leadership, and equipping your team with the right tools and knowledge to succeed.

To truly elevate your standards, consider these next steps:

- Conduct Regular Self-Audits: Don't wait for the health inspector. Use this checklist to perform weekly or bi-weekly self-inspections. Assign different team members to lead the audits to foster a sense of shared ownership and keep a fresh set of eyes on your procedures.

- Gamify Your Training: Move beyond static training modules. Create friendly competitions around handwashing compliance, a "best-labeled" shelf of the week, or quizzes on temperature danger zones. Rewarding top performers can make learning engaging and memorable.

- Invest in Your Infrastructure: Outdated or failing equipment is a common source of health code violations. A refrigerator that can't hold a consistent temperature or a dishwasher that doesn't reach sanitizing heat levels puts your entire operation at risk. Upgrading your kitchen infrastructure is not just an expense; it's an investment in consistency, efficiency, and peace of mind.

Key Insight: A passing grade on a health inspection is the minimum standard. The real objective is to create an environment where food safety is so ingrained in your culture that you could welcome an inspector, announced or unannounced, at any time with complete confidence.

The Tangible Benefits of a Proactive Approach

Mastering your restaurant health inspection checklist delivers benefits that extend far beyond avoiding fines or closures. It directly impacts your bottom line and brand perception. A pristine kitchen and a well-trained staff lead to reduced food waste, lower risk of foodborne illness outbreaks, and improved employee morale. Most importantly, it builds trust with your diners. In an age of online reviews and instant social media feedback, a reputation for cleanliness and safety is invaluable marketing. Customers who feel safe and cared for become loyal patrons and vocal advocates for your brand. By prioritizing these operational fundamentals, you are not just meeting regulatory requirements; you are building a resilient, reputable, and profitable business poised for long-term success.

Are you ready to upgrade your kitchen with equipment that makes compliance easier and more reliable? At Encore Seattle Restaurant Equipment, we provide Pacific Northwest restaurants with top-tier new and used equipment that meets stringent health and safety standards. Explore our inventory today to find exclusive deals on everything from NSF-certified refrigeration to high-performance dishwashers and start building a safer, more successful kitchen.