Improve Your Profit with the Best Inventory Format for Restaurant

Share

A poorly designed inventory format for restaurant operations is more than a minor headache; it's a silent profit killer. The right format isn't just about ticking boxes—it's your command center for wrangling food costs, slashing waste, and making purchasing decisions that actually help your bottom line. Stay informed about industry trends and discover exclusive deals on the restaurant equipment and supplies you need to succeed.

Why Your Current Inventory System Is Costing You Money

Let's be honest. That "good enough" spreadsheet or the dog-eared notepad you've been using feels comfortable, but it's probably the biggest leak in your restaurant's profitability. The real-world costs of a messy or inconsistent inventory format are staggering, showing up in subtle ways that slowly bleed your profits dry.

Think about the last time you had a surprise stockout of a key ingredient during a dinner rush. Or the constant, nagging loss from spoilage you can't quite pin down. These problems almost always trace back to a lack of clear, actionable data from your inventory counts.

The whole point isn't just to count what's on the shelves. It’s to build a system that gives you real financial control. A standardized, well-thought-out inventory format turns a boring chore into one of your most powerful business intelligence tools.

The Real Cost of Inaccurate Counts

I once worked with a popular bistro that was constantly battling fluctuating weekly food costs. Their "system" was a chaotic mix of handwritten notes and a basic spreadsheet where nobody used the same name for an item twice. They were losing a surprising amount of money every week, especially on dairy and produce, simply from over-ordering and spoilage.

Once we put a standardized format in place with clear categories, consistent units of measure, and established par levels, the problem became obvious. They were consistently overstocked on their most perishable items by 15-20%. That one small change saved them hundreds of dollars a week. It’s proof that the precision in your format translates directly to your bank account.

The hidden costs of a bad system are almost always found in these areas:

- Excess Spoilage: Without a clear picture of what's moving and what's sitting, perishable items are easily forgotten until it's too late.

- Uncontrolled Food Waste: Inaccurate tracking makes it impossible to know if waste is coming from over-portioning, prep mistakes, or even potential theft.

- Poor Purchasing Decisions: Ordering becomes a guessing game. You either tie up cash in costly overstock or lose sales because you ran out of a popular dish.

A well-designed inventory format acts as a financial diagnostic tool. It doesn't just tell you what you have; it tells you where your money is going and why.

At the end of the day, adopting a better inventory format for a restaurant is one of the highest-impact changes you can make to boost your operational efficiency and protect those razor-thin margins. For a deeper dive into the broader world of inventory control, exploring comprehensive inventory management resources can provide even more valuable insights.

Designing Your Foundational Inventory Template

Alright, let's get down to business. It’s time to build an inventory template that actually works for a real, bustling restaurant—not just a basic list of items. A truly effective template is built around a handful of non-negotiable data fields. These are what give you total clarity over your stock and transform a simple count into a powerful financial tool.

This isn't just a "nice to have" anymore. With rising food costs and unpredictable supply chains, tight inventory management has become absolutely critical. In fact, a staggering 87% of restaurateurs recently reported a spike in their food costs, and 82% don't see that trend stopping anytime soon. When your profit margins are already hovering between a slim 3-5%, every little inaccuracy hurts. Detailed tracking is essential to survival.

Structuring Your Template Categories

Here’s the first, and maybe most important, tip for a faster, more accurate count: organize your template to mirror the physical layout of your restaurant. Forget one giant, alphabetical list. Instead, create separate tabs or sections in your spreadsheet that match your actual storage areas.

This small change makes the classic "sheet-to-shelf" counting method a breeze.

Your main categories should line up with where things live in your kitchen:

- Walk-In Cooler: This is for all your proteins, dairy, fresh produce, and anything prepped that needs to stay cold.

- Dry Storage: Think pastas, grains, canned goods, spices, and all your other shelf-stable items.

- Freezer: Pretty straightforward—all frozen goods, from vegetables and proteins to pre-made sauces.

- Bar/Beverage Station: Give all your spirits, wine, beer, syrups, and garnishes their own dedicated section.

When your template matches your storeroom, your staff isn't running back and forth trying to find items. This alone will dramatically cut down on count times and the silly mistakes that creep in when people are rushed. For more ideas on getting your space in order, check out these tips on https://encoreseattle.com/blogs/seattle-restaurant-equipment/commercial-kitchen-storage-solutions.

The Essential Columns Every Template Needs

Once you have your categories set, it's time to define the columns that will capture all the critical data. Each field here has a specific job to do, all working together to calculate your costs and give you a true picture of your inventory's value. When you're building this, it's also a good idea to see how a Standard Operating Procedure template can help create consistent processes around your inventory counts.

To build a really solid template, you need to capture the right information. Here are the must-have columns I recommend for every inventory sheet.

Essential Columns for Your Restaurant Inventory Sheet

| Column Name | Purpose | Example |

|---|---|---|

| Item Name | The specific name of the product. | Ground Beef, 80/20 |

| Category | The storage area where the item is located. | Walk-In Cooler |

| Purchase Unit | How you buy the item from your supplier. | Case |

| Purchase Price | The cost for one purchase unit. | $80.00 |

| Count Unit | The unit you use to count the item on the shelf. | Pound (LB) |

| Conversion Factor | How many count units are in one purchase unit. | 40 (i.e., 40 lbs per case) |

| Unit Cost | The cost per count unit (Purchase Price / Conversion) | $2.00/lb |

| On-Hand Qty | The physical amount counted on the shelf. | 25 lbs |

| Total Value | The total monetary value of the on-hand stock. | $50.00 |

Getting these columns right from the start will save you countless headaches down the road by ensuring your data is clean, consistent, and actually useful.

If you take away only one thing, let it be this: The Conversion Factor is the single most important column for accuracy. It's the magic number that connects how you buy an item (by the case) with how you use it (by the pound or by the 'each'). Get this right, and your data will always be spot-on.

Using Inventory Metrics to Make Smarter Decisions

Your new inventory template is more than just a list of what's on the shelves; it's a treasure map. When you learn how to read it, it'll point you directly to where your profits are hiding—and where they're slipping away. Moving beyond simple counts and dollar values is how you turn a chore into a powerful business tool.

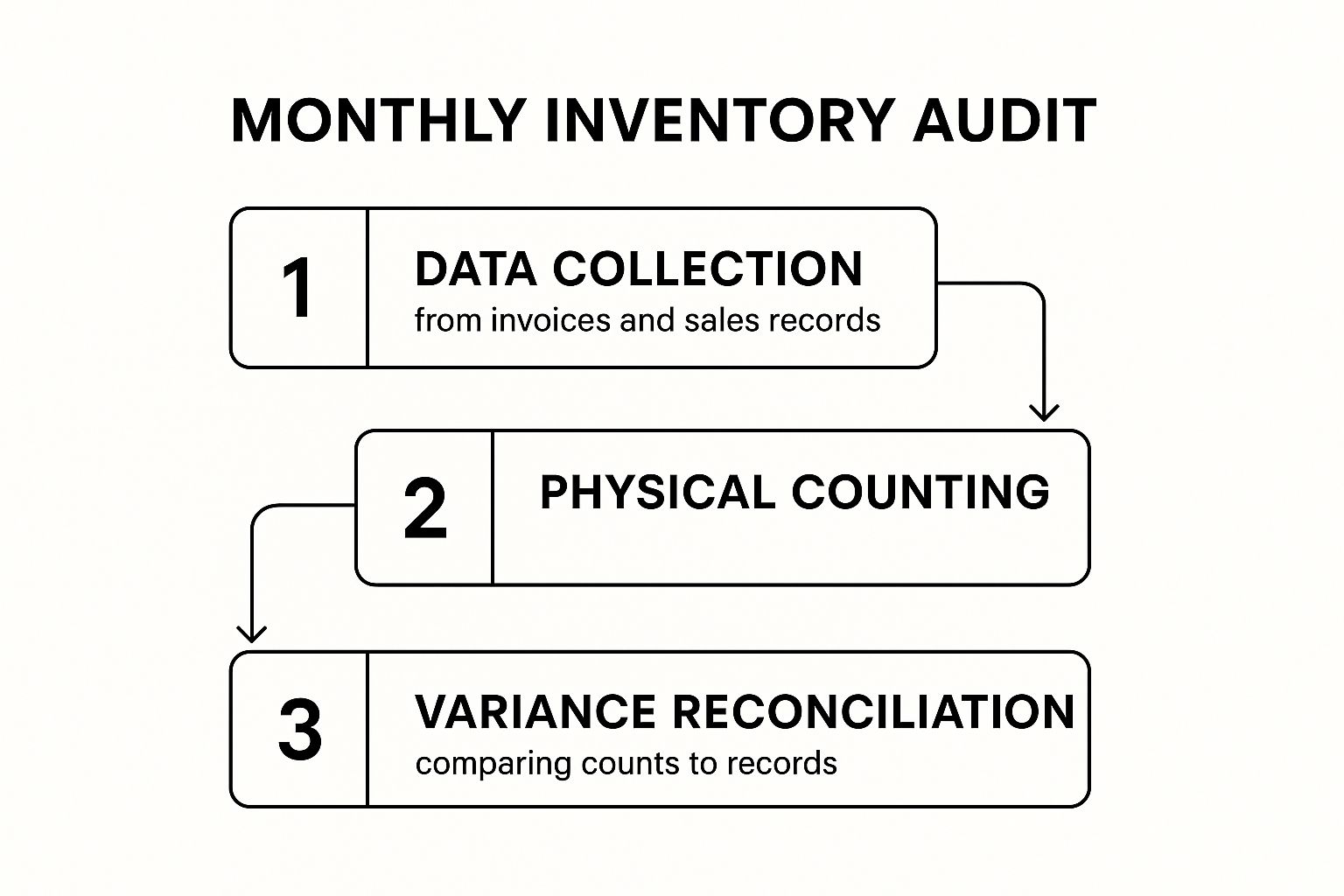

This all starts with a rock-solid monthly audit. Without consistent, reliable data, you're just guessing. The process itself is straightforward, but it’s the discipline that counts.

This rhythm—gathering paperwork, doing the physical count, and then hunting down the differences—is the bedrock of everything. The real magic happens when you reconcile those numbers and figure out why they don't match. That's where the insights live.

Key Metrics to Pull From Your Inventory Sheet

Once you have clean data, you can start calculating the numbers that actually move the needle. The big one, of course, is your Cost of Goods Sold (COGS). This tells you exactly how much you spent on the ingredients that went into the dishes you sold over a certain period.

The formula is a classic for a reason:

COGS = (Beginning Inventory + Purchases) - Ending Inventory

Your job is to keep a close eye on this number. For most spots, a healthy food COGS lands somewhere between 28% and 35% of your food sales. If you see it creeping up past that range, it's a flashing red light. That could mean anything from portioning issues and kitchen waste to a supplier quietly raising prices on you.

To see how this single metric ripples through your entire financial picture, plug your numbers into a good restaurant profit margin calculator. It really puts things into perspective.

Next up is your inventory turnover rate. This is a fantastic metric for measuring efficiency. It shows you how many times you've sold through and replaced your entire stock in a given period. Think of it as a measure of how well you're managing the cash tied up in your walk-in and dry storage.

Here's the formula:

Inventory Turnover Rate = COGS / Average Inventory

A high turnover rate is usually a great sign. It means products are moving, cash is flowing, and spoilage is low. But watch out—if it's too high, you might be running lean and risking an "86" on a popular item during a Saturday night rush.

A high-volume pizza shop, for example, is going to turn over its flour and cheese way faster than a fine-dining restaurant turns over its saffron and truffles. The key is to track your own rate over time to find that sweet spot between having what you need and not letting cash sit on a shelf.

Turning Numbers Into Action

These numbers are completely useless if you don't do anything with them. They're meant to spark questions and drive decisions.

Let's say you notice the inventory turnover for that expensive prime rib is painfully low. That's not just a statistic; it's a story.

- Is the dish working? Maybe the price point is off, or it's just not resonating with your guests. Could it be time to run it as a weekend special to create buzz, or is it time to cut it from the menu?

- Are you buying too much? A low turnover means your cash is literally frozen. Instead of buying a whole case to get a slight discount, maybe you should negotiate smaller, more frequent deliveries. Even if the per-unit cost is a bit higher, your improved cash flow could more than make up for it.

The same goes for tracking your food waste. By actually measuring what gets thrown out—spoilage, kitchen mistakes, food sent back by customers—you can start seeing patterns. Is one cook on the line generating more waste than others? This isn't about blame; it's about identifying a training opportunity. By digging into the why behind the numbers, you can make targeted changes that directly boost your bottom line.

Making Your Inventory Routines Stick

Look, a perfect inventory template is only half the battle. If your team isn't filling it out correctly and consistently, it's just a fancy spreadsheet. The real magic happens when you build solid, repeatable routines that turn inventory from a dreaded chore into a powerful business habit.

This is all about creating a system that becomes part of your restaurant's DNA. You want it to be so ingrained in your daily and weekly operations that nobody thinks twice about it. This is how you translate good intentions into real financial control.

Count Smarter, Not Harder: The Sheet-to-Shelf Method

One of the best pieces of advice I can give is to use the sheet-to-shelf counting method. It’s simple but incredibly effective. All you do is organize your inventory spreadsheet to match the physical layout of your storage areas.

Think about it: your list should flow just like your storeroom. Top shelf of the walk-in, then the next shelf down, then the dry goods from left to right. When your manager grabs the clipboard or tablet, they can just walk the line without constantly jumping around the page to find the right item. This little trick slashes counting time and cuts down on the simple mistakes people make when they’re frustrated and disorganized.

Consistency Is King

A haphazard approach to inventory will give you exactly what you’d expect: haphazard results. You have to lock in a firm, consistent schedule.

Maybe you do a full, wall-to-wall count once a month. That's fine. But for your high-cost, fast-moving items—think steak, fresh fish, dairy, and liquor—you need to be counting them weekly. This frequency lets you catch problems like over-portioning, spoilage, or even theft right away, instead of getting a nasty surprise at the end of the month.

This isn’t just busywork; it directly hits your bottom line. Food waste is a massive problem in our industry, with some estimates suggesting 30-40% of the food supply in restaurants gets thrown out. Getting a handle on your stock with regular counts and proper rotation can slash your food costs by 3-5%. That's pure profit.

To really dial in your process and make sure your stock is always accurate, it’s worth brushing up on essential inventory management best practices.

Building Accountability and Good Habits

Creating a culture of accuracy comes down to having clear rules that everyone understands. A couple of non-negotiable practices will make a huge difference in how reliable your numbers are.

-

Buddy Up for Counts: Whenever you can, have two people do the inventory count together. One person physically counts and calls out the numbers, while the other enters the data. This "caller and counter" system provides an instant double-check and catches errors before they ever mess up your reports.

-

Get Serious About FIFO: First-In, First-Out isn't just a suggestion; it's a critical rule for preventing spoilage and waste. Train your team relentlessly on this. New deliveries always go to the back of the shelf, and older stock gets pulled forward. No exceptions.

At the end of the day, your inventory data is only useful if you can trust it. Disciplined, consistent routines are the only way to be sure the numbers you're using to make big-picture decisions are actually telling you the truth.

When to Upgrade to Inventory Management Software

Spreadsheets are an incredible tool when you're just starting out. They're simple, cheap, and get the job done. But as your restaurant grows, that trusty template you built starts to feel less like a tool and more like a ball and chain. Manual entry becomes a major time sink, and the hours you spend counting and calculating are hours you’re not spending leading your team or developing your menu.

So, how do you know when you've outgrown it? The signs are usually pretty obvious. Your inventory counts start taking hours, not minutes. You’re finding costly ordering mistakes that trace back to a simple typo in a cell. Or you’re flying blind during a busy service, with no real-time idea of what you actually have on the shelves. For anyone trying to manage multiple locations with a spreadsheet, the chaos multiplies quickly.

Moving Beyond Manual Entry

Switching to dedicated inventory management software isn't about starting from scratch. It’s about taking all the sound inventory principles you've been using and putting them on autopilot. You're still tracking units, costs, and waste, but the entire process becomes faster, smarter, and way more accurate.

The real magic happens when the software integrates directly with your Point of Sale (POS) system. This is an absolute game-changer. Every time a server punches in an order for a burger, the system automatically deducts one bun, one patty, a slice of cheese, and a handful of lettuce from your inventory. This live depletion gives you a stunningly accurate, up-to-the-minute picture of your stock levels.

The real value of inventory software is that it transforms your data from a historical record into a predictive tool. It stops you from looking at what you had last week and starts telling you what you'll need tomorrow.

The Power of Automation and AI

Modern restaurant tech is moving fast, and AI-driven systems are now doing the heavy lifting by monitoring stock in real-time and forecasting demand based on your own sales history. This means you get timely low-stock alerts and predictive ordering suggestions, which helps prevent that dreaded 86'ing of a popular dish during a dinner rush.

It's not just a trend for a few high-tech spots, either. Around 55% of food businesses in Southeast Asia alone have already adopted digital inventory tools. The shift saves countless labor hours, but more importantly, it unlocks a deeper level of strategic insight into your business.

Here are a few key software features that make a massive difference:

- Automated Ordering: The system can generate purchase orders automatically when key ingredients hit a pre-set par level. You'll never run out of avocados on a Saturday again.

- Waste Tracking: Finally, an easy way to log spoilage, comps, or staff meals. This gives you a true picture of your food costs beyond just what you sold.

- Supplier Management: All your vendor info, pricing sheets, and order histories live in one place, making it simple to compare costs and manage relationships.

- Recipe Costing: Instantly see the exact plate cost for every item on your menu. This is critical for pricing your dishes for maximum profitability.

Making the switch is a strategic investment in your restaurant's future. And for specific needs, like a complex beverage program, dedicated tools can make an even bigger impact—you can dive deeper into bar inventory management systems to see just how specialized this tech can get.

When your manual spreadsheet starts holding you back, it's a clear sign it's time to let technology take over.

Common Questions (And Real-World Answers) About Restaurant Inventory

Even with the best template in hand, the reality of a busy kitchen always throws a few curveballs. Things come up that just don't fit neatly into a spreadsheet column. Let's dig into some of the most common questions I hear from owners and managers trying to get their inventory process dialed in.

Getting these little details right is what turns a basic stock count into a serious tool for managing your money. Here are some straight answers to those tricky, everyday challenges.

How Often Should I Really Be Counting Inventory?

Look, a full "wall-to-wall" count once a month is the bare minimum. But if that's all you're doing, you're flying blind. For your high-cost, fast-moving items—think proteins, fresh produce, dairy, and especially liquor—weekly counts are the industry gold standard. There's just no substitute.

Why so often? Because it lets you calculate your Cost of Goods Sold (COGS) every single week. More importantly, it helps you catch problems like theft, waste, or over-portioning right away, not three weeks after the fact when the money's already gone. You might get away with a monthly count for low-cost dry goods, but the ingredients that make or break your profit margins need a weekly set of eyes on them.

What's the Single Biggest Mistake People Make?

I see it all the time. The most common and costly mistake, by a long shot, is inconsistency with the 'Unit of Measure.' This one thing can completely torpedo your entire inventory system.

Here's a classic scenario: your supplier invoice says you received one case of tomatoes, so that's what you log. But when your staff does the physical count, they're counting individual tomatoes. Without a clear conversion, your numbers will be wildly off, and you won't be able to trust any of the data.

Your inventory sheet absolutely needs separate, clearly labeled fields for 'Purchase Unit' (e.g., Case) and 'Count Unit' (e.g., Each, Lb). That little conversion factor between the two is the key to making the whole system accurate.

Can I Just Use My POS System's Inventory Module?

It's a great starting point, but it's not the whole picture. The inventory module in a Point of Sale (POS) system is brilliant at tracking what should be on your shelves based on what you've sold. It automatically subtracts ingredients as orders are punched in, giving you a theoretical count.

The problem is, POS systems are blind to everything that happens outside of a sale. They don't see:

- Waste & Spoilage: That case of lettuce that wilted or the steak that got dropped? The POS never knows it existed.

- Staff Meals: Unless you're meticulously ringing them in, those meals are using up ingredients that are never recorded.

- Portioning Creep: If the recipe calls for four ounces of cheese but a line cook is consistently using six, your POS has no idea.

Think of it this way: your POS tells you one story, and your physical count tells you another. The magic happens when you compare the two. That's where you find your hidden costs and fix the operational leaks.

How Do I Handle Daily Specials?

This is a great question. Rotating specials can make your main inventory sheet a chaotic mess if you're not careful.

The best way to handle this is to create a separate tab or a dedicated section in your spreadsheet labeled 'Specials' or 'Features.' Instead of adding every single potential ingredient to your main list, just track the key, high-value items for that specific special on the days you run it.

This keeps your primary inventory sheet clean and focused on your core menu, but still gives you the power to accurately cost out and track the profitability of your most creative dishes.

At Encore Seattle Restaurant Equipment, we help restaurant owners and chefs discover the latest news and exclusive deals on restaurant equipment and supplies. From walk-in coolers to precision cooking equipment, we provide the gear you need to run an efficient and profitable operation. Explore our extensive selection of new and used equipment to find the perfect fit for your restaurant.