Perfect Scoop Ice Cream Refrigeration Guide

Share

If you've ever pulled a tub of what should have been creamy, delicious ice cream from the freezer, only to find it gritty and full of ice crystals, you already know the stakes. For any chef or restaurant owner serious about frozen desserts, getting refrigeration right isn't just a technical detail—it's everything. It's the difference between a memorable treat and a disappointing, icy mess.

This guide is for anyone who has battled with texture and flavor loss. It’s about more than just keeping things cold; it's about mastering the science of temperature to protect your quality, your consistency, and ultimately, your reputation. Here, we'll help you discover the latest news, industry trends, and even exclusive deals on the restaurant equipment and supplies that will elevate your dessert program.

The Science Behind the Perfect Scoop

Serving a truly great scoop of ice cream is part art, part science. The magic that customers crave—that incredible creaminess that melts perfectly on the tongue—all comes down to something you can't even see: the size of the ice crystals. And the single most important tool you have for controlling those crystals is your refrigeration.

Think about what happens when ice cream is first made. In a batch freezer, the base is churned and rapidly chilled at the same time. This process, called dynamic freezing, is designed to create millions of incredibly tiny ice crystals, usually no bigger than 10 to 20 micrometers. That's what gives fresh-from-the-machine ice cream its signature smooth texture. But the journey from the machine to the customer's bowl is where things can go wrong.

Preserving Creaminess Through Stable Temperatures

Once that freshly churned ice cream goes into storage, a new phase begins. This is what we call static freezing, or "hardening," and it’s where the real challenge lies. The goal is to preserve those microscopic crystals, but any fluctuation in temperature can undo all your hard work. Even a change of a few degrees can cause the smallest crystals to melt slightly, only to refreeze onto their larger neighbors.

This destructive cycle is known as heat shock.

Heat shock is the primary culprit behind grainy or icy ice cream. It’s a slow-motion process where temperature swings cause small, desirable ice crystals to merge into large, crunchy ones, permanently ruining the smooth texture.

This is precisely why you can't just toss your artisanal ice cream into a standard kitchen freezer and hope for the best. You need specialized ice cream refrigeration. The mission is to hold a rock-solid, stable temperature, ideally at or below 0°F (-18°C) for long-term storage. This deep, unwavering cold literally locks the ice crystals in place, stopping them from growing.

For a chef who cares about quality, understanding this is fundamental. It's why a general-purpose freezer, with its constant defrost cycles and temperature swings every time the door opens, is the enemy of premium ice cream. The right refrigeration choice directly impacts:

- Product Texture: It stops those large, unpleasant ice crystals from ever forming.

- Flavor Integrity: It protects delicate flavors from breaking down due to temperature abuse.

- Customer Satisfaction: It ensures you’re serving the same high-quality, creamy dessert every single time.

When you master the science of cold, your freezer stops being just a box and becomes your most important tool for dessert excellence.

Why Standard Freezers Ruin Ice Cream

To really get why you need special ice cream refrigeration, you first have to understand what makes ice cream great in the first place. It’s not just the ingredients—it’s the structure. Think of it like a brick wall: the mortar is your sweet, creamy base, and the "bricks" are millions of microscopic ice crystals.

When those ice crystal "bricks" are tiny and packed together uniformly, you get that luxurious, smooth texture everyone loves. But when they start to grow and fuse, the result is a grainy, icy disappointment. There’s a name for this destructive process that every chef should fear: heat shock.

Heat shock is the slow-motion enemy of premium ice cream. It’s what happens when the product partially thaws and then refreezes, causing those small, delicate ice crystals to merge into larger, crunchier ones. Once this occurs, there's no going back. You can't undo that damage. This is precisely why your choice of freezer is so critical.

The Problem with Auto-Defrost Cycles

Most standard commercial freezers—the kind you’d toss frozen fries or burger patties into—are built with an auto-defrost cycle. For general-purpose use, this feature is fantastic. It prevents frost from building up by periodically warming the interior coils just enough to melt it away.

For ice cream, however, this convenience is a total disaster. Every single defrost cycle creates a subtle but incredibly damaging temperature swing. Even a few degrees of warming is all it takes to start melting your ice cream, setting the stage for that dreaded heat shock.

Research has shown that ice cream stored in a typical freezer with auto-defrost can become noticeably icy in as little as four weeks. Those constant, minor temperature fluctuations are enough to ruin even the highest-quality product over a surprisingly short time.

This is why a standard freezer, while a workhorse for many kitchen tasks, actively works against you when it comes to serving perfect scoops. The very feature designed to make it low-maintenance is what destroys your dessert’s delicate structure.

Storage vs. Serving Temperatures

Another thing you have to nail down is the difference between long-term storage and ready-to-serve temperatures. These are two completely different jobs that demand different conditions, and mixing them up is a rookie mistake.

- Hardening & Storage: For long-term storage or for "hardening" freshly churned ice cream, you need a deep, stable freeze. The ideal temperature is 0°F (-18°C) or even colder. This keeps the ice cream rock-solid, locking those tiny crystals in place and stopping them from growing.

- Dipping & Serving: When it's time to serve, the ice cream needs to be soft enough to scoop without a fight, but not so warm that it’s a soupy mess. That scooping sweet spot is usually between 6°F and 10°F (-14°C to -12°C).

Trying to make one freezer do both jobs just doesn't work. A freezer cold enough for proper storage will make your ice cream too hard to scoop. On the other hand, a cabinet set at a perfect serving temperature isn't cold enough to prevent degradation over the long haul.

This is exactly why professional scoop shops have separate hardening cabinets and dipping cabinets. The demand for great ice cream has fueled huge investment in this specialized gear. In the United States, for instance, where the average person consumes about 20 pounds of ice cream annually, the industry contributes over USD 13.1 billion to the economy. You can explore more data about the massive ice cream freezer market and see its economic impact for yourself.

Static Cooling: The Key to Stability

To fight heat shock, professional ice cream freezers rely on static cooling instead of the forced-air, auto-defrost systems found in regular units. Here’s the difference:

Forced-Air Cooling: This is what most standard freezers use. A fan blows cold air around, which is great for chilling things down quickly. But that moving air also causes freezer burn and contributes to the temperature swings during the essential auto-defrost cycle.

Static Cooling: This method is much gentler. Cooling coils are built right into the freezer walls, radiating cold without any fans. This creates a far more stable, consistent, and humid environment that doesn't batter the ice cream. These freezers almost always require manual defrosting, but that’s the whole point. It completely eliminates the damaging temperature cycles. It's a trade-off that serious chefs and shop owners gladly make: a little more work for a lot more quality.

How to Choose the Right Refrigeration Equipment

Picking out the right ice cream refrigeration is one of the most critical equipment decisions you'll make for your business. This isn't just about finding a freezer that fits your floor plan; it’s about getting the right tool for a very specific job. You see, each type of freezer is built to master one stage of the ice cream's journey, from its creation in a liquid base to the final, perfect scoop.

If you get this choice wrong, you're setting yourself up for daily operational headaches and, even worse, a drop in your product's quality. Let's walk through the main types of commercial ice cream freezers so you can confidently match the equipment to your business, your workflow, and your menu. By staying informed on industry trends and deals, you can make the smartest investment.

Batch Freezers For In-House Production

If you plan on making your own ice cream from scratch, a batch freezer isn't optional—it's the heart of your operation. This machine isn't for storage. Think of it as the engine of your dessert program, the place where your liquid cream base gets churned and chilled into a beautiful, semi-frozen product.

A batch freezer works its magic by churning and flash-freezing the mix at the same time. This constant movement, paired with intense cold, is what creates the millions of tiny ice crystals needed for that signature smooth, creamy mouthfeel.

When you're shopping for one, keep these points in mind:

- Capacity: How many gallons or liters can it churn out per hour? Make sure this number can keep up with your busiest days.

- Dasher Design: The internal scraper, called a dasher, is crucial. A good one will freeze the mix efficiently and keep ice from building up on the cylinder walls.

- Footprint: These are not small machines. Double-check that you have enough space and the right electrical hookups.

Hardening Cabinets For Setting and Storage

The moment your ice cream leaves the batch freezer, it isn't quite ready to serve. It's only partially frozen, with a texture that's closer to soft-serve. This is where a hardening cabinet, sometimes called a "blast freezer," steps in. Its one and only job is to "statically freeze" the ice cream solid, and to do it fast.

These units get incredibly cold, often running at -20°F to -30°F (-29°C to -34°C). By crashing the temperature so quickly without any air blowing around, they lock in that smooth texture and stop large, gritty ice crystals from forming. Just a few hours in a hardening cabinet transforms your fresh product, getting it ready for long-term storage or its debut in the dipping cabinet.

I see this mistake all the time: shops move ice cream straight from the batch freezer into a serving cabinet to save time. This shortcut absolutely tanks the product's shelf life and creates a noticeably icy texture within just a couple of days.

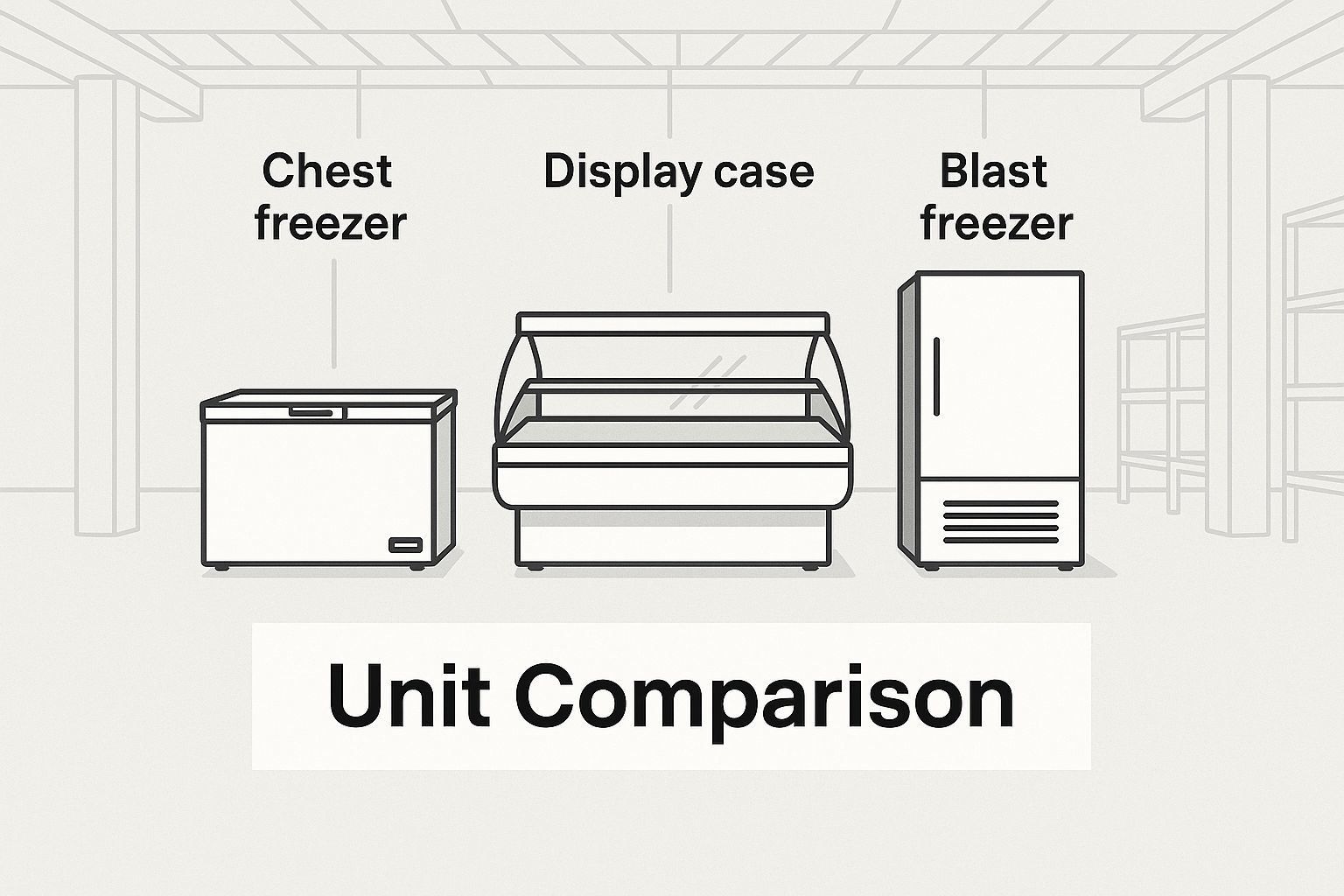

This quick visual guide breaks down the most common refrigeration units you'll encounter.

As you can see, every freezer—from a basic chest freezer to a powerful blast freezer—is designed for a very distinct purpose in the kitchen.

Commercial Ice Cream Freezer Comparison

To make things even clearer, here's a table comparing the primary types of ice cream freezers. Use this to quickly see how each one functions and decide which equipment is essential for your business needs.

| Freezer Type | Primary Function | Typical Temperature Range (°F) | Best For |

|---|---|---|---|

| Batch Freezer | Production | Churning/Freezing Process | Making ice cream from scratch. |

| Hardening Cabinet | Rapid Freezing | -20°F to -30°F | Setting freshly churned ice cream to preserve texture. |

| Dipping Cabinet | Serving/Display | +6°F to +10°F | Front-of-house scooping and customer display. |

| Storage Freezer | Bulk Storage | 0°F or below | Holding hardened, ready-to-serve inventory. |

Choosing the right combination of these freezers is the secret to maintaining top-tier quality from production all the way to the customer's cone.

Dipping Cabinets For Perfect Scooping

Up front, where your customers are, the dipping cabinet is the star of the show. It's the visual and functional centerpiece of any scoop shop. Its design is focused on two key things: maintaining the ideal scooping temperature and showing off your product beautifully.

Dipping cabinets hold a temperature between 6°F to 10°F (-14°C to -12°C). This is the sweet spot—cold enough to keep the ice cream firm, but just warm enough to make it scoopable. You'll find that most have a glass sneeze guard, bright lighting, and room for plenty of tubs, which is perfect for enticing customers with all your amazing flavors. A quick tip: these are almost always manual defrost to prevent the temperature spikes from an auto-defrost cycle that can ruin your ice cream's texture.

Storage Freezers For Bulk Inventory

Finally, you'll need a reliable storage freezer to hold all your hardened, ready-to-sell inventory. These are usually chest or upright freezers that are built for stable, long-term cold, not for display. Just like hardening cabinets, the best ones for ice cream use static cooling and manual defrost.

Their main job is to hold a steady temperature at or below 0°F (-18°C) to protect your product from heat shock. When picking one out, focus on its capacity, energy efficiency, and especially the quality of the door seals. A leaky seal lets in warm, moist air, which makes the compressor work overtime and creates temperature swings—the enemy of great ice cream.

As you start planning your layout, just remember that each freezer is one piece of a bigger puzzle. For a full picture of all the gear you might need, our detailed commercial kitchen equipment checklist can help make sure you've got all your bases covered, from the cook line to cold storage.

Essential Features of Modern Ice Cream Freezers

Once you’ve figured out the right type of freezer for your shop, it’s time to get into the details. This is where you separate a workhorse unit from one that will give you headaches down the road. The right features don't just make your day-to-day work easier; they are the frontline defense for your product quality and can seriously impact your bottom line. This is what effective ice cream refrigeration is all about.

Beyond just getting cold, today’s freezers are built for precision, efficiency, and the rough-and-tumble reality of a commercial kitchen. Let's dig into the features that every owner or chef needs to have on their radar.

Defrost Systems: Manual vs. Automatic

The defrost system might be the single most important feature for your ice cream's quality. It’s the classic trade-off between hands-on work and product perfection, and your choice here will affect every scoop you serve.

-

Manual Defrost: These freezers are the purist's choice. They rely on static cooling, where coils are built right into the walls. Because there are no automatic heating cycles, the temperature inside stays rock-solid. The catch? You have to manually power down and defrost the unit whenever ice builds up to about a quarter-inch thick. It’s more labor, no doubt, but it's the gold standard for protecting ice cream texture.

-

Auto-Defrost (or Frost-Free): These are certainly more convenient. They use fans and tiny heaters to melt away frost automatically. The problem, as we've talked about, is that these temperature swings are the very definition of heat shock—the enemy that creates icy, grainy textures. For any dipping cabinet or long-term storage freezer holding your precious product, auto-defrost is a feature to avoid.

If you’re serving a high-end product like artisanal ice cream, manual defrost isn't just a nice-to-have; it's a must. The occasional inconvenience is a tiny price to pay for ensuring every customer gets that perfectly creamy, delicious scoop you worked so hard to create.

Energy Efficiency and Cost Savings

Let’s be honest: a commercial freezer is an energy hog, chugging away 24/7. Investing in an energy-efficient model isn't just about being green; it's a smart business move that shows up directly on your monthly utility bill. Savvy chefs keep an eye out for news on energy-efficient models and deals on new supplies.

Keep an eye out for the ENERGY STAR® logo. A freezer with this certification has been proven to be, on average, 20% more energy-efficient than a standard model. This isn't magic—it comes from better insulation, higher-quality compressors, and door gaskets that actually seal properly. The initial price might be a bit higher, but the savings on your electric bill can easily pay back the difference in just a few years.

On top of that, many new units use eco-friendly refrigerants like R290 (propane). This natural hydrocarbon has a much lower environmental impact than older chemicals and is also more thermodynamically efficient, which means it uses less energy to do its job.

Precision Controls and Durable Construction

The days of guessing with an old-school analog dial are over. Modern ice cream refrigeration demands precision, and that starts with the controls.

Digital Temperature Controls: These systems let you set and monitor the temperature with incredible accuracy. A clear, external display means you can check on things with a quick glance—no need to open the door and let all that precious cold air out. This level of control is vital for holding that perfect scooping temperature in a dipping cabinet or maintaining the deep-freeze conditions your bulk storage needs.

Durable Materials: How a freezer is built tells you a lot about how long it will last and how easy it will be to clean. You want to see stainless steel inside and out. It’s tough, resists rust and dings, and its non-porous surface is a breeze to sanitize, helping you nail your food safety protocols. High-quality door seals are another non-negotiable to prevent costly air leaks. Exploring the latest industry news can help you discover brands known for durability.

Finally, especially for dipping cabinets, don't forget about the lighting. Bright, cool-running LED lights make your flavors pop, drawing customers in without adding extra heat that could compromise the product.

Best Practices for Peak Performance and Longevity

Having the right freezer is a great first step, but what you do day-to-day is what really safeguards your ice cream and your equipment. Think of your ice cream refrigeration unit as a high-performance vehicle; it needs simple, regular tune-ups to keep running smoothly. If you ignore the basics, you're looking at poor performance, sky-high energy bills, and worst of all, subpar ice cream.

These practices aren't complicated. In fact, weaving them into your daily and weekly routines is one of the smartest investments you can make in your operation. It’s how you guarantee every scoop you serve is just as perfect as the day it was made.

Master Your Maintenance Routines

Consistent maintenance is the bedrock of a long-lasting, efficient freezer. A little bit of preventative care goes a long, long way in heading off expensive repairs and frustrating downtime. Make these tasks a non-negotiable part of your shop's standard procedures.

Here are the most important jobs to tackle:

-

Cleaning Condenser Coils: These coils, typically found on the back or bottom of your freezer, are what release heat from the unit. When they get caked with dust and grime, the compressor has to work overtime, which wastes energy and puts a ton of stress on the system. Give them a good cleaning with a stiff brush and a vacuum at least every 90 days.

-

Inspecting Door Seals: A bad gasket is like leaving the front door open. Cold air escapes, warm air seeps in, and you end up with temperature swings and frost. Once a month, give the seals a quick check for any cracks and make sure they create a tight seal all the way around.

-

Performing Manual Defrosts: For manual defrost freezers—which are the best option for holding ice cream—you can't let frost get more than a quarter-inch thick. Any more than that and the ice starts acting like an insulator, making your freezer work harder for no reason. Schedule your defrosts for slower periods and always have a backup freezer on standby for your inventory.

Organize for Quality and Efficiency

How you arrange the inside of your freezer matters just as much as how you maintain the outside. A well-organized unit isn't just about faster service; it’s absolutely critical for maintaining stable temperatures and product quality.

The name of the game is airflow. Never cram your freezer so full that air can't circulate. When you stack boxes right up against the walls or block the vents, you create warm spots. Those warm spots lead to heat shock, which is the fastest way to ruin ice cream's creamy texture. Always leave a few inches of breathing room between your products and the freezer walls.

The First-In, First-Out (FIFO) system isn't just a suggestion—it's essential for ice cream. New tubs always go to the back, and you always pull from the front. This simple rotation ensures your product is served at peak freshness and stops older tubs from getting lost in the back until they're unusable.

To make FIFO work, you need a system. Make it a hard-and-fast rule that no tub enters the freezer without a clearly marked production or "use by" date. This discipline protects your product, your reputation, and your bottom line.

Adopt Daily Operational Best Practices

It’s the small, consistent actions throughout the day that make the biggest difference for your freezer's health and the quality of the ice cream inside. Train your team on these simple habits until they become second nature.

Here’s a quick checklist for daily success:

-

Minimize Door Openings: Every time that freezer door swings open, cold air rushes out and the compressor has to kick on to compensate. Encourage your team to think ahead and grab everything they need in one go instead of opening the door over and over.

-

Cool Items Before Freezing: Never, ever put warm or hot items directly into your freezer. This forces the unit into overdrive to bring the temperature back down, stressing the whole system and potentially warming up the products already inside.

-

Wipe Spills Immediately: A little spill can quickly freeze onto a surface, making it a pain to clean later and creating a potential spot for bacteria to grow. Clean them up on the spot to keep things hygienic and easy to manage.

By building these simple cleaning, organization, and operational habits into your workflow, you guarantee your ice cream refrigeration equipment remains a reliable asset—one that helps, rather than hinders, your mission to serve the perfect scoop.

Connecting Quality Refrigeration to Your Bottom Line

We’ve covered the nitty-gritty of ice crystals, different freezer types, and how to keep them running smoothly. Now, let’s tie all that technical talk to what really matters for any restaurateur or chef: your bottom line. Think of great ice cream refrigeration not as just another kitchen task, but as a direct pipeline to your business's financial health.

Every time you save a tub of ice cream from turning into an icy, grainy mess due to heat shock, you're literally protecting your profit margin. That lost tub isn't just a shame; it's a direct hit to your food costs. In that light, proper storage isn't an expense—it's an insurance policy on the inventory you've already invested in.

From Quality to Customer Loyalty

Let's be honest: one of the best marketing tools you have is consistently serving incredible ice cream. A perfect scoop isn't just dessert; it's a memorable experience that builds a loyal following. Those repeat customers are the bedrock of a healthy business, coming back again and again because they trust the quality you deliver.

This is especially true as the market for artisanal and premium frozen treats continues to boom. When people are willing to pay more for a top-tier product, their expectations are sky-high. Flawless storage and serving conditions simply aren't negotiable.

Excellent ice cream refrigeration is a strategic investment in quality, customer loyalty, and long-term profitability. It transforms a standard freezer from a simple appliance into a cornerstone of your brand's promise to its customers.

Don't forget the ripple effect. Happy customers lead to fantastic word-of-mouth recommendations and glowing online reviews—free advertising that's priceless for attracting new business. Every delicious scoop you serve reinforces your reputation for excellence.

A Growing Market Demands Excellence

The craving for high-quality frozen desserts isn't just a local fad; it's a global phenomenon. The numbers speak for themselves. The refrigerated ice cream merchandise market is already massive, valued at around USD 13.2 billion. And it’s not slowing down. Projections show it climbing to USD 23.1 billion by 2034, all thanks to growing consumer demand. As you can learn more about refrigerated merchandise market trends, it's obvious that having the right equipment is key to grabbing a piece of that pie.

If you want to compete, you have to deliver a top-notch product every single time. This is where your investment in proper ice cream refrigeration truly proves its worth, paying you back over and over by ensuring you meet the high standards of today’s customers.

At the end of the day, the gear in your kitchen is about more than just keeping things cold—it's about strategy. Making a smart investment in refrigeration allows you to:

- Protect Your Inventory: Slash product waste and keep your food cost percentages in line.

- Build Your Brand: Serve a consistently fantastic product that builds trust and a stellar reputation.

- Increase Customer Loyalty: Craft those memorable experiences that keep people coming back for more.

- Drive Profitability: Turn a necessary appliance into a powerful tool for long-term financial success.

When you look at your freezers this way, you're no longer just buying equipment. You're making a strategic decision that shores up every part of your business.

Frequently Asked Questions About Ice Cream Refrigeration

Even for seasoned chefs and restaurateurs, the world of professional ice cream refrigeration can have its tricky spots. Let's tackle some of the most common questions that come up, giving you the clear answers you need to keep your product perfect and your equipment humming.

What Are the Ideal Temperatures for Storing and Serving Ice Cream?

Think of it in two stages: deep storage and ready-to-serve. For long-term storage in the back of the house, you need to keep your ice cream at a rock-solid 0°F (-18°C) or even colder. This ultra-low temperature is crucial for preventing the growth of large, crunchy ice crystals that completely ruin a creamy texture.

When it's time to serve, that's a different story. You'll want to bring the temperature up to a more scoopable range of 6°F to 10°F (-14°C to -12°C). This is why having separate holding freezers and front-of-house dipping cabinets is a non-negotiable for any serious ice cream program.

Can I Use a Regular Commercial Freezer for Ice Cream?

You technically can, but if you care about quality, you absolutely shouldn't. The problem with standard commercial freezers is their auto-defrost cycle. This feature, while convenient for general use, causes small but consistent temperature fluctuations.

This constant, subtle thawing and refreezing is a phenomenon known as "heat shock." It's the number one enemy of smooth ice cream, leading directly to that dreaded grainy, icy texture. For a deeper dive into this and other common questions, check out our main frequently asked questions page.

Specialized ice cream freezers, especially manual defrost models, are built for one purpose: to provide the unwavering, stable cold that protects the integrity of your product. They are designed specifically to avoid the temperature swings that standard freezers introduce.

How Often Should I Defrost My Manual Defrost Freezer?

A good rule of thumb is to defrost the unit whenever the ice buildup gets to be about a quarter-inch thick. Once it gets thicker than that, the frost acts like a blanket, insulating the interior and making the compressor work overtime just to keep things cold.

This wastes energy and puts a huge strain on your equipment. Regular defrosting is simply critical maintenance. Just make sure you have another freezer ready to temporarily store your product while you do it!

For top-tier new and used restaurant equipment designed to perfect your dessert program, trust the experts at Encore Seattle Restaurant Equipment. We provide the reliable refrigeration solutions you need to protect your product and delight your customers, along with the latest industry news and exclusive deals. https://encoreseattle.com