A Guide to Commercial Food Warming Tables

Share

For any busy chef or restaurant owner, a food warming table isn't just another piece of equipment—it's the backbone of a smooth service. It's the silent workhorse that keeps food safe, delicious, and ready to go, turning a potentially chaotic dinner rush into a well-oiled machine. Think of it as your most reliable line cook, one that never fails to maintain quality from the moment food leaves the pan to the second it hits the customer's table. Stay informed on the latest industry trends and exclusive deals to give your kitchen a competitive edge.

The Role of Food Warming Tables in Your Kitchen

Picture the Saturday night rush. The ticket machine is churning, the grill is roaring, and every second is precious. Your team has just perfected a big batch of creamy mashed potatoes, rich gravy, and crisp roasted vegetables. Without the right holding gear, all that hard work can be undone in minutes as food cools, textures suffer, and flavors fade. Worse yet, it creates a major food safety risk.

This is exactly where a food warming table proves its worth. It acts as the critical link between cooking and plating, holding everything at a consistent, safe temperature. Its main job is to keep food well above the dreaded temperature "danger zone"—that hazardous range between 40°F and 140°F where bacteria can multiply at an alarming rate.

Boosting Kitchen Efficiency and Food Quality

At its core, a food warming table is an engine for efficiency. It gives your chefs the freedom to cook popular sides and sauces in batches before the main rush hits, confident that everything will be held at the perfect temperature for service. This simple change can slash ticket times and take a huge amount of pressure off your cooks when they're in the weeds.

The impact on your guests' experience is immediate and obvious:

- Consistent Quality: Every dish is served at its ideal temperature. Nobody wants lukewarm soup or fries that have gone soft.

- Enhanced Safety: Holding food properly is non-negotiable for preventing foodborne illness, which protects both your customers and your hard-earned reputation.

- Improved Workflow: The whole line becomes more streamlined. Cooks can focus on firing proteins to order, knowing all the supporting components are hot and ready.

By keeping prepared foods out of the danger zone, a food warming table is your first line of defense against both poor customer reviews and potential health code violations. It’s an investment in consistency, safety, and operational speed.

This guide will walk you through everything you need to know to make a smart choice for your kitchen. We’ll break down the different heating technologies, help you select the right size for your operation, and share best practices for installation and maintenance. To get a feel for what's out there, you can explore a wide selection of hot holding equipment to see how different models can solve different problems. From big stationary steam tables to portable countertop units, knowing your options is the first step toward a smoother, more profitable service.

Understanding Food Warming Technology

When you first look at a food warming table, it seems like a pretty straightforward piece of gear. But the technology inside is what really makes the difference, and it’s all about what your menu needs to stay at its best. The big question you need to ask yourself is this: does my food need a gentle steam bath or a consistent, dry warmth?

Getting that answer right is everything. Each heating method treats food differently, and picking the right one is crucial for holding the texture and moisture you worked so hard to perfect. One approach keeps your gravy silky smooth, while the other makes sure your fried chicken stays crispy right up to the last serving.

Wet Heat: The Gentle Steam Bath

Wet heat is the classic steam table, sometimes called a bain-marie. It’s your go-to for anything with a lot of moisture. Just think of it as a giant double boiler. The unit heats a pan of water, creating steam that gently warms the food pans sitting above it. This humid environment is a lifesaver for delicate dishes, stopping them from drying out, scorching, or breaking down.

It’s the perfect solution for keeping certain foods just right.

- Soups and Stews: Steam stops that unappealing skin from forming on top and maintains the perfect consistency.

- Sauces and Gravies: It keeps them from getting too thick or separating, so they stay smooth and ready to serve.

- Mashed Potatoes and Mac & Cheese: That moist heat is the secret to keeping these classics creamy instead of stiff and crusty.

A wet heat table is like a protective shield for your food. It locks in moisture, preserving the texture and quality of your most delicate items. It's how you make sure your creamy polenta is just as amazing for the last customer as it was for the first.

Dry Heat: The Consistent Warm Embrace

On the flip side, dry heat tables work without any water at all. They rely on heating elements, usually tucked under the wells, that radiate a consistent, dry warmth directly into the food pans. This is the champion for any food where crispiness is king. Adding steam to these dishes would be a disaster, turning them into a soggy mess in minutes.

Dry heat is perfect for a whole different set of menu favorites. It keeps fried chicken skin crackling, holds roasted vegetables firm without letting them get mushy, and preserves that satisfying crunch of onion rings or fries. It’s a more direct heat, for sure, but it’s absolutely essential for holding foods that would be ruined by moisture.

This kind of tech is popping up more and more as kitchens need more versatile holding gear. In fact, the whole market for related equipment like food warming trays is growing fast, pushed by the boom in hospitality and the rise of things like outdoor dining. You can see just how much this is growing by checking out the growth of the food warming trays market on imarcgroup.com. It's a clear sign that the industry is moving toward equipment that can handle a wider variety of foods.

Wet Heat vs. Dry Heat Comparison for Food Warming Tables

Deciding between a gentle steam bath and a consistent, dry warmth can feel tricky. It all comes down to what you're serving. This table breaks down the key differences to help you match the technology to your menu.

| Feature | Wet Heat (Bain-Marie) | Dry Heat (Radiant/Conduction) |

|---|---|---|

| Best For | Moisture-rich foods: soups, sauces, stews, mashed potatoes, pasta. | Crispy & dry foods: fried chicken, french fries, roasted vegetables, breaded items. |

| How It Works | Heats water to create steam, providing gentle, indirect heat. | Electric elements provide direct, radiant heat to the food pans. |

| Moisture Control | Excellent. Creates a humid environment that prevents drying out. | Poor. The dry air can dehydrate moist foods over long periods. |

| Texture Preservation | Keeps creamy and soft foods from forming a skin or becoming crusty. | Maintains crispiness and firmness; prevents sogginess. |

| Heat Distribution | Very even and gentle, reducing the risk of scorching. | Can have hot spots if elements are not well-designed; risk of overcooking. |

| Maintenance | Requires regular filling with water and descaling to prevent mineral buildup. | Simpler cleanup; no water to manage, just wipe down the wells. |

| Energy Efficiency | Can be less efficient due to heat loss from evaporating water. | Generally more energy-efficient as all heat is directed to the food. |

Ultimately, many kitchens find they need both. A wet heat table might be essential for your gravy and mashed potatoes, while a dry heat unit sits right next to it, keeping the fried fish perfectly crisp.

Choosing Your Power Source: Electric vs. Gas

Once you’ve settled on wet or dry heat, there’s one last piece to the puzzle: how to power it. You’ll find both electric and gas models out there, and the right choice usually comes down to your kitchen's current setup and your day-to-day needs.

Electric food warming tables are the champs of portability and easy setup. You just plug one into a standard outlet, which makes them fantastic for catering gigs, food trucks, or any kitchen where you need the flexibility to move things around. They give you very precise temperature control but can sometimes take a bit longer to heat up.

Gas food warming tables, on the other hand, usually pack more of a punch and get hot much faster. They can also be cheaper to run if natural gas is more affordable than electricity in your area. The trade-off is that they need a dedicated gas line and professional installation, so they’re more of a permanent fixture. They’re a great fit for busy, high-volume kitchen lines where you need speed and raw heating power above all else.

How to Choose the Right Food Warming Table

Picking the right food warming table is more than just plugging a hole in your kitchen line. It's a strategic move that affects your service speed, food quality, and ultimately, your profits. You wouldn't use a paring knife to chop through bone, and you shouldn't use a small countertop unit for a massive hotel buffet. The wrong choice creates bottlenecks and waste.

To get it right, you have to be honest about what you actually need. Take a hard look at your menu, your busiest service times, the real estate you have to work with, and your budget. This simple assessment will point you toward a unit that will be a genuine workhorse for your operation, not a headache.

Evaluating Your Operational Needs

First things first: match the equipment to your service style. A bustling cafeteria slinging lunch to hundreds of people has completely different needs than a fine-dining spot holding a delicate sauce at a perfect, unwavering temperature. Think about what this unit’s primary job will be in your daily workflow.

Ask yourself these key questions:

- Menu Diversity: Are you holding mostly "wet" foods like stews, soups, and mashed potatoes? Or do you need to keep fried chicken and roasted veggies crispy? Many kitchens need the flexibility to do both.

- Service Volume: During your absolute busiest rush, how many different pans of food do you need to hold at once? This number directly tells you how many wells you need.

- Kitchen Space: Is this going to be a permanent fixture in your main line, or do you need something you can move for catering gigs or squeeze into a tight spot? Get out the tape measure before you even start looking at models.

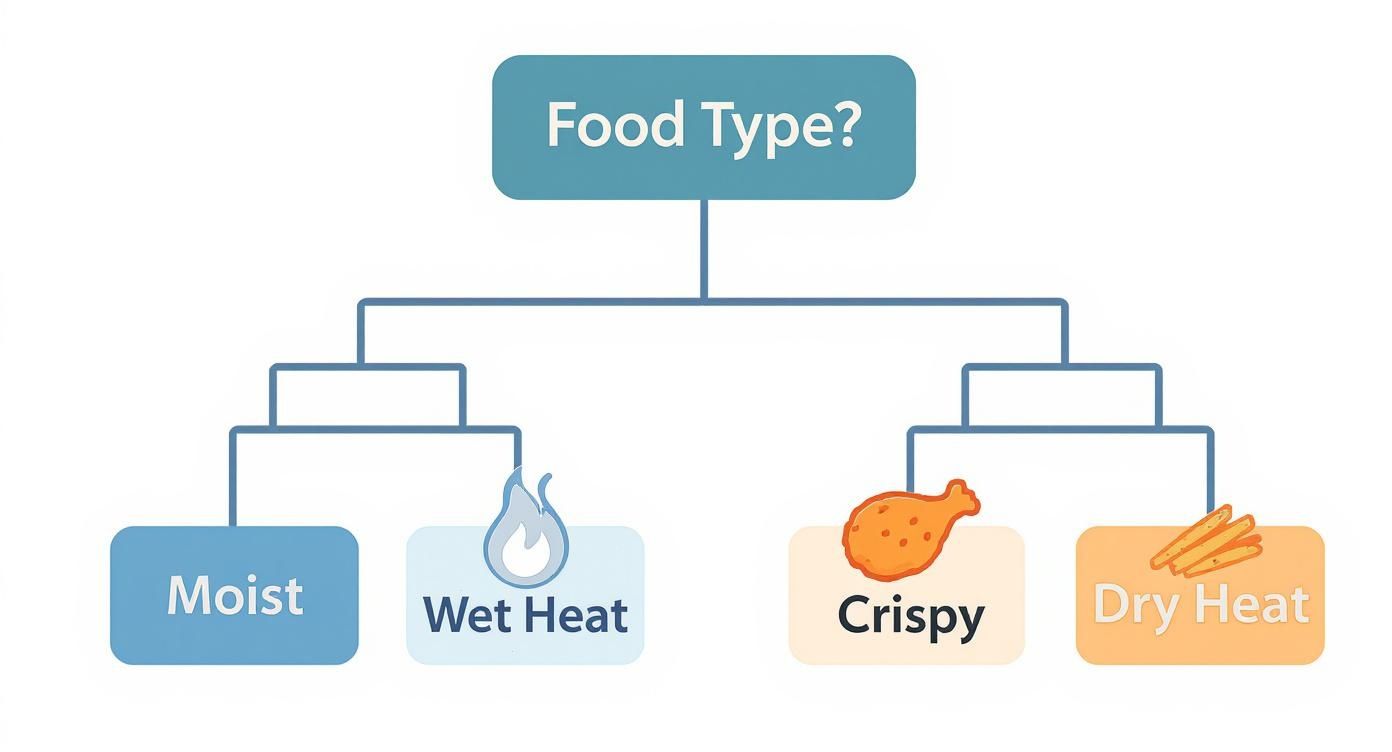

This simple chart helps visualize that very first decision you need to make based on your food.

As you can see, the texture you're trying to preserve—moist or crispy—is the fundamental fork in the road that leads to either a wet or dry heat table.

Matching Models to Common Scenarios

Once you've got your needs figured out, you can start digging into the different types of warming tables out there. Each one is built to solve a specific problem.

For example, stationary steam tables are the big, multi-well workhorses that anchor buffet lines and high-volume institutional kitchens. They are built for endurance and capacity, designed to be a permanent part of a service area.

On the flip side, portable countertop units are all about flexibility. These smaller models are a godsend for food trucks, concession stands, and caterers who are constantly setting up and breaking down. Their popularity is surging for a reason.

The global market for countertop food warmers recently hit US$ 2,428 million and is projected to reach US$ 3,081 million by 2031. This isn't just a random number; it shows a real shift toward compact, efficient solutions for the booming grab-and-go and quick-service world. You can dig deeper into this by reading the complete countertop food warmers market analysis.

A third common style is the drop-in model. These are individual warming wells built to be installed flush into a custom countertop. They give you that seamless, integrated look you see in hotel breakfast bars and upscale cafeterias—a clean aesthetic that doesn't sacrifice performance.

Focusing on Durability and Safety

Beyond the type and size, you have to look at how the thing is built. Always look for units made from high-quality stainless steel; it's the industry standard for a reason. It resists rust, stands up to abuse, and is easy to keep clean. If you can, go for 304 stainless steel, which is a premium grade known for its superior durability.

Most importantly, never buy a piece of equipment that isn't NSF certified. That little NSF mark is your guarantee that the unit meets strict public health and safety standards. It’s not just a nice-to-have; your health inspector will be looking for it.

Finally, think about the little things that make life easier for your crew. Look for coved corners in the wells, which means no sharp 90-degree angles where gunk can build up. Check for easy-to-reach drain valves on steam tables. These details might seem small, but they make a huge difference in how quickly and effectively your staff can clean, saving you labor costs and keeping your equipment in great shape for years.

Mastering Temperature Control for Food Safety

More than just keeping food tasty, a food warming table's most important job is to guard against foodborne illness. Let's be frank: one mistake with temperature can turn a fantastic meal into a health hazard, putting your customers and your reputation on the line. This is one area where you simply can't afford to cut corners.

The whole game is about keeping hot food hot. That means holding it at a temperature where nasty bacteria can't throw a party and multiply. Knowing the exact temperature range to steer clear of is the first, most critical lesson for anyone using this kind of equipment.

Navigating the Temperature Danger Zone

The FDA has a name for the temperature range where bacteria thrive: the temperature danger zone. It's the span between 40°F and 140°F (5°C to 60°C). In this zone, pathogens like Salmonella and E. coli can double their numbers in as little as 20 minutes. A food warmer's entire mission is to keep your food safely above that line.

A food warming table isn't a slow cooker. It’s not for reheating. Think of it as a holding unit—its only job is to maintain a safe temperature of 140°F or higher and act as a fortress against bacterial growth.

This is a hard-and-fast rule in any commercial kitchen. Sticking to these temperatures is a core piece of any real food safety plan. To see how this fits into the bigger picture, check out our guide on what is HACCP food safety, which explains how to build these kinds of safety checks into your daily operations.

A Step-by-Step Guide to Safe Hot Holding

Using a food warmer correctly is a process, not just a matter of flipping a switch. Follow these steps every single time to protect both your food quality and your customers.

-

Preheat the Unit Thoroughly: Never, ever put hot food into a cold warming table. You’ll immediately drag the food’s temperature down. Get the unit up to your target holding temp—usually 150°F to 160°F—before adding food. For wet heat models, this means getting the water hot first.

-

Verify Food Temp Before You Transfer: Use a good food thermometer to make sure your food is cooked to the right internal temperature before it even sees the warmer. Chicken, for example, needs to hit 165°F before it's ready to be held.

-

Use Lids and Covers: Keep those food pans covered. It's a simple step, but it’s essential for trapping heat, locking in moisture, and keeping anything from the air from falling into the food.

-

Monitor, Monitor, Monitor: Don't just set it and forget it. You need to be checking the internal temperature of each food item with a clean, sanitized probe thermometer at least every two hours. Keep a log of these checks; it’ll be your best friend during a health inspection.

Best Practices for Optimal Performance

Even when you've got the temperature right, a few good habits can make a huge difference in how well your food warming tables work and how great your food tastes.

- Stir and Rotate Regularly: For things like soups, sauces, and chilis, give them a stir now and then to keep the heat evenly distributed. For solid items like chicken breasts or lasagna, rotating the pans ensures nothing gets too hot or too cool.

- Don't Overcrowd the Pans: Piling food to the very brim of a pan is a mistake. It blocks heat from circulating properly. Leave a little space at the top so the heat can wrap all the way around the food.

- Get the Water Level Right (Wet Models): With steam tables, follow the manufacturer’s guide for the water level. Too little water, and you risk scorching your pans. Too much, and you'll have a boiling, sputtering mess.

- Avoid Adding Cold Food: Never add a batch of cold or room-temperature food to a pan that's already being held in the warmer. This will crash the temperature of the entire pan, potentially plunging it right back into the danger zone.

Extending the Life of Your Equipment

https://www.youtube.com/embed/JEKeaqgHuC0

Buying a quality food warming table is a great start, but getting years of reliable service out of it? That comes down to smart installation and consistent maintenance. Think of it like a new car—its performance over the long haul depends less on the brand and more on how you treat it from day one. A proper setup and a simple care routine are what stand between you and a costly breakdown.

This process starts the second that unit rolls through your door. Installation isn't just about finding a spot and plugging it in; it's your first chance to set your team and your equipment up for a long, efficient life.

Setting Up for Success

A little forethought during installation can make a world of difference. Nailing the setup means focusing on three key areas to make sure your table runs safely and effectively right from the get-go.

-

Proper Ventilation and Clearance: Every piece of kitchen equipment puts off heat. Your warming table needs room to breathe, so check the manufacturer’s specs for required clearance. Good airflow prevents overheating, which is a fast track to fried internal components and a potential fire hazard.

-

Access to Utilities: Plan your placement around your power and water. You want direct access to the right electrical outlets or gas lines—never rely on extension cords, as they can be a serious safety risk. For wet heat models, having a water source and a drain nearby makes filling and emptying a breeze instead of a chore.

-

Ergonomic Placement: Position the unit where it makes sense in your kitchen's workflow. The ideal spot is usually between the cooking line and the service area. This cuts down on unnecessary steps, reduces staff fatigue, and helps get plates out faster.

A Practical Maintenance Schedule

Once your table is in place, staying on top of maintenance is the secret to its longevity. A simple, consistent care schedule helps you catch small problems before they turn into emergency repairs that take down your hot line mid-service. The best way to do this is with a clear checklist. Implementing solid equipment maintenance SOPs for food service will ensure your tables operate efficiently for years.

This approach breaks down the work into manageable daily, weekly, and monthly tasks.

Daily Tasks (5-10 Minutes)

At the end of every day, a basic clean-up is non-negotiable. It’s crucial for both food safety and the health of your equipment.

- Wipe down all exterior surfaces with a food-safe sanitizer.

- Pull out all the food pans and give the wells a thorough cleaning to get rid of spills and debris.

- Clean and sanitize all the food pans and lids.

Weekly Tasks (15-20 Minutes)

These jobs go a little deeper to tackle buildup.

- For wet heat models, drain the water and descale the reservoir. Mineral deposits from hard water can act like an insulator on your heating elements, making them work harder and burn out faster.

- Check for any loose hardware, like knobs or legs, and tighten them up.

- Give the power cords a quick inspection for any fraying or damage.

Monthly Checks (20-30 Minutes)

A more detailed monthly inspection can help you spot trouble before it starts.

- Test the thermostat. Is it holding temperature accurately? Use a good kitchen thermometer to double-check.

- Examine the heating elements on dry units for any signs of corrosion or burnout.

- Check gaskets and seals for any cracks or wear. A bad seal means you're just leaking heat and wasting energy.

Proactive care isn’t an expense; it’s an investment. A well-maintained food warming table not only lasts longer but also performs more consistently, uses less energy, and ensures food safety day in and day out.

For a deeper dive into keeping all your equipment running smoothly, check out our complete guide on commercial kitchen equipment maintenance for tips that protect your entire operation.

Smart Ways to Purchase Your Equipment

Buying a key piece of equipment like a food warming table is a big decision, and it’s about more than just the initial price tag. You’re really looking for the best long-term value for your business—something that will work reliably, day in and day out, without draining your profits on energy or repairs. Savvy restaurant owners and chefs are always looking for the latest deals on restaurant equipment to stay ahead.

It helps to know you’re investing in a cornerstone of the foodservice industry. The market for this kind of hot-holding gear is huge. Just last year, the global market for heated shelf warmers alone was valued at USD 4,904.7 million. And it's on track to hit USD 7,401 million by 2035, which tells you just how critical this equipment is for operators everywhere. You can dive deeper into the heated shelf food warmer market trends at futuremarketinsights.com to see where the technology is heading.

New Versus Used Equipment

One of the first forks in the road is deciding between brand new and pre-owned. A new unit is great—it comes with the latest features, a full factory warranty, and that fresh-out-of-the-box smell. Of course, you pay a premium for it.

On the flip side, quality used equipment can be an absolute game-changer for your budget. Going the refurbished route can lead to smart savings through refurbished equipment without giving up much in terms of performance. A solid, certified-used table from a supplier you trust can easily be a workhorse for years, and you'll have more cash on hand for other things your business needs.

Partnering With a Trusted Supplier

This is where working with a dealer like Encore Seattle really pays off. It’s one thing to look at a picture online, but it’s another to come into a showroom and kick the tires yourself. You can feel the build quality, fiddle with the controls, and get a real sense of how it will fit into your kitchen's flow. Discovering exclusive deals through a trusted partner is a key industry trend.

A strategic equipment partner does more than sell you a box. They offer expert guidance, cost-saving options like free local freight, and flexible financing that makes essential purchases manageable for any budget.

A good supplier also understands that not everyone can drop a huge chunk of cash at once. They can set you up with financing that fits your budget, turning a major purchase into a predictable monthly expense. By offering both certified used food warming tables and smart financing, the right partner isn't just selling you equipment—they're investing in your restaurant's success.

Frequently Asked Questions

When you're looking to buy or use any piece of kitchen equipment, a lot of practical questions come up. With food warming tables, getting the right answers is key to keeping your food safe, your quality high, and your investment protected. Here are some of the most common things chefs and restaurateurs ask us.

Can I Cook Food in a Warming Table?

Let's get this one out of the way first, because it's a big safety issue: absolutely not. Food warming tables are built for one job and one job only—holding already cooked, hot food at a safe temperature (above 140°F or 60°C). They simply don't have the power or the right design to cook raw food from scratch.

Trying to cook in one is a recipe for disaster. Your food will sit in the temperature "danger zone" for way too long, which is a major risk for bacterial growth. Always use the right tool for the job—ovens, grills, ranges—to get food up to its proper internal temperature before it ever touches the warming table.

What Is the Difference Between a Steam Table and a Dry Warmer?

The real difference boils down to how they heat the food, and that determines what kind of dishes they're good for.

- Steam Table (Wet Heat): This is your classic setup. It uses a well of hot water to generate steam, which gently heats the food pans sitting above it. That moist heat is perfect for things you don't want drying out, like mashed potatoes, gravies, sauces, or stews.

- Dry Food Warmer: Instead of water, this type uses heating elements that radiate dry heat directly onto the pans. It's the go-to for keeping crispy foods crispy. Think fried chicken, french fries, or roasted vegetables that would turn into a soggy mess in a steam table.

Honestly, the right choice comes down to your menu. A lot of kitchens end up using both wet and dry units to handle everything they serve.

How Often Should I Check Food Temperatures?

To be completely on top of food safety and quality, you need to be checking and logging the temperature of every single food item at least every two hours. Grab a calibrated food thermometer, make sure it's sanitized, and stick it into the thickest part of the food for an accurate read.

This constant checking is the only way to be sure everything stays safely above that 140°F (60°C) mark. If you find something has dropped below that temperature, you have to either reheat it quickly to 165°F (74°C) before putting it back, or just throw it out based on your food safety plan.

What Should I Look for When Buying a Used Model?

Going with a used food warming table can be a great way to save money, but you have to be smart about it. The very first thing to check for is an NSF certification sticker. That little seal means it was built to meet public health and sanitation standards.

Next, give it a good, hard look. Check for rust, big dents, or any other damage, especially around the wells where the pans sit and near the heating elements. If you can, plug it in and test it. Does it heat up? Are the thermostat controls working and accurate? Buying from a reputable dealer who certifies their used equipment is always the safest bet—it gives you peace of mind that the unit is clean, functional, and ready for work.

At Encore Seattle Restaurant Equipment, we have a huge selection of both new and certified used hot holding equipment for any kitchen and any budget. Our team is here to help you find exactly what you need to make your service safer and more efficient. Check out our collection online at https://encoreseattle.com or stop by our Seattle showroom.