Choosing Dishwashing Machines for Restaurants

Share

Choosing the right dishwashing machines for restaurants isn't just about buying another piece of equipment. It’s a make-or-break decision that ripples through your kitchen's workflow, your hygiene standards, and ultimately, your bottom line. Think of a commercial dishwasher as the engine of your entire operation—it’s what keeps everything clean, safe, and moving forward. Stay informed about the latest industry trends and exclusive deals to make the best choice for your business.

Why Your Dishwasher Is Your Kitchen's MVP

In the controlled chaos of a busy kitchen, the flow of dirty to clean dishes can either grind your service to a halt or become a seamless, humming part of the process. The right machine isn't just for cleaning; it’s the heart of your sanitation system, working tirelessly behind the scenes to make your restaurant successful in ways you might not even realize.

A top-notch dishwasher is a silent partner in your business. It’s your first line of defense in protecting your reputation, ensuring every plate, glass, and fork meets stringent health codes and eliminates the risk of foodborne illness. That peace of mind is what builds and maintains customer trust.

Driving Core Restaurant Benefits

Beyond just keeping things clean, the right machine is a massive productivity booster. When your team isn't stuck scrubbing pots by hand or waiting on a slow, clunky machine, they can focus on what really matters—prepping amazing food and taking care of guests. This efficiency gain makes your kitchen run smoother, faster, and more profitably.

It’s no surprise the demand for these workhorses is growing. The industrial dishwasher market was recently valued at around $2.61 billion and is still climbing, fueled by a foodservice industry that absolutely depends on efficiency and safety. You can explore the full market research on this trend yourself.

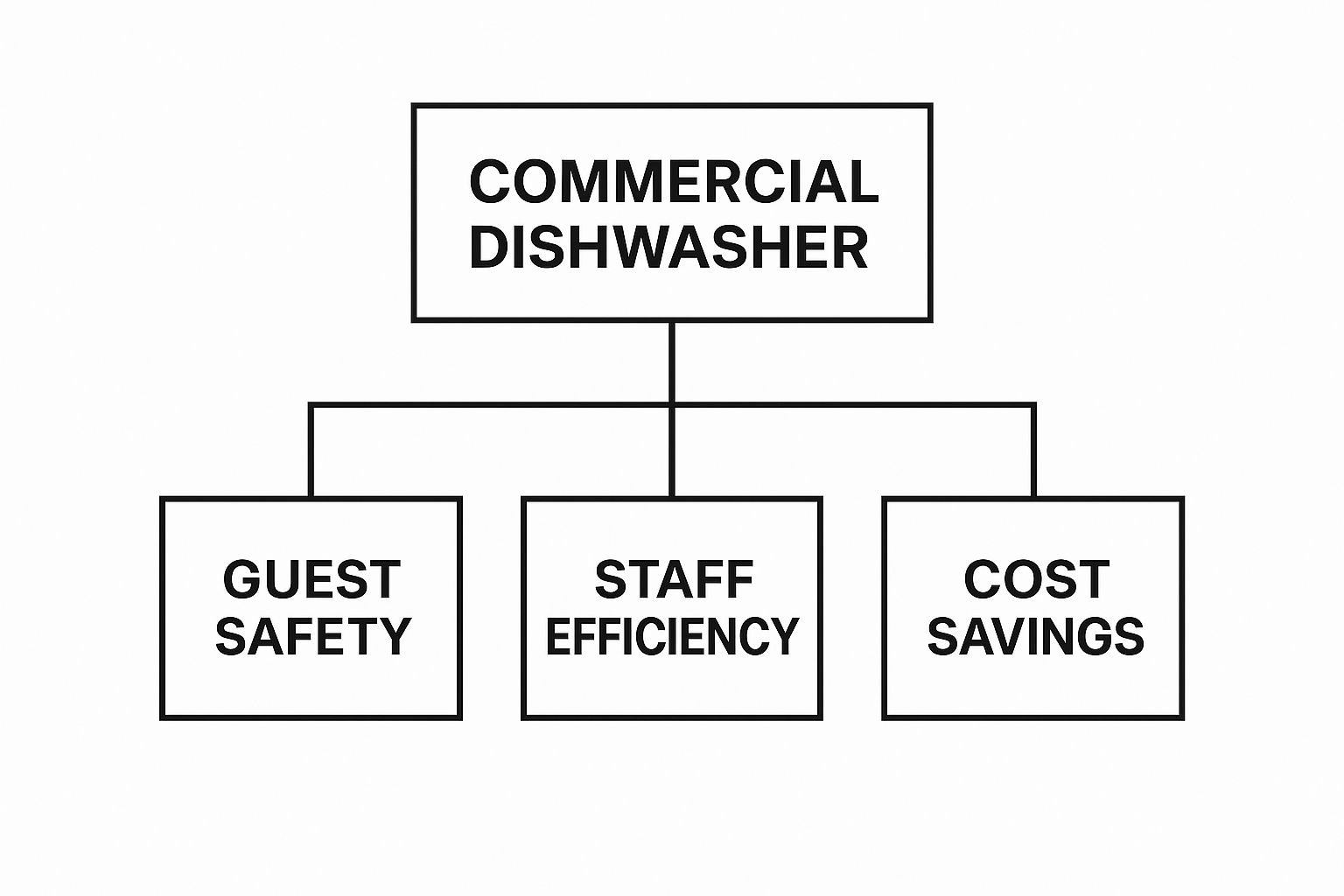

This infographic breaks down how one machine delivers three critical benefits to your restaurant.

As you can see, this single piece of equipment is a powerhouse, directly supporting guest safety, improving your team's efficiency, and creating real cost savings.

A commercial dishwasher is far more reliable for sanitizing than washing by hand. Machines are built to use precise chemical doses and consistent water temperatures, guaranteeing certifiable results every single time. That’s a level of consistency that’s nearly impossible to achieve with a three-compartment sink.

At the end of the day, putting your money into the right dishwashing machines for restaurants pays you back in spades. It’s a direct investment in:

- Guest Safety: Serving on ware that’s not just clean, but properly sanitized to health department standards.

- Staff Efficiency: Slashing manual labor so your team can focus on more valuable tasks in the kitchen.

- Operational Profitability: Cutting down on water, energy, and labor costs while speeding up your entire service.

What Are the Main Types of Commercial Dishwashers?

Picking a commercial dishwasher isn't like grabbing one off the shelf. The right machine for your kitchen really depends on how much space you have, how many dishes you're cranking out, and how your team moves. It's kind of like choosing a vehicle: a small coffee shop might just need a compact, efficient car, while a slammed diner needs a heavy-duty pickup truck, and a massive hotel requires a whole fleet of buses to keep up.

Getting this choice right is a huge deal. The wrong machine creates a bottleneck that can bring your entire service to a screeching halt. But the right one? It becomes the quiet, powerful engine of your back-of-house operations. Let's walk through the main types of dishwashing machines for restaurants to help you discover the perfect fit for your operation.

To make things easier, here’s a quick rundown of the machines we’re about to cover.

Commercial Dishwasher Types at a Glance

| Dishwasher Type | Typical Capacity (Racks/Hour) | Footprint | Best For |

|---|---|---|---|

| Undercounter | 20-40 | Small | Small cafés, bars, coffee shops, or secondary bar units |

| Door Type | 30-120 | Medium | Most small to medium-sized restaurants, diners, and schools |

| Conveyor | 200-1,000+ | Large | High-volume cafeterias, hospitals, hotels, large institutions |

| Glasswasher | 20-40 | Small | Bars, wineries, and fine dining with delicate glassware |

This table gives you a starting point, but the real story is in how these machines work and where they shine. Let's dig in.

Undercounter Dishwashers: The Compact Solution

Imagine the power and sanitizing capability of a commercial dishwasher squeezed into the size of a machine you’d find in a home kitchen. That's an undercounter dishwasher. These units are built to slide right under a standard 34-inch high counter, making them a lifesaver for kitchens where every square inch counts.

They're the go-to for small cafés, intimate bistros, and especially bars. While their capacity is on the lower end—usually around 20-40 racks per hour—they represent a massive leap in efficiency and safety over washing by hand. They’re also perfect as a second machine in a bigger kitchen, maybe tucked away at the bar to handle just the glassware.

Door Type Dishwashers: The Industry Workhorse

If you walk into just about any busy, independent restaurant kitchen, you'll probably spot a door-type dishwasher. These are the tried-and-true workhorses of the industry for a good reason. The process is simple and fast: slide in a rack of dirty dishes, pull the big hood-like door down, and let it run. When it’s done, you lift the door, and the clean rack slides out the other side.

This pass-through design is incredibly efficient for a steady stream of dishes. A standard door-type machine can muscle through anywhere from 30 to 120 racks per hour, which is the sweet spot for most medium-sized restaurants, busy diners, and schools that need reliability without dedicating a huge chunk of their kitchen to a giant machine.

Quick reminder: The whole point of a commercial dishwasher is proper sanitization. These machines use either extremely hot water (a 180°F final rinse) or chemical sanitizers to kill germs—a level of clean that a three-compartment sink and a busy employee can rarely match consistently.

Conveyor Dishwashers: The High-Volume Powerhouse

For the big leagues—think sprawling hotel kitchens, university dining halls, and hospitals—only a conveyor dishwasher can keep up. This isn't just a machine; it's a full-blown automated assembly line for dirty dishes. Racks are placed on a conveyor belt that pulls them through a long tunnel with separate chambers for pre-washing, washing, rinsing, and sanitizing.

These beasts are built for one thing: speed. They can churn through an incredible 200 to over 1,000 racks per hour. Of course, they come with a massive footprint and hefty utility demands, but for any operation that serves thousands of meals a day, their efficiency isn't a luxury—it's an absolute necessity.

Glasswashers: The Finishing Touch

Last but not least, we have the glasswasher. At first glance, it might look like a small undercounter unit, but it’s a highly specialized piece of equipment. These machines are engineered specifically for delicate glassware, using lower water pressure and gentler chemicals to avoid chipping or etching.

For any place where pristine, spot-free glasses are part of the customer experience—like bars, wineries, or fine-dining spots—a dedicated glasswasher is non-negotiable. It protects your investment in expensive stemware and ensures every drink is served in a brilliantly clean glass.

How to Select the Perfect Dishwasher for Your Kitchen

Knowing the type of dishwasher you need is the first big hurdle. Now comes the nitty-gritty: picking the exact model that will become the unsung hero of your kitchen. This isn’t just about filling a space; it’s a serious investment in your restaurant's future. Make the right call now, and you’ll be rewarded for years with lower utility bills, a less stressed-out crew, and an endless supply of sparkling clean wares.

Think of it like a chef building a new recipe. You don’t just toss ingredients in a bowl. You meticulously balance flavors, costs, and prep time. It’s the same with dishwashing machines for restaurants. You have to weigh capacity, efficiency, and the unique rhythm of your kitchen to find that perfect fit.

Let’s walk through what really matters.

Calculate Your True Capacity Needs

The single biggest mistake I see restaurant owners make is underestimating just how many dishes they’ll be washing. Glancing at your total seating gives you a number, but it doesn't capture the chaos of a real service. The only number that counts is your peak hour demand—that Saturday night rush when every plate, glass, and fork you own is in constant motion.

Here’s a solid rule of thumb: figure out the number of dishes you'd need for 1.5 times your seating capacity during that busiest hour. So, for a 100-seat spot, you need to be able to wash and cycle enough dishes for 150 guests. That extra buffer is your safety net. It accounts for dropped plates, multi-course orders, and the rapid turnover you need to keep the dining room humming.

A common pitfall is buying a machine that can barely keep up on an average day. This guarantees it will become a bottleneck during your peak periods, slowing down table turns and frustrating both your front-of-house and back-of-house teams. Always plan for your busiest moments.

High-Temp vs. Low-Temp: The Sanitizing Showdown

Once you’ve got your capacity nailed down, the next big fork in the road is how the machine sanitizes. This decision echoes through your utility bills, chemical budget, and even the flow of your dish pit.

-

High-Temperature Dishwashers: These powerhouses use a built-in booster heater to hit dishes with a final rinse of 180°F water. That searing heat obliterates bacteria. A fantastic bonus? The dishes are so hot they "flash-dry" almost instantly when they hit the cooler air. This means no more time-consuming towel drying, which can just reintroduce germs anyway. The downside is they slurp more energy and often require a vent hood to handle all that steam.

-

Low-Temperature Dishwashers: These models are the chemical wizards. They wash at a lower temperature (around 120-140°F) and use a chemical sanitizer in the final rinse to ensure everything is food-safe. They’re kinder to your energy bill and you can usually skip the expensive vent hood. The trade-off is the recurring cost of sanitizer and the fact that dishes take longer to air-dry.

Look Past the Price Tag to Energy and Water Efficiency

It's easy to get fixated on the initial cost, but that's just a small piece of the puzzle. An Energy Star certified commercial dishwasher might have a higher sticker price, but it's engineered to save you money every single day. These machines are lean, mean, cleaning machines, using significantly less water and power with every cycle.

Over the life of the unit, those daily utility savings can easily add up to more than the initial price difference. You get a much better return on your investment in the long run.

The industry is moving this way for a reason. The global dishwasher market is set to hit USD 44.42 billion by 2033, with the commercial side in North America growing to about $5.17 billion. That growth is fueled by kitchens demanding better hygiene and efficiency, making these energy-saving models the new standard.

Take a Hard Look at Your Kitchen's Infrastructure

Before you sign on the dotted line, grab a tape measure and have a serious talk with your plumber and electrician. This is the practical reality check that prevents massive headaches and surprise renovation bills later.

- Space and Layout: Do you actually have the footprint for this machine? Measure carefully. For a door-type model, you need room for the door to swing open without hitting anything, plus space for dirty and clean dish tables on either side.

- Plumbing: Check your water lines. Can they deliver the water pressure and flow rate the machine needs? Is your drain ready to handle the gallons of water it will be pumping out?

- Electrical: These machines are hungry for power. You need to confirm your electrical panel can handle the voltage (120V, 208V, or 240V) and has a dedicated circuit ready to go.

Thinking through these logistics ensures the machine you choose will actually work in your space. And if you're on a tight budget, don't forget to look at all your options. In our guide on used commercial dishwashing machines, we break down how to find a reliable, pre-owned unit that delivers incredible value without compromising on clean.

Planning for a Smooth Installation

You've picked out the perfect machine. That’s a huge win, but don't pop the champagne just yet. The real work starts with installation. This is the critical step that bridges your smart investment to its actual performance on a busy Saturday night.

Think of it this way: you can buy a Formula 1 engine, but if it's not mounted and connected perfectly, you're not winning any races. It's the exact same story with dishwashing machines for restaurants. A flawless installation isn't just a nice-to-have; it's the only way to guarantee safety and efficiency.

Getting this right is about more than just finding an outlet. It's a technical puzzle that has to fit perfectly with your kitchen's existing layout and utilities. Skipping over these details is a rookie mistake that almost always leads to expensive delays, a machine that never quite works right, and even dangerous working conditions. Let's walk through the pre-installation checklist so everything goes off without a hitch.

Verifying Your Utility Connections

Long before that big delivery truck rumbles up to your back door, you need to play detective with your kitchen's utility hookups. A commercial dishwasher is a workhorse, and it needs a lot of resources to do its job. Get ahead of any potential headaches by confirming these three things:

- Plumbing and Water Pressure: Every machine has a sweet spot for water pressure, measured in PSI. Dig into the manufacturer’s specs and then make sure your water lines can actually deliver that. While you're at it, check that your floor drains can handle the gush of water that's going to be dumped after every cycle.

- Electrical System: These things are power hogs. You have to be certain your electrical panel can handle the voltage (208V or 240V) and amperage. This is non-negotiable: the dishwasher needs its own dedicated circuit. If it doesn't have one, you’re practically guaranteeing tripped breakers right in the middle of dinner service.

- Water Temperature: Your hot water needs to be, well, hot. Most machines require an incoming supply of around 140°F. If your water heater isn't up to the task, the dishwasher's internal booster will have to work overtime, which means longer cycles and a higher energy bill.

Don't Forget About Ventilation

If you went with a high-temp dishwasher, you also signed up for a whole lot of steam. Every time that door opens, a massive cloud of hot, moist air is going to billow out. Without a plan to manage it, that steam will turn your floors into a slip-and-slide, crank up the kitchen's humidity, and can even lead to mold.

A professionally installed ventilation or condensate hood isn't just a good idea for high-temp machines—it's often required by local health and safety codes. It captures that steam right at the source, keeping your dish pit safe and the air in your kitchen breathable.

The Non-Negotiable Step: Hiring a Professional

I get it. The temptation to save some cash and have your handiest team member tackle the installation is real. But this is one of those times where a DIY approach can be catastrophic. The risks are just too big, from slow leaks that cause thousands in hidden water damage to electrical screw-ups that pose a serious fire hazard.

Even more importantly, just about every manufacturer’s warranty becomes instantly voided if the machine isn’t installed by a certified technician. Paying for a professional install isn't an extra cost; it's part of the investment. It ensures your machine runs safely, is up to code, and keeps your warranty intact.

When you're looking at different sinks and dishwashers, budget for professional installation from the very beginning. Getting your new machine set up by an expert is the only way to guarantee it works as promised from day one, protecting your staff, your restaurant, and your investment.

Mastering Daily Care and Long-Term Maintenance

Think of your commercial dishwasher as the workhorse of your kitchen. It’s a serious piece of machinery and a major investment in your restaurant's hygiene. Just like the engine in a delivery truck, it'll run like a top for years if you give it regular tune-ups, but ignoring it is a surefire way to end up with a costly breakdown right in the middle of a dinner rush.

Treating maintenance as a proactive system, not a reactive chore, is the key. Simple habits, performed consistently every day, are your best defense against the most common headaches—clogs, spotty dishes, and sudden equipment failures. Getting your team on board with a clear, simple routine is what keeps that machine humming and your operation running smoothly.

Creating Your Daily Maintenance Checklist

The best way to turn good intentions into solid habits? A simple checklist posted right in the dish pit. These tasks only take a few minutes at the end of a shift, but they can literally add years to your machine's life.

- Drain and Clean the Interior: Once service is done, drain the machine completely. Get in there and clear out any large bits of food lingering in the wash tank.

- Remove and Clean Filters: Pull out all the filters and screens. Give them a good scrub with a brush under hot water to blast away grease and trapped food particles.

- Inspect and Clean Spray Arms: Gently take out the spray arms. Look closely at the nozzles to make sure they aren't clogged with food debris or mineral scale. A small brush or tool can clear them out.

- Wipe Down the Exterior: A quick wipe-down of the outside with a soft cloth and mild cleaner keeps things looking professional and clean.

Weekly and Monthly Proactive Care

Daily cleanings handle the immediate grime, but a slightly deeper dive on a weekly and monthly basis is what stops long-term problems in their tracks. These steps are vital for keeping your dishwashing machines for restaurants running efficiently and sanitizing effectively.

Once a week, make it a point to check the chemical levels on low-temp machines. Make sure the detergent, rinse aid, and sanitizer tubes aren't pinched or empty and that the pumps are working as they should. This is also a great time to give your dish racks a once-over for any cracks or damage that could chip your plates and glassware.

Proper maintenance isn't just about keeping things clean—it's a cornerstone of food safety. A well-cared-for commercial dishwasher hits the FDA Food Code's strict sanitization standards every single time, offering a level of consistency that's nearly impossible to match with a three-compartment sink.

The Battle Against Hard Water Buildup

If there's a silent killer for commercial dishwashers, it's hard water. Over time, minerals like calcium and magnesium build up inside, creating a chalky residue called limescale. This gunk is notorious for clogging spray jets, wrecking heating elements, and leaving that dreaded cloudy film on your "clean" glasses.

This is where deliming comes in. How often you need to do it depends entirely on the water quality in your area.

- Moderate Hard Water: You'll likely need to delime every 3-4 months.

- Very Hard Water: You might have to tackle this as often as once a month.

Skipping this task forces your dishwasher to work overtime, burning through more energy and delivering mediocre results. It's a critical maintenance step that helps you dodge expensive repair bills. For a broader look at keeping all your gear in top shape, our guide to commercial kitchen equipment maintenance is a great resource.

Finally, don't forget about the drain. A slow or blocked drain can bring your entire kitchen to a grinding halt. Knowing the basics of fixing a clogged dishwasher drain fast can be a lifesaver, but consistently cleaning the drain filters is the best way to prevent that emergency from ever happening.

Boosting Your Dish Pit Workflow and Efficiency

A top-of-the-line commercial dishwasher is a great start, but it's only one piece of the puzzle. The real magic happens when you build a smart, efficient system around it. A chaotic dish pit creates a bottleneck that can bring your entire kitchen to a standstill, no matter how fast your machine is.

The trick is to think of it like a one-way street. Dirty dishes come in on one end, move through a logical sequence of scraping, rinsing, and washing, and come out the other side clean, sanitized, and ready for storage. This setup eliminates wasted motion, keeps your team from tripping over each other, and—most importantly—prevents cross-contamination between dirty and clean wares.

Building a High-Performance Dish Pit

To really get the most out of your setup, you need to look beyond the machine itself. The right accessories and a well-thought-out layout are what truly supercharge your dishwashing machines for restaurants. Investing a little extra here pays for itself almost immediately in saved labor and a smoother service.

Here are a few must-have components for an efficient workflow:

- Landing Tables: You need dedicated space for both dirty and clean racks. A "dirty" table lets racks queue up neatly before going into the machine, preventing a chaotic pile-up. A "clean" table on the other side gives sanitized dishes a place to air-dry without causing a traffic jam.

- Pre-Rinse Sprayers: A high-pressure sprayer is absolutely non-negotiable. It blasts off the heavy, caked-on food so the dishwasher can focus on its real job: sanitizing. The result is consistently spotless dishes.

- Specialized Racks: Don't just throw everything into a generic rack. Using the right tool for the job protects your investment and gets things cleaner. Use peg racks for plates, flat racks for sheet pans or bowls, and compartment racks for your glassware to stop chipping and ensure water hits every surface.

A common mistake is treating the dish pit as an afterthought in kitchen design. A well-planned workflow can reduce staff movement by up to 20%, freeing up valuable time and energy during the busiest shifts.

When every rack moves smoothly through the process, your whole kitchen benefits. To learn more about getting the best performance and cost savings, check out these expert tips for maximising dishwasher efficiency. By focusing on the entire dish pit ecosystem, you can turn a potential weak point into one of your operation's greatest strengths.

Answering Your Top Commercial Dishwasher Questions

Choosing a major piece of equipment like a commercial dishwasher always stirs up some last-minute questions. It's a big investment, and you want to be sure you're making the right call. We've gathered the most common queries we hear from restaurant owners to give you clear, no-nonsense answers.

Think of this as your final checklist. We'll cut through the technical jargon and focus on what really matters in a busy kitchen, so you can buy with confidence.

What Is the Real Difference Between High-Temp and Low-Temp Dishwashers?

It all comes down to how they sanitize your wares.

High-temperature machines are the workhorses that rely on pure heat. They use a built-in booster heater to blast dishes with a final rinse of 180°F water. This scalding-hot water kills bacteria on contact and has the added benefit of making dishes "flash dry" almost instantly when the door opens. The trade-offs? They use more energy and will almost certainly require an expensive vent hood to handle the steam.

Low-temperature machines take a different approach, using chemicals to do the heavy lifting. They wash and rinse with cooler water (around 120-140°F) and then introduce a chemical sanitizer into the final rinse cycle. This makes them much more energy-efficient and lets you skip the vent hood. However, you'll have an ongoing cost for the sanitizing chemicals, and since the dishes aren't as hot, they'll need more time and space to air dry.

How Do I Calculate the Capacity I Need for My Restaurant?

This is a classic mistake: don't size your dishwasher based on your total number of seats. You need to plan for your absolute busiest hour.

A solid rule of thumb is to calculate for 1.5 times your seating capacity in dishes during your peak rush. For a 100-seat restaurant, that means you need a machine that can handle the load from 150 guests per hour. You also have to consider your menu. A fine-dining spot with multiple courses will generate a mountain of dishes compared to a simple sandwich shop.

A Quick Note on Terminology: Keep in mind that "sanitized" does not mean "sterilized." As defined by the FDA Food Code, sanitization kills the germs and pathogens relevant to a food service environment. Sterilization is a much more intense process reserved for medical settings. A well-maintained commercial dishwasher is engineered to meet and exceed all restaurant sanitization requirements.

Are Energy Star Certified Commercial Dishwashers Worth It?

In a word: yes. While a unit with the Energy Star label might cost a bit more upfront, it’s a smart long-term play.

These machines are specifically designed to use less water and electricity with every single cycle. Over the lifespan of the dishwasher, the savings on your monthly utility bills will almost always eclipse that initial price difference. It’s an investment that pays you back, making it both a sound financial decision and a more responsible choice for your business.

Ready to find the perfect workhorse for your kitchen? The team at Encore Seattle Restaurant Equipment offers an extensive selection of new and used dishwashing machines to fit any operation and budget. Discover exclusive deals and stay informed on the latest restaurant equipment and supplies. Explore our inventory and get expert advice at https://encoreseattle.com today.